Technical Contents

Engineering Guide: Boat Rubber Trim

Engineering Insight: Material Selection in Boat Rubber Trim

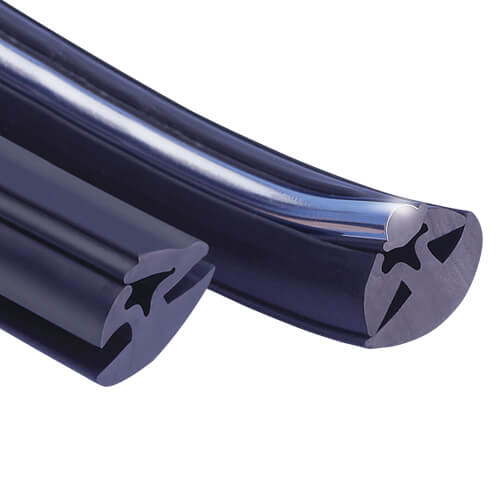

In marine environments, rubber trim components serve far more than aesthetic purposes. They are critical interfaces between structural elements, providing sealing, vibration damping, impact resistance, and protection against environmental degradation. Despite their apparent simplicity, off-the-shelf rubber trims frequently fail in real-world marine applications due to inadequate material engineering. The root cause lies in the mismatch between generic formulations and the unique, dynamic stressors present in marine conditions.

Boat rubber trim is exposed to a synergistic combination of UV radiation, saltwater immersion, oxidative aging, repeated mechanical compression, and wide thermal fluctuations. Standard elastomers such as natural rubber (NR) or low-grade EPDM may appear cost-effective initially but lack the necessary resistance to ozone cracking, hydrolysis, and thermal degradation. These materials often exhibit surface chalking, hardening, or softening within 12 to 18 months of marine service, leading to seal failure, water ingress, and structural fatigue.

At Suzhou Baoshida Trading Co., Ltd., we emphasize compound-specific engineering. High-performance boat rubber trim requires a tailored balance of polymer backbone, filler dispersion, crosslink density, and protective additives. For instance, marine-grade EPDM with high ethylene content and third monomer optimization offers superior ozone and heat resistance. When combined with premium carbon black or silica reinforcement and a robust antioxidant package, such compounds maintain elasticity and tensile strength over extended service cycles.

Equally important is the control of compression set and Shore hardness. A trim that permanently deforms under continuous load will lose its sealing integrity. Our formulations target a Shore A hardness of 55–70 and a compression set below 25% after 70 hours at 100°C, ensuring long-term resilience.

Below is a comparative specification table highlighting key performance metrics between standard and engineered marine rubber trims.

| Property | Standard Off-the-Shelf Trim | Engineered Marine-Grade Trim (Baoshida) |

|---|---|---|

| Base Polymer | Low-grade EPDM or NR | High-purity, high-ethylene EPDM |

| Shore A Hardness | 50–60 | 60–70 |

| Tensile Strength (MPa) | ≥7 | ≥12 |

| Elongation at Break (%) | ≥250 | ≥350 |

| Compression Set (70h @ 100°C) | ≤35% | ≤22% |

| Ozone Resistance (100 pphm) | Poor (cracking in 24h) | Excellent (no cracking after 96h) |

| UV Resistance (QUV, 1000h) | Moderate chalking | Minimal surface change |

| Saltwater Immersion (500h) | Swelling >15%, softening | Swelling <5%, no property loss |

The data underscores a fundamental principle: precision in material science directly correlates with service longevity. Off-the-shelf trims are mass-produced for general use, not for the aggressive marine environment. They sacrifice performance for economy.

Custom-engineered rubber trim, developed through rigorous testing and OEM collaboration, ensures dimensional stability, environmental resilience, and functional reliability. At Baoshida, we partner with boat manufacturers to analyze load profiles, exposure conditions, and lifecycle expectations—delivering not just a product, but a performance-guaranteed solution.

Material Specifications

Material Specifications for Marine Rubber Trim Applications

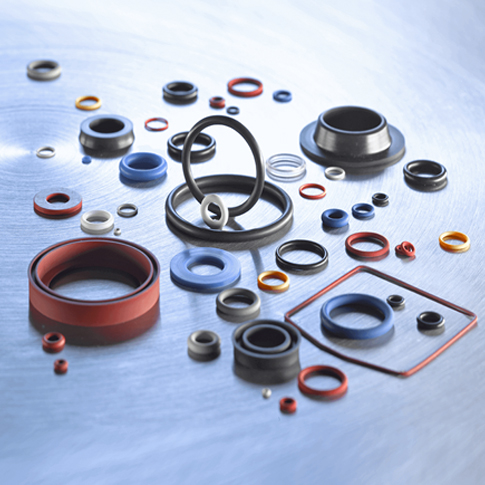

Selecting the optimal elastomer for boat rubber trim is a critical engineering decision directly impacting product longevity, safety, and performance in demanding marine environments. Exposure to saltwater, UV radiation, ozone, fuel oils, hydraulic fluids, and wide temperature fluctuations necessitates precise material formulation. At Suzhou Baoshida Trading Co., Ltd., we supply rigorously tested compounds meeting stringent OEM specifications for Viton (FKM), Nitrile (NBR), and Silicone (VMQ) rubber trims. Each material offers distinct advantages and limitations requiring careful evaluation against specific vessel operational profiles and component functions.

Viton fluoroelastomers provide the highest level of chemical and thermal resistance among standard marine elastomers. Their saturated fluorocarbon backbone delivers exceptional resistance to petroleum-based fuels, lubricants, hydraulic fluids, and solvents commonly encountered in engine compartments and fuel systems. Viton maintains integrity across an extreme temperature range from -20°C to 230°C, resisting hardening at low temperatures and degradation at high temperatures far better than hydrocarbon rubbers. This makes it ideal for critical seals near engines, fuel lines, and exhaust components. However, its superior performance comes with a higher material cost and reduced low-temperature flexibility compared to NBR or Silicone. Standard grades meet ASTM D2000 classification FC 744.

Nitrile rubber remains a cost-effective workhorse for general marine trim applications requiring strong resistance to aliphatic hydrocarbons, vegetable oils, and water. Its good abrasion resistance and mechanical properties suit it for deck edging, non-critical hatch seals, and fender strips. Standard NBR compounds (typically 34-45% acrylonitrile content) function reliably between -30°C and 120°C. Critical limitations include poor resistance to aromatic fuels, ozone cracking, and significant hardening below -40°C. For extended outdoor service, NBR formulations require robust antioxidant and antiozonant packages. ASTM D2000 classification is commonly BCM 745 for marine grades.

Silicone rubber excels in applications demanding extreme temperature stability (-60°C to 200°C) and excellent UV/ozone resistance. Its inherent flexibility across this broad range is advantageous for seals subject to thermal cycling. Silicone also offers good electrical insulation properties. However, it possesses relatively poor resistance to petroleum-based fluids, lower tensile strength, and higher compression set than Viton or NBR. It is susceptible to tearing and abrasion, making it less suitable for high-wear trim edges. Silicone is best reserved for non-fuel-exposed areas like cabin windows, non-critical deck fittings, or where extreme cold flexibility is paramount. ASTM D2000 classification typically falls under M2BG 707.

The following table provides a comparative overview of key properties for informed material selection:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range | -20°C to 230°C | -30°C to 120°C | -60°C to 200°C |

| Fuel/Oil Resistance | Excellent | Good to Very Good | Poor |

| Ozone Resistance | Excellent | Poor (Requires protection) | Excellent |

| UV Resistance | Very Good | Fair | Excellent |

| Water/Saltwater | Excellent | Excellent | Excellent |

| Low Temp Flexibility | Good | Very Good | Excellent |

| Tensile Strength | Good | Very Good | Fair |

| Compression Set | Very Good | Good | Fair to Poor |

| Abrasion Resistance | Good | Very Good | Poor |

| Typical ASTM Class | FC 744 | BCM 745 | M2BG 707 |

| Primary Marine Use | Fuel systems, engine seals | Deck trim, general seals | Non-fuel seals, extreme cold |

Our engineering team collaborates closely with OEM partners to validate material selection against specific environmental stressors and functional requirements, ensuring optimal performance and lifecycle cost for every boat rubber trim application. Material choice must balance chemical exposure, thermal demands, mechanical stresses, and total cost of ownership.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability is anchored in deep technical expertise and a systematic approach to industrial rubber manufacturing. We maintain a dedicated team of five certified mould engineers and two specialized rubber formula engineers, enabling us to deliver fully integrated OEM solutions tailored to the demanding requirements of marine applications—particularly boat rubber trim systems. This dual-engineering model ensures precision in both physical tooling and material science, providing clients with optimized performance, durability, and cost-efficiency.

Our mould engineers bring over 15 years of cumulative experience in precision rubber mould design, utilizing advanced CAD/CAM software including SolidWorks, AutoCAD, and UG NX. Each engineer follows a strict design-for-manufacturability (DFM) protocol, ensuring that every mould is optimized for cycle efficiency, part consistency, and long-term wear resistance. We specialize in multi-cavity compression, transfer, and injection moulds, with tolerances held to ±0.1 mm. All tooling is fabricated in-house or through tightly controlled partner facilities, with rigorous first-article inspection and SPC monitoring.

Complementing our mould engineering strength is our proprietary rubber formulation capability. Our two formula engineers hold advanced degrees in polymer chemistry and elastomer science, with focused experience in marine-grade compounds. They develop custom formulations using EPDM, silicone, neoprene, and NBR base polymers, tailored to resist UV degradation, saltwater corrosion, ozone exposure, and extreme temperature fluctuations—critical for boat trim performance. Each compound is subjected to accelerated aging tests, Shore A hardness validation, and tensile strength verification per ASTM and ISO standards.

Our OEM process begins with collaborative design review, where both mould and material engineers work directly with client specifications. We support full prototyping, material certification, and PPAP documentation. Once approved, we transition seamlessly into high-volume production with traceability at every stage. Our facility operates under IATF 16949-aligned quality management practices, ensuring repeatability and compliance.

This integrated engineering model—combining precision tooling with advanced material science—allows us to solve complex sealing, vibration-damping, and aesthetic challenges inherent in boat rubber trim applications. Whether replacing legacy parts or developing new profiles, we deliver engineered-to-spec solutions with reduced time-to-market and long-term reliability.

Typical Rubber Trim Specifications

| Property | Test Method | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 50–80 ±5 |

| Tensile Strength | ASTM D412 | ≥8 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Compression Set (22 hrs, 70°C) | ASTM D395B | ≤25% |

| Operating Temperature Range | — | -40°C to +120°C |

| Resistance | Salt Spray, UV, Ozone | Excellent |

| Common Base Polymers | — | EPDM, Neoprene, Silicone |

Through this combination of human expertise, technical infrastructure, and quality discipline, Suzhou Baoshida stands as a trusted OEM partner in the industrial rubber sector.

Customization Process

Customization Process for Marine Rubber Trim Components

Suzhou Baoshida Trading Co., Ltd. executes a rigorously defined customization workflow for boat rubber trim, ensuring dimensional precision, environmental resilience, and seamless OEM integration. Our four-phase methodology eliminates design-to-production ambiguities while adhering to stringent marine industry standards.

Drawing Analysis initiates the process, where our engineering team conducts a granular review of client-provided CAD files or technical schematics. Critical parameters including cross-sectional tolerances (±0.1mm), sealing surface geometries, and mounting interface specifications undergo computational validation against ISO 3302-1:2014 standards. We identify potential stress concentration zones and material flow constraints during molding, providing actionable feedback within 72 hours to prevent downstream tooling revisions. This phase confirms compatibility with marine assembly protocols and verifies compliance with ISO 868 for Shore hardness measurement points.

Formulation Engineering follows, leveraging our 15-year compound database to develop purpose-built elastomer matrices. For boat trim applications exposed to saltwater immersion, UV radiation, and ozone, we prioritize EPDM or silicone base polymers with tailored additive packages. Key considerations include: peroxide curing systems for superior hydrolytic stability, carbon black grades optimized for UV attenuation, and proprietary anti-ozonants to prevent surface cracking. Each formulation is validated via ASTM D2000 material classification codes, targeting specific resistance to marine fuels, cleaning agents, and temperature extremes (-40°C to +120°C continuous service).

Prototyping utilizes CNC-machined or 3D-printed molds for low-volume production of functional samples. We subject prototypes to accelerated aging per ASTM D471 (70 hours in 100°C seawater bath), tensile testing (ASTM D412), and compression set analysis (ASTM D395). Dimensional verification employs CMM scanning against original CAD data, with critical sealing surfaces checked for surface finish Ra ≤ 3.2μm. Client validation occurs within 10 business days, incorporating real-world feedback from OEM assembly trials before final tooling release.

Mass Production commences only after formal client sign-off on prototype performance data. Our ISO 9001-certified facility deploys automated injection molding lines with real-time cavity pressure monitoring. Every production batch undergoes:

In-process Shore A hardness checks (every 30 minutes)

Full physical property requalification per ASTM standards (bi-weekly)

100% visual inspection for flash, voids, or surface defects

Traceability via serialized lot numbering compliant with IMO MSC.362(92)

This phased approach reduces time-to-market by 30% while ensuring boat trim components withstand 10+ years of marine service. Our OEM partnership model includes lifetime formulation audits to adapt to evolving material regulations.

Critical Performance Specifications for Marine Trim

| Property | Test Standard | Target Value | Significance for Boat Applications |

|---|---|---|---|

| Shore A Hardness | ASTM D2240 | 60 ± 5 | Ensures proper sealing force without distortion |

| Tensile Strength | ASTM D412 | ≥ 10 MPa | Resists tearing during installation/use |

| Elongation at Break | ASTM D412 | ≥ 300% | Accommodates hull flexure and thermal expansion |

| Compression Set (22h/70°C) | ASTM D395 | ≤ 25% | Maintains sealing integrity after prolonged compression |

| Saltwater Resistance | ASTM D471 | ΔTensile ≤ 15% | Prevents degradation in marine environments |

Contact Engineering Team

For industrial manufacturers and OEM partners seeking precision-engineered rubber solutions, Suzhou Baoshida Trading Co., Ltd. stands at the forefront of high-performance boat rubber trim development and production. With deep expertise in custom elastomer formulations and advanced extrusion techniques, our team delivers durable, weather-resistant, and dimensionally stable rubber profiles tailored to marine applications. Whether you require fender strips, hull seals, deck edging, or custom trim profiles, our engineering team ensures optimal material selection, mechanical performance, and long-term reliability under harsh marine conditions.

Our boat rubber trims are formulated using high-grade EPDM, neoprene, or silicone compounds—each selected for superior UV resistance, ozone stability, and resilience against saltwater exposure. Every product is manufactured under strict ISO-compliant processes, ensuring consistent quality, tight tolerances, and seamless integration with vessel structures. We specialize in co-extruded profiles with dual durometer zones, integrated mounting channels, and colored trims for aesthetic and functional performance. Our in-house R&D lab conducts rigorous testing for compression set, tensile strength, elongation, and low-temperature flexibility to meet the demands of commercial, recreational, and military marine platforms.

Suzhou Baoshida serves as a strategic partner for global OEMs, offering end-to-end support from concept validation to mass production. Our technical team collaborates directly with design engineers to optimize part geometry, material hardness, and installation methodology. We support rapid prototyping, tooling development, and on-site quality audits to ensure alignment with your manufacturing timelines and performance standards.

To initiate a technical consultation or request a custom quote, contact Mr. Boyce, Rubber Formula Engineer and OEM Manager, directly at [email protected]. Mr. Boyce brings over 12 years of experience in marine elastomer systems and leads our application engineering division with a focus on material science innovation and client-specific problem solving. He will coordinate sample submissions, technical data packages, and feasibility assessments tailored to your project requirements.

Below are key specifications for our standard marine-grade boat rubber trim series:

| Property | Test Method | Value (Typical) |

|---|---|---|

| Material Type | — | EPDM / Neoprene / Silicone |

| Hardness (Shore A) | ASTM D2240 | 60 ± 5 |

| Tensile Strength | ASTM D412 | ≥10 MPa |

| Elongation at Break | ASTM D412 | ≥300% |

| Compression Set (24h, 70°C) | ASTM D395 | ≤25% |

| Operating Temperature Range | — | -40°C to +120°C |

| UV and Ozone Resistance | ASTM D1149/D471 | Excellent |

| Specific Gravity | ASTM D297 | 1.25 ± 0.05 |

| Color Options | — | Custom (RAL/Pantone) |

Contact Mr. Boyce today to discuss material compatibility, regulatory compliance (including REACH and RoHS), and scalable supply solutions for your next marine trim project. At Suzhou Baoshida Trading Co., Ltd., we engineer rubber not just to fit— but to perform.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).