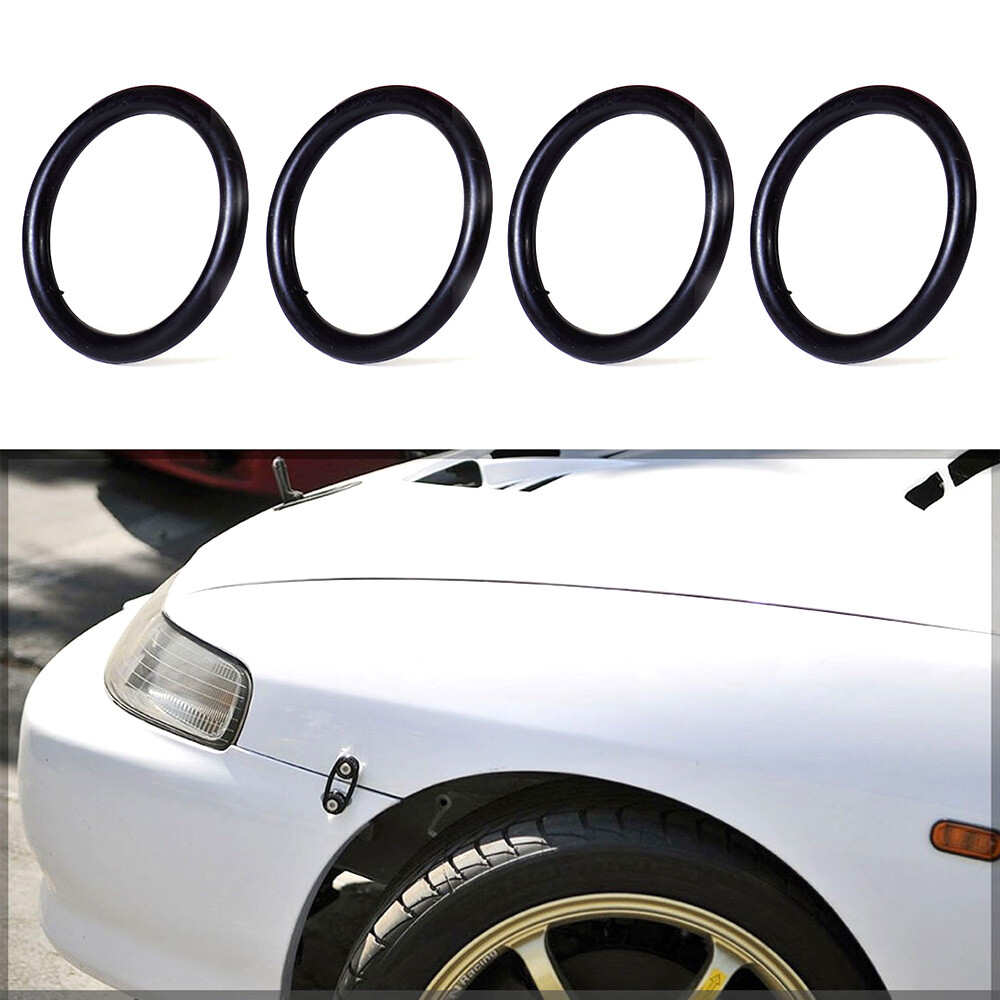

Technical Contents

Engineering Guide: Car Fender Bumper

Engineering Insight: Material Selection in Car Fender Bumper Manufacturing

The performance and longevity of a car fender bumper are fundamentally determined by the precision of material selection during the engineering phase. In industrial rubber applications, especially within automotive exterior components, off-the-shelf elastomeric solutions are frequently adopted under the assumption of cost efficiency and availability. However, such generic materials often fail to meet the dynamic mechanical, environmental, and regulatory demands imposed on modern vehicle bumpers, leading to premature degradation, reduced impact resistance, and non-compliance with OEM standards.

Car fender bumpers are subjected to a complex combination of mechanical stress, UV exposure, temperature fluctuations, and chemical contact from road salts, fuels, and cleaning agents. Standard rubber compounds such as generic EPDM or unmodified SBR lack the tailored cross-linking density, filler dispersion, and polymer architecture required to sustain performance under these conditions. For instance, unoptimized EPDM formulations exhibit poor abrasion resistance and limited elasticity recovery after compression, resulting in permanent deformation and cracking at stress points.

At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered rubber solutions where material composition is aligned with application-specific load profiles. Our approach integrates dynamic mechanical analysis (DMA), accelerated aging tests, and finite element simulation to develop custom formulations that balance tensile strength, elongation at break, Shore A hardness, and resilience. This ensures that the bumper maintains structural integrity during low-speed impacts while resisting environmental aging over a 10+ year service life.

A critical differentiator lies in the use of specialty additives and reinforcing fillers. High-structure carbon black or silica systems enhance tear strength and UV stability, while proprietary antioxidant packages mitigate ozone-induced cracking. Furthermore, co-polymer blending—such as integrating polycarbonate urethanes into rubber matrices—can significantly improve low-temperature flexibility and scratch resistance, crucial for vehicles operating in extreme climates.

Below is a comparative specification table highlighting the performance gap between standard off-the-shelf rubber and our engineered solution for car fender bumpers:

| Property | Standard Off-the-Shelf EPDM | Engineered Rubber (Baoshida) |

|---|---|---|

| Tensile Strength (MPa) | 8.5 | 14.2 |

| Elongation at Break (%) | 280 | 450 |

| Shore A Hardness | 65 | 70 |

| Compression Set (22 hrs, 70°C) | 28% | 12% |

| Heat Aging Resistance (150°C) | Moderate degradation | Minimal change |

| UV/Ozone Resistance | Poor | Excellent (per ASTM D1149) |

| Low-Temperature Flexibility | -30°C | -50°C |

| Abrasion Loss (Taber, mg) | 120 | 65 |

This data illustrates that off-the-shelf materials fall short in key durability metrics. Our engineered rubber formulations are validated through OEM-level testing protocols, ensuring compliance with international standards such as ISO 1817, ASTM D412, and FMVSS No. 215.

In conclusion, material selection is not a commodity decision but a core engineering imperative. For automotive manufacturers seeking reliability, longevity, and regulatory compliance, customized rubber solutions are not optional—they are essential.

Material Specifications

Material Specifications for Automotive Fender Bumper Applications

Selecting the optimal elastomer for car fender bumpers demands rigorous evaluation of environmental exposure, mechanical stress, and regulatory compliance. Fender bumpers endure continuous assault from road debris, UV radiation, ozone, automotive fluids, and extreme temperature fluctuations. At Suzhou Baoshida Trading Co., Ltd., we prioritize materials that balance chemical resistance, durability, and cost-efficiency for OEM integration. Viton (FKM), Nitrile (NBR), and Silicone (VMQ) represent the primary candidates, each exhibiting distinct performance profiles under operational stressors.

Viton fluorocarbon rubber delivers unparalleled resistance to hydrocarbons, acids, and high-temperature degradation, making it ideal for bumpers near engine compartments or exhaust systems. Its continuous service temperature range spans -20°C to 230°C, with intermittent tolerance up to 300°C. However, Viton exhibits lower elasticity and higher material costs compared to alternatives, necessitating precise formulation for dynamic flex fatigue resistance. Nitrile rubber offers a cost-effective solution for general-purpose fender applications, particularly where exposure to oils, greases, and aliphatic hydrocarbons occurs. Standard NBR compounds function reliably between -40°C and 120°C, with acrylonitrile content directly influencing fuel resistance—higher ACN percentages (40-50%) enhance hydrocarbon barrier properties but reduce low-temperature flexibility. Silicone rubber provides exceptional thermal stability (-60°C to 200°C continuous) and UV/ozone resistance, critical for exterior bumper components. Its inherent flexibility ensures consistent sealing under vibration, though low tensile strength and poor abrasion resistance limit use in high-impact zones without reinforced compounding.

The comparative analysis below details critical specifications for informed OEM material selection:

| Material Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Continuous Temp Range | -20°C to 230°C | -40°C to 120°C | -60°C to 200°C |

| Fluid Resistance | Excellent (fuels, acids, oils) | Good (oils, greases) | Poor (hydrocarbons) |

| Tensile Strength (MPa) | 8–15 | 15–25 | 5–10 |

| Elongation at Break (%) | 150–300 | 200–500 | 200–700 |

| Hardness Range (Shore A) | 50–90 | 40–90 | 30–80 |

| Key Automotive Use Case | Engine bay proximity | Fluid-exposed zones | Exterior trim/seals |

OEMs must prioritize fluid compatibility testing per SAE J200 standards, as fender bumpers face complex chemical cocktails including brake fluids, coolant splashes, and biodiesel residues. For instance, NBR formulations with 40-45% acrylonitrile content optimize resistance to modern low-sulfur diesel while maintaining -30°C flexibility. Viton remains indispensable for turbocharger-adjacent components requiring ISO 1817 compliance against aggressive ester-based lubricants. Silicone’s superiority in thermal cycling makes it suitable for bumper overlays in electric vehicles with high-heat battery enclosures, though surface treatments are essential to mitigate abrasion wear.

Suzhou Baoshida Trading Co., Ltd. validates all compounds through ASTM D2000 rigorous aging protocols, ensuring dimensional stability after 72 hours at 150°C. Material selection must align with regional regulatory frameworks—particularly REACH and ELV directives governing heavy metals and end-of-life recyclability. Partner with our engineering team to develop application-specific formulations that meet OEM durability targets without over-engineering costs.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability in industrial rubber solutions is anchored in deep technical expertise and a disciplined approach to OEM manufacturing. We specialize in high-performance rubber components for automotive applications, with a focused emphasis on car fender bumpers that demand precision, durability, and material resilience. Our team comprises five dedicated mould engineers and two certified rubber formula engineers, enabling us to deliver fully integrated product development—from concept to mass production—under one roof.

Our mould engineers bring over 75 combined years of experience in precision tooling design for rubber compression, transfer, and injection moulding processes. They utilize advanced CAD/CAM software, including SolidWorks and UG NX, to develop optimized mould geometries that ensure consistent part quality, minimal flash, and extended tool life. Each design undergoes rigorous simulation for flow, shrinkage, and stress distribution, reducing trial iterations and accelerating time-to-market. With in-house CNC machining and EDM capabilities, we maintain tight tolerances up to ±0.05 mm, critical for sealing and fitment performance in automotive bumper systems.

Complementing our tooling strength is our proprietary rubber formulation expertise. Our two formula engineers hold advanced degrees in polymer science and have led the development of over 120 custom rubber compounds tailored to OEM specifications. They specialize in EPDM, silicone (VMQ), NBR, and FKM formulations engineered for extreme temperature resistance (from -50°C to +200°C), UV stability, compression set performance, and dynamic mechanical strength. Every compound is validated through ASTM and ISO-certified testing protocols for tensile strength, elongation, hardness, and aging resistance.

We operate as a full-service OEM partner, supporting global automotive suppliers with design validation, DFM analysis, PPAP documentation, and batch traceability. Our facility is IATF 16949-certified, ensuring adherence to automotive quality management standards. With an annual production capacity exceeding 8 million units and scalable cleanroom production lines, we accommodate both prototype runs and high-volume manufacturing.

The following table outlines key engineering specifications we support for car fender bumper applications:

| Parameter | Specification |

|---|---|

| Material Types | EPDM, NBR, VMQ, FKM, SBR, CR |

| Hardness Range (Shore A) | 40–90 ±5 |

| Operating Temperature | -50°C to +200°C (material-dependent) |

| Tensile Strength | Up to 25 MPa |

| Elongation at Break | Up to 600% |

| Compression Set (24h @ 100°C) | ≤25% |

| Mould Tolerance | ±0.05 mm |

| Standard Compliance | ASTM D2000, ISO 3302, ISO 2768, GB/T 3672 |

| Production Capacity | 8M+ units/year |

| Lead Time (Prototype) | 25–35 days |

Our engineering synergy between mould design and material science allows Suzhou Baoshida to deliver technically superior, application-specific rubber solutions that meet the evolving demands of modern automotive systems.

Customization Process

Customization Process for Automotive Fender Bumper Rubber Components

Suzhou Baoshida Trading Co., Ltd. executes a rigorously structured customization pathway for industrial rubber fender bumper solutions, ensuring seamless integration with OEM manufacturing standards. Our process begins with Drawing Analysis, where engineering teams dissect CAD models and technical specifications provided by the client. Critical dimensions, tolerances per ISO 2768-mK, material callouts, and environmental exposure requirements undergo systematic validation. Finite Element Analysis (FEA) simulates stress points under dynamic load conditions, identifying potential failure zones such as mounting interfaces or impact zones. This phase confirms geometric feasibility and alignment with vehicle assembly constraints, preventing downstream production deviations.

Subsequent Formulation Development leverages our proprietary material science database to engineer compound compositions meeting exact performance criteria. Key parameters include Shore A hardness (typically 60–85), tensile strength (≥10 MPa), elongation at break (≥250%), and resilience to UV degradation, ozone, and automotive fluids. We prioritize sustainable polymer systems like EPDM or TPE, optimizing filler dispersion and crosslink density to balance flexibility with structural integrity. Accelerated aging tests per ASTM D2000 verify long-term durability under temperature extremes (-40°C to +120°C), ensuring compliance with OEM lifespan expectations.

Prototyping transitions validated formulations into physical samples using precision tooling. Each prototype undergoes multi-stage validation: dimensional inspection via CMM (Coordinate Measuring Machine), dynamic fatigue testing on hydraulic shakers simulating 100,000+ road cycles, and adhesion strength verification for bonded assemblies. Environmental chambers replicate real-world conditions, including salt spray (ASTM B117) and thermal cycling. Client feedback at this stage refines surface texture, color matching (Pantone or RAL standards), and secondary operations like painting or plating adhesion.

Upon sign-off, Mass Production initiates under IATF 16949-certified protocols. Automated mixing systems ensure batch-to-batch repeatability with ±0.5% compound variance. In-line sensors monitor vulcanization temperature and pressure in real-time, while statistical process control (SPC) tracks critical dimensions. Every shipment includes full material traceability certificates and third-party test reports for compression set (≤25% at 70°C/22h) and flammability (FMVSS 302 compliance). Our lean manufacturing framework guarantees on-time delivery with zero-defect shipment targets.

Material performance specifications for common fender bumper compounds are summarized below:

| Material Type | Key Properties | Application Suitability |

|---|---|---|

| EPDM | Shore A 65–80, Tensile ≥12 MPa, Temp Range -50°C to +135°C | High UV/ozone resistance; ideal for exterior trim in harsh climates |

| TPE | Shore A 70–85, Tensile ≥9 MPa, Recyclable, Low VOC | Sustainable interior/exterior components requiring soft-touch finish |

| SBR | Shore A 60–75, Tensile ≥10 MPa, Cost-effective | Secondary seals and non-critical impact zones with moderate weather exposure |

Suzhou Baoshida’s end-to-end process eliminates guesswork through data-driven material science and closed-loop quality management. Contact our engineering team to initiate a technical consultation with your CAD files and performance requirements.

Contact Engineering Team

For precision-engineered rubber components in automotive fender and bumper systems, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in industrial rubber solutions. With years of specialized expertise in material formulation, compression molding, and performance validation, we deliver components that meet the rigorous demands of modern vehicle design. Our engineered rubber products are integral to sealing, vibration damping, and impact absorption in fender and bumper assemblies, ensuring durability, noise reduction, and long-term reliability under dynamic environmental conditions.

We invite OEMs, Tier 1 suppliers, and automotive system integrators to engage directly with our technical team to discuss custom solutions tailored to your next-generation vehicle platforms. Mr. Boyce, our lead Rubber Formula Engineer and OEM Manager, oversees all client technical engagements, ensuring that every specification, from Shore hardness to compression set resistance, aligns precisely with your engineering requirements. Whether you are developing lightweight composite bumpers, adaptive front-end modules, or noise-optimized fender liners, our team provides end-to-end support—from material selection and prototype development to full-scale production and quality assurance.

Our manufacturing processes adhere to ISO 9001 standards, and we utilize advanced testing protocols including thermal aging, dynamic fatigue analysis, and fluid resistance evaluation to guarantee field performance. We specialize in EPDM, TPE, silicone, and custom-blend compounds engineered for UV stability, ozone resistance, and low-temperature flexibility—critical attributes for exterior automotive applications exposed to extreme climates.

To initiate a technical collaboration or request a material datasheet, please contact Mr. Boyce directly at [email protected]. We respond to all inquiries within 24 business hours and offer virtual technical consultations for international clients. Our team is equipped to review CAD models, perform DFMEA input, and support rapid prototyping through our network of certified production facilities in Eastern China.

Below are representative specifications for a standard rubber bumper mounting bushing, manufactured under our controlled process parameters:

| Property | Test Method | Typical Value |

|---|---|---|

| Material Type | ASTM D1418 | EPDM 70 durometer |

| Hardness (Shore A) | ASTM D2240 | 70 ± 5 |

| Tensile Strength | ASTM D412 | ≥12 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Compression Set (22 hrs, 70°C) | ASTM D395 | ≤25% |

| Operating Temperature Range | ISO 1817 | -40°C to +130°C |

| Fluid Resistance (Brake Fluid, Coolant) | ASTM D471 | Pass (volume swell <15%) |

| Density | ASTM D297 | 1.25 g/cm³ |

Partnering with Suzhou Baoshida means access to deep technical knowledge, responsive engineering support, and scalable manufacturing capacity. For specifications beyond standard parameters, including conductive or flame-retardant compounds, we provide custom formulation services backed by in-house lab validation.

Contact Mr. Boyce today at [email protected] to discuss your fender or bumper application requirements. Let us help you achieve optimal performance, cost efficiency, and compliance with global automotive standards.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).