Technical Contents

Engineering Guide: Butchers Curtains

Engineering Insight: Critical Material Selection for Butcher’s Curtains

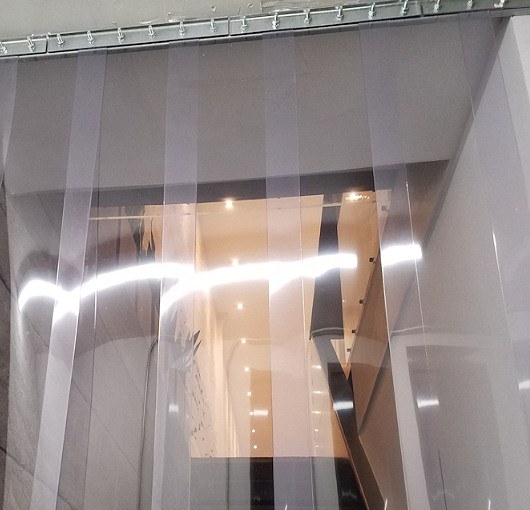

Butcher’s curtains represent a critical hygiene and operational barrier in meat processing facilities. Their primary function extends beyond simple physical separation; they must maintain hygienic integrity under extreme thermal cycling, constant mechanical impact, and aggressive chemical exposure from blood, fats, bone fragments, and sanitation protocols. Off-the-shelf rubber curtain solutions, often designed for light commercial or general industrial use, consistently fail in this demanding environment due to fundamental material limitations. Understanding the specific polymer science required is non-negotiable for operational reliability and food safety compliance.

Standard curtain materials, typically plasticized PVC or low-grade synthetic rubbers, suffer rapid degradation. Thermal shock from repeated transitions between deep-freeze environments (-25°C) and warm processing areas causes embrittlement and cracking in unsuitable polymers. Simultaneously, exposure to animal fats, proteins, and common sanitizers like sodium hypochlorite or peracetic acid leads to swelling, plasticizer migration, and surface degradation in non-resistant formulations. This compromises the curtain’s structural integrity, creates harborage points for pathogens, and necessitates frequent, costly replacements. Furthermore, impacts from trolleys, carcasses, and equipment demand exceptional tear strength and resilience – properties absent in generic materials. Each failure event translates directly to production downtime, increased sanitation labor, potential contamination risks, and significant unplanned expenditure. The cumulative cost of using inadequate off-the-shelf products far exceeds the initial investment in a purpose-engineered solution.

At Suzhou Baoshida, our butcher’s curtains utilize a proprietary EPDM-based compound specifically formulated for the meat processing sector. This advanced elastomer system delivers superior resistance to thermal extremes, ozone (generated by bone saws), and the full spectrum of biological and chemical agents encountered. Enhanced polymer morphology provides exceptional tensile strength, tear resistance, and low-temperature flexibility, ensuring the curtain withstands daily impacts without permanent deformation or failure. The formulation excludes migratory plasticizers, guaranteeing long-term dimensional stability and compliance with food contact regulations. This engineered approach eliminates the recurring failure cycle inherent in generic alternatives.

The performance differential is quantifiable through critical material properties:

| Property | Standard PVC Curtain | Baoshida EPDM Butcher’s Curtain |

|---|---|---|

| Temperature Range | -10°C to +60°C | -40°C to +150°C |

| Tensile Strength (MPa) | 10-15 | ≥ 25 |

| Tear Strength (kN/m) | 40-60 | ≥ 100 |

| Blood/Fat Resistance | Poor (Swelling >15%) | Excellent (Swelling <5%) |

| Ozone Resistance | Low | Exceptional |

Selecting the correct material is not a cost item but a strategic investment in operational continuity and food safety. Generic solutions fail because they lack the precise polymer chemistry required for the butcher’s unique stress profile. Suzhou Baoshida provides OEM partners with scientifically validated, application-specific rubber solutions engineered to eliminate downtime and ensure hygienic performance throughout the curtain’s extended service life. Partner with us to specify the exact material properties your facility demands.

Material Specifications

Material selection for industrial-grade butchers curtains is critical to ensuring performance, durability, and compliance in demanding environments. At Suzhou Baoshida Trading Co., Ltd., our expertise in industrial rubber solutions enables us to provide precision-engineered butchers curtains tailored to rigorous operational standards. These curtains are commonly used in food processing, cold storage, and high-traffic industrial zones where hygiene, temperature resistance, and mechanical resilience are paramount. The choice of elastomer directly influences functional longevity and environmental compatibility.

Viton (FKM), a fluorocarbon-based rubber, offers exceptional resistance to high temperatures, oils, fuels, and a broad range of chemicals. Its thermal stability ranges from -20°C to 200°C, making it ideal for applications involving frequent exposure to hot washdowns or chemical sterilization. Viton’s low gas permeability and outstanding aging characteristics ensure long-term integrity in aggressive environments. However, due to its higher material cost and limited flexibility at sub-zero temperatures, Viton is typically selected for specialized high-performance zones rather than general-purpose use.

Nitrile rubber (NBR) is a preferred choice for applications requiring strong resistance to oils, greases, and aliphatic hydrocarbons. With an operational temperature range of -30°C to 100°C, NBR provides reliable performance in cold storage and food processing areas where fat and protein buildup is common. It exhibits good abrasion resistance and mechanical strength, contributing to extended service life under repeated physical contact. While not as chemically resistant as Viton, Nitrile offers a cost-effective balance of performance and durability for medium-exposure environments.

Silicone rubber (VMQ) excels in extreme temperature applications, functioning reliably from -60°C to 230°C. Its inert nature, UV resistance, and compliance with food-grade standards (such as FDA 21 CFR 177.2600) make it highly suitable for sanitary environments. Silicone maintains flexibility at cryogenic temperatures and resists microbial growth, a critical factor in food safety protocols. Although it has lower abrasion resistance compared to Nitrile, its thermal and biological stability supports use in cleanrooms, freezer entrances, and areas requiring frequent sterilization.

The following table summarizes key physical and chemical properties of these materials for comparative evaluation in butchers curtain applications.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 | -30 to 100 | -60 to 230 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–8 |

| Elongation at Break (%) | 150–250 | 200–500 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils & Fuels | Excellent | Good to Excellent | Poor |

| Resistance to Aliphatic Hydrocarbons | Excellent | Good | Poor |

| Resistance to Water & Steam | Good | Fair | Good |

| UV/Ozone Resistance | Excellent | Fair | Excellent |

| FDA Compliance | Yes (specific grades) | Yes (specific grades) | Yes |

Material selection must be aligned with the operational profile of the installation site. Suzhou Baoshida Trading Co., Ltd. provides customized formulation and testing support to ensure optimal material pairing for each industrial application.

Manufacturing Capabilities

Engineering Excellence in Industrial Rubber Solutions for Butcher’s Curtains

Suzhou Baoshida Trading Co., Ltd. delivers precision-engineered rubber solutions for high-demand industrial applications, including specialized butcher’s curtains. These critical barrier systems require exacting material science and structural integrity to withstand extreme temperature fluctuations, repeated physical impact, and rigorous sanitation protocols. Our integrated engineering team—comprising five dedicated mold engineers and two advanced rubber formula specialists—ensures every product meets OEM-specific performance benchmarks while optimizing lifecycle durability and operational safety.

Our formula engineers develop bespoke polymer compounds tailored to environmental stressors inherent in meat processing facilities. Through rigorous laboratory testing and computational modeling, we refine base polymers, plasticizers, and stabilizers to achieve non-negotiable properties: consistent flexibility at -35°C, resistance to microbial degradation under frequent chemical washdowns, and minimal static cling during high-traffic use. This scientific approach eliminates common field failures such as cracking, fogging, or premature hardening, directly reducing client downtime and replacement costs. Concurrently, our mold engineering division leverages CAD/CAM simulations and finite element analysis (FEA) to design precision tooling that guarantees dimensional accuracy across complex curtain profiles. This synergy between material science and mold architecture ensures uniform thickness distribution, seamless edge sealing, and optimal hang dynamics—critical factors for maintaining temperature differentials in refrigerated zones.

As a certified OEM partner, we implement a closed-loop validation process from concept to量产. Clients provide operational parameters (e.g., door dimensions, ambient humidity, chemical exposure), and our team co-engineers solutions through iterative prototyping. We validate prototypes against ASTM D2240 (hardness), ISO 188 (heat aging), and custom abrasion tests simulating 500,000+ cycle lifespans. This collaborative framework accelerates time-to-market while guaranteeing compliance with HACCP and FDA 21 CFR §177.2600 standards for indirect food contact surfaces.

Material performance is quantifiable. The table below illustrates how our formulations exceed industry baselines for butcher’s curtain applications:

| Material Property | Standard Formulation | Baoshida Custom Formulation | Performance Impact |

|---|---|---|---|

| Low-Temperature Flexibility | -25°C | -35°C | Zero cracking in sub-zero zones |

| Abrasion Resistance (Taber) | 120 mg/1000 cycles | ≤65 mg/1000 cycles | 2.5x extended service life |

| Tensile Strength (MPa) | 14.0 | 18.5 | Resists tearing from forklifts |

| Hydrolysis Resistance | Moderate | Excellent | No fogging after 500 bleach washes |

This technical rigor positions Suzhou Baoshida as the strategic partner for OEMs demanding fail-safe barrier systems. We transform material constraints into engineered advantages—ensuring butcher’s curtains function as reliable operational assets, not maintenance liabilities. Contact our engineering team to co-develop solutions calibrated to your facility’s exact thermal, mechanical, and regulatory requirements.

Customization Process

Drawing Analysis

The customization process for industrial rubber solutions, such as butchers curtains, begins with a comprehensive drawing analysis. This initial phase is critical in ensuring dimensional accuracy, functional compatibility, and compliance with operational requirements. At Suzhou Baoshida Trading Co., Ltd., engineering teams evaluate customer-supplied technical drawings or CAD models to assess key parameters including curtain dimensions, hanging mechanisms, overlap zones, and edge reinforcement zones. Tolerance analysis is conducted to confirm suitability for high-traffic environments typical in meat processing and cold storage facilities. Any ambiguities or design inefficiencies are addressed through direct consultation with the client to refine geometry and mounting specifications prior to material selection.

Formulation Development

Following drawing validation, the rubber compound formulation is engineered to meet the specific environmental and mechanical demands of the application. Butchers curtains are exposed to frequent impact, temperature fluctuations (-20°C to +40°C), organic contaminants, and stringent hygiene protocols. Our rubber chemists formulate EPDM or PVC-based compounds enhanced with antimicrobial additives, UV stabilizers, and plasticizers for low-temperature flexibility. Hardness is optimized between 55–70 Shore A to balance durability and pliability. Tear resistance exceeds 45 kN/m, and fogging resistance is maintained per ISO 6941 to prevent visibility obstruction in refrigerated zones. All formulations comply with FDA 21 CFR 177.2600 for indirect food contact, ensuring safety in food processing environments.

Prototyping and Validation

A functional prototype is manufactured using precision die-cutting and high-frequency welding techniques to simulate final production conditions. The prototype undergoes rigorous performance testing, including cyclic flexing (100,000+ cycles), low-temperature impact resistance at -18°C, and microbial challenge testing over 72 hours. Dimensional verification is performed using coordinate measuring systems to ensure alignment with the approved drawing. Clients are provided with physical samples and test reports for evaluation. Feedback is incorporated into final design or material adjustments, ensuring optimal field performance prior to scale-up.

Mass Production and Quality Assurance

Once approved, the project transitions to automated mass production. Continuous extrusion lines produce uniform curtain panels, which are cut, welded, and finished under ISO 9001-controlled conditions. Each batch undergoes inline inspection for thickness consistency, weld integrity, and visual defects. Final products are packaged in moisture-resistant wrapping with serialized traceability labels.

Below are the standard technical specifications for customized butchers curtains:

| Parameter | Standard Value |

|---|---|

| Material | EPDM or PVC (FDA-compliant) |

| Thickness Range | 2.0 – 4.0 mm |

| Hardness | 55 – 70 Shore A |

| Operating Temperature | -20°C to +40°C |

| Tear Resistance | ≥ 45 kN/m |

| Light Transmission | 85 – 90% (clear variants) |

| Antimicrobial Protection | Silver-ion additive (ISO 22196) |

| Weld Strength | ≥ 80% of base material |

| Custom Lengths | Up to 3000 mm per panel |

| Lead Time (Post-Approval) | 15–20 days for 500 m² |

Contact Engineering Team

Contact Suzhou Baoshida for Precision Engineered Butcher’s Curtain Solutions

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of industrial rubber innovation, delivering mission-critical butcher’s curtain systems engineered for demanding food processing and cold storage environments. Our proprietary rubber formulations, developed through rigorous polymer science and validated under extreme operational conditions, ensure optimal thermal retention, microbial resistance, and mechanical resilience. As your dedicated OEM partner, we transcend standard manufacturing by integrating material science expertise with precise production tolerances, directly addressing energy loss, cross-contamination risks, and operational downtime inherent in subpar curtain systems. Our commitment to ASTM D2000 and ISO 188 compliance guarantees that every curtain strip meets the stringent safety and performance benchmarks required by global food safety authorities.

Central to our value proposition is the ability to tailor curtain specifications to your exact facility parameters. The table below outlines our core technical capabilities, reflecting the precision achievable through our closed-loop manufacturing process and in-house compound development laboratory.

| Specification Parameter | EPDM Standard Grade | FKM Cryogenic Grade | Measurement Standard |

|---|---|---|---|

| Temperature Range | -40°C to +120°C | -50°C to +200°C | ASTM D1329 |

| Thickness Tolerance | ±0.2 mm | ±0.15 mm | ISO 3302-1 |

| Abrasion Resistance | ≤ 120 mm³ | ≤ 85 mm³ | ASTM D5963 |

| Food Contact Compliance | FDA 21 CFR 177.2600 | EC 1935/2004 | EN 1186 |

| Rebound Resilience | ≥ 55% | ≥ 48% | ASTM D1054 |

These specifications are not theoretical ideals but consistently achieved production metrics, verified through our on-site quality control systems. Unlike generic suppliers, we optimize the polymer matrix—adjusting filler dispersion, crosslink density, and plasticizer stability—to ensure curtains maintain flexibility at cryogenic temperatures without compromising tensile strength or ozone resistance. This scientific approach directly translates to extended service life, reduced replacement frequency, and quantifiable energy savings in high-traffic facility entrances.

Our engineering team collaborates directly with OEM clients to refine curtain geometry, durometer profiles, and surface textures based on door cycle rates, ambient humidity, and hygiene protocols. Whether retrofitting legacy systems or designing integrated solutions for new facilities, we provide comprehensive technical documentation, including material traceability certificates and accelerated aging test data, to support your validation requirements.

Initiate a technical dialogue with Mr. Boyce, our Lead Rubber Formulation Engineer and OEM Account Manager, to advance your butcher’s curtain performance. Mr. Boyce possesses 12 years of specialized experience in elastomer development for food-grade applications and will conduct a facility-specific analysis to identify efficiency gaps in your current system. Contact him directly at [email protected] to request:

A customized compound datasheet aligned with your operational temperature and regulatory framework

Sample kits for on-site performance validation under your exact conditions

A lifecycle cost analysis comparing our engineered solution against industry benchmarks

Do not compromise facility integrity with off-the-shelf rubber products. Suzhou Baoshida delivers scientifically validated, application-optimized butcher’s curtains that safeguard product quality, regulatory compliance, and operational efficiency. Email Mr. Boyce with your facility specifications and throughput requirements to receive a technical proposal within 48 business hours. Partner with us to transform passive barriers into precision-engineered assets that actively enhance your cold chain management.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).