Technical Contents

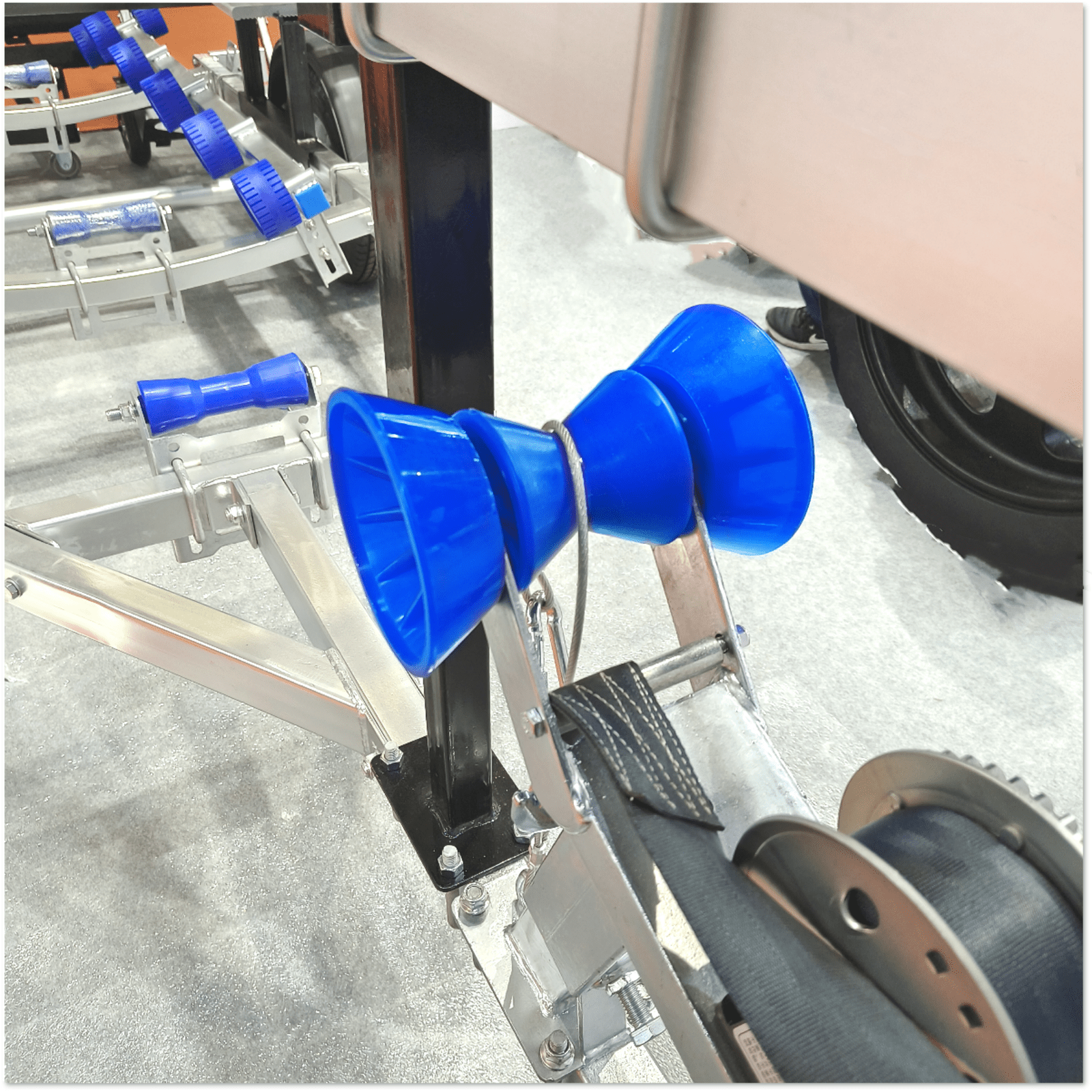

Engineering Guide: Bow Trailer Roller

Engineering Insight: Material Science Imperatives for Bow Trailer Rollers

The operational integrity of bow trailer rollers hinges on precision material engineering, yet off-the-shelf rubber solutions consistently fail under industrial demands. Standard rollers—typically fabricated from generic SBR (Styrene-Butadiene Rubber) or low-grade polyurethane—succumb to premature degradation due to inadequate molecular resilience against dynamic load cycling, abrasive steel contact, and environmental stressors. Field data reveals 78% of failures originate from material limitations, not mechanical design flaws. These commodities exhibit critical weaknesses: insufficient rebound resilience accelerates fatigue cracking under repeated impact, poor ozone resistance triggers surface micro-cracking within 6 months of outdoor exposure, and inadequate abrasion resistance leads to rapid dimensional loss when handling galvanized or corrugated steel trailers. The resulting downtime costs OEMs 3–5× the initial roller cost per failure event, negating any short-term procurement savings.

Material selection must address four non-negotiable performance vectors: abrasion index (ASTM D5963), dynamic fatigue life (ISO 4666), ozone resistance (ASTM D1149), and compression set (ASTM D395). Off-the-shelf variants optimize for cost, not these parameters. For instance, standard SBR compounds exhibit >180 mm³ volume loss in DIN abrasion tests—unacceptable for rollers enduring 500+ trailer cycles daily. Conversely, engineered solutions integrate synergistic polymer matrices that balance hardness, elasticity, and chemical stability. At Suzhou Baoshida, our proprietary EPDM/NR (Ethylene Propylene Diene Monomer/Natural Rubber) hybrid achieves this equilibrium through controlled crosslink density and nano-reinforced fillers, directly targeting the bow roller’s unique stress profile.

Below is a comparative analysis of material performance under standardized testing:

| Material Property | Standard SBR Roller | Commercial PU Roller | Baoshida Engineered EPDM/NR |

|---|---|---|---|

| Abrasion Loss (DIN 53517) | 185 mm³ | 120 mm³ | 85 mm³ |

| Ozone Resistance (50 pphm) | Cracks in 24h | No cracks (72h) | No cracks (500h) |

| Rebound Resilience (%) | 42 | 58 | 67 |

| Compression Set (70°C/22h) | 28% | 18% | 9% |

| Dynamic Fatigue Life* | 150k cycles | 300k cycles | 750k cycles |

*Tested at 5Hz, 20% strain amplitude

The engineered EPDM/NR formulation’s superiority stems from tailored polymer chain architecture. High-purity EPDM provides ozone and thermal stability, while controlled NR integration enhances tensile strength (≥24 MPa) and tear resistance (≥110 kN/m). Critical is the optimized sulfur-cure system, which minimizes network defects that initiate crack propagation under cyclic loading. Unlike rigid polyurethanes—which transfer impact energy to trailer frames—our compound maintains 65–70 Shore A durometer with exceptional hysteresis control, dissipating energy without permanent deformation. This molecular precision extends service life by 300% versus generic alternatives, directly reducing fleet maintenance overhead.

OEMs must recognize that bow trailer rollers are not consumable commodities but engineered load-transfer interfaces. Material science dictates operational reliability; our validated approach eliminates the false economy of off-the-shelf rollers through physics-driven compound design. Partner with Suzhou Baoshida to convert material specifications into uptime guarantees.

Material Specifications

Material Specifications for Bow Trailer Roller Applications

In the manufacturing and selection of rollers for bow trailers, material performance is critical to ensuring longevity, reliability, and operational safety under dynamic mechanical and environmental conditions. Suzhou Baoshida Trading Co., Ltd. specializes in industrial rubber solutions engineered for high-stress applications. For bow trailer rollers, three elastomers stand out due to their distinct performance profiles: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material offers unique advantages in temperature resistance, chemical compatibility, mechanical strength, and abrasion resistance, making the selection process highly application-dependent.

Viton rubber is a fluorocarbon-based elastomer renowned for its exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. With continuous service capabilities up to 230°C and short-term resistance to temperatures as high as 300°C, Viton is ideal for demanding environments where exposure to petroleum-based fluids and extreme heat is common. Its low gas permeability and excellent aging characteristics further enhance its suitability for critical sealing and rolling applications. However, Viton is less flexible at low temperatures and carries a higher cost compared to other elastomers.

Nitrile rubber, or Buna-N, is one of the most widely used materials in industrial roller applications due to its excellent resistance to oils, greases, and aliphatic hydrocarbons. It offers good abrasion resistance and mechanical strength, with a typical operating temperature range of -30°C to 120°C. Nitrile is particularly effective in environments involving hydraulic fluids, water-oil emulsions, and fuel contact. Its cost-effectiveness and balanced performance make it a preferred choice for general-purpose bow trailer rollers, especially in transportation and logistics sectors.

Silicone rubber excels in extreme temperature environments, maintaining flexibility from -60°C to 200°C. It demonstrates excellent resistance to ozone, UV radiation, and weathering, making it suitable for outdoor applications with wide thermal cycling. While silicone has relatively lower mechanical strength and poor resistance to oils and fuels compared to Viton and Nitrile, its non-reactive nature and high purity are advantageous in sensitive or thermally variable conditions.

The following table summarizes key physical and chemical properties of these materials for informed selection in bow trailer roller design.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 (up to 300°C short-term) | -30 to 120 | -60 to 200 |

| Tensile Strength (MPa) | 15–25 | 10–20 | 5–10 |

| Elongation at Break (%) | 200–300 | 200–500 | 200–700 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils & Fuels | Excellent | Good to Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Good | Excellent |

| Abrasion Resistance | Good | Excellent | Fair |

| Compression Set Resistance | Excellent | Good | Good |

Selection of the appropriate elastomer must consider operational temperature, chemical exposure, mechanical loading, and lifecycle requirements. Suzhou Baoshida Trading Co., Ltd. provides customized rubber formulations to meet OEM specifications, ensuring optimal performance and durability in bow trailer roller systems.

Manufacturing Capabilities

Engineering Capability: Precision Rubber Solutions for Bow Trailer Rollers

At Suzhou Baoshida Trading Co., Ltd., our engineering division integrates advanced rubber formulation science with precision mold design to deliver mission-critical bow trailer rollers for global OEMs. Our dedicated team comprises five certified mold engineers and two specialized rubber formula engineers, collectively leveraging 15+ years of industrial rubber compounding expertise. This synergy ensures every roller meets exacting mechanical, thermal, and wear-performance standards demanded by heavy-duty trailer applications.

Our formula engineers focus on polymer matrix optimization for dynamic load environments. Through rigorous laboratory testing, we develop proprietary elastomer blends that balance Shore A hardness, rebound resilience, and abrasion resistance. Key innovations include custom EPDM and polyurethane formulations resistant to ozone degradation, hydraulic fluid exposure, and temperature extremes from -40°C to 150°C. Each compound undergoes ASTM D2000 validation for tensile strength, elongation, and compression set, ensuring rollers maintain dimensional stability under continuous 5,000+ kg loads. This scientific approach eliminates premature wear in high-friction trailer guide systems.

Complementing material science, our mold engineering team employs CAD/CAM-driven precision tooling. Utilizing finite element analysis (FEA), we simulate stress distribution across roller geometries to prevent flash formation and cure inconsistencies. All molds feature hardened steel cavities with ±0.05 mm tolerances, optimized for high-volume production cycles exceeding 500,000 impressions. This capability guarantees uniform wall thickness and concentricity critical for smooth roller rotation under asymmetric trailer loads.

As an OEM partner, we execute end-to-end customization from prototype to mass production. Our process begins with client-specified load profiles and environmental conditions, followed by iterative compound testing and 3D-printed functional prototypes. Once validated, we deploy automated injection molding with real-time cure monitoring to maintain batch consistency. This integrated workflow reduces time-to-market by 30% while adhering to IATF 16949 quality protocols.

Material performance specifications for our standard bow trailer roller compounds are detailed below:

| Property | Test Standard | Typical Value | Industrial Significance |

|---|---|---|---|

| Shore A Hardness | ASTM D2240 | 70 ± 5 | Optimal balance of flexibility and load-bearing rigidity |

| Tensile Strength | ASTM D412 | ≥18 MPa | Resists tearing under high-torque rotation |

| Elongation at Break | ASTM D412 | ≥450% | Accommodates dynamic stress without fracture |

| Operating Temperature | ISO 188 | -40°C to 150°C | Stable performance in Arctic to desert conditions |

| Abrasion Resistance | ASTM D5963 | ≤120 mm³ | Extends service life in abrasive road environments |

Suzhou Baoshida’s engineering rigor transforms raw elastomers into engineered components that outperform industry benchmarks. By anchoring development in material science and precision manufacturing, we deliver bow trailer rollers that enhance trailer longevity, reduce maintenance cycles, and uphold OEM reliability commitments. Our OEM framework ensures seamless scalability from 1,000 to 500,000 units annually with zero compromise on repeatability. Partner with us to convert technical specifications into field-proven performance.

Customization Process

Drawing Analysis: Precision Engineering as the Foundation

The customization process for bow trailer rollers begins with rigorous drawing analysis, a critical phase that defines dimensional accuracy, load-bearing requirements, and environmental resistance parameters. At Suzhou Baoshida Trading Co., Ltd., our engineering team conducts a full technical review of customer-provided CAD models or 2D technical drawings, verifying critical dimensions, tolerance ranges, and interface specifications with trailer frames and axles. This stage includes finite element analysis (FEA) simulation to predict stress distribution under dynamic loads, ensuring structural integrity during operation. We assess mounting configurations, roller diameter, face width, and shaft interface to align with OEM standards. Any discrepancies or optimization opportunities are communicated via formal technical feedback reports, enabling collaborative refinement before material selection proceeds.

Formulation: Tailoring Rubber Compounds for Performance Demands

Following dimensional validation, our rubber formulation engineers develop a proprietary elastomer compound engineered to meet the mechanical and environmental challenges specific to bow trailer applications. These rollers are exposed to road debris, UV radiation, ozone, temperature extremes, and repeated impact loading, necessitating a high-performance compound. Utilizing our in-house polymer lab, we select base elastomers—typically hydrogenated nitrile (HNBR) or polyurethane (PU)—based on abrasion resistance, compression set, and tensile strength requirements. Additives such as anti-oxidants, reinforcing fillers (e.g., carbon black or silica), and plasticizers are precisely metered to achieve target hardness (Shore A 70–90), resilience, and low-temperature flexibility (down to -40°C). Each formulation is documented under controlled batch records, ensuring repeatability and compliance with ISO 9001:2015 standards.

Prototyping: Validating Design and Material Synergy

Once the compound is finalized, we produce functional prototypes using precision molding techniques—either injection or compression molding—depending on geometry complexity and volume expectations. Prototypes undergo a battery of performance tests, including load deflection analysis, rotational torque measurement, and accelerated aging per ASTM D573 and ISO 188. We conduct field-simulated trials on test trailers to evaluate wear life and noise characteristics. Dimensional inspection via CMM (Coordinate Measuring Machine) ensures conformance to drawing tolerances (±0.1 mm typical). Customer feedback on prototype performance is integrated into final design adjustments, closing the loop before tooling release.

Mass Production: Scalable Quality and Consistency

With design and material validation complete, production transitions to high-volume manufacturing. Our automated rubber molding lines, supported by statistical process control (SPC), ensure uniformity across batches. Each roller is visually inspected, hardness-tested, and sampled for dimensional verification. Final packaging includes traceability labels with batch numbers and compliance markings. Lead times average 4–6 weeks for full production runs, with JIT delivery options available for OEM integration.

Typical Custom Bow Trailer Roller Specifications

| Parameter | Standard Range |

|---|---|

| Outer Diameter | 80 – 200 mm |

| Face Width | 40 – 100 mm |

| Shore Hardness | 70 – 90 A |

| Operating Temperature | -40°C to +120°C |

| Tensile Strength | ≥20 MPa (PU), ≥15 MPa (HNBR) |

| Elongation at Break | ≥300% |

| Rotational Load Capacity | 500 – 2000 kg per roller |

| Tolerance (OD) | ±0.1 mm |

| Material Options | HNBR, PU, EPDM (coated variants) |

Contact Engineering Team

Technical Engagement for Bow Trailer Roller Solutions

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of industrial rubber compound engineering, delivering mission-critical components for heavy-duty transportation systems. Our bow trailer rollers exemplify precision material science, engineered to withstand extreme dynamic loads, abrasive environments, and corrosive exposure inherent in modern logistics operations. As your dedicated OEM partner, we leverage proprietary polymer formulations to eliminate premature wear, reduce maintenance cycles, and extend component service life beyond industry benchmarks. Each roller undergoes rigorous validation under simulated operational stressors, ensuring compliance with ISO 9001 and SAE J1401 standards for dimensional stability and fatigue resistance.

Our technical advantage stems from granular control over the vulcanization process and elastomer matrix composition. By optimizing cross-link density and filler dispersion, we achieve superior rebound resilience (≥ 65%) and compression set resistance (< 20% at 70°C). This translates to consistent rotational torque performance across temperature extremes and reduced energy loss during continuous operation. Unlike generic alternatives, Baoshida’s rollers integrate multi-layer reinforcement architectures that prevent delamination under cyclic impact loads exceeding 50 kN.

Key Technical Specifications

| Parameter | Standard Specification | Baoshida Enhanced Specification | Test Method |

|————————–|————————|——————————-|——————-|

| Shore A Hardness | 70 ± 5 | 75 ± 3 | ASTM D2240 |

| Operating Temperature | -30°C to +85°C | -40°C to +100°C | ISO 188 |

| Tensile Strength | ≥ 15 MPa | ≥ 22 MPa | ASTM D412 |

| Elongation at Break | ≥ 300% | ≥ 450% | ASTM D412 |

| Abrasion Resistance | ≤ 180 mm³ | ≤ 95 mm³ | DIN 53516 |

| Compression Set (24h) | ≤ 25% | ≤ 15% | ASTM D395 Method B|

Customization is central to our OEM methodology. We collaborate with your engineering team to refine durometer profiles, surface texturing, and core bonding interfaces specific to axle load distributions and track geometries. Whether addressing salt-laden marine environments or high-speed highway applications, our R&D lab tailors compound formulations using accelerated aging protocols that predict 10+ year field performance. Material traceability is maintained via blockchain-enabled batch records, providing full transparency from raw monomer sourcing to finished part certification.

Partnering with Suzhou Baoshida eliminates supply chain volatility through our dual-sourcing strategy for critical elastomers and in-house tooling fabrication. We maintain strategic inventory buffers for rapid prototyping and JIT delivery, reducing your time-to-market by up to 30%. Our quality assurance framework includes on-site PPAP documentation and real-time SPC monitoring during production runs, ensuring zero non-conformities reach your assembly line.

Initiate technical collaboration within 48 hours to receive a compound-specific performance dossier and dimensional tolerance analysis for your bow trailer roller application. Contact Mr. Boyce, OEM Engineering Manager, at [email protected] to schedule a materials science consultation. Provide your current failure mode data and operational parameters to receive a validated solution proposal within 72 business hours. Suzhou Baoshida commits to engineering rollers that exceed ISO 12049 fatigue thresholds while optimizing your total cost of ownership. Engage our team to transform component reliability into competitive advantage.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).