Technical Contents

Engineering Guide: Can Light Gasket

Engineering Insight: Material Selection in Can Light Gasket Performance

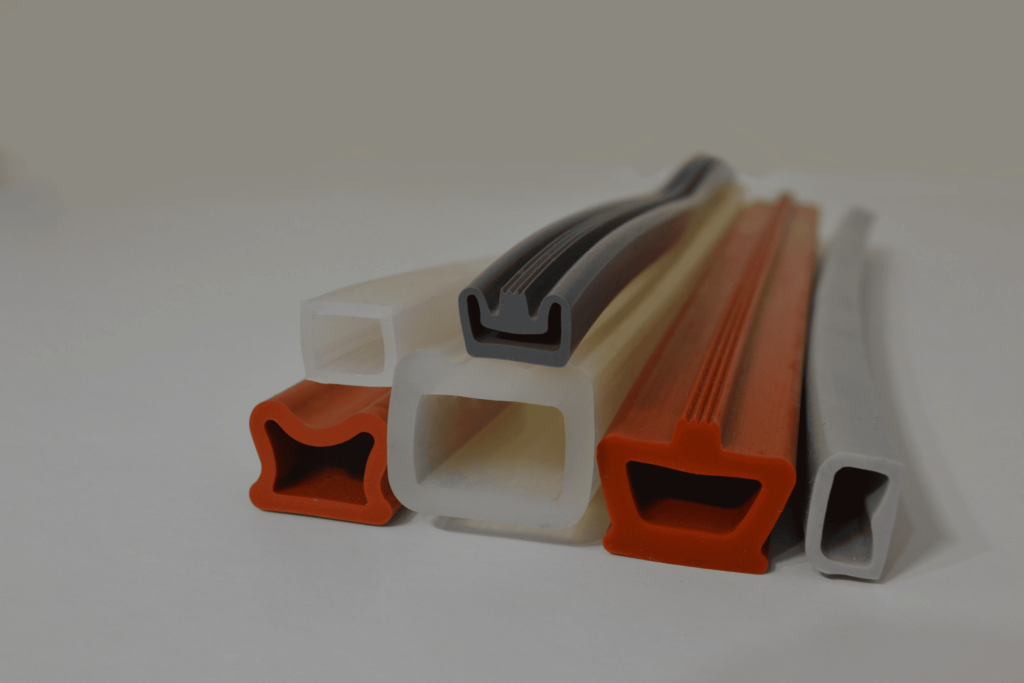

In the precision-driven domain of architectural lighting, the can light gasket serves a dual role—ensuring environmental sealing and maintaining structural integrity under thermal and mechanical stress. While seemingly a minor component, the gasket is pivotal in preventing air leakage, moisture ingress, and thermal bridging in recessed lighting installations. Off-the-shelf gasket solutions, often marketed as universal fit, frequently fail to meet these demands due to inadequate material properties tailored to specific operational environments.

Material selection is not a secondary consideration—it is the cornerstone of long-term reliability. Standard gaskets manufactured from generic rubber compounds such as low-grade EPDM or unmodified silicone exhibit poor compression set resistance and limited temperature resilience. In can light applications, where fixtures are exposed to sustained thermal cycling (often exceeding 80°C during operation), these materials degrade rapidly. This leads to loss of sealing force, gasket hardening, cracking, and ultimately, system failure.

At Suzhou Baoshida Trading Co., Ltd., our engineering approach prioritizes application-specific elastomer formulation. High-performance can light gaskets require materials with a balanced profile of thermal stability, compression recovery, and resistance to UV and ozone exposure. For example, custom-formulated silicone rubber with reinforced filler systems demonstrates superior performance in elevated temperature environments, maintaining elasticity after 1,000+ hours of thermal aging at 150°C. Similarly, specialty EPDM compounds with controlled ethylene content offer enhanced weatherability and low-temperature flexibility, critical in exterior or unconditioned spaces.

Another critical factor is adhesion compatibility. Many off-the-shelf gaskets fail not due to bulk material breakdown, but because of interfacial delamination from housing substrates. Our engineered solutions incorporate co-extruded or selectively treated surfaces that promote strong bonding to aluminum housings and plastic trims without requiring additional adhesives—reducing assembly complexity and long-term maintenance.

Furthermore, regulatory compliance in building codes demands materials that meet flame retardancy standards such as UL 94 V-0 and ASTM E84 Class A. Generic gaskets often fall short, posing safety risks in plenum-rated installations. Our formulations are rigorously tested to ensure compliance without compromising sealing performance.

The table below outlines key material performance metrics for standard versus engineered gasket compounds:

| Property | Standard Off-the-Shelf Gasket | Engineered Gasket (Baoshida) |

|---|---|---|

| Temperature Range | -30°C to 100°C | -55°C to 180°C |

| Compression Set (22h, 100°C) | ≥ 35% | ≤ 15% |

| Tensile Strength | 4.0 MPa | 7.5 MPa |

| Elongation at Break | 180% | 320% |

| Flame Rating | UL 94 HB | UL 94 V-0 |

| UV/Ozone Resistance | Moderate | Excellent |

In conclusion, reliance on generic gasket solutions introduces unacceptable risk in performance-critical lighting systems. Precision engineering begins with molecular-level material design—ensuring that every gasket performs reliably across its intended lifecycle. At Baoshida, we deliver not just components, but engineered sealing solutions.

Material Specifications

Material Specifications for Can Light Gaskets

Precision material selection is non-negotiable for can light gaskets, where failure risks fire hazards, energy leakage, and structural compromise. Suzhou Baoshida Trading Co., Ltd. engineers these critical seals to withstand extreme thermal cycling, moisture ingress, and chemical exposure inherent in recessed lighting installations. We rigorously qualify three elastomers for this application: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material exhibits distinct molecular properties dictating performance boundaries. Viton leverages fluorocarbon chemistry for unparalleled resistance to high-temperature degradation and aggressive solvents, making it optimal for commercial fixtures near HVAC ducts or industrial kitchens. Nitrile provides cost-effective resilience against oils, greases, and moderate heat encountered in standard residential environments, though its lower thermal ceiling necessitates careful application vetting. Silicone delivers exceptional flexibility across extreme cold-to-heat transitions and inherent flame retardancy compliant with UL 94 V-0, yet requires formulation adjustments to mitigate compression set in prolonged high-load scenarios. Shore A hardness is calibrated between 50–70 to balance sealing force with installation tolerances, while tensile strength must exceed 10 MPa per ASTM D412 to prevent tearing during housing compression.

Critical performance parameters are quantified below for engineering validation. All materials comply with ASTM D2000 M2BA714 and RoHS directives, with traceable batch certifications available.

| Material | Base Polymer | Continuous Temp Range (°C) | Key Fluid Resistances | Hardness Range (Shore A) | Primary Limitations |

|---|---|---|---|---|---|

| Viton (FKM) | Fluoroelastomer | -20 to +200 | Hydraulic fluids, brake fluids, aromatics, acids | 60–75 | Poor ketone resistance; higher cost; requires specialized molding |

| Nitrile (NBR) | Acrylonitrile Butadiene Rubber | -30 to +120 | Aliphatic hydrocarbons, water, alcohols, vegetable oils | 50–70 | Swells in ozone, fuels, and chlorinated solvents; limited high-temp stability |

| Silicone (VMQ) | Polysiloxane | -60 to +180 | Water, steam, ozone, UV radiation, diluted acids/bases | 45–65 | Low tear strength; permeable to gases; susceptible to compression set above 150°C |

OEM integration demands matching material properties to fixture operational profiles. Viton is mandated for IC-rated fixtures exceeding 130°C ambient or solvent-exposed settings. Nitrile suffices for non-IC residential units under 100°C with minimal chemical exposure. Silicone excels in cold-climate installations requiring sub-zero flexibility but requires design validation for long-term compression recovery. Suzhou Baoshida subjects all compounds to 1,000-hour thermal aging at maximum rated temperature per UL 1598, with post-aging tensile retention ≥75% and elongation retention ≥60% as non-negotiable pass criteria. This data-driven approach ensures gasket integrity across the fixture lifecycle, preventing air leakage that degrades insulation performance and elevates energy costs. Consult our engineering team for application-specific validation testing protocols.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our core strength in manufacturing precision rubber seals for can light gaskets lies in our integrated engineering expertise. We maintain a dedicated team of five certified mould engineers and two specialized rubber formula engineers, enabling full in-house control from concept to production. This technical synergy ensures that every gasket we produce meets exacting performance standards for thermal resistance, compression set, and long-term sealing integrity under dynamic operating conditions.

Our mould engineers utilize advanced CAD/CAM systems, including SolidWorks and AutoCAD, to design precision tooling optimized for silicone and EPDM rubber compounds. Each mould is engineered with strict attention to parting lines, gate placement, and venting to eliminate flash and ensure consistent dimensional accuracy. Finite element analysis (FEA) is routinely applied to simulate material flow and predict shrinkage behavior, reducing prototype cycles and accelerating time-to-market. All tooling is fabricated using hardened P20 or H13 steel with surface treatments such as nitriding to extend service life under high-volume production.

Complementing our tooling expertise, our two rubber formula engineers specialize in custom elastomer development tailored to the unique demands of LED lighting applications. They formulate compounds that balance flexibility, resilience, and thermal stability across a range of -40°C to +200°C. Our in-house laboratory conducts rigorous testing on durometer, tensile strength, elongation at break, and compression deflection to validate performance. All formulations are RoHS and REACH compliant, with options for UL94 V-0 flame resistance when required.

We operate a fully integrated OEM manufacturing platform, supporting customers from initial design consultation through to mass production. Our engineers collaborate directly with lighting OEMs to refine gasket geometry, optimize sealing force, and select the appropriate base polymer—whether liquid silicone rubber (LSR), EPDM, or fluorosilicone—based on environmental exposure and cost targets. This collaborative approach minimizes design iterations and ensures seamless integration into automated assembly lines.

Our production facility is equipped with 120-ton to 200-ton electric and hybrid injection moulding machines, enabling tight process control and repeatability. Inline monitoring systems track pressure, temperature, and cycle time to maintain ±0.1 mm dimensional tolerances. With a monthly production capacity exceeding 2 million units, we support both low-volume prototyping and high-volume supply contracts with global logistics coordination.

The following table outlines typical material and performance specifications for our standard can light gasket offerings.

| Property | LSR (Shore A 40) | EPDM (Shore A 50) | Fluorosilicone (Shore A 60) |

|---|---|---|---|

| Temperature Range | -50°C to +200°C | -40°C to +150°C | -20°C to +175°C |

| Tensile Strength | ≥7.0 MPa | ≥8.5 MPa | ≥6.0 MPa |

| Elongation at Break | ≥450% | ≥350% | ≥300% |

| Compression Set (22h, 150°C) | ≤20% | ≤25% | ≤18% |

| Hardness Tolerance | ±2 Shore A | ±2 Shore A | ±2 Shore A |

| Flame Resistance | UL94 V-0 (standard) | UL94 HB | UL94 V-0 |

This engineering-led approach ensures that Suzhou Baoshida delivers technically superior, application-specific gasket solutions with consistent reliability and scalability for global lighting manufacturers.

Customization Process

Customization Process for Can Light Gasket Manufacturing

At Suzhou Baoshida Trading Co., Ltd., our precision rubber seal customization adheres to a rigorously defined engineering workflow. This ensures optimal performance in demanding can light applications where thermal stability, flame resistance, and dimensional accuracy are non-negotiable. The process begins with comprehensive Drawing Analysis. Our engineering team scrutinizes OEM technical specifications, focusing on critical geometric dimensions, tolerances per ASME Y14.5, and functional interfaces. We validate material compatibility with housing substrates (e.g., aluminum, steel) and assess thermal expansion coefficients to prevent seal failure during thermal cycling. Any ambiguities in GD&T callouts or surface finish requirements trigger immediate collaborative clarification with the client.

Following drawing validation, Formulation Engineering commences. Material selection is driven by application-specific stressors: sustained operating temperatures (typically 100–150°C), exposure to LED driver chemicals, and mandatory UL 94 V-0 flame resistance. Our proprietary rubber compounds—primarily EPDM and high-temperature silicone—are tailored using accelerated aging data and finite element analysis (FEA) simulations. Key parameters like Shore A hardness, compression set, and tensile strength are optimized to balance sealing force retention against compression stress relaxation. For instance, a Shore 60A EPDM formulation may be enhanced with ceramic fillers to achieve <25% compression set after 70 hours at 150°C.

Prototyping then validates theoretical performance. We produce 5–10 sample gaskets via precision compression molding, adhering strictly to the validated tool design. Each prototype undergoes OEM-specified testing: thermal cycling (-40°C to 150°C), water ingress simulation (IP67), and flame resistance verification per UL 94. Dimensional reports with CMM data (±0.05mm tolerance) and material test certificates are provided within 10 business days. Iterative adjustments occur here; if compression set exceeds 20% at 125°C, we reformulate crosslink density before retesting.

Upon prototype approval, Mass Production initiates under ISO 9001:2015 controls. Tooling is monitored via real-time cavity pressure sensors, while automated vision systems inspect every gasket for flash, voids, or dimensional drift. Statistical Process Control (SPC) charts track critical parameters like durometer (±3 Shore points) and weight consistency (±0.5g). Full traceability—from raw material batch codes to operator IDs—is maintained for every shipment. Production volumes scale from 5,000 to 500,000 units monthly with zero-defect delivery targets.

Material Specification Comparison for Can Light Gaskets

| Property | EPDM Compound BD-60HT | Silicone Compound BD-SIL70 | Test Standard |

|---|---|---|---|

| Shore A Hardness | 60 ± 3 | 70 ± 3 | ASTM D2240 |

| Temperature Range | -50°C to +150°C | -60°C to +200°C | ASTM D573 |

| Compression Set (22h/150°C) | ≤ 25% | ≤ 18% | ASTM D395 Method B |

| Tensile Strength | ≥ 10 MPa | ≥ 7 MPa | ASTM D412 |

| Flame Rating | UL 94 V-0 | UL 94 V-0 | UL 94 |

| Specific Gravity | 1.45 ± 0.02 | 1.50 ± 0.02 | ASTM D297 |

This structured approach ensures Suzhou Baoshida delivers can light gaskets that exceed OEM durability and safety benchmarks while minimizing time-to-market. Every phase integrates client feedback loops to align engineering outcomes with real-world performance demands.

Contact Engineering Team

Contact Suzhou Baoshida for Precision Can Light Gasket Solutions

Suzhou Baoshida Trading Co., Ltd. specializes in the engineering and supply of high-performance rubber seals for industrial, commercial, and residential lighting applications. As a trusted OEM partner in the precision rubber components sector, we deliver can light gaskets that meet rigorous standards for thermal resistance, compression set, and long-term sealing integrity. Our formulations are optimized for durability in demanding environments, ensuring reliable performance in recessed lighting fixtures exposed to temperature fluctuations, moisture, and installation stress.

If your manufacturing operation requires consistent, high-volume supply of can light gaskets with exacting dimensional tolerances and material stability, direct engagement with our technical team is the next step. Mr. Boyce, our dedicated OEM Manager and Rubber Formula Engineer, leads client collaboration from concept to production. With over 15 years of experience in elastomer science and industrial sealing solutions, Mr. Boyce ensures that every gasket formulation is tailored to your application’s mechanical, thermal, and regulatory requirements.

We invite lighting manufacturers, fixture designers, and procurement managers to initiate a technical dialogue. Whether you are developing a new luminaire series, optimizing existing gasket performance, or scaling production, our team provides full material traceability, batch consistency, and rapid prototyping support. Our production facilities in Eastern China operate under ISO 9001-certified quality management systems, enabling tight process control and compliance with international standards.

Contact Mr. Boyce directly at [email protected] to discuss your gasket specifications, request samples, or schedule a technical review. Include details such as operating temperature range, required durometer, compression deflection values, and environmental exposure conditions to accelerate the evaluation process. We respond to all technical inquiries within 12 business hours and offer virtual or on-site engineering consultations for strategic partners.

Our commitment extends beyond supply—we partner with clients to solve sealing challenges at the design phase, reducing field failures and improving product lifecycle performance. By integrating material science with precision manufacturing, Suzhou Baoshida delivers gaskets that enhance fixture reliability and reduce total cost of ownership.

Below are typical technical specifications for our standard can light gasket formulations. Custom compounds are available upon request.

| Property | Silicone Rubber | EPDM Rubber | Nitrile (NBR) Rubber |

|---|---|---|---|

| Hardness (Shore A) | 40–70 ±5 | 50–60 ±5 | 55–65 ±5 |

| Temperature Range | -60°C to +200°C | -50°C to +150°C | -30°C to +120°C |

| Compression Set (22h, 150°C) | ≤25% | ≤30% | ≤28% |

| Tensile Strength | ≥6.0 MPa | ≥7.5 MPa | ≥8.0 MPa |

| Elongation at Break | ≥250% | ≥300% | ≥250% |

| Flame Resistance (UL94) | V-0 | V-1 | HB |

| Typical Color | Translucent, White, Black | Black | Black |

Initiate your project with a partner who combines material expertise with industrial reliability. Contact Mr. Boyce today at [email protected] for a comprehensive technical consultation and sample submission.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).