Technical Contents

Engineering Guide: Boat Weather Stripping

Engineering Insight: Material Selection in Boat Weather Stripping

In marine environments, weather stripping serves as a critical barrier against water ingress, vibration, noise, and environmental degradation. While off-the-shelf rubber profiles may appear cost-effective for boat weather stripping applications, they frequently fail to meet the rigorous demands of prolonged maritime exposure. The root cause lies in inadequate material selection, which directly impacts service life, sealing performance, and overall vessel integrity.

Marine-grade weather stripping must endure continuous exposure to saltwater, ultraviolet radiation, wide thermal fluctuations, and mechanical compression. Standard elastomers such as generic EPDM or low-grade PVC often degrade rapidly under these conditions, exhibiting cracking, hardening, or compression set. These failures compromise watertight seals, leading to interior damage, increased maintenance costs, and potential safety hazards.

At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered rubber solutions tailored to the specific operational profile of the vessel. High-performance materials such as marine-grade EPDM (ethylene propylene diene monomer) with enhanced UV and ozone resistance, or hydrogenated nitrile butadiene rubber (HNBR) for oil and fuel resistance, offer superior longevity. Additionally, closed-cell silicone foams provide excellent thermal insulation and moisture resistance in cabin and hatch applications.

Material selection must also consider dynamic vs. static sealing requirements. Hatches, doors, and windows undergo repeated compression cycles, necessitating elastomers with low compression set and high resilience. Shore hardness, tensile strength, and elongation at break are critical parameters that determine performance under mechanical stress.

Another often-overlooked factor is adhesion compatibility. Off-the-shelf strips may not bond effectively to marine substrates such as fiberglass, aluminum, or composite panels, leading to delamination. Custom formulations include primers and adhesive layers engineered for specific substrates, ensuring long-term durability.

The following table outlines key material properties for common elastomers used in marine weather stripping:

| Material | Shore A Hardness | Tensile Strength (MPa) | Elongation at Break (%) | Operating Temp Range (°C) | Key Resistance Properties |

|---|---|---|---|---|---|

| Marine EPDM | 50–70 | 12–18 | 300–500 | -50 to +150 | UV, ozone, saltwater, weathering |

| HNBR | 60–80 | 20–28 | 250–400 | -40 to +170 | Oil, fuel, heat, abrasion |

| Silicone (Closed-cell) | 40–60 | 4–8 | 200–300 | -60 to +200 | Extreme temps, UV, moisture |

| Neoprene | 50–70 | 10–15 | 250–350 | -40 to +120 | Mild oil, flame, weathering |

Generic solutions rarely account for these nuanced requirements. In contrast, precision-engineered weather stripping from Suzhou Baoshida integrates material science with application-specific design, ensuring reliable performance across diverse marine platforms. By prioritizing material integrity and environmental compatibility, OEMs can significantly reduce lifecycle costs and enhance end-user satisfaction.

Material Specifications

Material Specifications for Marine Weather Stripping Applications

Selecting optimal elastomer compounds for boat weather stripping demands rigorous evaluation of environmental stressors including saltwater immersion, UV exposure, fuel/oil contact, and thermal cycling. At Suzhou Baoshida Trading Co., Ltd., our OEM-engineered solutions prioritize long-term sealing integrity under dynamic marine conditions. Viton (FKM), Nitrile (NBR), and Silicone (VMQ) represent industry-standard materials, each exhibiting distinct performance profiles validated per ASTM D2000 classification systems. Material selection directly impacts service life, with improper specification leading to premature compression set, extrusion, or chemical degradation compromising hull integrity.

Viton fluoroelastomers deliver exceptional resistance to marine diesel, biofuels, and hydraulic fluids, maintaining seal performance at continuous temperatures up to 230°C. Their high fluorine content provides superior ozone and oxidation stability critical for exposed deck hardware. However, Viton’s stiffness at low temperatures (-20°C) necessitates specialized formulations for cold-climate cruising vessels. Nitrile rubber offers a cost-effective balance for general marine use, with acrylonitrile content (34-50%) tailoring oil resistance. Standard NBR compounds withstand -30°C to 100°C but exhibit vulnerability to UV degradation and ozone cracking without protective additives, requiring carbon-black reinforcement for extended deck exposure. Silicone rubber excels in extreme temperature ranges (-60°C to 200°C) and demonstrates unmatched UV resistance, making it ideal for sun-intensive applications like cabin windows. Its low surface energy resists marine growth adhesion yet presents challenges in fuel resistance and abrasion tolerance, limiting use in fuel hatch seals.

The comparative analysis below details critical parameters for informed material selection:

| Material | Continuous Temp Range (°C) | Key Fluid Resistance | Compression Set (ASTM D395, 70h/100°C) | Critical Marine Limitations |

|---|---|---|---|---|

| Viton (FKM) | -20 to 230 | Excellent: Diesel, lube oils, hydraulic fluids | ≤25% | Poor low-temp flexibility; high cost; incompatible with ketones |

| Nitrile (NBR) | -30 to 100 | Good: Water, aliphatic oils; Fair: Aromatics | ≤35% | Moderate UV/ozone resistance; swells in fuels; requires stabilizers |

| Silicone (VMQ) | -60 to 200 | Poor: Fuels, oils; Excellent: Water, salts | ≤20% | Low tensile strength; prone to tearing; requires surface treatment for adhesion |

Suzhou Baoshida’s OEM division customizes compound formulations to address application-specific stressors. For engine compartment gaskets requiring fuel resistance, we deploy peroxide-cured Viton with 66% fluorine content. NBR blends incorporate 48% acrylonitrile and EPDM co-polymers for enhanced ozone resistance in deck hardware. Marine-grade Silicone utilizes platinum-cured VMQ with reinforced silica fillers to improve tear strength for window seals. All compounds undergo ISO 1817 immersion testing in synthetic seawater and marine diesel for 1,000 hours prior to certification. Partner with our engineering team to validate material suitability against your vessel’s operational profile, ensuring weather stripping performance meets stringent SOLAS and IMO durability standards. Precision material science is non-negotiable in preventing catastrophic water ingress.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability in industrial rubber solutions is anchored in deep technical expertise and a disciplined approach to material science and mold design. We maintain a dedicated team of five certified mold engineers and two specialized rubber formula engineers, enabling us to deliver fully integrated OEM solutions for demanding applications such as boat weather stripping. This cross-functional engineering structure allows seamless coordination between material development and mold precision, ensuring optimal performance, durability, and manufacturability.

Our formula engineers specialize in elastomer chemistry, focusing on EPDM, silicone, and specialty rubber compounds engineered for marine environments. They develop custom formulations that meet stringent requirements for UV resistance, ozone stability, compression set, and low-temperature flexibility—critical factors in marine sealing performance. Each compound is rigorously tested for aging, water immersion, and dynamic sealing under simulated sea conditions. By controlling the formulation process in-house, we ensure batch-to-batch consistency and compliance with international standards such as ISO 1817 and ASTM D2000.

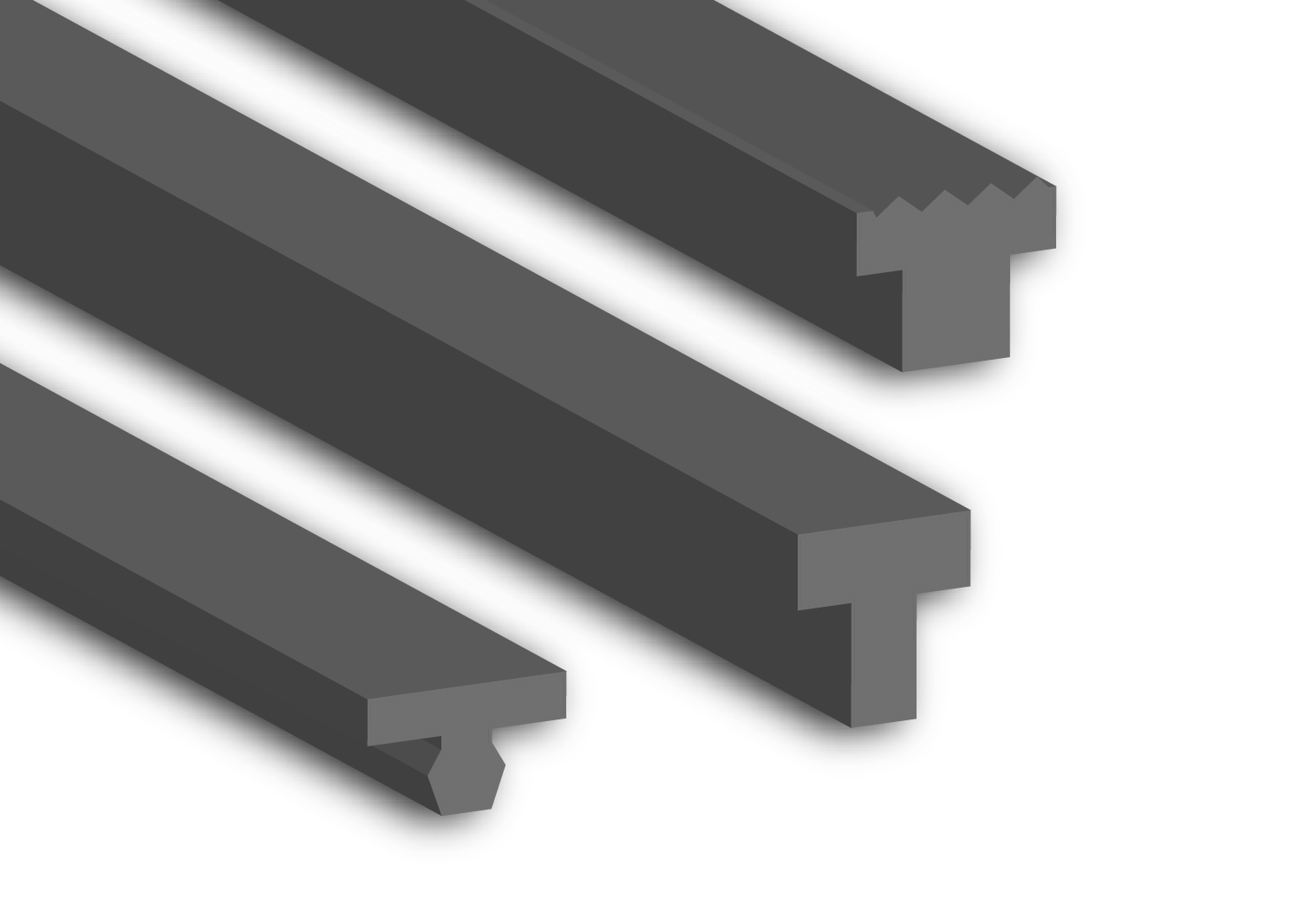

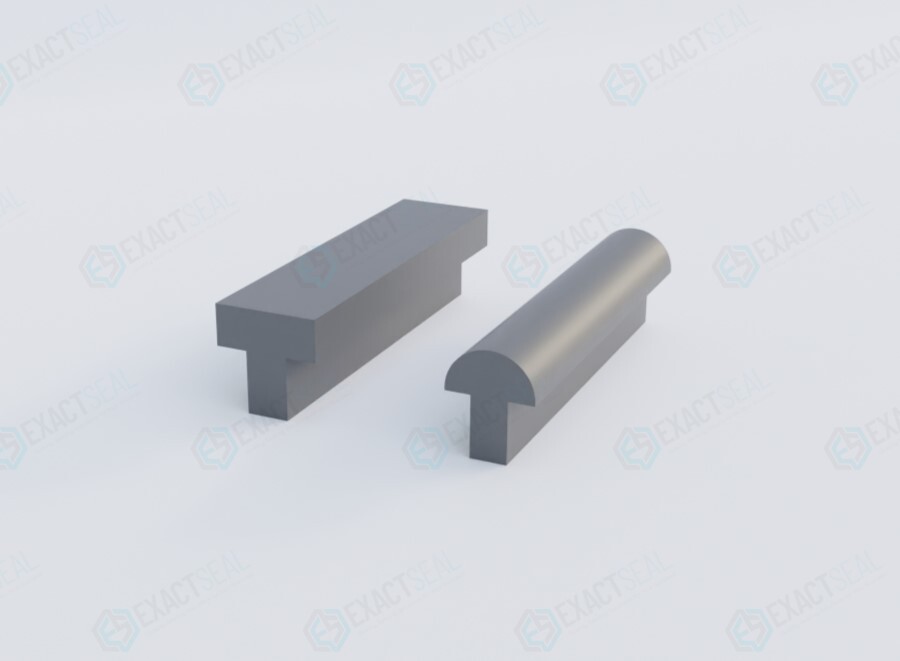

Complementing our material expertise, our five mold engineers bring extensive experience in precision tooling for extruded, molded, and co-extruded rubber profiles. Utilizing advanced CAD/CAM software and 3D simulation tools, they design molds that ensure dimensional accuracy, optimal flow dynamics, and minimal flash. For boat weather stripping, this translates into tight tolerances, clean parting lines, and consistent cross-sectional geometry—essential for reliable sealing against water ingress, wind, and noise.

We support full OEM service from concept to mass production. Our engineering team collaborates directly with clients to interpret technical drawings, reverse-engineer legacy profiles, and optimize designs for manufacturability. Prototyping is conducted in-house with rapid tooling, allowing for functional testing and fast iteration. Once validated, we scale to high-volume production using automated vulcanization lines and robotic handling systems, maintaining quality and throughput.

Our integrated engineering model reduces development cycle time and eliminates third-party dependencies. This vertical control—from raw compound formulation to final mold production—ensures intellectual property protection and faster time-to-market for our OEM partners.

Below are typical technical specifications we achieve for custom boat weather stripping solutions:

| Property | Test Standard | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 50–80 ±5 |

| Tensile Strength | ASTM D412 | ≥8 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Compression Set (22h, 70°C) | ASTM D395 | ≤25% |

| Water Absorption (7 days) | ISO 1817 | <2% |

| Operating Temperature Range | — | -40°C to +120°C |

| UV and Ozone Resistance | ASTM D1149 | No cracking after 168h |

Our engineering team is committed to solving complex sealing challenges in marine environments through scientific rigor and precision manufacturing. With full OEM capability and in-house technical control, Suzhou Baoshida delivers reliable, high-performance rubber solutions tailored to the exact needs of boat manufacturers and marine component suppliers.

Customization Process

Customization Process for Marine Weather Stripping Solutions

At Suzhou Baoshida Trading Co., Ltd., our customization process for boat weather stripping integrates rigorous scientific methodology with industrial precision to ensure optimal performance in harsh marine environments. The sequence begins with Drawing Analysis, where engineering teams dissect client-provided CAD files and technical specifications. We prioritize dimensional tolerances, cross-sectional geometry, and dynamic sealing requirements under variable hull flex conditions. Critical parameters include compression set limits (ASTM D395), Shore A hardness compatibility with marine substrates, and UV exposure thresholds. Any ambiguities in material callouts or environmental stressors trigger immediate client consultation to prevent downstream deviations. This phase employs GD&T validation to align with ISO 1127 standards for marine sealing interfaces.

Following drawing validation, Formulation Development commences in our ISO 17025-certified laboratory. Material selection focuses on EPDM polymers enhanced with silica-based fillers and proprietary antioxidant packages to resist saltwater immersion, ozone degradation, and 120°C+ thermal cycling. Shore A hardness is fine-tuned between 55–75 to balance compression recovery and wind/water resistance. Each compound undergoes accelerated aging per ASTM D2000 M2BA714, with dynamic mechanical analysis confirming resilience at -40°C to 100°C operational ranges. Critical additives include non-staining waxes for UV protection and low-extractable plasticizers to prevent leaching in bilge environments.

Prototyping executes validated formulations via precision extrusion or injection molding, replicating production tooling geometry. Three iterative prototype batches undergo stringent validation:

Salt spray testing (ASTM B117) for 1,000 hours

Compression deflection force measurement (ISO 3384)

Full-scale boat door/window cycle testing (50,000+ operations)

Client feedback on prototype fitment and sealing efficacy informs final adjustments before tooling sign-off.

Mass Production initiates only after PPAP Level 3 documentation approval. Continuous inline monitoring tracks durometer (±2 Shore A), extrusion consistency (laser micrometer QC), and cure state (moving die rheometer). Every batch includes traceable material certificates and undergoes final inspection per AQL 1.0 standards. Production scalability supports volumes from 500 to 50,000+ linear meters monthly, with JIT delivery coordination for global shipyards.

Material Performance Comparison for Marine Applications

| Property | Standard Automotive Seal | Baoshida Marine-Grade EPDM |

|---|---|---|

| Compression Set (70h/100°C) | 35% max | 18% max |

| Shore A Hardness Range | 60–70 | 55–75 (marine-optimized) |

| Saltwater Resistance | Moderate (swell >15%) | Excellent (swell <8%) |

| UV/Ozone Resistance | 500 hrs (cracking) | 2,000+ hrs (no degradation) |

| Low-Temperature Flex | -30°C | -45°C |

This closed-loop process ensures weather stripping exceeds ISO 868 and ISO 188 marine durability benchmarks while minimizing total cost of ownership through extended service life. Suzhou Baoshida’s engineering oversight guarantees every meter of extruded profile delivers watertight integrity across oceanic conditions.

Contact Engineering Team

Contact Suzhou Baoshida for Premium Boat Weather Stripping Solutions

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of industrial rubber manufacturing, delivering high-performance sealing solutions tailored to the marine industry. Our boat weather stripping products are engineered to meet the rigorous demands of marine environments, where resistance to saltwater, UV exposure, ozone degradation, and extreme temperature fluctuations is non-negotiable. As your dedicated OEM partner, we combine advanced rubber compounding expertise with precision extrusion technologies to produce custom weather stripping profiles that ensure watertight integrity, noise reduction, and long-term durability across all vessel types.

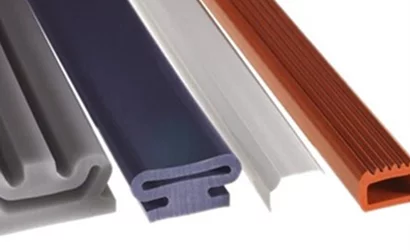

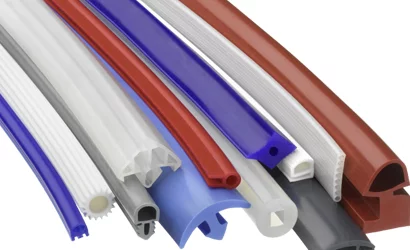

Our engineering team specializes in formulating EPDM, silicone, neoprene, and thermoplastic rubber (TPR) compounds optimized for marine sealing applications. Each profile is developed with attention to compression set resistance, tensile strength, and Shore A hardness to ensure optimal sealing force without premature wear or deformation. Whether you require sponge rubber for door gaskets, solid rubber for hatch seals, or co-extruded profiles with rigid and flexible zones, Suzhou Baoshida delivers consistent quality under ISO 9001-certified production standards.

Below is a representative specification table for our standard marine-grade EPDM weather stripping, commonly used in boat cabin doors, hatches, and window perimeters:

| Property | Test Method | Typical Value |

|---|---|---|

| Material | — | EPDM (Closed-Cell Sponge) |

| Density | ASTM D3574 | 0.55 g/cm³ |

| Hardness (Shore A) | ASTM D2240 | 45 ± 5 |

| Tensile Strength | ASTM D412 | ≥ 1.8 MPa |

| Elongation at Break | ASTM D412 | ≥ 180% |

| Compression Set (22 hrs @ 70°C) | ASTM D395 | ≤ 20% |

| Temperature Range | — | -40°C to +120°C |

| UV & Ozone Resistance | ASTM D1149 | Excellent |

| Color Options | — | Black, White, Gray, Custom |

| Standard Lengths | — | 1m, 2m, 5m, or continuous |

All profiles can be customized in cross-section, durometer, color, and length, with options for adhesive backing (3M 4229P or equivalent), magnetic strips, or integration with aluminum reinforcement for structural retention. We support low-volume prototyping and high-volume production with lead times optimized for global logistics.

For technical collaboration, material samples, or custom profile design support, contact Mr. Boyce, OEM Project Manager at Suzhou Baoshida Trading Co., Ltd. Mr. Boyce brings over 12 years of experience in rubber extrusion and marine sealing systems, offering direct engineering consultation to ensure your weather stripping solution meets exact performance and dimensional requirements. Reach out via email at [email protected] to initiate a technical review, request a quote, or discuss compliance with marine standards such as ISO 8666 or ABYC A-18. Our team responds to all inquiries within 6 business hours and supports English, Mandarin, and German communication. Partner with Suzhou Baoshida for precision-engineered rubber solutions built for the sea.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).