Technical Contents

Engineering Guide: Boat Non Slip Pads

Engineering Insight: Material Selection for Boat Non-Slip Pads

In marine environments, the performance of non-slip pads is not merely a matter of surface texture—it is a direct function of material engineering. Off-the-shelf rubber solutions often fail under real-world marine conditions due to inadequate resistance to environmental stressors and mechanical degradation. At Suzhou Baoshida Trading Co., Ltd., we emphasize that material selection is the cornerstone of functional durability in boat non-slip applications.

Standard rubber compounds, typically based on natural rubber (NR) or low-grade SBR (styrene-butadiene rubber), degrade rapidly when exposed to UV radiation, saltwater, and temperature fluctuations. These materials exhibit poor ozone resistance, leading to surface cracking and loss of structural integrity. Furthermore, their coefficient of friction diminishes significantly when wet—a critical flaw for marine safety. In contrast, engineered elastomers such as EPDM (ethylene propylene diene monomer) and nitrile rubber (NBR) offer superior performance due to their saturated polymer backbone and resistance to polar substances.

EPDM provides exceptional UV and ozone resistance, making it ideal for prolonged outdoor exposure. Its thermal stability across a wide range (–50°C to +150°C) ensures consistent performance in varying climates. NBR, while slightly less UV-resistant, excels in oil and fuel resistance—essential for engine room or deck areas prone to hydrocarbon exposure. Both materials can be compounded with anti-slip fillers and textured via precision molding to achieve optimal traction under wet and oily conditions.

Another failure point of generic non-slip pads lies in adhesion. Many off-the-shelf products rely on pressure-sensitive adhesives that delaminate under thermal cycling or moisture ingress. Industrial-grade solutions require dual-phase bonding systems: chloroprene-based contact adhesives combined with mechanical anchoring through molded interlocking patterns. This ensures long-term adhesion to marine substrates such as fiberglass, aluminum, and marine-grade composites.

Additionally, Shore hardness must be optimized. Too soft (below 50 Shore A), and the pad deforms under load, reducing slip resistance; too hard (above 80 Shore A), and the surface becomes brittle and less forgiving under dynamic loads. The ideal range for marine non-slip pads is 60–70 Shore A, balancing resilience, comfort, and grip.

Custom compounding allows for the integration of antimicrobial agents and pigments for UV stability, further extending service life. These enhancements are rarely found in mass-market alternatives, which prioritize cost over performance.

Below is a comparison of common rubber materials used in marine non-slip applications:

| Material | Shore A Hardness | Tensile Strength (MPa) | Elongation at Break (%) | Key Resistance Properties | Service Temperature Range |

|---|---|---|---|---|---|

| Natural Rubber (NR) | 55–65 | 18–25 | 400–600 | Water, flex fatigue | –20°C to +80°C |

| SBR | 60–70 | 15–20 | 350–500 | Abrasion, water | –30°C to +100°C |

| EPDM | 60–75 | 10–18 | 300–450 | UV, ozone, heat, water | –50°C to +150°C |

| Nitrile (NBR) | 65–75 | 12–20 | 250–350 | Oil, fuel, water | –30°C to +120°C |

Material selection is not a one-size-fits-all proposition. For boat non-slip pads, the operational environment dictates the compound. Suzhou Baoshida Trading Co., Ltd. provides OEM-grade rubber solutions engineered for longevity, safety, and compliance with marine performance standards.

Material Specifications

Material Specifications for Marine Non-Slip Pads

Selecting the optimal elastomer for boat non-slip pads is critical for ensuring safety, durability, and performance in harsh marine environments. Suzhou Baoshida Trading Co., Ltd. leverages advanced rubber compounding expertise to tailor solutions addressing saltwater exposure, UV degradation, thermal cycling, and mechanical abrasion. The three primary materials—Viton, Nitrile, and Silicone—exhibit distinct properties that must align with operational demands. Viton (FKM) offers exceptional resistance to fuels, oils, and high temperatures, making it ideal for engine compartments or areas exposed to petroleum-based contaminants. Its molecular stability prevents swelling and degradation in aggressive chemical environments, though it commands a higher cost. Nitrile rubber (NBR) provides an optimal balance of oil resistance, abrasion tolerance, and cost efficiency for general deck applications. With customizable acrylonitrile content, NBR formulations achieve targeted hardness and flexibility while maintaining reliable grip on wet surfaces. Silicone rubber excels in extreme temperature resilience (-60°C to 230°C) and UV stability, ensuring consistent performance under prolonged sun exposure. Its inherent hydrophobicity reduces algae adhesion, but lower abrasion resistance necessitates reinforcement for high-traffic zones.

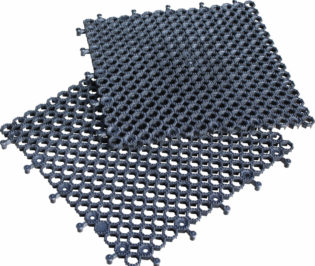

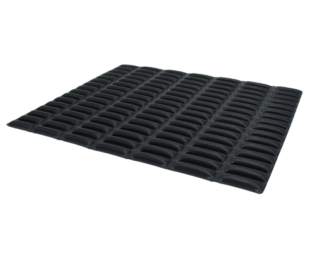

All materials undergo rigorous testing per ISO 188 (heat aging), ASTM D471 (fluid resistance), and ISO 48 (hardness) to validate marine suitability. Hardness is precisely controlled within Shore A 50–70 to balance slip resistance and comfort underfoot. Compression set values below 25% after 70 hours at 100°C guarantee long-term shape retention, preventing pad deformation under static loads. Tensile strength must exceed 10 MPa to withstand mechanical stress during vessel motion, while elongation at break (≥250%) accommodates thermal expansion without cracking. Surface texture is engineered via molded patterns (e.g., pyramid, diamond) to maximize coefficient of friction (>0.8 wet/dry) per DIN 51130 standards. Crucially, all compounds incorporate marine-grade antioxidants and UV stabilizers to mitigate ozone-induced cracking and color fading.

Material Comparison for Boat Non-Slip Applications

| Property | Viton (FKM) | Nitrile (NBR) | Silicone |

|---|---|---|---|

| Shore A Hardness Range | 60–75 | 50–70 | 45–65 |

| Temperature Range (°C) | -20 to 250 | -30 to 120 | -60 to 230 |

| Tensile Strength (MPa) | 12–18 | 10–15 | 6–10 |

| Fuel/Oil Resistance | Excellent | Good to Excellent | Poor |

| Saltwater Resistance | Excellent | Good | Excellent |

| UV/Ozone Stability | Excellent | Fair | Excellent |

| Compression Set (%) | ≤15 (250°C) | ≤25 (100°C) | ≤20 (200°C) |

| Typical Marine Use Case | Engine rooms, fuel zones | Main decks, walkways | Cockpits, sun-exposed areas |

Suzhou Baoshida prioritizes application-specific formulation over generic solutions. For instance, NBR pads destined for commercial fishing vessels integrate ceramic fillers to enhance abrasion resistance against deck salt crystals, while Viton compounds for superyachts include conductive carbon to dissipate static electricity. Silicone variants for tropical climates utilize platinum-cure systems to eliminate peroxide byproducts that accelerate aging. Each material’s density (1.3–1.9 g/cm³) is optimized to minimize weight without compromising structural integrity. OEM partners receive full traceability via batch-specific certificates of conformance, ensuring compliance with ISO 9001 and marine regulatory frameworks. This precision engineering guarantees non-slip pads maintain functional reliability across 10,000+ hours of marine service, directly reducing slip-related incident risks.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of industrial rubber solutions, delivering engineered performance to demanding marine and industrial applications. Our core strength in producing high-performance boat non slip pads lies in a tightly integrated approach combining advanced rubber formulation with precision mold design. At the heart of this capability are our dedicated engineering teams: five experienced mold engineers and two specialized rubber formula engineers who work in parallel to ensure every product meets exacting OEM standards.

Our mold engineering team leverages CAD/CAM/CAE platforms to design, simulate, and optimize mold structures for complex non slip tread patterns. These engineers specialize in multi-cavity and family mold configurations, enabling efficient production of varied pad geometries while maintaining dimensional accuracy and surface fidelity. Through finite element analysis (FEA), they anticipate material flow, cooling behavior, and ejection dynamics, minimizing defects and cycle times. This precision ensures consistent replication of aggressive tread profiles essential for superior traction under wet, oily, or dynamic marine conditions.

Complementing mold design is our in-house rubber formulation expertise. Our formula engineers develop custom elastomer compounds tailored to marine environments, focusing on abrasion resistance, hydrolytic stability, and long-term UV and ozone resistance. Using a base of high-quality SBR, EPDM, or NBR polymers, they fine-tune crosslink density, filler dispersion, and additive packages to achieve optimal Shore A hardness (typically 55–70), tensile strength, and anti-slip coefficient. Each formulation undergoes rigorous testing for slip resistance on wet surfaces, compression set, and resistance to saltwater immersion—critical parameters for marine safety and durability.

This synergy between mold and material engineering enables Suzhou Baoshida to offer full OEM support, from initial concept sketches to mass production. We work directly with boat manufacturers and marine equipment suppliers to co-develop non slip pads that integrate seamlessly into deck layouts, meet regulatory requirements (such as ISO 10240 for marine non-slip surfaces), and deliver consistent performance across batch runs. Our facility supports low-volume prototyping and high-volume manufacturing, with full traceability and quality control per ISO 9001 standards.

The following table outlines typical technical specifications for our standard boat non slip pad formulations:

| Property | Test Method | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 60 ± 5 |

| Tensile Strength | ASTM D412 | ≥12 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Tear Resistance | ASTM D624 | ≥40 kN/m |

| Slip Resistance (wet) | ASTM F2913 | DCOF ≥0.6 |

| Operating Temperature Range | — | -40°C to +100°C |

| Water Absorption (7 days) | ASTM D570 | <1.5% |

By combining deep materials science with precision tooling, Suzhou Baoshida ensures that every non slip pad is not only functionally robust but also engineered for longevity and safety in the harshest marine environments.

Customization Process

Customization Process for Marine Non-Slip Pads

At Suzhou Baoshida Trading Co., Ltd., our customization process for boat non-slip pads integrates rigorous engineering protocols to ensure optimal safety, durability, and performance in marine environments. We adhere to a structured four-phase methodology, beginning with precise drawing analysis and culminating in scalable mass production. This systematic approach minimizes iteration cycles while guaranteeing compliance with ISO 10993 (biocompatibility) and ASTM F1637 (slip resistance) standards.

Drawing Analysis initiates the workflow. Our engineering team dissects client-provided CAD files or technical sketches to validate critical parameters: surface contour compatibility, drainage channel geometry, and load-bearing zones. We assess tolerances to ±0.2 mm for molded edges and verify anti-hydroplaning groove depths per ISO 13036-4. Any dimensional conflicts with vessel deck substrates trigger immediate collaborative redesigns, ensuring seamless integration during installation.

Formulation follows, where material science dictates performance. We optimize the rubber compound using SBR (Styrene-Butadiene Rubber) or EPDM bases, compounded with silica fillers and marine-grade anti-oxidants. Shore A hardness is calibrated between 55–70 to balance flexibility and abrasion resistance, while traction coefficients are engineered for wet CoF ≥0.65 (ASTM E303). Key specifications are validated through predictive modeling before prototyping:

| Parameter | Target Range | Test Standard |

|---|---|---|

| Shore A Hardness | 55–70 | ASTM D2240 |

| Wet Coefficient of Friction | ≥0.65 | ASTM E303 |

| UV Resistance (1,000h) | ΔE ≤ 3.0 | ISO 4892-2 |

| Tensile Strength | ≥12 MPa | ASTM D412 |

| Saltwater Immersion | No delamination | ISO 175 |

Prototyping employs CNC-machined aluminum molds for initial batches of 5–10 units. Each pad undergoes accelerated aging (85°C/85% RH for 72h), dynamic slip testing on wet steel decks, and adhesion validation per ASTM D3330. Client feedback on texture depth, colorfastness, and edge integrity is incorporated within 72 hours, with finite element analysis (FEA) confirming stress distribution under 1.5x operational loads.

Mass Production commences only after formal sign-off on PPAP Level 3 documentation. We deploy multi-cavity compression molding with in-line IR curing (160°C ±2°C) and automated vision inspection for surface defects. Batch traceability is maintained via laser-etched QR codes, tracking raw material lots (e.g., silica from Evonik VN3) through to final packaging. Production volumes scale from 500 to 50,000 units monthly, with statistical process control (SPC) ensuring <0.25% defect rates per ISO 2859-1.

This end-to-end customization framework eliminates guesswork, delivering non-slip pads that withstand continuous saltwater exposure, thermal cycling (-40°C to +80°C), and heavy foot traffic. Suzhou Baoshida’s OEM partnership guarantees technical ownership from concept to container load, with full material disclosure and 24-month performance warranties.

Contact Engineering Team

For industrial buyers seeking high-performance boat non-slip pads engineered for durability, safety, and long-term resistance in marine environments, Suzhou Baoshida Trading Co., Ltd. delivers precision rubber solutions tailored to OEM and bulk manufacturing demands. As a specialized provider in industrial rubber components, we combine material science expertise with rigorous quality control to produce non-slip pads that meet stringent maritime safety standards. Our products are designed to withstand prolonged exposure to saltwater, UV radiation, oil, and extreme temperature fluctuations—critical requirements for commercial and recreational marine applications.

Our boat non-slip pads are manufactured using high-density EPDM and NBR rubber compounds, selected for their superior grip, weather resistance, and mechanical resilience. Each pad undergoes compression molding to ensure consistent thickness, uniform texture, and optimal adhesion properties. The surface pattern is precisely engineered to maximize slip resistance under wet or oily conditions while remaining comfortable underfoot during extended use. Custom formulations can be developed to meet specific Shore A hardness requirements, color coding standards, or flame retardancy certifications (e.g., UL 94, IMO FTP Code).

We support global OEMs, marine equipment manufacturers, and industrial distributors with scalable production runs, strict batch traceability, and full documentation packages including material test reports (MTR), RoHS compliance, and REACH certification. Our quality assurance protocols follow ISO 9001 standards, with in-house testing for tensile strength, elongation at break, compression set, and abrasion resistance.

To ensure seamless integration into your manufacturing or supply chain operations, we offer technical collaboration from concept to delivery. Our engineering team works directly with clients to adjust dimensions, backing systems (adhesive, mechanical fasteners, or flush-mount designs), and performance parameters based on vessel type, deck material, and operational environment.

Below are the standard technical specifications for our most widely deployed boat non-slip pad series:

| Property | Specification |

|---|---|

| Material | EPDM / NBR Blend |

| Hardness (Shore A) | 60 ± 5 |

| Density | 1.35 g/cm³ |

| Tensile Strength | ≥ 8.5 MPa |

| Elongation at Break | ≥ 250% |

| Operating Temperature Range | -40°C to +120°C |

| Slip Resistance (DIN 51130 V10) | R11 Rated |

| Flame Resistance | UL 94 HB Compliant |

| Color Options | Black, Gray, Beige (custom colors available) |

| Standard Thickness | 3 mm, 5 mm, 8 mm |

| Surface Profile | Diamond plate, pyramid, or custom emboss |

For technical inquiries, sample requests, or volume pricing discussions, contact Mr. Boyce, OEM Account Manager at Suzhou Baoshida Trading Co., Ltd. We respond to all industrial partnership inquiries within 12 business hours. Direct communication ensures accurate technical alignment and faster project turnaround.

Contact Mr. Boyce at [email protected] to initiate a technical consultation, request material data sheets, or submit custom drawings for quotation. Our team supports English and Chinese correspondence and coordinates international logistics with DDP, FOB, and EXW terms based on client requirements. Partner with Suzhou Baoshida for reliable, engineered rubber solutions that enhance marine safety and product performance.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).