Technical Contents

Engineering Guide: Carbon Fibre Honeycomb Sheet

Engineering Insight: Material Selection in Carbon Fibre Honeycomb Sheet Applications

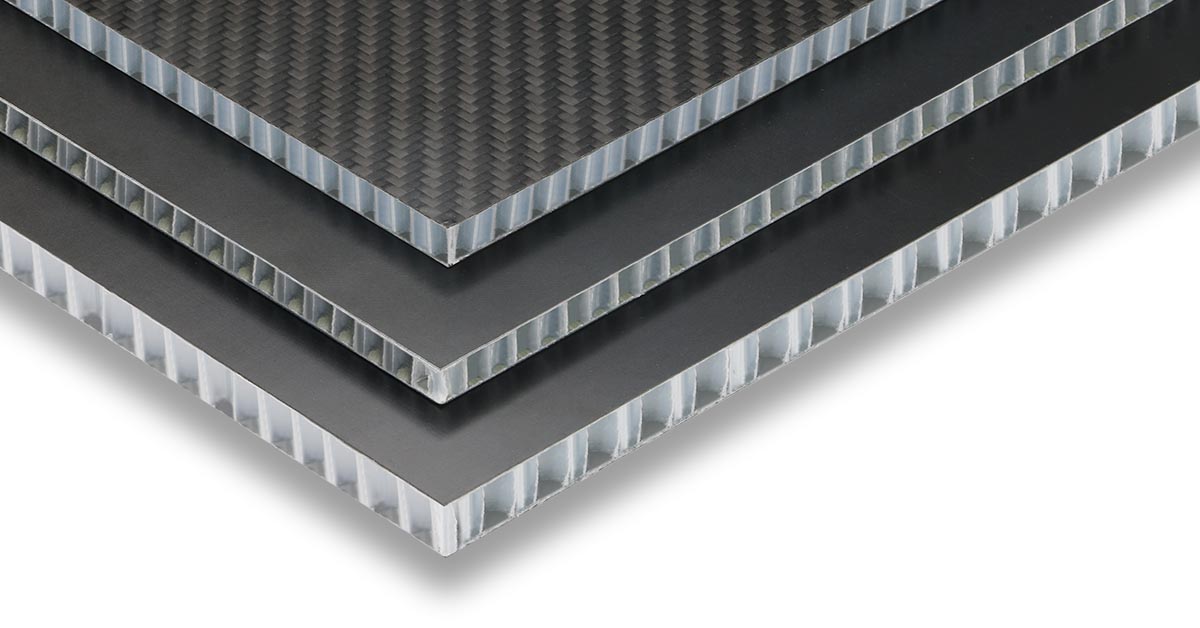

In high-performance industrial environments, the carbon fibre honeycomb sheet is increasingly specified for its exceptional strength-to-weight ratio, dimensional stability, and resistance to thermal expansion. However, despite its advanced composite nature, material selection remains a critical determinant of long-term performance. Off-the-shelf carbon fibre honeycomb solutions often fail to meet application-specific demands due to oversimplification in structural, environmental, and load-bearing assumptions.

Standardized sheets are typically manufactured with generic resin systems, core geometries, and fibre orientations designed for broad compatibility rather than targeted functionality. This one-size-fits-all approach neglects the nuanced requirements of dynamic industrial applications such as aerospace substructures, robotic end-effectors, or precision tooling. For instance, exposure to continuous thermal cycling or chemical agents can degrade improperly formulated matrix resins, leading to delamination and structural compromise. Similarly, inadequate core cell size or wall thickness may result in buckling under localized compressive loads, particularly in unsupported spans.

At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered material selection as a foundational step in deploying carbon fibre honeycomb sheets. The integration of application-specific parameters—such as service temperature range, vibration damping requirements, and surface bonding compatibility—ensures that the composite performs reliably under real-world conditions. Our industrial rubber solutions division specializes in hybrid material systems where elastomeric damping layers are co-bonded with carbon fibre honeycomb cores, enhancing fatigue resistance in high-vibration environments.

Moreover, the interfacial adhesion between the carbon skins and the honeycomb core is often overlooked in commercial-grade products. Poor bonding techniques or incompatible adhesives can initiate core-skin debonding under shear stress, a failure mode frequently observed in off-the-shelf panels used in dynamic load scenarios. Precision-controlled curing cycles and aerospace-grade film adhesives are essential to achieving durable, void-free interfaces.

Customization extends beyond material chemistry to include geometric optimization. Tailoring cell size, core height, and fibre weave orientation allows for targeted stiffness and weight distribution, crucial in applications requiring precise inertial control. This level of engineering is rarely found in mass-produced alternatives.

The following table outlines key performance specifications that differentiate engineered carbon fibre honeycomb sheets from generic equivalents:

| Parameter | Generic Off-the-Shelf Sheet | Engineered Solution (Baoshida OEM) |

|---|---|---|

| Core Material | Standard phenolic | High-temperature cyanate ester |

| Skin Fibre Orientation | 0°/90° only | Multi-axial (±45°, 0°, 90°) |

| Density (kg/m³) | 80–100 | 60–120 (customizable) |

| Compressive Strength (MPa) | 8–12 | 18–25 |

| Operating Temperature (°C) | -40 to +80 | -60 to +200 |

| Interlaminar Shear (MPa) | 1.5–2.0 | 3.0–4.5 |

| Customization Lead Time | None (fixed stock) | 4–6 weeks (application-optimized) |

In conclusion, successful implementation of carbon fibre honeycomb sheets requires a shift from procurement based on availability to engineering based on performance criteria. At Baoshida, we support OEMs with material science expertise to ensure that every composite solution is functionally robust, not merely structurally present.

Material Specifications

Material Specifications for Carbon Fibre Honeycomb Sheet Integration

Carbon fibre honeycomb sheets present unique challenges in sealing and bonding applications due to their low surface energy, rigidity, and cellular structure. At Suzhou Baoshida Trading Co., Ltd., we engineer elastomeric solutions optimized for adhesion, compression recovery, and environmental resilience when interfacing with these advanced composites. Material selection directly impacts seal integrity, vibration damping, and service life in demanding industrial environments such as aerospace, automotive, and cleanroom manufacturing. Our formulations prioritize molecular cohesion under thermal cycling, chemical exposure, and sustained compressive loads to prevent delamination or extrusion at honeycomb cell boundaries.

Viton® (FKM) fluoroelastomers deliver exceptional resistance to aggressive chemicals, including jet fuels, hydraulic fluids, and aromatic solvents, making them ideal for aerospace honeycomb panel seals. Their high fluorine content ensures stability up to 230°C continuous service temperature while maintaining low compression set below 25% after 70 hours at 200°C. This molecular stability prevents swelling-induced bond failure when exposed to hydrocarbon-based media penetrating honeycomb cells. Nitrile rubber (NBR) offers a cost-effective solution for moderate-temperature applications below 120°C, with outstanding resistance to aliphatic hydrocarbons and mineral oils. Its balanced tensile strength and elongation properties accommodate the micro-movement of honeycomb structures under mechanical stress, though it exhibits higher compression set (30–40%) compared to fluoropolymers. Silicone rubber (VMQ) provides unparalleled flexibility across extreme temperatures from -60°C to 200°C, critical for cryogenic or high-heat cycling scenarios. Its low glass transition temperature (-125°C) ensures consistent sealing force in honeycomb joints despite thermal contraction, though compatibility with non-polar solvents remains limited.

All materials undergo rigorous surface energy modification at Baoshida to enhance adhesion to carbon fibre substrates. Plasma treatment or proprietary primers elevate surface energy from 35–40 mN/m (untreated carbon fibre) to 60–70 mN/m, enabling covalent bonding with elastomer matrices. Compression deflection testing per ASTM D575 confirms optimal durometer ranges: 60–80 Shore A for Viton, 50–75 Shore A for NBR, and 40–60 Shore A for Silicone to balance sealing force against honeycomb crush strength.

The following table details critical performance parameters for honeycomb-integrated elastomer selection:

| Material | Tensile Strength (MPa) | Elongation at Break (%) | Continuous Service Temp (°C) | Key Chemical Resistance | Compression Set (22h, 150°C) |

|---|---|---|---|---|---|

| Viton® (FKM) | 15–20 | 150–250 | -20 to 230 | Jet fuels, acids, halogens, aromatics | ≤20% |

| Nitrile (NBR) | 10–15 | 200–400 | -30 to 120 | Aliphatic hydrocarbons, water, glycols | 30–40% |

| Silicone (VMQ) | 6–10 | 300–600 | -60 to 200 | Ozone, UV, steam, alcohols | 25–35% |

Suzhou Baoshida’s OEM partnerships leverage this data to customize formulations, ensuring elastomer-honeycomb interfaces meet ISO 2230 and AMS 3217 standards. Precision in durometer, cure kinetics, and surface activation protocols prevents interfacial failure modes inherent in cellular composite assemblies. Contact our technical team for application-specific validation testing under your operational parameters.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability is built on a foundation of material science expertise and precision-driven manufacturing. While our core specialization lies in industrial rubber solutions, our technical team is uniquely equipped to support advanced composite applications such as carbon fibre honeycomb sheet integration into rubber-based systems. This cross-material proficiency enables us to deliver high-performance, hybrid engineered components tailored for demanding industrial environments.

Our engineering division comprises five dedicated mould engineers and two specialized rubber formula engineers. This multidisciplinary team works in close synergy to ensure optimal material compatibility, structural integrity, and production efficiency. The mould engineers focus on precision tooling design, cavity optimization, and thermal management for complex forming processes, ensuring dimensional accuracy and repeatability in high-volume production. Their expertise extends to multi-material moulding techniques, which are critical when integrating rigid carbon fibre honeycomb structures with flexible or semi-flexible rubber matrices.

Complementing this is our dual rubber formula engineering capability. Our formula engineers specialize in developing custom elastomer compounds that meet exact mechanical, thermal, and chemical resistance requirements. Whether bonding rubber to carbon fibre substrates or encapsulating honeycomb cores for vibration damping, impact absorption, or sealing performance, our formulations are rigorously tested for adhesion, durability, and long-term stability under operational stress. This level of material control is essential in applications such as automotive lightweighting, rail transit components, aerospace interiors, and industrial equipment.

Our OEM capabilities are fully supported by in-house R&D, rapid prototyping, and DFMEA (Design Failure Modes and Effects Analysis) integration. We collaborate directly with clients from concept to mass production, offering technical consultation on material selection, joint design, and manufacturability. Our facility supports small-batch customization as well as large-scale serial production, ensuring flexibility across project scales.

We maintain strict quality control through ISO-compliant processes and advanced testing protocols, including tensile strength analysis, aging resistance, and dynamic mechanical testing. This ensures that every component meets both client specifications and international performance standards.

The following table outlines key technical parameters relevant to rubber-integrated carbon fibre honeycomb sheet applications:

| Parameter | Typical Value | Test Standard |

|---|---|---|

| Tensile Strength (Rubber Compound) | 12–20 MPa | ISO 37 |

| Elongation at Break | 250–450% | ISO 37 |

| Hardness (Shore A) | 50–80 | ISO 48 |

| Operating Temperature Range | -40°C to +150°C | ASTM D1329 |

| Adhesion Strength (to Carbon Fibre) | ≥ 6 kN/m | ISO 4624 |

| Density (Composite Assembly) | 0.6–1.2 g/cm³ | ISO 1183 |

| Compression Set (24h at 70°C) | ≤ 20% | ISO 815 |

Through combined expertise in rubber formulation, precision moulding, and composite integration, Suzhou Baoshida delivers engineered solutions that meet the evolving demands of modern industrial design.

Customization Process

Customization Process: Carbon Fibre Honeycomb Sheet Integration with Rubber Solutions

Suzhou Baoshida Trading Co., Ltd. executes a rigorous, science-driven customization pathway for carbon fibre honeycomb sheet components requiring integrated rubber solutions. This process ensures optimal performance, durability, and seamless assembly within demanding industrial applications. Our methodology begins with comprehensive Drawing Analysis. Engineering teams meticulously dissect client-provided CAD models and technical specifications, focusing on critical interface zones between the carbon fibre honeycomb core and the required rubber elements. We assess load paths, environmental exposure points, thermal expansion differentials, and bonding surface geometries. This phase identifies potential stress concentrations and defines precise rubber application zones, ensuring the composite structure meets functional and regulatory requirements before material selection commences.

The subsequent Formulation stage leverages our deep expertise in polymer science. Based on the environmental and mechanical demands identified in the drawing review—such as operating temperature range, chemical exposure, vibration damping needs, and required Shore hardness—we develop a bespoke rubber compound. This involves precise selection of base polymers (e.g., EPDM for weathering, NBR for oil resistance, Silicone for extreme temperatures), reinforcement fillers, curatives, and specialty additives. Computational modeling predicts cure kinetics and final physical properties, optimizing the formulation for adhesion to the carbon fibre substrate and the specific service conditions. Every component ratio is quantified to achieve target performance metrics without compromising processability.

Prototyping validates the theoretical design and material selection. We fabricate initial samples using the approved formulation and specified honeycomb core parameters. These prototypes undergo stringent laboratory testing, including tensile adhesion strength (ASTM D429 Method B), compression set (ASTM D395), thermal cycling, and application-specific dynamic fatigue tests. Dimensional accuracy is verified against the original CAD using CMM. Client feedback on prototype functionality and fitment is incorporated, triggering iterative refinements to the rubber formulation or bonding process parameters if necessary. This phase mitigates risk by confirming performance under simulated operational stress prior to full-scale commitment.

Upon prototype approval, Mass Production commences under stringent OEM-controlled protocols. We implement statistical process control (SPC) for both the rubber molding/extrusion and the core integration stages. Real-time monitoring of key variables—mold temperature, cure time, pressure, and adhesive application parameters—ensures batch-to-batch consistency. Each production run includes in-process checks and final QA verification against the approved specification sheet. Full material traceability, from raw carbon fibre and rubber batch lots to the finished component, is maintained, providing critical data for aerospace, automotive, or industrial equipment OEMs requiring rigorous compliance documentation.

Critical Performance Specifications for Validated Carbon Fibre Honeycomb/Rubber Assemblies

| Property | Target Value | Test Standard | Tolerance | Units |

|---|---|---|---|---|

| Density (Composite) | 120 – 180 | ASTM D792 | ±5 | kg/m³ |

| Compressive Strength | 8.0 – 12.0 | ASTM C365 | ±0.5 | MPa |

| Tensile Adhesion Strength | ≥ 4.5 | ASTM D429 B | +0.3 / -0.0 | MPa |

| Operating Temperature | -55 to +150 | Internal | ±2 | °C |

| Dimensional Tolerance | Per Drawing | ISO 2768-mK | ±0.5 | mm |

Contact Engineering Team

Contact Suzhou Baoshida for Advanced Carbon Fibre Honeycomb Sheet Solutions

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of industrial composite material supply, delivering high-performance solutions tailored to the rigorous demands of aerospace, automotive, marine, and precision manufacturing sectors. Our expertise in advanced materials extends to carbon fibre honeycomb sheets—engineered composites that combine exceptional strength-to-weight ratios, thermal stability, and structural rigidity. As a trusted OEM partner and technical supplier, we provide fully customized carbon fibre honeycomb configurations to meet exact engineering specifications and production volume requirements.

Carbon fibre honeycomb sheets are critical in applications where weight reduction cannot compromise mechanical integrity. These laminated sandwich structures utilize a carbon fibre face sheet bonded to an aramid or aluminium honeycomb core, resulting in a material that exhibits high flexural stiffness, impact resistance, and fatigue durability. Whether used in drone fuselages, high-speed rail interiors, or robotic end-effectors, our honeycomb composites are manufactured under strict quality control protocols to ensure dimensional accuracy and long-term performance.

At Suzhou Baoshida, we support global manufacturers with end-to-end technical collaboration—from material selection and prototyping to large-scale production and logistics. Our engineering team works closely with clients to optimize composite layup, core density, resin systems, and surface treatments based on operational environments and load profiles. We offer both standard and custom-tailored sheet dimensions, with options for fire-retardant, ESD-safe, or UV-resistant finishes.

For technical inquiries, project consultation, or sample requests, contact Mr. Boyce, OEM Manager and Rubber Formula Engineer at Suzhou Baoshida Trading Co., Ltd. Mr. Boyce brings over a decade of experience in industrial rubber and composite integration, ensuring that every client receives scientifically validated, application-specific solutions. He is available to discuss your engineering challenges, material performance targets, and volume production needs.

To initiate a technical dialogue or request a quotation, reach out directly via email at [email protected]. We respond to all inquiries within 12 business hours and offer virtual technical meetings for international clients. Our supply chain supports containerized shipments worldwide, with documentation compliance for CE, RoHS, and ISO standards.

Below are key technical specifications for our standard carbon fibre honeycomb sheet offerings:

| Property | Value | Test Standard |

|---|---|---|

| Density (core) | 32–96 kg/m³ | ASTM D792 |

| Tensile Strength (face sheet) | ≥ 2800 MPa | ASTM D3039 |

| Flexural Modulus | ≥ 120 GPa | ASTM D7264 |

| Compressive Strength (core) | 1.2–3.8 MPa | ASTM C365 |

| Operating Temperature Range | -60°C to +120°C | ISO 11359 |

| Thickness Range (total) | 6 mm to 50 mm | Custom |

| Surface Finish | Gloss, Matte, or Anti-Slip Coating | ISO 2813 |

| Fire Rating | FST Compliant (optional) | FAR 25.853 |

Partner with Suzhou Baoshida to integrate next-generation carbon fibre honeycomb sheets into your advanced manufacturing workflows. Contact Mr. Boyce today at [email protected] for engineering support and material certification packages.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).