Technical Contents

Engineering Guide: Clear Pvc

Engineering Insight: Material Selection in Clear PVC Applications

In industrial environments where clarity, chemical resistance, and dimensional stability are paramount, clear PVC (polyvinyl chloride) remains a material of choice across sectors including medical device manufacturing, food processing, and semiconductor handling. However, despite its widespread availability, off-the-shelf clear PVC formulations frequently underperform in demanding applications. This discrepancy stems from a fundamental oversight: treating clear PVC as a commodity rather than an engineered solution.

Commercial-grade clear PVC is typically formulated for cost efficiency and general-purpose use. These materials often sacrifice performance in thermal stability, UV resistance, and long-term mechanical integrity. In dynamic systems—such as vacuum transfer lines, sight glasses, or sterile fluid conduits—such compromises manifest as premature cracking, clouding, or plasticizer migration. These failures not only disrupt operations but can compromise product purity and safety, especially in regulated industries.

At Suzhou Baoshida Trading Co., Ltd., we emphasize that successful implementation begins with precise material tailoring. The base resin grade, plasticizer type, stabilizer package, and processing conditions must align with the operational profile of the end application. For instance, in high-temperature environments exceeding 60°C, standard phthalate-based plasticizers in off-the-shelf PVC begin to volatilize, leading to embrittlement. Substituting with polymeric or adipate plasticizers enhances thermal endurance and reduces extractables—critical for pharmaceutical or food-contact compliance.

Likewise, optical clarity is not merely a surface property but a function of homogeneity at the molecular level. Resin impurities or inadequate dispersion during compounding introduce haze and refractive inconsistencies, impairing visual monitoring in transparent tubing or enclosures. Our engineered clear PVC formulations utilize ultra-pure suspension-grade resins and optimized processing aids to ensure consistent light transmission and minimal distortion.

Mechanical performance must also be application-specific. Standard clear PVC exhibits moderate tensile strength and elongation, but under continuous flexing or cyclic pressure, it is prone to stress whitening and fatigue. By modifying the formulation with impact modifiers and reinforcing fillers at controlled loadings, we achieve a balance of transparency and durability suitable for dynamic sealing or repeated sterilization cycles.

The following table outlines key performance parameters of standard versus engineered clear PVC formulations:

| Property | Standard Clear PVC | Engineered Clear PVC (Baoshida) |

|---|---|---|

| Tensile Strength (MPa) | 40–45 | 48–52 |

| Elongation at Break (%) | 200–250 | 280–320 |

| Heat Deflection Temp (°C) | 55–60 | 70–75 |

| Light Transmission (%) | 85–88 | 90–92 |

| Plasticizer Migration (24h) | High (phthalate-based) | Low (polymeric/adipate) |

| UV Resistance | Poor | Enhanced with stabilizers |

| Sterilization Compatibility | Limited (autoclave) | Validated for 100+ cycles |

Material selection is not a passive step in design—it is a proactive engineering decision. Off-the-shelf clear PVC may meet initial cost targets, but its limitations become liabilities over time. At Baoshida, we deliver formulations where clarity does not compromise performance, ensuring reliability in the most rigorous industrial settings.

Material Specifications

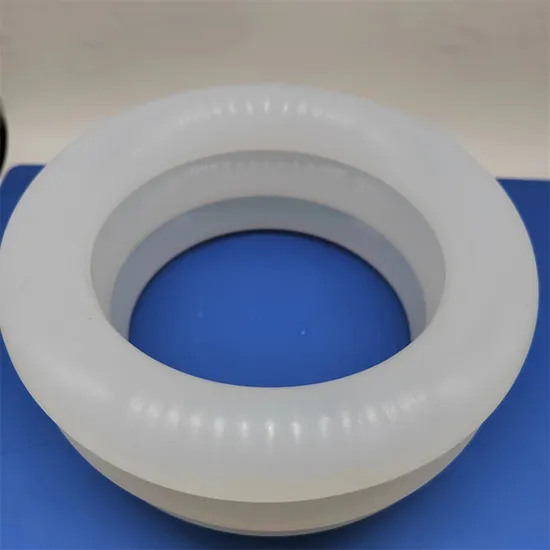

Material Specifications: Critical Elastomer Selection for Industrial Applications

Suzhou Baoshida Trading Co., Ltd. emphasizes precision in elastomer selection for industrial sealing and fluid-handling systems. While clear PVC (polyvinyl chloride) is occasionally requested for transparent tubing, it is a thermoplastic—not a rubber compound—and lacks the resilience, temperature tolerance, and chemical resistance required for demanding OEM applications. For true rubber solutions, Viton®, Nitrile (NBR), and Silicone remain the industry benchmarks. Each material exhibits distinct performance profiles governed by molecular structure, curing systems, and additive packages. Misapplication risks premature failure, contamination, or safety hazards. Below we detail technical specifications to guide optimal material selection per ASTM D2000 and ISO 37 standards.

Viton® (FKM) fluorocarbon rubber delivers unparalleled resistance to extreme temperatures, aggressive chemicals, and hydrocarbons. Its saturated backbone structure prevents degradation in fuels, acids, and hydraulic fluids where other elastomers fail. Nitrile (NBR) offers cost-effective resilience against oils, greases, and aliphatic hydrocarbons but suffers in ozone, ketones, and high-temperature environments. Silicone (VMQ) provides exceptional flexibility across -60°C to 230°C and biocompatibility for medical/food-grade use yet exhibits poor tensile strength and fuel resistance. Hardness ranges (Shore A 40–90) and compression set values must align with dynamic sealing pressures and service duration. Suzhou Baoshida formulates all compounds with traceable raw materials and rigorous QC testing to ensure dimensional stability and longevity.

Elastomer Performance Comparison

| Material | Temperature Range (°C) | Key Chemical Resistances | Key Limitations | Typical Hardness (Shore A) | Compression Set (22 hrs, 150°C) |

|---|---|---|---|---|---|

| Viton® (FKM) | -20 to 230 | Fuels, oils, acids, hydraulic fluids | Poor ketone/steam resistance | 60–90 | ≤25% |

| Nitrile (NBR) | -30 to 120 | Aliphatic hydrocarbons, water, glycols | Weak ozone/weathering resistance | 40–90 | ≤35% |

| Silicone (VMQ) | -60 to 230 | Ozone, UV, water, steam, food compounds | Low tensile strength, poor fuel resistance | 30–80 | ≤20% |

Suzhou Baoshida’s OEM engineering team mandates fluid immersion testing per ASTM D471 for all custom formulations. For instance, NBR seals in biodiesel systems require elevated acrylonitrile content (≥45%) to mitigate swelling, while Viton® grades for aerospace fuel systems incorporate peroxide curing for superior hot-air aging. Silicone compounds destined for semiconductor manufacturing undergo ultra-pure filtration to eliminate ionic contaminants. We reject generic material substitutions—each application demands compound-specific validation against OEM fluid compatibility matrices and dynamic stress profiles. Partner with our technical team to specify durometer, tensile strength, and elongation properties that align with your operational lifecycle requirements. Precision in rubber formulation is non-negotiable for industrial reliability.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Development for Clear PVC Solutions

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the specialized domain of clear PVC formulation and product development. With a dedicated team comprising five mould engineers and two formula engineers, we maintain rigorous control over both the material science and physical design aspects of manufacturing. This integrated approach ensures that every clear PVC component we produce meets exacting standards for clarity, durability, chemical resistance, and dimensional accuracy.

Our formula engineers possess deep expertise in polymer chemistry, with a focused understanding of plasticizer selection, stabilizer systems, and transparency optimization in PVC compounds. Clear PVC presents unique challenges—such as susceptibility to yellowing, plasticizer migration, and thermal degradation—requiring precise balance in formulation. We develop custom recipes tailored to application-specific requirements, whether for medical tubing, transparent industrial hoses, or aesthetic consumer components. Each formulation undergoes accelerated aging, UV exposure, and mechanical testing to validate long-term performance under real-world conditions.

Complementing our material development is a team of five experienced mould engineers who specialize in precision tooling for clear PVC injection and extrusion processes. Optical clarity demands flawless surface replication, making mould finish, venting, and flow dynamics critical. Our engineers utilize advanced CAD/CAM software and mold-flow simulation tools to optimize gate placement, cooling channels, and ejection systems—minimizing defects such as flow lines, bubbles, or sink marks. We design and validate moulds in-house, enabling rapid prototyping and faster time-to-market for OEM partners.

Suzhou Baoshida Trading Co., Ltd. operates as a full-service OEM manufacturer, offering end-to-end development from concept to mass production. Our clients benefit from a seamless workflow where material formulation and mould design are developed in parallel, reducing iteration cycles and ensuring compatibility between compound behavior and tooling performance. This synergy is particularly vital in clear PVC applications, where processing sensitivity can significantly impact final product quality.

We support low-volume prototyping and high-volume production runs, with strict adherence to ISO standards and traceability protocols. Our facility maintains controlled environments for material drying, processing, and inspection, ensuring batch-to-batch consistency essential for optical and functional performance.

The following table outlines key technical parameters we optimize in clear PVC development:

| Parameter | Standard Range | Testing Method | Application Impact |

|---|---|---|---|

| Hardness (Shore A) | 50–95 | ASTM D2240 | Flexibility vs. structural integrity |

| Tensile Strength | 12–25 MPa | ASTM D412 | Mechanical durability |

| Elongation at Break | 200–400% | ASTM D412 | Resistance to cracking |

| Light Transmission | ≥85% (at 1mm) | ASTM D1003 | Optical clarity |

| Heat Aging (70°C, 7 days) | Max 20% change in properties | ASTM D573 | Long-term stability |

| Plasticizer Migration | <5% weight loss | Custom gravimetric test | Compatibility with adjacent materials |

Our engineering framework enables Suzhou Baoshida to deliver technically robust, visually flawless clear PVC products tailored to the demanding needs of industrial, medical, and consumer OEMs.

Customization Process

Clear PVC Customization Process: Precision Engineering for Industrial Applications

At Suzhou Baoshida Trading Co., Ltd., our clear PVC customization process integrates rigorous scientific methodology with industrial-scale precision. This ensures optimal performance for demanding applications in medical devices, food packaging, and automotive components. The workflow begins with comprehensive drawing analysis, where our engineering team verifies dimensional tolerances, material callouts, and application environment factors including temperature exposure, chemical resistance requirements, and optical clarity thresholds. Critical deviations from ISO 2768-mK geometric tolerancing standards are flagged immediately, with cross-functional consultation to resolve ambiguities prior to formulation initiation.

Formulation development leverages our proprietary additive matrix system, calibrated to achieve specific transparency and mechanical targets. We prioritize non-phthalate plasticizers like DINCH or DOTP for biocompatibility, alongside UV stabilizers and optical brighteners to maintain >90% light transmission after 500 hours of accelerated aging. Each compound undergoes dynamic mechanical analysis (DMA) to confirm glass transition temperature alignment with client operating conditions, typically targeting -10°C to 60°C service ranges. Rheological profiling ensures extrusion or injection molding compatibility, with melt flow indices adjusted between 3–8 g/10min at 190°C/2.16kg.

Prototyping employs client-approved tooling under controlled ISO Class 8 cleanroom conditions. Initial samples undergo multi-axis optical distortion testing via collimated light projection systems, with haze measurements recorded per ASTM D1003. Mechanical validation includes tensile strength verification at 15–25 MPa and elongation at break of 250–350%, alongside critical compliance testing for FDA 21 CFR 177.2600 or EU 10/2011 food contact standards. Iterative refinement cycles address micro-voiding or surface defects, with formulation adjustments documented in our traceable LIMS database.

Mass production transitions occur only after formal client sign-off on 3 consecutive defect-free prototype batches. Automated batching systems maintain ±0.1% ingredient precision, while inline spectrophotometers monitor 400–700nm transmittance in real time. Each production lot receives full certification documentation, including CoA reports for heavy metals (Pb < 90ppm, Cd < 40ppm) and peroxide residues. Our statistical process control (SPC) protocols ensure dimensional stability within ±0.05mm tolerances across 50,000+ unit runs.

Key clear PVC performance specifications are maintained across all production tiers as follows

| Parameter | Standard Value | Test Method |

|---|---|---|

| Transparency | ≥90% (400-700nm) | ASTM D1003 |

| Shore A Hardness | 60–90 (adjustable) | ISO 868 |

| Tensile Strength | 15–25 MPa | ISO 37 |

| Elongation at Break | 250–350% | ISO 37 |

| Haze | ≤5% | ASTM D1003 |

This structured approach guarantees that every clear PVC component meets exacting industrial specifications while adhering to global regulatory frameworks. Suzhou Baoshida’s closed-loop engineering system minimizes time-to-market without compromising on the optical or mechanical integrity essential for mission-critical applications.

Contact Engineering Team

Contact Suzhou Baoshida for Premium Clear PVC Material Solutions

At Suzhou Baoshida Trading Co., Ltd., we specialize in delivering high-performance industrial rubber and polymer materials tailored to the exacting demands of modern manufacturing. As a trusted partner in the field of Industrial Rubber Solutions, we provide precision-engineered clear PVC compounds that meet stringent international quality standards. Whether your application requires transparency, chemical resistance, flexibility, or durability under dynamic conditions, our formulations are designed to perform reliably in diverse environments—from medical device housings to automotive trim, industrial tubing, and protective enclosures.

Our clear PVC materials are manufactured using advanced compounding techniques that ensure consistent clarity, excellent processability, and long-term stability. Each batch undergoes rigorous quality control testing to guarantee uniformity in color, hardness, tensile strength, and resistance to environmental stress cracking. We understand that performance consistency is critical in industrial supply chains, which is why we maintain full traceability and compliance documentation for every product we supply.

To support our global client base, we offer scalable production capacity, flexible packaging options, and logistics coordination to ensure timely delivery across North America, Europe, and Asia. Our technical team works closely with OEMs and contract manufacturers to optimize material selection, troubleshoot processing challenges, and support new product development initiatives.

For immediate assistance with sourcing high-quality clear PVC or to request custom formulation development, contact Mr. Boyce, OEM Manager at Suzhou Baoshida Trading Co., Ltd. With extensive experience in polymer science and industrial supply chain management, Mr. Boyce provides expert guidance on material specifications, regulatory compliance (including REACH and RoHS), and cost-effective sourcing strategies. He is your dedicated point of contact for technical inquiries, sample requests, and volume procurement planning.

Reach out via email at [email protected] to initiate a technical consultation or request a detailed quotation. We respond to all inquiries within 24 business hours and can provide material data sheets, sample kits, and processing guidelines upon request. Our goal is to become an extension of your engineering team—delivering not just materials, but integrated solutions that enhance product performance and manufacturing efficiency.

Below are key technical specifications for our standard clear PVC formulation:

| Property | Test Method | Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 90 ± 5 |

| Tensile Strength | ASTM D412 | ≥ 18 MPa |

| Elongation at Break | ASTM D412 | ≥ 300% |

| Specific Gravity | ASTM D792 | 1.38 – 1.42 |

| Transparency (% Transmission) | ASTM D1003 | ≥ 85% at 2mm |

| Operating Temperature Range | — | -10°C to +60°C |

| Flame Rating | UL94 | HB |

| Color | — | Crystal Clear (custom tints available) |

Partner with Suzhou Baoshida for reliable, scalable, and technically superior clear PVC materials engineered for industrial excellence. Contact Mr. Boyce today to advance your next project with confidence.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).