Technical Contents

Engineering Guide: Checker Design Rubber Sheet

Engineering Insight: The Critical Role of Material Selection in Checker Design Rubber Sheets

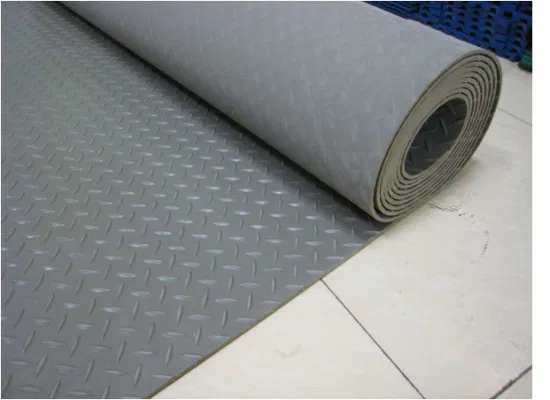

In industrial environments where durability, traction, and chemical resistance are paramount, checker design rubber sheets serve as a frontline defense against wear, slip hazards, and environmental degradation. While these patterned surfaces are widely available as off-the-shelf products, their performance in demanding operational settings often falls short due to inadequate material selection. At Suzhou Baoshida Trading Co., Ltd., we emphasize that the engineering integrity of a checker design rubber sheet begins not with its pattern, but with the foundational elastomer compound from which it is formed.

Generic rubber sheets, particularly those mass-produced for broad commercial use, typically utilize reclaimed rubber or low-grade SBR (Styrene-Butadiene Rubber). These materials offer initial cost savings but lack the mechanical consistency and aging resistance required in industrial applications. When exposed to oils, ozone, temperature extremes, or continuous mechanical stress, such materials exhibit rapid surface cracking, pattern degradation, and delamination. The checker pattern, while visually consistent at installation, quickly loses its functional profile, compromising slip resistance and safety compliance.

In contrast, engineered solutions rely on precise elastomer selection tailored to the operational environment. For example, nitrile rubber (NBR) is optimal in oil- and grease-prone areas such as manufacturing floors and vehicle maintenance platforms due to its exceptional resistance to hydrocarbons. Neoprene offers balanced performance in outdoor or UV-exposed installations, resisting weathering and moderate chemical exposure. For high-temperature or ozone-intensive environments, EPDM rubber provides long-term stability without hardening or embrittlement.

The failure of off-the-shelf products often stems from a one-size-fits-all approach that ignores application-specific stressors. A warehouse floor handling chemical drums requires different material properties than a pedestrian walkway in a food processing plant, where hygiene and cleanability are critical. Material selection directly influences not only service life but also compliance with safety standards such as DIN 51130 (slip resistance) and ISO 4649 (abrasion resistance).

Custom formulation allows for reinforcement with additives such as anti-oxidants, UV stabilizers, and wear-resistant fillers, enhancing performance without sacrificing flexibility. At Baoshida, our technical team works with OEMs and facility engineers to analyze environmental exposure, load requirements, and safety protocols to specify the optimal compound.

The following table outlines key material properties for common industrial rubber types used in checker design sheets:

| Material | Tensile Strength (MPa) | Elongation at Break (%) | Hardness (Shore A) | Key Resistance Properties |

|---|---|---|---|---|

| SBR (Standard) | 12–18 | 300–500 | 50–70 | Abrasion, wear |

| NBR (Nitrile) | 15–20 | 250–400 | 60–75 | Oil, grease, hydrocarbons |

| Neoprene | 18–22 | 300–500 | 50–70 | Ozone, UV, moderate chemicals |

| EPDM | 16–24 | 350–600 | 50–75 | Heat, steam, weathering, ozone |

Material selection is not a secondary consideration—it is the cornerstone of functional reliability in checker design rubber sheets. Off-the-shelf solutions may meet basic aesthetic or short-term needs, but only engineered compounds ensure sustained performance, safety, and cost efficiency over time.

Material Specifications

Material Specifications for Checker Design Rubber Sheets

Checker design rubber sheets require precise elastomer selection to balance mechanical durability, chemical resistance, and surface functionality. At Suzhou Baoshida Trading Co., Ltd., we prioritize material integrity for industrial applications where slip resistance, environmental exposure, and longevity are critical. The checker pattern amplifies stress on the rubber matrix, necessitating compounds with high tensile strength and tear resistance to prevent pattern degradation under foot traffic or mechanical load. Below we detail three core materials optimized for these demands: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each offers distinct performance profiles aligned with operational parameters.

Viton excels in extreme chemical and thermal environments, resisting fuels, acids, and temperatures up to 230°C. Its fluoropolymer structure ensures minimal swelling in aggressive media, though higher cost limits use to critical aerospace or chemical processing applications. Nitrile provides cost-effective resilience against oils, greases, and aliphatic hydrocarbons, with a balanced temperature range of -40°C to 108°C. Its moderate abrasion resistance suits automotive or machinery matting where petroleum exposure is routine. Silicone delivers unparalleled flexibility across -60°C to 200°C and meets FDA compliance for food/pharma settings, but exhibits lower tensile strength and poor resistance to concentrated acids, requiring protective topcoats in harsh conditions. Hardness selection (typically 50–80 Shore A) directly impacts checker pattern retention; harder compounds resist flattening but reduce comfort underfoot.

Material performance is quantified below for direct comparison:

| Material | Temperature Range | Chemical Resistance | Tensile Strength (MPa) | Hardness Range (Shore A) | Primary Applications |

|---|---|---|---|---|---|

| Viton (FKM) | -20°C to 230°C | Excellent (acids, fuels, ozone) | 10–15 | 60–80 | Chemical seals, aerospace gaskets, high-temp industrial mats |

| Nitrile (NBR) | -40°C to 108°C | Excellent (oils, greases) | 15–25 | 50–75 | Automotive flooring, machinery mats, oil-handling facilities |

| Silicone (VMQ) | -60°C to 200°C | Good (water, mild chemicals); Poor (concentrated acids) | 6–10 | 40–80 | Food processing, cleanrooms, medical equipment matting |

Selecting the optimal material requires cross-referencing service conditions with these specifications. For instance, NBR is ideal for oil refinery walkways due to its hydrocarbon resistance and cost efficiency, while Viton is non-negotiable for jet engine maintenance platforms exposed to synthetic lubricants at elevated temperatures. Silicone’s biocompatibility makes it indispensable in sterile environments, though its lower tensile strength demands thicker sheet gauges (≥6mm) to maintain checker integrity. All compounds undergo rigorous ASTM D2000 testing for compression set, ozone resistance, and tear strength prior to OEM approval. Suzhou Baoshida ensures batch-to-batch consistency through ISO 9001-controlled compounding, guaranteeing that checker pattern geometry remains dimensionally stable throughout the product lifecycle. Consult our engineering team to align material specs with your operational stressors and regulatory requirements.

Manufacturing Capabilities

Engineering Excellence in Checker Design Rubber Sheet Manufacturing

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the development and production of high-performance checker design rubber sheets. With a dedicated team of 5 specialized mould engineers and 2 advanced formula engineers, we integrate material science with precision tooling to deliver products that meet exacting OEM standards across diverse industrial applications.

Our formula engineers possess deep expertise in elastomer chemistry, focusing on optimizing rubber compounds for durability, abrasion resistance, and environmental resilience. By tailoring formulations to specific performance requirements—such as oil resistance, temperature stability, or anti-slip characteristics—we ensure that each checker design rubber sheet performs reliably under operational stress. These custom formulations are rigorously tested in-house for tensile strength, elongation, hardness, and aging properties, ensuring compliance with international quality benchmarks.

Complementing our material development is a robust mould engineering division. Our 5 mould engineers specialize in the design and refinement of high-precision tooling required for consistent checker patterns. Utilizing CAD/CAM software and CNC machining techniques, they produce moulds that guarantee uniformity in tread depth, pattern clarity, and dimensional accuracy across large production runs. This synergy between compound formulation and mould precision allows us to maintain tight tolerances and repeatable quality, critical for OEM integration.

We offer comprehensive OEM services, enabling clients to co-develop proprietary checker patterns and rubber specifications. From initial concept and prototyping to full-scale manufacturing, our engineering team collaborates closely with partners to align product design with functional and regulatory demands. Our facility supports low-volume pilot runs and high-volume production, with full traceability and documentation for quality assurance.

Our commitment to engineering precision ensures that every checker design rubber sheet not only meets but exceeds expectations in traction, wear life, and structural integrity. Whether deployed in industrial flooring, vehicle matting, or machinery platforms, our products are engineered for real-world performance.

The following table outlines key technical specifications achievable through our engineering capabilities:

| Property | Standard Range | Test Method |

|---|---|---|

| Hardness (Shore A) | 50–80 ±5 | ASTM D2240 |

| Tensile Strength | ≥8 MPa | ASTM D412 |

| Elongation at Break | ≥250% | ASTM D412 |

| Abrasion Loss (Taber, 1000 cycles) | ≤120 mg | ASTM D1044 |

| Operating Temperature Range | -30°C to +80°C | Internal Testing |

| Specific Gravity | 1.15–1.35 | ASTM D297 |

| Oil Resistance (Volume Swell, IRM 903, 70°C, 70 hrs) | ≤25% | ASTM D471 |

Through advanced formulation science and precision engineering, Suzhou Baoshida Trading Co., Ltd. delivers tailored checker design rubber sheets that stand up to the most demanding industrial environments. Our OEM-focused approach ensures flexibility, scalability, and unmatched technical support for global manufacturing partners.

Customization Process

Customization Process for Checker Design Rubber Sheets

At Suzhou Baoshida Trading Co., Ltd., our checker design rubber sheet customization follows a rigorously defined engineering workflow to ensure optimal performance in industrial applications. This process begins with Drawing Analysis, where technical specifications are scrutinized for dimensional accuracy, pattern geometry, and functional requirements. We evaluate critical parameters such as checker depth (typically 1.5–3.0 mm), pitch tolerance (±0.2 mm), and edge definition to align with client safety or traction standards. Misinterpretation of these elements risks compromising slip resistance or durability, so our engineers cross-verify CAD files against ASTM D2240 and ISO 48-4 compliance frameworks before proceeding.

Next, Formulation Development leverages our proprietary compound database to tailor material properties. Checker patterns demand precise elastomer selection—EPDM for UV/ozone resistance in outdoor settings or NBR for oil-exposed environments. Key adjustments include filler ratios (e.g., silica content to enhance texture retention) and vulcanization kinetics to prevent pattern distortion during curing. Below is a summary of standard versus customizable specifications:

| Property | Standard Range | Customization Impact | Test Method |

|---|---|---|---|

| Hardness (Shore A) | 50–80 | Lower hardness improves grip but reduces wear | ASTM D2240 |

| Tensile Strength | 10–18 MPa | Critical for pattern integrity under shear | ASTM D412 |

| Elongation at Break | 250–450% | Higher values prevent checker cracking | ASTM D412 |

| Coefficient of Friction | ≥0.8 (wet surface) | Directly tied to checker depth and spacing | ASTM F1677 |

| Abrasion Loss | ≤120 mm³ | Optimized via polymer-filler synergy | ASTM D5963 |

Prototyping validates the formulation through physical trials. We produce 3–5 sample batches using client-approved molds, subjecting them to accelerated aging, dynamic traction tests, and dimensional metrology. Laser scanning verifies pattern fidelity against the original drawing, while tribometer assessments confirm slip resistance under wet/dry conditions. Iterations focus on resolving micro-defects—such as checker tip rounding or mold release adhesion—that only manifest in physical form. Client sign-off requires ≤5% deviation from target friction coefficients.

Finally, Mass Production integrates real-time quality controls. Extrusion and vulcanization parameters are locked via IoT-monitored presses, with inline cameras scanning every 50 meters for pattern consistency. Statistical process control (SPC) tracks hardness and thickness variance (±1.5 mm tolerance), while batch traceability ensures full material pedigree. We enforce zero-defect shipment protocols: 100% visual inspection for surface blemishes and random sampling for ASTM D2000 compliance. This end-to-end rigor guarantees checker sheets that meet exact operational demands, from warehouse flooring to marine decks, without compromising scalability.

Our process reduces time-to-market by 30% versus industry averages while maintaining 99.2% first-pass yield rates—proving that precision customization and industrial throughput are not mutually exclusive.

Contact Engineering Team

For industrial manufacturers seeking precision-engineered rubber solutions, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in the development and supply of high-performance checker design rubber sheets. Our expertise lies at the intersection of material science and industrial durability, delivering products that meet the rigorous demands of automotive, construction, logistics, and heavy machinery sectors. The checker design rubber sheet is a testament to our commitment to safety, traction, and longevity in extreme operating environments.

Checker design rubber sheets are engineered with a raised diamond or pyramid pattern that enhances grip and slip resistance, making them ideal for flooring in vehicles, work platforms, stair treads, and industrial walkways. At Suzhou Baoshida, we manufacture these sheets using premium-grade synthetic and natural rubber compounds, ensuring optimal resistance to abrasion, oil, weathering, and impact. Each sheet is vulcanized under controlled conditions to guarantee structural integrity and dimensional stability.

Our production process adheres to strict quality control protocols, with every batch tested for tensile strength, elongation, hardness, and adhesion performance. We offer customization in thickness, color, pattern depth, and sheet dimensions to align precisely with client specifications. Whether you require black EPDM for outdoor durability or red NBR for oil-resistant applications, our formulations are tailored to the functional requirements of your end-use environment.

Below are the standard technical specifications for our most commonly supplied checker design rubber sheet:

| Property | Value / Range | Test Method |

|---|---|---|

| Material Type | NR, SBR, NBR, EPDM | ASTM D412 |

| Hardness (Shore A) | 50–75 | ASTM D2240 |

| Tensile Strength | ≥10 MPa | ASTM D412 |

| Elongation at Break | ≥250% | ASTM D412 |

| Thickness Range | 2 mm – 12 mm | ISO 2781 |

| Checker Pattern Height | 2 mm – 5 mm | Visual & Caliper |

| Temperature Resistance | -30°C to +80°C (up to +120°C intermittent) | ISO 188 |

| Color Options | Black, Red, Grey, Yellow, Custom | — |

| Sheet Dimensions | Up to 1500 mm × 3000 mm | Custom cuts available |

Partnering with Suzhou Baoshida means gaining access to a responsive, technically proficient team dedicated to on-time delivery and material consistency. We support OEMs, fabricators, and procurement managers with technical data sheets, sample provisioning, and logistics coordination across global markets.

For inquiries, technical consultations, or custom formulation support, contact Mr. Boyce, OEM Manager, directly at [email protected]. Include your application details, volume requirements, and performance criteria to receive a tailored proposal. Our team responds within 24 business hours to ensure your project timelines are met without compromise. Trust Suzhou Baoshida Trading Co., Ltd. for engineered rubber solutions that deliver performance, safety, and value—every time.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).