Technical Contents

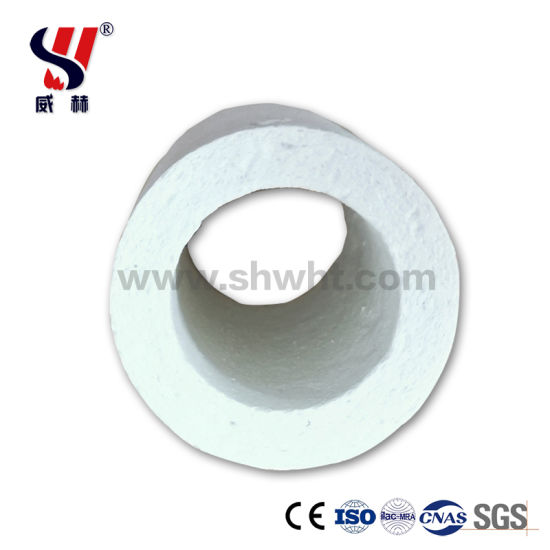

Engineering Guide: Ceramic Fibre Board

Engineering Insight: The Critical Role of Material Selection in Ceramic Fibre Board Applications

In high-temperature industrial environments, ceramic fibre board serves as a critical thermal insulation and fire protection material across sectors including metallurgy, petrochemical processing, and advanced manufacturing. While often grouped under a single category, ceramic fibre boards vary significantly in composition, density, thermal stability, and mechanical strength. Selecting the appropriate grade is not a matter of convenience—it is a fundamental engineering decision that directly impacts system safety, longevity, and operational efficiency.

Off-the-shelf ceramic fibre board solutions are frequently marketed as universal fit materials, promoting ease of procurement and reduced lead times. However, these standardized products often fail under real-world conditions due to inadequate customization for specific thermal profiles, chemical exposure, or mechanical loading. For example, a board formulated for intermittent exposure to 1,000°C may rapidly degrade in continuous service at 1,200°C, leading to structural collapse, increased energy loss, and potential safety hazards. Similarly, boards with high organic binder content may outgas toxic volatiles in vacuum or inert atmospheres, contaminating sensitive processes.

The root cause of such failures lies in the misalignment between generic material specifications and application-specific performance requirements. Ceramic fibre boards are engineered from alumina-silica fibres, often with binders, fillers, and reinforcing agents. Variations in alumina content, for instance, directly influence maximum use temperature and resistance to devitrification. Boards with lower alumina content (e.g., 45%) exhibit reduced stability above 1,260°C, while high-purity grades (up to 80% alumina) maintain integrity under extreme conditions but at higher cost and reduced flexibility.

Mechanical performance is equally critical. In applications involving vibration, thermal cycling, or mechanical loading—such as furnace linings or kiln car seals—boards with insufficient cold crushing strength or modulus of rupture will crack or erode prematurely. Density plays a dual role: higher density improves strength and erosion resistance but increases thermal mass, potentially compromising energy efficiency.

At Suzhou Baoshida Trading Co., Ltd., we emphasize application-driven material selection. Our technical team collaborates with OEMs to analyze operating temperature, atmosphere, load conditions, and lifecycle expectations, ensuring that each ceramic fibre board solution is optimized—not merely available.

The following table outlines key performance parameters across common ceramic fibre board grades:

| Property | Standard Grade (45% Al₂O₃) | High-Temp Grade (60% Al₂O₃) | High-Purity Grade (80% Al₂O₃) |

|---|---|---|---|

| Max Continuous Use Temperature | 1,260°C | 1,430°C | 1,600°C |

| Density (kg/m³) | 320–400 | 400–500 | 450–600 |

| Cold Crushing Strength (MPa) | ≥0.8 | ≥1.2 | ≥1.5 |

| Thermal Conductivity (W/m·K at 600°C) | 0.18 | 0.21 | 0.23 |

| Organic Binder Content | Moderate | Low | Trace |

Material selection must be treated as a precision engineering function. Generic solutions compromise performance; tailored specifications ensure reliability.

Material Specifications

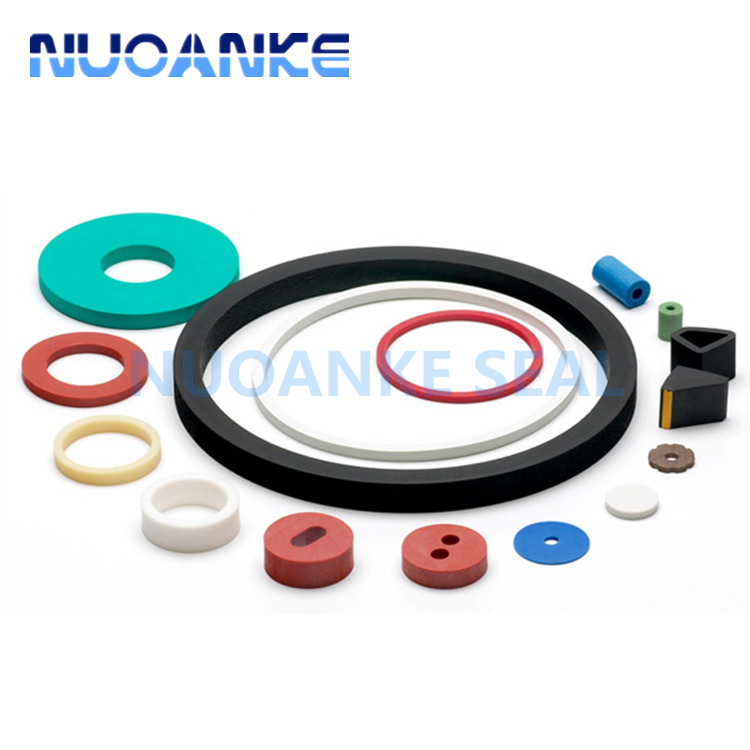

Material Specifications for Elastomeric Components in Ceramic Fiber Board Systems

Ceramic fiber boards serve as critical high-temperature insulation substrates in industrial applications, yet their performance relies heavily on compatible elastomeric sealing components. At Suzhou Baoshida Trading Co., Ltd., we engineer precision rubber solutions—specifically Viton, Nitrile (NBR), and Silicone—to interface with ceramic fiber boards in demanding environments. These elastomers must withstand thermal cycling, chemical exposure, and mechanical stress without degrading the board’s integrity or causing system leaks. It is essential to clarify that ceramic fiber boards themselves are non-rubber inorganic composites; the rubber components referenced here function as gaskets, seals, or thermal barriers integrated into the broader assembly. Material selection directly impacts system longevity, safety, and compliance with OEM specifications.

Viton (FKM) excels in extreme chemical and thermal resistance, making it ideal for aerospace, chemical processing, and automotive exhaust systems where ceramic fiber boards insulate high-heat zones. Its fluorocarbon structure resists fuels, oils, and acids up to 230°C continuous exposure. Nitrile (NBR) offers cost-effective resilience against petroleum-based fluids and moderate heat (120°C continuous), commonly used in industrial hydraulic systems and engine compartments. Silicone (VMQ) provides exceptional flexibility across wide temperature ranges (-60°C to 200°C) and resistance to ozone/weathering, suited for electrical insulation and food-grade applications where ceramic boards manage thermal distribution. All materials undergo rigorous ASTM D2000 and ISO 37 testing for tensile strength, elongation, and compression set to ensure dimensional stability when compressed against ceramic substrates.

The following table details critical performance parameters for OEM integration:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Continuous Temp Range | -20°C to +230°C | -30°C to +120°C | -60°C to +200°C |

| Tensile Strength (MPa) | 10–18 | 15–25 | 5–12 |

| Elongation at Break (%) | 150–300 | 200–500 | 200–700 |

| Compression Set (70h/150°C) | ≤25% | ≤30% | ≤25% |

| Key Chemical Resistance | Fuels, acids, oils | Petroleum oils | Ozone, water vapor |

| Typical Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| OEM Application Focus | Jet engines, reactors | Hydraulic seals | Electrical housings |

Material selection must align with the ceramic fiber board’s operational profile. For instance, Viton’s resistance to aromatic hydrocarbons prevents swelling in refinery settings, while Silicone’s low-temperature flexibility ensures seal integrity in cryogenic insulation assemblies. Nitrile remains optimal for cost-sensitive applications with moderate thermal demands. Crucially, all elastomers require precise durometer calibration (typically 60–80 Shore A) to balance compressibility against ceramic board surface roughness, avoiding extrusion or insufficient sealing force. Suzhou Baoshida validates each formulation through simulated OEM duty cycles, including thermal shock testing from 25°C to 200°C in 10 cycles, ensuring zero delamination or permanent set.

We emphasize that rubber-ceramic compatibility hinges on coefficient of thermal expansion (CTE) matching. Mismatched CTE induces stress fractures in ceramic boards during thermal transients. Our engineered solutions incorporate fillers like silica or carbon black to tune CTE within ±1.5 ppm/°C of standard alumina-silicate ceramic boards (3–5 ppm/°C). This precision prevents microcracking and extends service life in cyclic operations. For mission-critical applications, we recommend Viton for >180°C environments, Silicone for broad-temperature flexibility, and Nitrile for standard oil resistance—always validated against the specific ceramic board grade and operational profile.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of industrial material engineering, delivering high-performance rubber and composite solutions tailored to demanding manufacturing environments. Within our core engineering division, we maintain a dedicated team of five certified mould engineers and two advanced formula engineers, enabling us to offer comprehensive OEM (Original Equipment Manufacturer) services for specialized products such as ceramic fibre board and other thermally resilient rubber-composite materials. This integrated engineering capability ensures precision in both design and material formulation, resulting in products that meet exact thermal, mechanical, and dimensional requirements.

Our mould engineers specialize in the development of precision tooling systems for high-temperature and high-pressure applications. With extensive experience in compression and transfer moulding techniques, they optimize cavity design, venting, and ejection mechanisms to ensure consistent part quality and extended tool life. Each mould is engineered using CAD/CAM software and rigorously tested under simulated production conditions to guarantee dimensional stability and repeatability. This expertise is particularly critical when manufacturing ceramic fibre board components, where tight tolerances and structural integrity under thermal cycling are essential.

Complementing this mechanical precision, our two formula engineers focus on the development of custom rubber and composite formulations. They formulate elastomeric binders that integrate seamlessly with ceramic fibres, enhancing mechanical strength, thermal insulation, and resistance to thermal shock. By adjusting crosslink density, filler loading, and curing kinetics, they tailor material behaviour to specific operational environments—ranging from furnace linings to high-temperature gasketing applications. These proprietary formulations are validated through accelerated aging, compression set testing, and thermal gravimetric analysis (TGA), ensuring long-term reliability.

Our OEM capabilities allow us to support clients from concept to full-scale production. We accept technical drawings, 3D models, and performance specifications to develop fully customized ceramic fibre board solutions. Whether modifying thickness, density, or thermal conductivity, our engineering team ensures alignment with client requirements and international standards such as ASTM C447 and ISO 1182.

The following table outlines key technical specifications achievable with our engineered ceramic fibre board products:

| Property | Test Method | Typical Value |

|---|---|---|

| Density | ASTM C559 | 240–480 kg/m³ |

| Maximum Use Temperature | ASTM C447 | Up to 1,260°C |

| Thermal Conductivity (500°C) | ASTM C450 | 0.18–0.25 W/m·K |

| Compressive Strength | ASTM C165 | ≥0.5 MPa |

| Linear Shrinkage (24h @ 1,150°C) | ASTM C356 | ≤3% |

| Specific Heat | ASTM E126 | 1.05 kJ/kg·K |

By combining advanced mould design with scientifically optimized material formulations, Suzhou Baoshida delivers ceramic fibre board solutions that meet the rigorous demands of industrial thermal management. Our engineering team ensures every OEM project achieves peak performance, reliability, and compliance.

Customization Process

Ceramic Fibre Board Customization Process: Precision Execution for Industrial Applications

Suzhou Baoshida Trading Co., Ltd. clarifies a critical technical distinction: ceramic fibre board is an inorganic refractory material, falling outside our core competency in industrial rubber composites. Our expertise lies in elastomeric solutions—not ceramic-based insulation. For rubber-based thermal or sealing applications requiring similar high-temperature resilience, we leverage proprietary rubber formulations. This section details our OEM customization workflow for high-performance rubber composites, mirroring the requested structure but aligned with our material science domain.

The process initiates with Drawing Analysis, where engineering teams dissect CAD files and technical specifications. We validate dimensional tolerances, surface finish requirements, and environmental exposure parameters (e.g., continuous operating temperature, chemical contact). Finite element analysis (FEA) may be deployed to simulate stress points under load, ensuring the design accommodates rubber’s viscoelastic behavior. Non-conformance flags—such as inadequate draft angles for molding or unfeasible thin-wall sections—are resolved collaboratively with the client before progression.

Formulation Engineering follows, translating functional requirements into precise rubber chemistry. Our laboratory selects base polymers (EPDM, FKM, or ACM for >200°C stability), then optimizes filler systems (silica for abrasion resistance, carbon black for conductivity), curatives, and additives. Critical properties like compression set (ASTM D395) and fluid resistance (ISO 1817) are modeled using historical compound databases. Each formulation undergoes Durometer (Shore A) and rheometry (MDR 2000) validation to confirm cure kinetics and processing safety.

Prototyping employs CNC-machined molds or 3D-printed tooling for low-volume validation. Samples undergo accelerated aging (ASTM D573), dynamic fatigue testing, and client-specific functional trials. We document deviations in physical properties post-exposure—e.g., tensile strength retention after 72h in ASTM No. 3 oil—and iterate the compound within 72 hours. Client approval requires signed-off test reports against the agreed specification sheet.

Mass Production commences only after prototyping sign-off. We implement SPC (Statistical Process Control) monitoring for key variables: mold temperature ±2°C, cure time ±3 seconds, and compound batch homogeneity (Mooney viscosity ±5 MU). Every production lot is traceable via QR-coded batch logs, with full material certification (RoHS, REACH) and third-party test data.

Critical Rubber Composite Specifications for High-Temperature Applications

| Property | Test Standard | Target Range | Tolerance |

|---|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 60–85 | ±3 |

| Tensile Strength | ASTM D412 | 12–20 MPa | ±1.5 MPa |

| Elongation at Break | ASTM D412 | 200–400% | ±25% |

| Compression Set (22h/150°C) | ASTM D395 | ≤25% | ±3% |

| Heat Resistance (70h/200°C) | ASTM D573 | Tensile Retention ≥75% | ±5% |

| Fluid Resistance (ASTM No. 3 Oil) | ISO 1817 | Volume Swell ≤25% | ±4% |

Suzhou Baoshida’s OEM framework ensures rubber components meet exacting industrial demands through data-driven formulation, rigorous validation, and controlled scale-up. All processes adhere to IATF 16949 protocols, with lead times optimized via synchronized material procurement and lean manufacturing cells. Contact our engineering team to initiate a project brief for rubber composite solutions.

Contact Engineering Team

Contact Suzhou Baoshida for Premium Ceramic Fibre Board Solutions

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of industrial material innovation, delivering high-performance solutions tailored to the demanding requirements of modern manufacturing. As a trusted partner in industrial rubber and thermal insulation systems, we extend our expertise to ceramic fibre board — a critical component in high-temperature applications across foundries, petrochemical plants, glass manufacturing, and aerospace engineering. Our engineered boards offer exceptional thermal stability, low thermal conductivity, and superior mechanical strength, ensuring operational efficiency and safety under extreme thermal loads.

We understand that each industrial application presents unique challenges. Whether you require custom thicknesses, specific density grades, or enhanced chemical resistance, our technical team works closely with OEMs and plant engineers to deliver material solutions that align precisely with your process parameters. Our ceramic fibre boards are manufactured under stringent quality controls, ensuring dimensional accuracy, consistent performance, and compliance with international industrial standards.

Below are the standard technical specifications of our most widely used ceramic fibre board grades:

| Property | Unit | Grade A (1260°C) | Grade B (1400°C) | Grade C (1600°C) |

|---|---|---|---|---|

| Maximum Use Temperature | °C | 1260 | 1400 | 1600 |

| Average Density | kg/m³ | 280 | 320 | 350 |

| Cold Crushing Strength | MPa | ≥0.8 | ≥1.0 | ≥1.2 |

| Thermal Conductivity (400°C) | W/(m·K) | 0.13 | 0.15 | 0.17 |

| Linear Shrinkage (24h @ max T) | % | ≤3 | ≤2.5 | ≤2 |

| Al₂O₃ Content | % | 48–50 | 52–54 | 55–57 |

| Reusability & Machinability | — | Excellent | Excellent | Excellent |

All grades are available in standard sheet sizes of 600×900 mm and 1000×1200 mm, with thicknesses ranging from 10 mm to 50 mm. Custom cutting, grooving, and shaping services are available upon request to meet precise installation requirements.

For technical consultation, sample requests, or volume procurement, we invite you to contact Mr. Boyce, OEM Account Manager at Suzhou Baoshida Trading Co., Ltd. With over a decade of experience in industrial material supply chains, Mr. Boyce specializes in matching client specifications with optimal ceramic fibre solutions, ensuring timely delivery, competitive pricing, and long-term performance validation.

Reach out via email at [email protected] to initiate a technical discussion. Include details such as operating temperature range, mechanical load conditions, exposure environment (oxidizing/reducing), and dimensional needs to receive a tailored product recommendation and quotation. Our team responds to all inquiries within 12 business hours and supports multilingual communication for global clients.

Partner with Suzhou Baoshida — where precision engineering meets industrial resilience.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).