Technical Contents

Engineering Guide: Clear Molds

Engineering Insight: The Critical Role of Material Selection in Clear Mold Applications

In the production of custom molded rubber parts, clear molds present unique engineering challenges that demand precision in both design and material selection. Unlike opaque rubber components, where minor inconsistencies may remain visually undetected, clarity amplifies every flaw—be it from improper compounding, contamination, or suboptimal curing. This makes material selection not merely a functional consideration but a fundamental determinant of optical and mechanical performance.

Off-the-shelf rubber compounds, while cost-effective for general applications, frequently fail in clear mold environments due to inherent inconsistencies in polymer purity, filler content, and processing additives. Standard formulations often include pigments, carbon black, or high levels of reinforcing fillers that scatter light and compromise transparency. Even trace impurities or inconsistent dispersion during mixing can result in haze, cloudiness, or refractive defects that render the final part unsuitable for optical or aesthetic-critical applications.

At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered material solutions tailored to the optical and environmental demands of clear molded components. The foundation of a successful clear rubber part lies in selecting base polymers with naturally high clarity and low light scattering properties. Silicone rubber (VMQ) and transparent fluoroelastomers (FKM) are among the most effective choices due to their inherent UV stability, thermal resistance, and optical purity when properly compounded.

However, achieving clarity is not solely dependent on the base polymer. Additives such as plasticizers, stabilizers, and curing agents must also be selected with compatibility and solubility in mind. Poorly matched additives can phase-separate or crystallize during vulcanization, leading to microstructural defects. Furthermore, curing kinetics must be tightly controlled—under-cure leads to tackiness and haze, while over-cure can induce yellowing or surface cracking, especially in high-temperature environments.

Processing conditions are equally critical. Clear molds require pristine tooling surfaces, precise temperature control, and contamination-free environments. Even minor silicone buildup from previous runs or airborne particulates can become permanently embedded, affecting both appearance and performance.

The following table outlines key material properties for common transparent elastomers used in precision clear molding:

| Material | Hardness Range (Shore A) | Tensile Strength (MPa) | Elongation at Break (%) | Transmittance (% at 1mm thickness) | Temperature Range (°C) |

|---|---|---|---|---|---|

| Transparent Silicone (VMQ) | 30–80 | 6–9 | 400–700 | 90–92 | -60 to +200 |

| Clear Fluorosilicone (FVMQ) | 50–75 | 5–7 | 300–500 | 85–88 | -55 to +175 |

| Transparent FKM | 60–85 | 8–12 | 150–250 | 80–85 | -20 to +200 |

| Optical-Grade EPDM | 40–70 | 4–6 | 300–600 | 70–75 | -50 to +150 |

Ultimately, success in clear mold manufacturing hinges on a holistic approach—integrating material science, precision tooling, and controlled processing. Off-the-shelf compounds lack the tailored formulation required to meet these exacting standards. By prioritizing engineered materials and process integrity, Suzhou Baoshida ensures optical clarity without sacrificing mechanical reliability in every custom rubber component we support.

Material Specifications

Material Specifications for Precision Clear Molded Rubber Components

Selecting optimal elastomers for clear molded rubber parts demands rigorous attention to optical clarity, chemical compatibility, and thermal stability. At Suzhou Baoshida Trading Co., Ltd., we prioritize molecular homogeneity and ultra-low particulate content to achieve >90% light transmittance while meeting stringent OEM performance criteria. Standard rubber compounds contain opacifying fillers like carbon black; however, our clear formulations utilize high-purity precipitated silica or specialty transparent fillers to maintain visual integrity without compromising mechanical resilience. Critical variables include refractive index consistency (±0.005 tolerance), absence of gels or scorch particles, and precise control of cure systems to prevent yellowing. Each material must undergo accelerated aging per ASTM D573 and haze measurement via ASTM D1003 to validate long-term clarity retention under operational stressors.

The following table details key specifications for Viton®, Nitrile (NBR), and Silicone—three premier elastomers for optical applications. All values reflect Baoshida’s optimized clear-grade formulations processed under ISO 9001-controlled conditions.

| Property | Viton® (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -30 to +125 | -60 to +200 |

| Tensile Strength (MPa) | 12–18 | 15–22 | 6–10 |

| Elongation at Break (%) | 150–250 | 200–400 | 400–700 |

| Specific Gravity | 1.85–1.95 | 1.05–1.15 | 1.10–1.20 |

| Refractive Index (589 nm) | 1.39–1.41 | 1.48–1.50 | 1.40–1.42 |

| Transmittance (3mm thickness) | >85% | >90% | >92% |

| Key Chemical Resistances | Fuels, acids, ozone | Oils, hydraulic fluids | Steam, alcohols |

| Primary Limitations | Cost, low-temp flexibility | Poor ozone/weathering | Low tear strength |

Viton® excels in aerospace and semiconductor tooling where resistance to aggressive chemicals and extreme temperatures is non-negotiable, though its higher refractive index may necessitate anti-reflective coatings for precision optics. Nitrile offers the best cost-to-performance ratio for automotive fuel system seals requiring clarity for leak detection, but UV exposure mandates protective additives. Silicone dominates medical and food-grade applications due to biocompatibility and exceptional flexibility, though achieving optical clarity requires platinum-cure systems to eliminate peroxide byproducts that cause cloudiness.

Suzhou Baoshida’s OEM management protocol mandates strict batch traceability for raw materials, with silica particle size distribution controlled to D50 <15µm to prevent light scattering. Our molding process employs nitrogen-purged cavities and multi-stage temperature profiling to eliminate flow lines and internal stresses. Crucially, secondary operations such as flash removal utilize cryogenic tumbling—not manual trimming—to preserve surface finish critical for optical paths. For mission-critical components, we implement in-process refractive index verification via Abbe refractometry, ensuring every part meets the client’s spectral transmission requirements. This integrated approach guarantees that clarity is not merely aesthetic but a functional performance metric aligned with your engineering specifications.

Manufacturing Capabilities

Engineering Excellence in Custom Rubber Molding

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our custom rubber molding services. With a dedicated team of five experienced mold engineers and two specialized rubber formula engineers, we deliver precision-driven solutions tailored to the exacting demands of industrial OEM clients. Our integrated approach ensures that every stage—from concept and formulation to mold design and production—meets the highest standards of performance, durability, and repeatability.

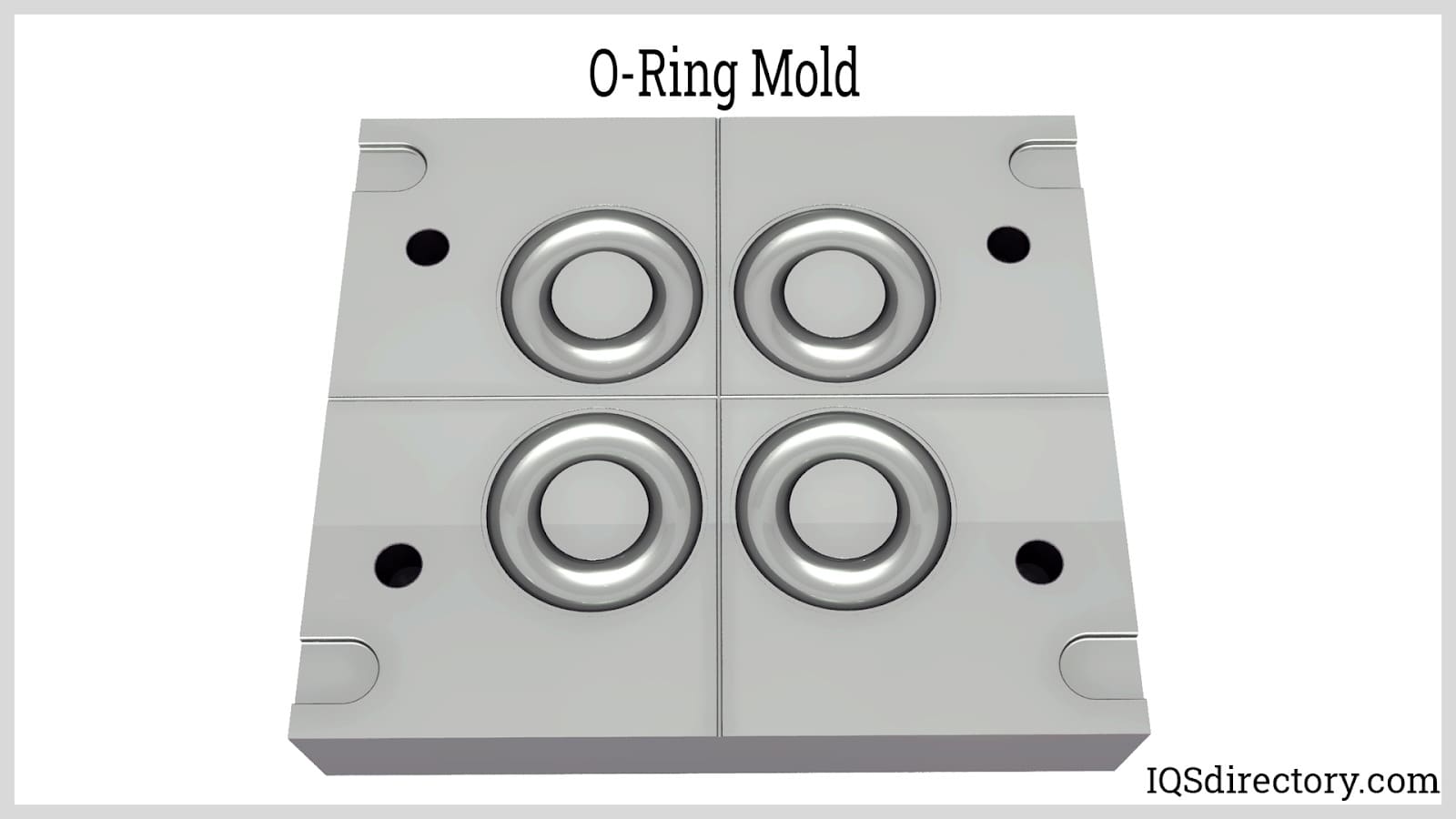

Our mold engineers bring over a decade of combined experience in designing high-precision molds for complex rubber components. They utilize advanced CAD/CAM software including SolidWorks, AutoCAD, and UG NX to simulate mold flow, optimize gating systems, and validate part geometry prior to manufacturing. This digital-first approach minimizes trial iterations, reduces lead times, and ensures dimensional accuracy within ±0.05 mm tolerance. We specialize in multi-cavity, family, and insert molds, supporting both compression and transfer molding processes across a range of elastomers.

Complementing our mold design expertise, our two in-house rubber formula engineers focus on material science and compound customization. They develop proprietary formulations for NBR, EPDM, silicone, FKM, and other specialty rubbers, adjusting hardness (30–90 Shore A), compression set, tensile strength, and fluid resistance to meet application-specific requirements. This vertical integration allows us to solve complex sealing, damping, or insulation challenges where off-the-shelf materials fall short.

Our OEM capabilities are built on a foundation of technical collaboration and process control. We work directly with client engineering teams to review design for manufacturability (DFM), conduct failure mode analysis (FMEA), and validate prototypes under real-world conditions. All molds are manufactured using hardened tool steels (e.g., H13, P20) with surface finishes ranging from SPI-SPE to mirror polish, ensuring longevity and consistent part quality across production runs from 1,000 to over 500,000 units annually.

We maintain full traceability through documented material certifications (e.g., RoHS, REACH, FDA), process validation reports, and first-article inspection (FAI) records. Our facility is equipped with precision metrology tools including CMM, optical comparators, and durometers to verify compliance with ISO 3302 and ISO 2768 standards.

This synergy between mold engineering and rubber formulation enables Suzhou Baoshida to deliver technically superior, cost-effective solutions for automotive, medical, industrial equipment, and consumer electronics OEMs.

Technical Specifications Overview

| Parameter | Capability Range |

|---|---|

| Mold Tolerance | ±0.05 mm |

| Rubber Hardness Range | 30–90 Shore A |

| Mold Materials | H13, P20, 420 Stainless, S136 |

| Surface Finish | SPI-SPE, SPI-SPC, Mirror Polish, Textured |

| Production Volume | 1,000 – 500,000+ units/year |

| Molding Processes | Compression, Transfer |

| Rubber Materials | NBR, EPDM, FKM, Silicone, CR, NR, IIR, ACM |

| Design Software | SolidWorks, AutoCAD, UG NX, Moldflow (simulation) |

| Quality Standards | ISO 3302, ISO 2768, RoHS, REACH, FDA (selected) |

Customization Process

Customization Process for Precision Clear Rubber Molds

Suzhou Baoshida Trading Co., Ltd. implements a rigorous, science-driven customization pathway for manufacturing optically clear rubber components. This process ensures dimensional accuracy, material integrity, and consistent optical performance demanded by medical, optical, and high-visibility industrial applications. Our methodology transitions seamlessly from client specifications to certified mass production.

The process commences with exhaustive Drawing Analysis. Our engineering team scrutinizes client CAD files and technical drawings, focusing specifically on optical surface geometry, critical dimensional tolerances (typically ±0.05mm for clear parts), draft angles, and gating requirements essential for bubble-free molding. We identify potential flow lines, knit lines, or ejection marks that could compromise transparency. Any dimensional deviations exceeding optical performance thresholds trigger immediate collaborative redesign consultation with the client. Material compatibility with the intended operating environment (e.g., UV exposure, chemical resistance) is cross-referenced at this stage.

Subsequent Formulation leverages our proprietary rubber chemistry expertise. Standard rubber compounds are unsuitable for clarity due to inherent impurities and light-scattering fillers. We exclusively develop ultra-pure, platinum-cured silicone or specialty transparent EPDM formulations. Key parameters include stringent control of monomer purity, elimination of conventional carbon black or silica fillers (replaced with nano-dispersed, index-matched alternatives), and precise catalyst ratios to prevent yellowing. Each formulation undergoes spectrophotometric validation to confirm baseline optical properties before prototyping. The table below outlines critical specification parameters for our standard clear rubber compounds.

| Parameter | Target Value (Platinum Silicone) | Target Value (Transparent EPDM) | Measurement Standard |

|---|---|---|---|

| Refractive Index | 1.405 – 1.412 | 1.510 – 1.520 | ASTM D542 |

| Light Transmission | ≥ 92% (at 2mm thickness, 550nm) | ≥ 85% (at 2mm thickness, 550nm) | ASTM D1003 (Haze < 3%) |

| Curing System | Platinum Catalyzed Addition Cure | Peroxide Cure (Special Grade) | Internal Process Control |

Prototyping utilizes dedicated, cleanroom-class molding cells to eliminate particulate contamination. Multi-cavity prototype tools validate flow dynamics, gate vestige impact on clarity, and ejection performance under production-equivalent conditions. Each prototype undergoes rigorous optical inspection via automated vision systems measuring haze, distortion, and birefringence, alongside dimensional CMM verification. Secondary operations like plasma surface treatment for adhesion are qualified during this phase. Client approval requires documented conformance to all optical and mechanical specs.

Upon prototype sign-off, Mass Production initiates under Suzhou Baoshida’s certified ISO 9001:2015 quality management system. Production runs employ real-time process monitoring with closed-loop control of temperature, pressure, and cure time to maintain optical consistency. Every batch undergoes 100% visual inspection under controlled lighting and statistical sampling for spectrophotometric validation. Full material traceability from raw polymer lot to finished part is maintained, ensuring compliance with stringent industry regulations. This integrated approach guarantees that every clear rubber component shipped meets the exact optical and functional requirements specified at project inception.

Contact Engineering Team

Contact Suzhou Baoshida for Precision Clear Mold Solutions

At Suzhou Baoshida Trading Co., Ltd., we specialize in the development and production of custom molded rubber parts, with a particular focus on high-precision clear molds for demanding industrial applications. Our engineering team combines advanced material science with state-of-the-art molding techniques to deliver transparent elastomeric components that meet exact optical, mechanical, and environmental specifications. Whether you require silicone, fluorosilicone, or other specialty polymers, our clear mold solutions are designed for performance in sectors such as medical devices, optical sensors, consumer electronics, and aerospace systems.

Our clear molds are manufactured using optimized curing processes, ultra-clean tooling, and degassed raw materials to ensure optical clarity, minimal internal stress, and consistent repeatability. Every part undergoes rigorous quality control, including visual inspection under controlled lighting, dimensional verification via CMM, and material property validation per ASTM and ISO standards. We understand that clarity is not just aesthetic—it is functional. That’s why we prioritize bubble-free molding, surface finish control, and refractive index stability in every production run.

For engineers and procurement managers seeking a reliable OEM partner, Suzhou Baoshida offers end-to-end support—from initial concept and material selection to prototyping, validation, and high-volume manufacturing. Our facility in Suzhou is equipped with cleanroom molding stations, automated inspection systems, and in-house tooling design, enabling rapid turnaround and full traceability.

To ensure your project meets both technical and commercial objectives, we recommend direct consultation with our lead engineer and OEM manager, Mr. Boyce. With over 15 years of experience in rubber formulation and precision molding, Mr. Boyce leads technical evaluations, supports DFMEA reviews, and oversees customer-specific qualification protocols. He is your dedicated point of contact for material data sheets, mold flow analysis, and regulatory compliance documentation.

We invite you to contact Mr. Boyce directly at [email protected] to discuss your clear mold requirements. Please include details such as desired material type, volume expectations, performance environment (e.g., temperature range, UV exposure, chemical resistance), and any applicable drawings or samples. Our team responds to all inquiries within 12 business hours and can provide preliminary feasibility assessments within 48 hours.

Below are typical specifications we support for clear molded rubber components:

| Parameter | Typical Range / Capability |

|---|---|

| Material Types | High-clarity silicone, fluorosilicone, EPDM |

| Hardness (Shore A) | 30–80 |

| Optical Clarity (Haze %) | <5% (per ASTM D1003) |

| Tolerance (Standard) | ±0.05 mm (tighter upon request) |

| Dimensional Range | 5 mm to 300 mm (linear) |

| Production Volume | Prototypes to 500,000 pcs/month |

| Secondary Operations | UV coating, plasma treatment, laser marking |

| Certifications | ISO 9001:2015, RoHS, REACH |

Partner with Suzhou Baoshida for technically robust, optically precise clear molded rubber parts. Initiate your project today by reaching out to Mr. Boyce.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).