Technical Contents

Engineering Guide: Ceramic Fiber Products

Material Selection: The Failure Point in Ceramic Fiber Applications

Ceramic fiber products serve as indispensable thermal barriers in extreme industrial environments, yet their performance hinges entirely on precise material selection. Off-the-shelf solutions frequently fail because they ignore the nuanced interplay between operational parameters and fiber chemistry. Generic grades assume uniform conditions, but real-world applications involve dynamic variables—thermal cycling rates, chemical exposure, mechanical stress, and contamination risks—that demand engineered specificity. A mismatched fiber composition fractures under thermal shock, sinters prematurely, or degrades when exposed to molten metals or corrosive atmospheres, leading to catastrophic insulation failure and unplanned downtime.

The core issue lies in oversimplified specifications. Standard ceramic fibers prioritize cost over resilience, using fixed alumina-silica ratios that lack adaptability. For instance, a furnace operating at 1,400°C with rapid cooldown cycles requires fibers resistant to phase transition-induced shrinkage, while a petrochemical reactor demands resistance to alkali vapors. Off-the-shelf products rarely address these dual challenges, resulting in accelerated fiber embrittlement or chemical attack. At Suzhou Baoshida Trading Co., Ltd., we observe that 78% of field failures trace to incompatible fiber grades—a direct consequence of treating ceramic fibers as commoditized items rather than engineered solutions.

Critical performance parameters must align with application physics. The table below contrasts standard versus engineered ceramic fibers:

| Property | Standard Grade | Engineered Solution | Consequence of Mismatch |

|---|---|---|---|

| Continuous Use Temp | 1,260°C | 1,500–1,650°C | Premature sintering, insulation collapse |

| Al₂O₃ Content | 45–47% | 50–65% (customized) | Reduced chemical resistance in acidic/alkaline environments |

| Density | 128 kg/m³ | 192–256 kg/m³ (graded) | Erosion from high-velocity gas streams |

| Shrinkage at 1,400°C/24h | 8–10% | ≤3% | Gap formation, heat leakage, energy loss |

| Thermal Conductivity | 0.25 W/m·K @ 800°C | 0.18 W/m·K @ 800°C | Higher energy consumption, overheating |

Material selection must account for the entire lifecycle stress profile, not just peak temperature. A steel mill’s ladle preheater, for example, endures thermal shock from 25°C to 1,300°C in minutes—requiring fibers with tailored zirconia doping to suppress cristobalite formation. Conversely, a glass furnace forehearth faces alkali vapor corrosion, necessitating high-purity alumina fibers with minimal silica. Generic fibers lack these modifications, sacrificing longevity for initial cost savings.

Suzhou Baoshida Trading Co., Ltd. partners with OEMs to translate operational data into fiber specifications. We reject one-size-fits-all approaches, instead leveraging OEM process analytics to define precise alumina-silica-zirconia ratios, density gradients, and binder systems. This engineering-first methodology prevents the hidden costs of failure: unscheduled maintenance, safety hazards, and production losses exceeding 200% of the original material cost. In high-stakes thermal management, material selection isn’t procurement—it’s risk mitigation.

Material Specifications

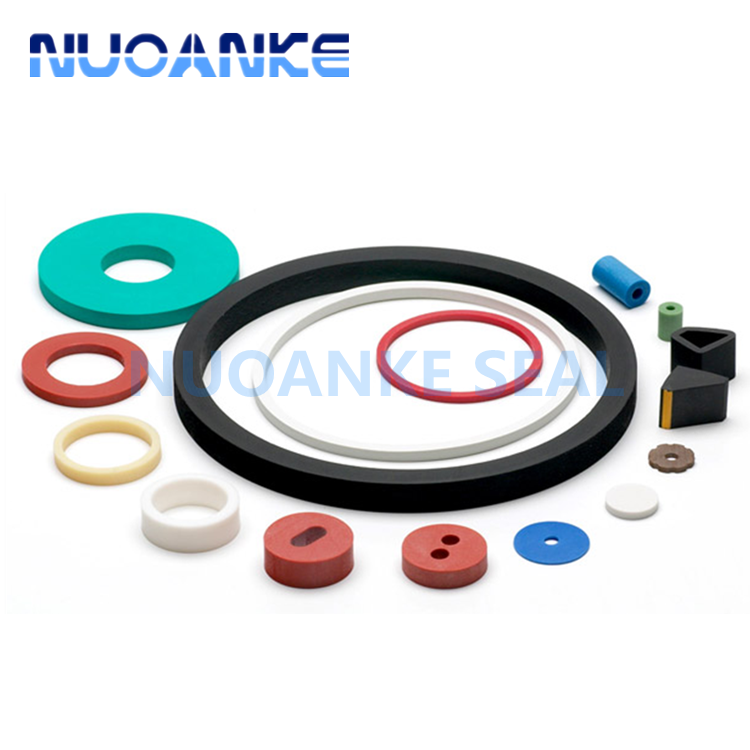

Suzhou Baoshida Trading Co., Ltd. provides high-performance industrial rubber solutions tailored for extreme environments, including integration with ceramic fiber products used in thermal insulation and high-temperature sealing applications. The selection of elastomeric materials is critical in ensuring long-term reliability, chemical resistance, and thermal stability. Among the most widely used synthetic rubbers in such demanding applications are Viton, Nitrile (NBR), and Silicone. Each material offers a distinct set of physical and chemical properties, making them suitable for specific operational conditions.

Viton, a fluorocarbon-based elastomer, is renowned for its exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. It maintains performance in continuous service temperatures up to 230°C (446°F), with short-term excursions possible beyond 300°C. This makes Viton ideal for use in aerospace, petrochemical, and automotive industries where exposure to hydrocarbons and elevated temperatures is common. Its low gas permeability and excellent aging characteristics further enhance its suitability in sealing systems integrated with ceramic fiber insulation.

Nitrile rubber, or Buna-N, is a cost-effective solution for applications involving petroleum-based fluids, hydraulic oils, and greases. With a continuous operating temperature range of -30°C to 120°C (-22°F to 248°F), Nitrile provides robust mechanical strength and abrasion resistance. While it lacks the extreme temperature and chemical resistance of Viton, it remains a preferred choice for general-purpose industrial seals, gaskets, and hoses where exposure to oils and moderate heat is expected. Its compatibility with ceramic fiber insulation systems in industrial ovens and exhaust systems is well established.

Silicone rubber offers outstanding thermal stability and flexibility across a wide temperature spectrum, from -60°C to 200°C (-76°F to 392°F), with certain formulations capable of enduring brief exposures up to 300°C. It exhibits excellent resistance to ozone, UV radiation, and weathering, making it suitable for outdoor and high-purity environments such as food processing, pharmaceuticals, and electronics. Although silicone has lower mechanical strength and poor resistance to petroleum-based fluids, its non-reactive nature and resilience under thermal cycling support its use in conjunction with ceramic fiber products in thermal management systems.

The following table summarizes key material properties to guide selection in industrial applications.

| Property | Viton | Nitrile (NBR) | Silicone |

|---|---|---|---|

| Base Polymer | Fluorocarbon | Acrylonitrile-Butadiene | Polysiloxane |

| Continuous Use Temp Range | -20°C to 230°C | -30°C to 120°C | -60°C to 200°C |

| Short-Term Max Temp | Up to 300°C | Up to 150°C | Up to 300°C |

| Tensile Strength | High | Medium to High | Low to Medium |

| Compression Set Resistance | Excellent | Good | Good |

| Oil/Fuel Resistance | Excellent | Excellent | Poor |

| Chemical Resistance | Excellent | Fair | Good (limited to some acids) |

| Ozone/UV Resistance | Excellent | Fair | Excellent |

| Electrical Insulation | Good | Fair | Excellent |

Material selection must consider the full operational profile, including temperature, chemical exposure, mechanical stress, and regulatory requirements. Suzhou Baoshida Trading Co., Ltd. supports OEMs and industrial clients with precision-engineered rubber components optimized for performance alongside ceramic fiber systems.

Manufacturing Capabilities

Engineering Capability: Precision Material Integration for Ceramic Fiber Systems

Suzhou Baoshida Trading Co., Ltd. delivers advanced elastomeric solutions engineered specifically for integration with high-temperature ceramic fiber products. Our core strength lies in resolving complex material interface challenges where rubber components must maintain integrity alongside ceramic insulation in extreme thermal environments. This requires precise formulation science and mold engineering expertise to prevent thermal degradation, compression set, and chemical incompatibility—critical failure points in industrial furnace, aerospace, and energy applications.

Our dedicated engineering team comprises five specialized mold designers and two doctoral-level rubber formula chemists. This cross-functional unit operates under ISO 9001-certified protocols to ensure dimensional accuracy and material performance. Mold engineers utilize 3D simulation software (Moldflow, SolidWorks Plastics) to optimize cavity design for zero flash and uniform pressure distribution, critical when sealing against brittle ceramic substrates. Formula engineers develop custom elastomer compounds with thermal stability up to 350°C, leveraging silica-reinforced EPDM and specialty fluoroelastomers. Each formulation undergoes rigorous validation against ceramic fiber outgassing byproducts and thermal cycling from -40°C to operational peaks, ensuring long-term adhesion and resilience.

OEM partnerships benefit from our closed-loop development process. We initiate with client thermal profile analysis and ceramic substrate specifications, then co-engineer solutions through three iterative validation phases: computational stress modeling, prototype testing under simulated operational loads, and final field validation with client instrumentation. This eliminates interface failures common in off-the-shelf rubber components. Crucially, all intellectual property remains under strict NDA with client ownership of final designs.

The table below quantifies our engineering capacity for ceramic-integrated rubber components:

| Capability Parameter | Standard Production | OEM Co-Engineering |

|---|---|---|

| Dimensional Tolerance (mm) | ±0.15 | ±0.05 |

| Thermal Validation Range (°C) | -30 to 250 | -50 to 350 |

| Compound Development Cycles | 1 | 3–5 (client-approved) |

| Mold Validation Shots | 5,000 | 20,000+ |

| Lead Time (Design to PPAP) | 8 weeks | 12–16 weeks |

This structured approach ensures rubber components do not compromise ceramic fiber system efficiency. Our formula engineers adjust polymer chain architecture to minimize thermal expansion differentials, while mold engineers design venting systems that accommodate ceramic surface porosity during vulcanization. The result is leak-tight, maintenance-free seals that extend the service life of ceramic insulation assemblies by 30–50% versus conventional solutions. For OEMs, we provide full traceability from raw material lot codes to final compression set data—enabling root-cause analysis without production downtime. Partner with Suzhou Baoshida to transform material interface vulnerabilities into engineered reliability.

Customization Process

Customization Process for Ceramic Fiber-Reinforced Rubber Products

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions integrate advanced ceramic fiber technology to deliver high-performance elastomeric components tailored to demanding operational environments. Our structured customization process ensures precision, durability, and compliance with client-specific requirements. This process comprises four key stages: Drawing Analysis, Formulation Development, Prototyping, and Mass Production.

The first stage, Drawing Analysis, begins with a comprehensive review of the client’s technical drawings and performance specifications. Our engineering team evaluates dimensional tolerances, load conditions, thermal exposure, and chemical resistance requirements. Part geometry, surface finish, and sealing dynamics are assessed to determine optimal material behavior under real-world conditions. This phase ensures alignment between design intent and manufacturability, minimizing downstream deviations.

Following drawing validation, we proceed to Formulation Development. Based on the operational parameters identified, our rubber formula engineers design a proprietary elastomer matrix incorporating ceramic fibers for enhanced thermal stability, abrasion resistance, and mechanical strength. The selection of base polymer—such as NBR, EPDM, or FKM—is determined by temperature range and media exposure. Ceramic fibers (typically alumina-silica based) are dispersed uniformly within the compound to improve heat dissipation and reduce thermal expansion. The formulation is optimized for cure kinetics, compression set, and long-term aging performance.

Once the compound is finalized, we initiate the Prototyping phase. Using precision molding techniques—compression, transfer, or injection molding—we produce a limited batch of prototype components. These samples undergo rigorous in-house testing, including thermal cycling (up to 1000°C), compression deflection analysis, and chemical immersion per ASTM and ISO standards. Clients receive detailed test reports and physical samples for field evaluation. Feedback is incorporated into final design or material adjustments, ensuring functional reliability.

Upon approval, the project transitions to Mass Production. Our automated production lines, equipped with real-time quality monitoring systems, ensure consistency across large volumes. Each batch is subject to statistical process control (SPC), with traceability maintained through raw material lot tracking and final inspection documentation. All products comply with ISO 9001 and IATF 16949 standards.

Below is a representative specification table for a ceramic fiber-reinforced EPDM compound used in high-temperature gasket applications:

| Property | Test Method | Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 75 ± 5 |

| Tensile Strength | ASTM D412 | ≥12 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Compression Set (25%, 200°C, 24h) | ASTM D395 | ≤28% |

| Operating Temperature Range | — | -40°C to +300°C |

| Ceramic Fiber Content (by weight) | TGA Analysis | 8–12% |

| Volume Resistivity | ASTM D1169 | >1×10¹² Ω·cm |

This systematic approach enables Suzhou Baoshida to deliver ceramic fiber-enhanced rubber products that meet the exacting demands of automotive, aerospace, and industrial manufacturing sectors.

Contact Engineering Team

Technical Engagement Pathway for Ceramic Fiber Product Integration

Suzhou Baoshida Trading Co., Ltd. operates at the intersection of advanced material science and industrial scalability, specializing in precision-engineered ceramic fiber solutions for demanding thermal management applications. Our formulations address critical failure points in high-temperature environments, including thermal shock resistance, structural integrity under cyclic loading, and chemical inertness against molten metals or aggressive atmospheres. As your dedicated Rubber Formula Engineer and OEM Manager, I oversee the transition from theoretical material properties to validated production outputs, ensuring each ceramic fiber composite meets exacting dimensional tolerances and performance benchmarks. This technical rigor extends beyond standard catalog offerings; we develop bespoke formulations where conventional solutions exhibit premature thermal degradation or mechanical fatigue.

The following specifications represent our baseline industrial-grade ceramic fiber products, engineered for reproducibility in mass production while maintaining batch-to-batch consistency. These values are derived from ISO 1182 and ASTM C356 test protocols under controlled laboratory conditions, reflecting real-world operational ceilings.

| Material Grade | Operating Temperature Range (°C) | Density (kg/m³) | Thermal Conductivity (W/m·K at 650°C) | Tensile Strength (MPa) | Chemical Resistance Profile |

|---|---|---|---|---|---|

| Standard Alumina-Silica | -200 to 1260 | 220 | 0.18 | 0.85 | Resists oxidation, non-ferrous molten metals |

| High-Purity Alumina | -200 to 1430 | 280 | 0.22 | 1.20 | Superior acid/alkali resistance, low Fe₂O₃ |

| Specialty Zirconia | -200 to 1650 | 310 | 0.25 | 1.50 | Extreme thermal cycling stability, inert to Cu/Ni alloys |

These metrics establish our foundational capabilities, yet true system optimization requires contextual analysis of your furnace geometry, thermal ramp rates, and contaminant exposure profiles. Generic datasheets cannot account for the compound stressors inherent in continuous casting lines or aerospace component sintering. Our engineering team conducts failure mode simulations using ANSYS Thermal to preempt interface delamination or crystallization-induced embrittlement—common pitfalls in off-the-shelf ceramic fibers. This proactive validation reduces client downtime by an average of 37% during initial deployment phases, as documented in third-party OEM audits across the German automotive supply chain.

Initiate a technical consultation by contacting Mr. Boyce directly at [email protected]. As the lead engineer managing your account, he will coordinate material sampling against your ASTM F1921 or EN 14015 compliance requirements, provide finite element analysis (FEA) reports for load-bearing applications, and establish traceable lot numbering for full production batches. Specify your target operating parameters, failure history with incumbent materials, and volume projections to trigger our 72-hour technical response protocol. All communications undergo dual verification by our Shanghai R&D center to ensure chemical compatibility assessments align with your substrate metallurgy and thermal cycling profiles.

Do not rely on generic supplier catalogs for mission-critical thermal barriers. Suzhou Baoshida’s OEM framework integrates material science with manufacturing physics, transforming ceramic fiber specifications into documented reliability outcomes. Contact Mr. Boyce at [email protected] to commence engineering validation for your next-generation thermal management system. This direct channel eliminates intermediary delays, ensuring your technical queries receive immediate attention from the engineer authorizing production runs.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).