Technical Contents

Engineering Guide: Children’S Interlocking Floor Tiles

Engineering Insight: Material Selection in Children’s Interlocking Floor Tiles

In the industrial production of children’s interlocking floor tiles, material selection is not merely a cost-driven decision—it is a foundational engineering imperative. These tiles are subjected to dynamic mechanical stresses, repeated impact loads, and frequent exposure to environmental contaminants such as moisture, cleaning agents, and UV radiation. Off-the-shelf solutions, often formulated from recycled rubber or low-grade EVA foams, fail to meet the rigorous performance standards required in high-traffic or commercial environments such as daycare centers, schools, and indoor play facilities. The degradation mechanisms observed in substandard materials include delamination, permanent indentation, color fading, and loss of interlock integrity—issues that stem directly from inadequate polymer formulation and poor filler dispersion.

At Suzhou Baoshida Trading Co., Ltd., we approach material selection through a precision-engineering lens. Our proprietary rubber compounds are based on vulcanized SBR (styrene-butadiene rubber) and EPDM (ethylene propylene diene monomer), both of which offer superior resilience, abrasion resistance, and thermal stability. Unlike generic blends, our formulations incorporate controlled cross-link density, optimized filler ratios (such as nano-silica and carbon black), and UV stabilizers to ensure long-term structural and aesthetic performance. The interlocking mechanism, often overlooked in mass-produced tiles, relies on dimensional stability of the polymer matrix. Low-grade materials exhibit creep under sustained load, leading to loosening of connections and trip hazards—failures that are eliminated through our engineered compound design.

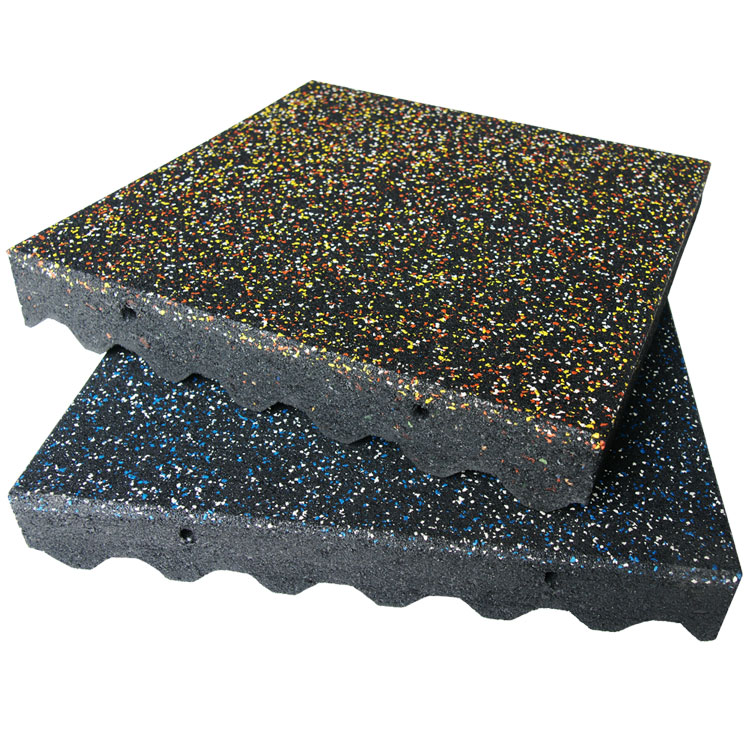

Another critical failure point in commercial applications is slip resistance under wet or oily conditions. Standard tiles may meet initial COF (coefficient of friction) requirements but degrade rapidly due to surface abrasion. Our tiles utilize a dual-density molding process, where a harder base layer ensures dimensional stability while a softer, textured top layer maintains consistent slip resistance over extended service life. This layered approach is only achievable with high-purity raw materials and precise control over curing parameters.

The following table outlines the material performance specifications of our engineered tiles compared to typical off-the-shelf alternatives:

| Property | Baoshida Engineered Tile | Off-the-Shelf Standard Tile |

|---|---|---|

| Material Base | Vulcanized SBR/EPDM blend | Recycled rubber or EVA foam |

| Tensile Strength (MPa) | ≥12.5 | 4.0–6.0 |

| Elongation at Break (%) | ≥280 | 120–180 |

| Shore A Hardness | 65 ± 5 | 45–55 (variable) |

| Abrasion Loss (mm³) | ≤120 | ≥250 |

| UV Resistance (1000h QUV) | Minimal fading, no cracking | Severe fading, surface cracking |

| Interlock Cycle Endurance | >5000 cycles | <1000 cycles |

| COF (Wet) | 0.65–0.75 | 0.40–0.50 (after 6 months) |

Material integrity directly correlates with safety, longevity, and total cost of ownership. While off-the-shelf tiles may present a lower initial price, their shortened service life and higher replacement frequency result in increased operational costs and liability risks. Our engineered solutions are designed for 8–10 years of continuous use in demanding environments, validated through accelerated aging and real-world performance testing. For OEMs and institutional buyers, the choice is not between cost and quality—it is between short-term savings and long-term reliability.

Material Specifications

Material Specifications for Children’s Interlocking Floor Tiles

Selecting the optimal elastomer for children’s interlocking floor tiles demands rigorous evaluation of performance, safety, and manufacturability. At Suzhou Baoshida Trading Co., Ltd., we prioritize materials meeting stringent global safety standards (ASTM F963, EN71-3) while ensuring durability against mechanical stress, UV exposure, and common household chemicals. Viton, Nitrile, and Silicone each offer distinct advantages, but suitability hinges on application environment and production constraints.

Viton (FKM) excels in extreme chemical and thermal resistance, withstanding temperatures from -20°C to +250°C. Its fluoropolymer backbone provides exceptional stability against oils, solvents, and ozone—critical for tiles in commercial play areas near automotive workshops or laboratories. However, Viton’s high raw material cost and complex curing process (requiring peroxide systems and extended press times) elevate production expenses. Its hardness range (70–90 Shore A) may compromise impact absorption for跌倒 protection, limiting use to specialized industrial-adjacent installations where chemical exposure outweighs cost sensitivity.

Nitrile (NBR) remains the industry standard for cost-effective, high-volume tile production. With a balanced Shore A hardness of 55–85, it delivers optimal cushioning for child safety while resisting abrasion, water, and mild solvents. NBR formulations can be tailored for enhanced UV stability via carbon black or specialty additives, ensuring colorfastness in indoor/outdoor settings. Processing advantages include rapid sulfur-cure kinetics (140–160°C, 5–8 minutes) and compatibility with standard compression molding equipment. While inferior to Viton in chemical resistance, NBR meets all regulatory requirements for phthalates and heavy metals in children’s products, making it ideal for residential and daycare environments.

Silicone (VMQ) offers unparalleled flexibility across -60°C to +200°C and inherent biocompatibility, satisfying FDA 21 CFR 177.2600 for food-contact surfaces. Its non-toxic, hypoallergenic nature is optimal for sensory play tiles, though premium pricing necessitates targeted application. Silicone’s low compression set ensures long-term shape retention under static loads, but high viscosity complicates molding—requiring precise injection parameters and secondary vulcanization. Critical for child safety, it emits minimal volatile organic compounds (VOCs) post-cure, supporting indoor air quality certifications like GREENGUARD Gold.

Comparative Material Specifications

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Hardness Range (Shore A) | 70–90 | 55–85 | 40–70 |

| Temp. Range (°C) | -20 to +250 | -30 to +120 | -60 to +200 |

| Tensile Strength (MPa) | 12–20 | 15–25 | 5–12 |

| Elongation at Break (%) | 150–300 | 200–500 | 200–800 |

| Key Processing Temp. (°C) | 170–190 | 140–160 | 120–150 |

| Cure Time (min) | 10–15 | 5–8 | 8–12 |

| Critical Compliance | REACH SVHC-free | ASTM F963-17 | FDA 21 CFR 177.2600 |

| Primary Use Case | Chemical-exposed zones | Residential/daycare | Sensory/medical-grade tiles |

Material selection directly impacts tile lifecycle performance and production yield. Suzhou Baoshida Trading Co., Ltd. provides OEM partners with customized compound formulations—optimizing filler systems, cure profiles, and regulatory documentation to align with target markets. We rigorously validate all materials against EN ISO 48-4 abrasion testing and ISO 188 aging protocols to guarantee 10+ years of service life under typical play conditions. Partner with us to translate material science into certified, child-safe flooring solutions.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Development for High-Performance Children’s Interlocking Floor Tiles

At Suzhou Baoshida Trading Co., Ltd., our engineering capability is anchored in a specialized team of five dedicated mould engineers and two advanced rubber formula engineers. This technical core enables us to deliver OEM solutions with exacting precision, durability, and safety compliance—critical for children’s interlocking floor tiles used in kindergartens, play centers, and home environments. Our integrated approach combines material science with precision tooling to ensure every product meets stringent industrial and regulatory standards.

Our two rubber formula engineers possess deep expertise in polymer chemistry and elastomer compounding. They formulate custom rubber blends using EVA, TPE, and recycled rubber compounds, optimizing each formulation for shock absorption, non-slip performance, and resistance to UV degradation and compression set. Each compound is engineered to maintain flexibility across temperature extremes while ensuring zero content of phthalates, formaldehyde, or heavy metals—meeting EN71-3, REACH, and ASTM F963 safety standards. The formulation process includes iterative lab testing for tensile strength, elongation at break, and aging resistance, ensuring long-term performance under dynamic loads.

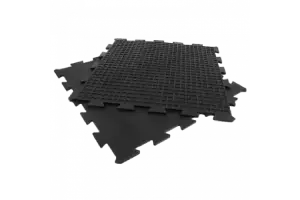

Complementing material development, our five mould engineers specialize in high-precision steel and aluminum tooling for complex interlocking geometries. Utilizing CAD/CAM software and CNC machining, they design multi-cavity moulds with micron-level tolerances to ensure seamless tile alignment and consistent thickness control. Each mould undergoes thermal analysis and flow simulation to eliminate weld lines and sink marks, critical for surface integrity and aesthetic uniformity. We support rapid prototyping with 3D-printed master patterns and short-run pre-production tooling, enabling clients to validate design functionality before full-scale manufacturing.

Our OEM capabilities are structured to support full product lifecycle development—from concept sketch to mass production. Clients provide performance targets or design specifications, and our engineers co-develop optimized solutions with material selection, structural analysis, and compliance documentation. We maintain a digital library of over 200 interlocking tile profiles, allowing for fast customization of size, thickness, color, and surface texture (e.g., anti-slip dimples, embossed patterns). All tooling and formulations are client-asset protected, ensuring exclusivity and intellectual property security.

The following table outlines key technical specifications achievable through our engineering integration:

| Parameter | Standard Range | Testing Method |

|---|---|---|

| Tile Thickness | 10 mm – 25 mm | ISO 2818 |

| Shore A Hardness | 45 ± 5 to 70 ± 5 | ISO 868 |

| Tensile Strength | ≥ 3.5 MPa | ISO 37 |

| Elongation at Break | ≥ 200% | ISO 37 |

| Compression Set (70°C, 22h) | ≤ 20% | ISO 815 |

| Slip Resistance (DSR) | ≥ 0.6 (wet & dry) | BS 7976 |

| Formulation Compliance | REACH, EN71-3, ASTM F963 | GC-MS, ICP-MS |

| Mould Tolerance | ±0.05 mm | CMM Inspection |

This synergy between formula and mould engineering ensures every interlocking floor tile we produce delivers safety, dimensional accuracy, and long-term resilience—hallmarks of Suzhou Baoshida’s industrial rubber expertise.

Customization Process

Customization Process for Children’s Interlocking Floor Tiles

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions for children’s interlocking floor tiles follow a rigorous, science-driven customization pathway. This ensures optimal safety, durability, and performance while adhering to stringent global regulatory standards. The process begins with Drawing Analysis, where engineering teams dissect client-provided CAD files and physical samples. Critical parameters—including interlock geometry tolerances (±0.1mm), surface texture depth, and drainage channel specifications—are validated against ISO 9001 protocols. We identify potential manufacturing constraints early, such as undercuts that could compromise mold release or gaps affecting structural integrity under ASTM F1292 impact attenuation requirements. Material compatibility with child-safe pigments and UV stabilizers is concurrently assessed to prevent future degradation.

Formulation Development leverages our 15+ years of rubber compounding expertise. Based on the analysis, we engineer a proprietary SBR/EPDM blend optimized for shock absorption (targeting 200–300 HIC values) and slip resistance (COF ≥0.6 wet per DIN 51130). Key variables include:

Hardness: Adjusted via silica/carbon black ratios to achieve Shore A 65–75 for cushioning without excessive deformation.

Tear Strength: Enhanced through peroxide curing to exceed 45 kN/m, preventing edge delamination during repeated interlocking.

Non-Toxicity: All additives comply with EN 71-3 heavy metal limits and REACH SVHC restrictions, verified via third-party GC-MS testing.

Prototyping utilizes precision steel molds (±0.05mm tolerance) to produce 3–5 validation batches. Each prototype undergoes accelerated aging (72h @ 70°C/95% RH), drop tests from 1.5m height, and interlock cycle validation (1,000+ engagements). Dimensional stability is confirmed via CMM scanning, while VOC emissions are monitored below 0.1 mg/m³. Client feedback on texture, color consistency, and assembly ergonomics triggers iterative refinements—typically 1–2 cycles—before final sign-off.

Mass Production commences only after full documentation approval. We deploy automated rubber injection molding lines with real-time rheometer monitoring to maintain Mooney viscosity (ML 1+4 @ 100°C: 45±3). Every 500 units undergo in-line checks for density, Shore hardness variance (<±3 points), and interlock force (measured at 15–25 N per connection). Final batches include traceable CoA reports covering raw material lot numbers, cure profiles, and compliance certificates for ASTM F963, CPSIA, and EU Toy Safety Directive 2009/48/EC.

Critical Material Specifications for Children’s Floor Tiles

| Parameter | Target Range | Test Standard | Significance |

|---|---|---|---|

| Shore A Hardness | 65–75 | ASTM D2240 | Balances impact absorption & structural support |

| Tensile Strength | ≥12 MPa | ISO 37 | Prevents tearing during installation/use |

| Compression Set (22h) | ≤25% | ASTM D395 | Ensures long-term shape retention |

| Density | 1.15–1.25 g/cm³ | ISO 2781 | Optimizes material cost vs. durability |

| VOC Emissions | <0.1 mg/m³ | ISO 16000-9 | Guarantees indoor air safety |

| Interlock Pull Force | 15–25 N | Internal Protocol | Secures tile stability without assembly strain |

This closed-loop methodology minimizes time-to-market while guaranteeing tiles exceed safety benchmarks for playgrounds, nurseries, and educational facilities. Suzhou Baoshida’s integration of polymer science and precision manufacturing delivers turnkey solutions where reliability is non-negotiable.

Contact Engineering Team

Contact Suzhou Baoshida for Premium Rubber-Based Children’s Interlocking Floor Tiles

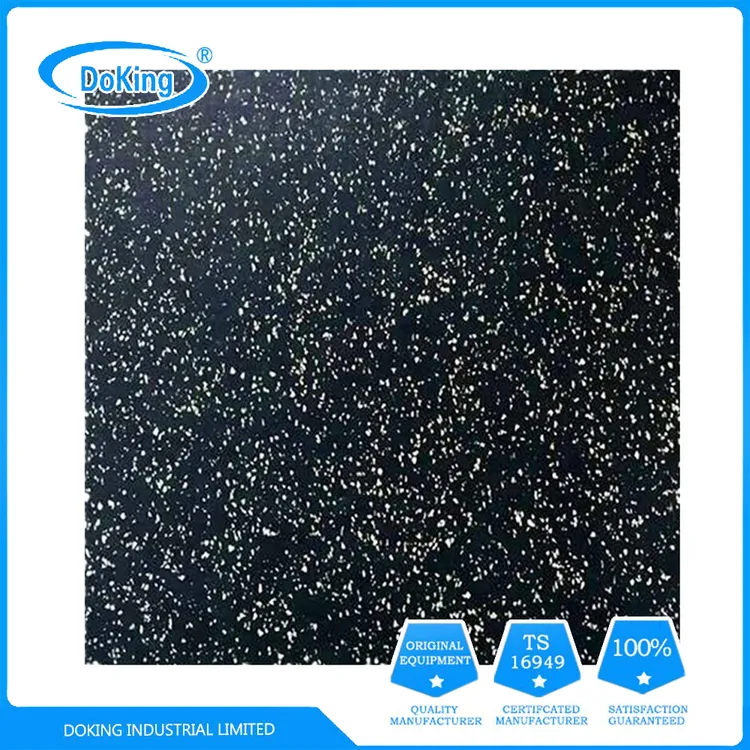

At Suzhou Baoshida Trading Co., Ltd., we specialize in industrial rubber solutions tailored to meet the rigorous demands of commercial and consumer applications. Our expertise extends into the development and supply of high-performance children’s interlocking floor tiles—engineered for safety, durability, and ease of installation in daycare centers, preschools, playrooms, and recreational facilities. These tiles are manufactured using premium-grade, non-toxic rubber compounds that comply with international safety standards, ensuring a resilient and slip-resistant surface ideal for active environments.

Our interlocking floor tiles are designed with both functionality and longevity in mind. Each tile features a precision-molded interlock system that ensures a secure fit, minimizing displacement under foot traffic while allowing for quick assembly and disassembly. The closed-cell rubber structure resists moisture absorption, inhibits mold and mildew growth, and maintains structural integrity under varying temperature and humidity conditions. Additionally, the surface texture is optimized to balance traction and comfort, reducing impact stress during play without compromising safety.

We understand that B2B buyers require consistency, scalability, and technical transparency. That is why every batch of our rubber tiles undergoes stringent quality control, including tensile strength testing, compression resistance evaluation, and VOC emissions screening. Our production process leverages advanced vulcanization techniques and computer-aided mold design to ensure dimensional accuracy and material homogeneity across large-volume orders.

For OEM partners and industrial buyers, Suzhou Baoshida offers customization options in color, thickness, density, and surface finish. Whether you require tiles with enhanced sound-dampening properties for indoor playgrounds or UV-stabilized variants for semi-outdoor use, our engineering team can formulate a solution aligned with your technical and regulatory requirements.

Below are the standard technical specifications for our most widely adopted children’s interlocking floor tile configuration:

| Property | Specification |

|---|---|

| Material Composition | SBR/NR blend (non-toxic, phthalate-free) |

| Tile Dimensions | 500 mm × 500 mm × 12 mm (customizable) |

| Interlock Type | Four-way symmetrical tab |

| Shore A Hardness | 65 ± 5 |

| Tensile Strength | ≥ 7.5 MPa |

| Elongation at Break | ≥ 200% |

| Compression Set (22 hrs @ 70°C) | ≤ 20% |

| Flame Spread Index (ASTM E84) | Class B |

| Safety Compliance | EN 71-3, ASTM F963, REACH, RoHS |

To discuss your project requirements, request samples, or initiate a bulk procurement agreement, contact Mr. Boyce, our dedicated OEM and Technical Sales Manager. With over 15 years of experience in industrial rubber product distribution, Mr. Boyce provides expert guidance on material selection, order scaling, and logistics coordination for global clients.

Reach out via email at [email protected] to receive a detailed product dossier, pricing schedule, and lead time estimates. We support MOQs starting at 500 m² with container-load shipments via FOB Shanghai. Partner with Suzhou Baoshida to deliver safe, high-quality rubber flooring solutions backed by technical rigor and industrial reliability.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).