Technical Contents

Engineering Guide: Carbon Steel Check Valve

Engineering Insight: Material Selection in Carbon Steel Check Valves

In industrial fluid control systems, the carbon steel check valve serves as a critical component for preventing backflow and ensuring unidirectional flow. While carbon steel offers high mechanical strength and cost-effective manufacturability, its performance is highly dependent on precise material selection tailored to operational parameters. Off-the-shelf solutions often fail because they prioritize general compatibility over application-specific demands, leading to premature degradation, leakage, or catastrophic system failure.

The core issue lies in the assumption that all carbon steel check valves are functionally equivalent. In reality, variations in carbon content, heat treatment, and surface finish significantly influence corrosion resistance, fatigue life, and sealing integrity. For example, environments with high moisture, chlorides, or acidic media accelerate oxidation in standard ASTM A216 WCB carbon steel, especially at elevated temperatures. Without proper protective coatings or internal linings—particularly in rubber-seated variants—these conditions initiate pitting and crevice corrosion, undermining structural reliability.

Furthermore, elastomeric sealing elements must be engineered in tandem with the valve body material. Mismatched durometer, chemical resistance, or thermal expansion characteristics between the rubber seal and carbon steel body result in seat extrusion, compression set, or loss of closure force. Standard NBR or EPDM seals may degrade rapidly when exposed to non-compatible hydrocarbons or ozone, even if the valve body appears intact. This underscores the necessity of holistic material pairing, not just isolated component selection.

Suzhou Baoshida Trading Co., Ltd. emphasizes system-level analysis before deployment. Our industrial rubber solutions integrate with carbon steel check valves through precision-matched elastomers—such as HNBR, FKM, or specialty EPDM formulations—designed for compatibility with media type, temperature range, and pressure cycling. We conduct accelerated aging tests and finite element analysis (FEA) to simulate real-world stress profiles, ensuring long-term performance under dynamic loads.

Customization extends beyond elastomers. We evaluate post-weld heat treatment (PWHT) requirements, non-destructive testing (NDT) protocols, and coating systems such as fusion-bonded epoxy (FBE) or rubber lining to enhance corrosion resistance. These engineered adaptations are rarely present in mass-produced valves, which often omit traceability, material certifications, or quality control documentation essential for critical applications.

The following table outlines key material and performance specifications that differentiate engineered carbon steel check valves from generic alternatives:

| Parameter | Standard Off-the-Shelf Valve | Engineered Solution (Baoshida) |

|---|---|---|

| Body Material | ASTM A216 WCB (as-cast) | ASTM A216 WCB + PWHT |

| Seat Material | Standard NBR (70 Shore A) | FKM or HNBR (80–90 Shore A) |

| Max Operating Temp | 150°C | 200°C (FKM), 180°C (HNBR) |

| Corrosion Protection | None or basic paint | FBE coating or internal rubber lining |

| Testing Standard | API 598 (basic leakage) | API 598 + Helium Leak Testing |

| Traceability | Batch-level | Individual serial traceability |

Material selection is not a commodity decision—it is a precision engineering requirement. At Suzhou Baoshida, we reject the one-size-fits-all paradigm, delivering integrated rubber and carbon steel solutions built for durability, compliance, and operational continuity.

Material Specifications

Material Specifications for Carbon Steel Check Valve Sealing Elements

The elastomeric sealing element is critical for carbon steel check valve integrity in demanding industrial applications. Material selection directly impacts chemical compatibility, thermal stability, and service life under pressure cycling. At Suzhou Baoshida Trading Co., Ltd., our rubber formulations undergo rigorous ASTM D2000 and ISO 3601 validation to ensure optimal performance against media exposure and mechanical stress. Viton, Nitrile, and Silicone represent the primary elastomer solutions for these valves, each engineered for specific operational envelopes.

Viton fluorocarbon rubber (FKM) delivers exceptional resistance to aggressive chemicals, including hydrocarbons, acids, and steam up to 200°C. Our standard GLT-grade Viton compound maintains tensile strength above 12 MPa after 70 hours at 177°C per ASTM D573, with volume swell under 15% in ASTM No. 3 oil. This material is indispensable for oil & gas pipelines handling sour gas or refinery process streams where NBR would degrade rapidly. However, its high cost and limited low-temperature flexibility (-20°C minimum) necessitate careful application analysis.

Nitrile rubber (NBR) remains the cost-effective standard for general-purpose carbon steel check valves. Our 40-50% ACN content formulations achieve -30°C low-temperature resilience (ASTM D1329) while resisting aliphatic hydrocarbons and water-based fluids. Compression set remains below 25% after 70 hours at 100°C (ASTM D395), ensuring reliable sealing in hydraulic systems and water treatment plants. Limitations include poor ozone resistance and significant swelling in aromatic solvents or phosphate esters, requiring protective housing in such environments.

Silicone rubber (VMQ) excels in extreme temperature applications from -60°C to 230°C but exhibits limited chemical versatility. Our platinum-cured compounds maintain elasticity in cryogenic LNG service while resisting steam sterilization cycles. Tensile strength typically ranges 6-8 MPa (ASTM D412), though tear resistance is inferior to NBR. Critical constraints include high gas permeability and severe degradation when exposed to concentrated acids or non-polar solvents, restricting use to food processing or pharmaceutical steam lines.

Elastomer Performance Comparison

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +200 | -30 to +120 | -60 to +230 |

| Tensile Strength (MPa) | ≥12 | ≥10 | 6-8 |

| Volume Swell in ASTM No. 3 Oil | ≤15% | ≤25% | >100% |

| Compression Set (100°C/70h) | ≤20% | ≤25% | ≤20% |

| Key Chemical Resistance | Aromatics, Acids, Steam | Aliphatics, Water | Steam, Silicone Oils |

| Primary Limitation | Cost, Low-temp flexibility | Ozone, Polar solvents | Hydrocarbons, Acids |

Suzhou Baoshida Trading Co., Ltd. engineers these compounds to OEM specifications, incorporating fillers and cure systems that enhance abrasion resistance and reduce extrusion in high-pressure valve seats. Material certification packages include full ASTM D2000 line callouts and batch-specific peroxide curing validation. For critical applications, we recommend accelerated aging protocols per ISO 188 to validate service life projections against your operational parameters.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Development for Industrial Rubber Applications

At Suzhou Baoshida Trading Co., Ltd., our engineering capability is the cornerstone of our industrial rubber solutions, particularly in the development and manufacturing of high-performance sealing components for critical applications such as carbon steel check valves. With a dedicated team of five experienced mould engineers and two specialized rubber formula engineers, we maintain full in-house control over the product development lifecycle—from concept and material formulation to precision tooling and final validation.

Our mould engineers bring extensive expertise in precision steel mould design, utilizing advanced CAD/CAM systems and CNC machining to ensure tight tolerances, optimal flow dynamics, and long-term durability. Each mould is engineered to accommodate the unique curing characteristics of rubber compounds, ensuring consistent part geometry and reliable sealing performance under fluctuating pressure and temperature conditions typical in industrial valve systems. This level of precision is essential for achieving zero-leakage performance in carbon steel check valves used in oil & gas, chemical processing, and water treatment applications.

Complementing our tooling expertise, our two rubber formula engineers specialize in developing custom elastomer compounds tailored to specific operational demands. Whether the application requires resistance to hydrocarbons, steam, acids, or extreme temperatures, our formulation team designs and tests proprietary rubber blends—primarily based on NBR, EPDM, FKM, and HNBR—to deliver optimal performance. These formulations are rigorously evaluated for compression set, tensile strength, hardness, and chemical compatibility, ensuring compatibility with ASTM, ISO, and OEM-specific standards.

Our integrated engineering approach enables seamless OEM collaboration. We work directly with valve manufacturers to reverse-engineer existing sealing components, validate material performance under real-world conditions, and develop cost-effective, scalable solutions. This capability extends to rapid prototyping, design for manufacturability (DFM) analysis, and full documentation packages, including material certifications and test reports.

Through this synergy of material science and precision engineering, Suzhou Baoshida delivers rubber sealing solutions that enhance the reliability and service life of carbon steel check valves.

| Property | Typical Test Standard | Performance Range |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 50–90 ±5 |

| Tensile Strength | ASTM D412 | 8–20 MPa |

| Elongation at Break | ASTM D412 | 200–500% |

| Compression Set (70 hrs, 70°C) | ASTM D395 | ≤25% |

| Operating Temperature Range | — | -30°C to +200°C (FKM) |

| Fluid Resistance | ASTM D471 | Excellent in oil, fuel, water, steam |

This technical foundation enables us to meet the stringent demands of global industrial markets while maintaining flexibility for customized OEM requirements.

Customization Process

Customization Process for Carbon Steel Check Valve Elastomer Components

Suzhou Baoshida Trading Co., Ltd. executes a rigorous four-phase customization protocol for elastomer components in carbon steel check valves, ensuring optimal performance under industrial fluid dynamics and chemical exposure. This methodology mitigates seal failure risks while adhering to OEM dimensional and operational specifications.

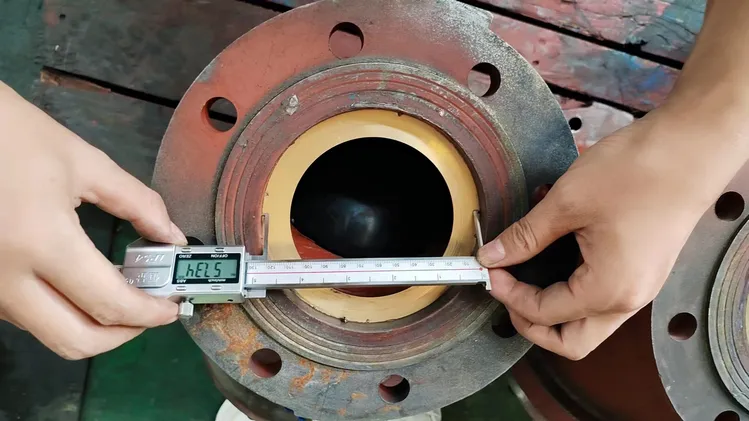

Drawing Analysis initiates the process, where our engineering team deconstructs client-provided CAD models and ISO 5208 leakage class requirements. Critical focus areas include groove geometry tolerances per ISO 2768-m, surface finish Ra values, and compression set parameters. We validate compatibility between the carbon steel valve body’s thermal expansion coefficient (12.0 µm/m·°C) and proposed elastomer compounds. Any dimensional deviation exceeding ±0.05mm triggers collaborative redesign with the client to prevent extrusion or compression loss during cyclic operation.

Formulation Development leverages our ISO 1798-certified laboratory to engineer bespoke rubber compounds. Based on media exposure analysis (e.g., crude oil, seawater, or 30% H₂SO₄), we select base polymers and reinforce with precision-scaled silica or carbon black. Key adjustments include: fluorocarbon (FKM) formulations for -20°C to 200°C service with 0.5% volume swell in ASTM No. 3 oil, or hydrogenated nitrile (HNBR) for sour gas environments requiring 85 Shore A hardness and 25 MPa tensile strength. Each formulation undergoes predictive modeling for compression set (ASTM D395 Method B) and permeation resistance prior to compounding.

Prototyping employs CNC-machined molds to produce 3–5 sample seals per iteration. Components undergo accelerated life testing per API 598: 10,000 pressure cycles at 1.5x rated pressure, followed by helium leak detection at 10⁻⁶ mbar·L/s sensitivity. Torque consistency across 500 open/close cycles is measured using calibrated digital force gauges. Client validation occurs within 15 business days, with material certificates (ASTM D2000 line callouts) and microhardness reports provided.

Mass Production commences only after prototype sign-off, utilizing cavity pressure monitoring systems to maintain ±0.3 Shore A hardness consistency. Every batch undergoes 100% visual inspection per ISO 3302-1 E2 and random抽样 for tensile properties (ASTM D412). Traceability is enforced via laser-etched lot codes linking to raw material COAs and vulcanization curves. Final shipment includes PPAP Level 3 documentation with statistical process control data.

The following table summarizes critical elastomer specifications for common carbon steel check valve applications:

| Compound Type | Temperature Range (°C) | Chemical Resistance | Key Applications |

|---|---|---|---|

| FKM (66% F) | -20 to 230 | Excellent: Acids, fuels, steam | Refinery crude oil lines |

| EPDM | -50 to 150 | Excellent: Alkalis, hot water | Power plant cooling systems |

| NBR (43% ACN) | -30 to 120 | Good: Hydraulic oils, alcohols | Hydraulic machinery |

| HNBR | -40 to 170 | Superior: Sour gas, amines | Offshore gas pipelines |

This structured workflow ensures carbon steel check valves achieve >99.95% sealing integrity in critical service, directly reducing plant downtime through material science precision. Baoshida’s integration of ASTM-standardized validation with OEM design collaboration delivers failure-resistant elastomer solutions for extreme industrial environments.

Contact Engineering Team

For industrial manufacturers and OEMs requiring high-performance sealing solutions in demanding environments, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in advanced rubber technology and engineered components. While our core expertise lies in industrial rubber solutions, we frequently collaborate with clients integrating elastomeric seals and gaskets into metal-bodied systems such as carbon steel check valves. These critical components rely on precise material compatibility and resilient sealing performance to ensure leak-free operation in oil & gas, chemical processing, water treatment, and power generation applications.

At Suzhou Baoshida, we specialize in formulating and manufacturing custom rubber parts that meet exacting industrial standards. Whether your carbon steel check valve requires NBR, EPDM, FKM (Viton™), or specialty compounds resistant to high temperature, pressure, or aggressive media, our team provides material selection guidance, rapid prototyping, and scalable production. Our engineering support extends beyond raw materials—we ensure dimensional accuracy, compression set resistance, and long-term durability under cyclic service conditions.

We understand that valve performance is only as reliable as its weakest component. That’s why our rubber elements are designed to complement the mechanical integrity of carbon steel bodies, ensuring tight shut-off, minimal backflow, and extended service life. Our quality management systems adhere to ISO standards, and all compounds can be certified for NSF, FDA, or ATEX compliance upon request.

To support your next project involving carbon steel check valves or any application requiring precision rubber components, we invite direct technical consultation with our lead engineer and OEM liaison, Mr. Boyce. With over 15 years of experience in industrial elastomer applications, Mr. Boyce provides client-specific guidance on material selection, cost optimization, and supply chain integration. His expertise ensures seamless alignment between your engineering requirements and our manufacturing capabilities.

Contact Mr. Boyce directly via email at [email protected] to discuss your technical specifications, request samples, or obtain a detailed quotation. We respond to all inquiries within 12 business hours and offer multilingual support for global clients.

Below are typical rubber compound specifications we provide for integration into carbon steel check valve assemblies:

| Property | NBR (Nitrile) | EPDM | FKM (Viton™) | Silicone |

|---|---|---|---|---|

| Temperature Range | -30°C to +100°C | -50°C to +150°C | -20°C to +200°C | -60°C to +180°C |

| Resistance to Oil/Fuel | Excellent | Poor | Excellent | Fair |

| Resistance to Ozone/UV | Good | Excellent | Excellent | Excellent |

| Compression Set (22 hrs, 150°C) | ≤ 25% | ≤ 30% | ≤ 20% | ≤ 35% |

| Hardness Range (Shore A) | 50–90 | 50–85 | 60–90 | 40–80 |

| Common Applications | Hydraulic systems, fuel handling | Water, steam, brake fluid | Chemical, oil, high-temp | High-purity, medical, electrical |

Partner with Suzhou Baoshida Trading Co., Ltd. for technically superior rubber solutions engineered to enhance the reliability of your carbon steel check valves. Initiate your project with confidence—reach out to Mr. Boyce today at [email protected].

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).