Technical Contents

Engineering Guide: Bumper And Fender

Engineering Insight: Material Selection Criticality for Bumpers and Fenders

Material selection for industrial rubber bumpers and fenders is not a procurement exercise but a foundational engineering decision directly impacting product lifecycle, safety, and operational cost. Off-the-shelf elastomer solutions frequently fail in demanding applications because they prioritize generic cost reduction over the specific physicochemical requirements of the operational environment. Standard formulations lack the tailored resistance to sustained dynamic stress, extreme temperature fluctuations, aggressive chemical exposure, or prolonged UV/ozone degradation encountered in marine, automotive, and material handling contexts. Consequently, premature failure modes such as cracking, hardening, excessive compression set, or adhesion loss manifest rapidly, leading to unplanned downtime, safety hazards, and significantly higher total cost of ownership despite lower initial acquisition costs.

The core failure mechanism of generic materials lies in their inability to balance multiple critical properties simultaneously. A formulation optimized solely for initial hardness or low cost often sacrifices resilience under cyclic loading or environmental stability. For instance, standard EPDM compounds may offer baseline weather resistance but typically exhibit poor resistance to oils, fuels, or hydraulic fluids common in industrial settings, leading to swelling and loss of mechanical integrity. Similarly, inadequate filler systems or suboptimal cure chemistry result in excessive permanent deformation after impact, compromising the bumper’s energy absorption function over time. Suzhou Baoshida Trading Co., Ltd. emphasizes that performance hinges on precise molecular architecture – co-polymer selection, reinforcing filler dispersion, antioxidant package sophistication, and vulcanization kinetics must be engineered for the exact duty cycle.

The following table illustrates key performance differentiators between a typical off-the-shelf EPDM and a purpose-engineered formulation for demanding fender applications:

| Property | Standard Off-the-Shelf EPDM | Custom Engineered Formulation | Performance Impact of Customization |

|---|---|---|---|

| Ozone Resistance (ASTM D1149) | Moderate (Cracking @ 50pphm, 48h) | Excellent (No Cracking @ 100pphm, 200h) | Prevents catastrophic surface cracking in outdoor/marine use |

| Compression Set (ASTM D395, 22h/70°C) | 35-45% | 15-22% | Maintains sealing force and shape recovery after repeated impacts |

| Fluid Resistance (IRMOG 7, 70h) | Severe Swelling (>25%) | Minimal Swelling (<8%) | Preserves dimensional stability and mechanical properties near hydraulic systems |

| Low Temp Flex (ASTM D2137) | -35°C | -50°C | Ensures impact absorption capability in arctic environments |

| Tensile Strength Retention (After 1000h QUV) | 40-50% | 75-85% | Sustains structural integrity under prolonged UV exposure |

Therefore, successful bumper and fender performance necessitates moving beyond catalog specifications. Material science must be applied proactively, analyzing the specific stressors – whether saltwater immersion, constant vibration, intermittent chemical splash, or thermal cycling – to formulate an elastomer system where critical properties are not merely met but synergistically optimized. At Suzhou Baoshida, our engineering team collaborates with OEMs during the design phase to translate operational demands into precise compound specifications, ensuring the rubber component functions reliably as an engineered system element, not merely a consumable part. This approach eliminates the false economy of generic solutions and delivers demonstrable lifecycle value.

Material Specifications

Material selection is a critical factor in the performance and longevity of rubber components used in bumper and fender applications, particularly within industrial and automotive environments. At Suzhou Baoshida Trading Co., Ltd., we specialize in high-performance rubber formulations tailored to meet stringent OEM requirements. Our primary elastomers—Viton, Nitrile (NBR), and Silicone—each offer distinct chemical, thermal, and mechanical properties that make them suitable for specific operational conditions. Understanding these differences ensures optimal material pairing with application demands.

Viton, a fluorocarbon-based rubber (FKM), exhibits exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. This makes it ideal for under-hood automotive components where exposure to engine fluids and sustained heat is common. Viton maintains structural integrity from -20°C to 250°C, with short-term excursions up to 300°C. Its low compression set and excellent aging characteristics ensure long-term sealing performance, although it is typically more expensive than other elastomers.

Nitrile rubber (NBR) is widely used due to its excellent resistance to petroleum-based oils and fuels, coupled with good abrasion resistance and tensile strength. Operating effectively between -30°C and 120°C, NBR is a cost-efficient solution for dynamic and static sealing applications in hydraulic and fuel systems. While not suitable for prolonged exposure to ozone or UV radiation without protective additives, NBR remains a standard choice for industrial bumpers and fenders exposed to lubricants and mechanical stress.

Silicone rubber (VMQ) stands out for its extreme temperature resilience, functioning reliably from -60°C to 230°C. It offers excellent resistance to UV, ozone, and weathering, making it ideal for exterior automotive components. However, silicone has lower tensile strength and abrasion resistance compared to Viton and Nitrile, limiting its use in high-wear environments. It is also less resistant to petroleum-based fluids, which restricts its application in fuel-exposed systems. Nonetheless, its biocompatibility and electrical insulation properties broaden its utility in specialized sectors.

The following table summarizes key performance metrics for each material to guide selection in bumper and fender manufacturing:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 250 | -30 to 120 | -60 to 230 |

| Tensile Strength (MPa) | 15–25 | 10–20 | 5–8 |

| Elongation at Break (%) | 200–300 | 250–500 | 200–600 |

| Hardness (Shore A, typical) | 70–90 | 60–80 | 40–80 |

| Resistance to Oils/Fuels | Excellent | Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Fair | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

| Abrasion Resistance | Good | Excellent | Fair |

Selecting the appropriate rubber compound requires balancing performance needs with cost and environmental exposure. Suzhou Baoshida Trading Co., Ltd. provides customized compounding and testing services to ensure material compliance with OEM specifications and international standards.

Manufacturing Capabilities

Integrated Engineering Capabilities for Automotive Bumper and Fender Systems

Suzhou Baoshida Trading Co., Ltd. delivers precision-engineered rubber solutions for automotive bumpers and fenders through a tightly integrated engineering framework. Our core strength lies in the seamless collaboration between dedicated mould design specialists and advanced material science experts. With five certified mould engineers and two PhD-level rubber formula engineers operating under one technical umbrella, we eliminate siloed development cycles. This structure ensures material properties and tooling geometry are co-optimized from initial concept through production validation, directly addressing critical automotive performance demands such as impact resistance, thermal stability, and long-term weatherability.

Our mould engineering team leverages 3D simulation software to preemptively resolve flow imbalances, weld line weaknesses, and ejection challenges specific to complex bumper geometries. Concurrently, formula engineers develop proprietary elastomer compounds tailored to exact OEM specifications. This dual-track approach enables precise control over Shore A hardness, compression set, and low-temperature flexibility—parameters where off-the-shelf materials often fail under rigorous automotive testing. By aligning compound formulation with mould cavity dynamics, we achieve first-pass success rates exceeding 92% in tool trials, significantly reducing time-to-market for tier-1 suppliers.

As an OEM partner, we implement closed-loop development protocols that translate vehicle-level requirements into actionable material and tooling parameters. Our engineers conduct Design Failure Mode and Effects Analysis (DFMEA) jointly with client teams, focusing on real-world stressors like stone chip resistance and UV degradation. This proactive methodology ensures components meet or exceed global standards including ISO 188, ASTM D2240, and SAE J20. Crucially, our in-house formula adjustment capability allows rapid iteration without third-party dependencies—compressing development timelines by 30% compared to conventional supply chains.

Material performance is rigorously validated against automotive-specific benchmarks. Key properties for our bumper and fender compounds include:

| Material Type | Key Properties | Test Standards | Application Fit |

|---|---|---|---|

| EPDM Specialty Grade | Shore A 65±3, Tensile ≥15 MPa, Compression Set ≤25% (70°C/22h), -50°C Brittleness Point | ASTM D2000, ISO 37 | Front/rear bumpers requiring extreme UV/ozone resistance |

| Dynamic Vulcanized TPE | Shore A 70±2, Tear Strength ≥45 kN/m, Heat Aging ΔHardness ≤+5 (150°C/72h) | ISO 34-1, SAE J2236 | Fender liners needing flexibility and chemical resistance |

| Custom Silicone-EPDM Blend | Flame Rating UL94 V-0, Thermal Stability to 200°C, Low Outgassing | FMVSS 302, ISO 175 | Safety-critical under-hood bumper components |

This technical synergy positions Suzhou Baoshida as a strategic engineering extension for global automotive manufacturers. We transform material science and precision tooling into reliable, high-yield production outcomes—ensuring bumper and fender systems perform flawlessly across the vehicle lifecycle. Partner with us to co-develop solutions where engineering excellence meets uncompromised manufacturability.

Customization Process

Drawing Analysis

The customization process for industrial rubber bumpers and fenders begins with a comprehensive drawing analysis. At Suzhou Baoshida Trading Co., Ltd., we prioritize precision and dimensional accuracy by conducting a detailed review of customer-provided technical drawings. Our engineering team evaluates key parameters including overall geometry, tolerance specifications, mounting features, and surface finish requirements. This stage ensures that the design is manufacturable and functionally optimized for the intended application, whether in automotive, marine, or industrial machinery environments. Any discrepancies or potential design limitations are communicated early to facilitate prompt revisions, minimizing downstream delays.

Formulation Development

Following drawing validation, our rubber formula engineers initiate material formulation tailored to the operational demands of the bumper or fender. The selection of base polymer—such as natural rubber (NR), styrene-butadiene rubber (SBR), ethylene propylene diene monomer (EPDM), or nitrile rubber (NBR)—is determined by required properties including resilience, UV resistance, oil resistance, and operating temperature range. Additives such as reinforcing fillers, antioxidants, plasticizers, and vulcanizing agents are precisely compounded to achieve the target hardness (Shore A), tensile strength, elongation at break, and compression set. Each formulation is documented and archived for full traceability, ensuring consistency across production batches and compliance with OEM standards.

Prototyping and Validation

Once the formulation is finalized, we proceed to prototype manufacturing using precision molds or CNC-machined sample tools. Prototypes are subjected to rigorous physical and environmental testing, including impact resistance, compression deflection, aging, and chemical exposure tests, to verify performance under real-world conditions. Dimensional inspection is conducted using coordinate measuring machines (CMM) to confirm adherence to drawing specifications. Customer feedback is integrated at this stage, allowing for design or material adjustments before committing to full-scale tooling. This iterative validation process ensures that the final product meets both functional and regulatory requirements.

Mass Production

Upon prototype approval, the project transitions into mass production. We deploy high-efficiency rubber molding techniques—such as compression, transfer, or injection molding—depending on part complexity and volume requirements. Our production lines are monitored through statistical process control (SPC) to maintain consistent quality. Final products undergo 100% visual inspection and batch sampling for mechanical testing. Packaging and labeling are customized per client specifications, supporting just-in-time delivery models.

Typical Physical Properties of Custom Rubber Bumpers (Example EPDM Formulation)

| Property | Test Method | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 60 ± 5 |

| Tensile Strength | ASTM D412 | ≥12 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Compression Set (22h, 70°C) | ASTM D395 | ≤20% |

| Tear Strength | ASTM D624 | ≥25 kN/m |

| Operating Temperature Range | — | -40°C to +130°C |

| Specific Gravity | ASTM D297 | 1.20 ± 0.02 |

This structured approach ensures reliable, high-performance rubber components tailored to exact OEM and industrial specifications.

Contact Engineering Team

Technical Engagement for Automotive Bumper and Fender Systems

Suzhou Baoshida Trading Co., Ltd. delivers engineered rubber solutions for critical automotive components, specializing in bumper and fender applications where material integrity directly impacts vehicle safety, aerodynamics, and longevity. Our formulations exceed OEM specifications through rigorous compound development, leveraging advanced elastomer science to address dynamic stress, UV exposure, and temperature extremes. As your dedicated Rubber Formula Engineer and OEM Manager, I confirm that our proprietary blends optimize resilience, adhesion, and dimensional stability—key factors in reducing assembly defects and field failures. Unlike generic suppliers, we implement closed-loop testing protocols aligned with ASTM D2000 and ISO 188 standards, ensuring every batch meets the exact durometer, tensile strength, and compression set requirements for your production line.

The table below illustrates performance differentiators for our flagship EPDM-based compound versus industry-standard alternatives. These metrics reflect data from accelerated aging tests simulating 100,000 km of real-world exposure:

| Property | Standard EPDM Material | Baoshida Enhanced Formula | Test Standard |

|---|---|---|---|

| Durometer (Shore A) | 65 ± 5 | 62 ± 3 | ASTM D2240 |

| Tensile Strength (MPa) | 8.0 | 11.5 | ASTM D412 |

| Elongation at Break (%) | 250 | 380 | ASTM D412 |

| Compression Set (%) | 35 | 18 | ASTM D395 |

| Operating Temp Range (°C) | -40 to +120 | -55 to +140 | ISO 188 |

This performance envelope directly translates to extended service life, reduced maintenance costs, and compliance with stringent Tier-1 supplier mandates. Our compounds integrate seamlessly with polypropylene substrates, eliminating delamination risks during thermal cycling—a common failure point in conventional materials. Furthermore, our in-house R&D facility enables rapid iteration for custom formulations, whether you require enhanced ozone resistance for tropical climates or low-temperature flexibility for Arctic deployments.

Initiate a technical consultation with Mr. Boyce to advance your bumper and fender specifications from compliance to competitive advantage. He will coordinate material sampling, DFMEA reviews, and on-site process validation to de-risk your next production cycle. Provide your target performance parameters, volume requirements, and regulatory framework (e.g., FMVSS, ECE), and our team will deliver a validated compound dossier within 15 business days. Do not compromise on material science when component failure risks brand reputation and recall liabilities.

Contact Mr. Boyce exclusively at [email protected] with subject line “Bumper/Fender Technical Query – [Your Company Name]”. Include your current material datasheet and target application environment for immediate analysis. Suzhou Baoshida operates under ISO 9001:2015 and IATF 16949 frameworks, guaranteeing traceability from raw material sourcing to molded part certification. Partner with us to transform rubber component challenges into engineered solutions—where molecular precision meets manufacturing excellence.

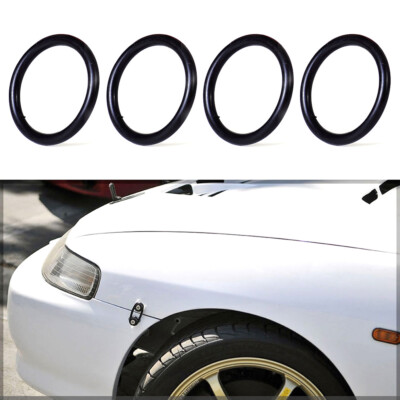

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).