Technical Contents

Engineering Guide: Coated Clothes

Engineering Insight: The Critical Role of Material Selection in Coated Fabrics for Industrial Applications

In the domain of industrial rubber solutions, coated fabrics serve as critical components in high-performance systems ranging from conveyor belts and protective barriers to hydraulic seals and expansion joints. At Suzhou Baoshida Trading Co., Ltd., we emphasize that the success of these components hinges not on generic fabrication techniques, but on precise material selection tailored to operational demands. Off-the-shelf coated fabric solutions often fail because they are engineered for average conditions, not the specific thermal, chemical, mechanical, and environmental stresses encountered in real-world industrial environments.

The primary failure mode in standard coated fabrics stems from inadequate polymer-to-fabric adhesion under dynamic loading. Many commercial products utilize generic PVC or low-grade NBR coatings laminated onto polyester or nylon weaves without sufficient cross-linking or surface priming. When exposed to elevated temperatures, abrasive particulates, or aggressive media such as oils, solvents, or ozone, these coatings delaminate, crack, or degrade, leading to premature system failure. In contrast, engineered solutions employ high-tensile fabrics—such as aramid, high-modulus polyethylene, or fiberglass—paired with purpose-formulated elastomers like chloroprene (CR), nitrile butadiene rubber (NBR), ethylene propylene diene monomer (EPDM), or silicone (VMQ), selected based on compatibility matrices.

Another overlooked factor is fabric architecture. The weave density, thread count, and yarn twist directly influence elongation, tear resistance, and dimensional stability. A loosely woven substrate may offer flexibility but lacks the tensile strength required in high-stress sealing or conveying applications. Conversely, overly rigid weaves can lead to flex fatigue. The coating thickness must also be optimized: too thin, and it fails to protect the fabric; too thick, and it induces brittleness and reduces flexibility.

At Suzhou Baoshida, we conduct rigorous application profiling before recommending a coated fabric solution. This includes evaluating temperature range, chemical exposure, dynamic flexing frequency, pressure differentials, and UV/ozone resistance. Only through this systematic approach can we ensure long-term reliability.

The table below outlines key material combinations and their performance characteristics for industrial use.

| Coating Material | Base Fabric | Temperature Range (°C) | Chemical Resistance | Tensile Strength (MPa) | Key Applications |

|---|---|---|---|---|---|

| Chloroprene (CR) | Aramid | -30 to +130 | Oil, UV, Ozone | 45 | Seals, Hoses |

| NBR | Polyester | -20 to +100 | Oil, Fuel | 35 | Conveyors |

| EPDM | Fiberglass | -50 to +150 | Steam, Water, Alkalis | 40 | Expansion Joints |

| Silicone (VMQ) | Glass Cloth | -60 to +260 | Extreme Heat, UV | 25 | Insulation Covers |

Material selection is not a commodity decision—it is an engineering imperative. Generic coated fabrics may offer short-term cost savings, but they compromise system integrity, increase downtime, and elevate total cost of ownership. At Suzhou Baoshida, we deliver precision-engineered rubber solutions where performance, durability, and consistency are non-negotiable.

Material Specifications

Material Specifications for Industrial Coated Clothes

Industrial coated clothes refer to rubber-coated textile substrates engineered for demanding sealing, gasketing, and protective applications in automotive, aerospace, chemical processing, and oil/gas sectors. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision-formulated coatings using Viton (FKM), Nitrile (NBR), and Silicone (VMQ) elastomers. Each material delivers distinct performance characteristics critical to operational integrity under extreme thermal, chemical, and mechanical stress. Specifications must align with OEM design requirements to ensure longevity and safety compliance.

Viton coatings exhibit exceptional resistance to high temperatures, aggressive chemicals, and hydrocarbon derivatives. With a continuous service range of -20°C to 250°C, Viton maintains stability in jet fuels, hydraulic fluids, and aromatic solvents where other elastomers degrade. Its tensile strength typically exceeds 15 MPa, with elongation at break around 200%. Viton is the premium choice for aerospace seals and chemical reactor linings but carries higher material costs.

Nitrile coatings balance cost efficiency with robust oil and fuel resistance, operating effectively from -30°C to 120°C. This material delivers high tensile strength (12–20 MPa) and elongation (150–300%), making it ideal for dynamic applications like automotive fuel hoses and industrial hydraulic seals. NBR’s acrylonitrile content directly correlates with oil resistance; formulations with 34% ACN content are standard for general-purpose use. However, it exhibits limited ozone and weathering resistance.

Silicone coatings provide unparalleled flexibility across extreme low-temperature environments (-60°C to 230°C) and meet stringent FDA/USP Class VI standards for food and medical applications. While tensile strength is moderate (6–10 MPa), elongation can reach 600%, ensuring resilience in thermal cycling scenarios. Silicone resists oxidation and UV exposure but demonstrates poor abrasion resistance and susceptibility to tearing under high mechanical loads. It is optimal for pharmaceutical diaphragms and extreme-temperature insulation.

The comparative analysis below details critical parameters for informed material selection. All values represent typical cured compound ranges; exact performance depends on specific formulations and substrate integration.

| Material | Temperature Range (°C) | Chemical Resistance | Tensile Strength (MPa) | Elongation at Break (%) | Hardness Range (Shore A) | Primary Applications |

|---|---|---|---|---|---|---|

| Viton (FKM) | -20 to 250 | Excellent (acids, fuels, solvents) | 15–20 | 150–250 | 60–90 | Aerospace seals, chemical linings, semiconductor O-rings |

| Nitrile (NBR) | -30 to 120 | Excellent (oils, aliphatic hydrocarbons) | 12–20 | 150–300 | 50–90 | Automotive fuel systems, hydraulic gaskets, printing rollers |

| Silicone (VMQ) | -60 to 230 | Good (water, alcohols, mild acids); Poor (concentrated acids, hydrocarbons) | 6–10 | 300–600 | 30–80 | Medical devices, food processing seals, extreme-temp insulation |

*Note: Chemical resistance profiles vary by compound grade. Viton excels in aromatic environments but may swell in ketones. NBR degrades in ozone-rich settings without protective additives. Silicone requires reinforcement for high-pressure applications. All materials undergo rigorous OEM validation per ASTM D2000 and ISO 3601 standards at Suzhou Baoshida. Consult our engineering team to optimize formulations for your operational parameters, including substrate adhesion, compression set, and fluid compatibility testing. Precision coating thickness (0.2–3.0 mm) and curing protocols are tailored to ensure dimensional accuracy and performance consistency in final assembly.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of industrial rubber solutions, delivering high-performance coated fabrics tailored to exacting technical standards. Central to our engineering capability is a dedicated team of five specialized mould engineers and two advanced formula engineers, collectively ensuring precision in both material development and product formation. This integrated technical team enables us to offer comprehensive OEM services, supporting clients from concept through to mass production with full engineering oversight.

Our mould engineers possess extensive experience in designing and optimizing tooling systems for rubber-to-fabric bonding processes. They utilize advanced CAD/CAM software and finite element analysis (FEA) to simulate stress distribution, compression behavior, and thermal dynamics during curing. This ensures optimal mould geometry, minimizing flash, improving cycle times, and enhancing dimensional stability. Each mould is rigorously tested and fine-tuned to meet the specific mechanical and environmental demands of the target application, whether in automotive sealing, industrial conveyor systems, or protective apparel.

Complementing this capability are our two in-house rubber formulation engineers, who specialize in developing custom elastomeric compounds for coated textile applications. Utilizing a systematic approach to polymer selection, cross-linking systems, and additive integration, they engineer rubber formulations that deliver precise performance characteristics—such as abrasion resistance, oil resistance, low-temperature flexibility, and flame retardancy. These formulations are specifically tailored to bond effectively with fabric substrates, including polyester, nylon, and aramid fibers, ensuring long-term adhesion under dynamic mechanical stress and extreme operating conditions.

Our OEM capabilities are built on this dual foundation of formulation science and precision tooling. Clients benefit from a fully integrated development cycle where material and mould design are co-engineered, eliminating interface inefficiencies common in outsourced manufacturing. We support low-volume prototyping with rapid tooling and scalable production runs using automated hydraulic presses and temperature-controlled curing systems.

To ensure consistency and reliability, all formulations and processes undergo rigorous quality validation. Below is a summary of our core technical parameters and engineering tolerances:

| Parameter | Specification |

|---|---|

| Rubber Hardness Range (Shore A) | 40–90 ±5 |

| Mould Tolerance | ±0.1 mm (critical dimensions) |

| Bond Strength (Peel Test, N/mm) | ≥4.5 (per ASTM D413) |

| Temperature Range (Operating) | -40°C to +150°C (compound-dependent) |

| Curing Time Range | 5–20 minutes (adjustable by formulation) |

| Fabric Substrate Compatibility | Polyester, Nylon, Aramid, Cotton Blends |

| Custom Formulation Lead Time | 2–4 weeks (including testing) |

This synergy between material science and precision engineering positions Suzhou Baoshida as a trusted OEM partner in the industrial coated fabrics sector. We deliver not only manufactured goods, but engineered solutions—grounded in technical rigor and industrial reliability.

Customization Process

Customization Process for Industrial Rubber-Coated Textile Substrates

At Suzhou Baoshida Trading Co., Ltd., our customization process for industrial rubber-coated textiles strictly adheres to engineering rigor and OEM compliance standards. This methodology ensures seamless transition from client specifications to high-volume manufacturing while maintaining material integrity and performance consistency. The process comprises four critical phases, each governed by ISO 9001 protocols and ASTM D2000 material classification systems.

Drawing Analysis initiates the workflow. Our engineering team dissects technical schematics, substrate specifications, and environmental exposure requirements. We validate dimensional tolerances, adhesion interfaces, and chemical resistance demands against the textile base (e.g., polyester, nylon, or aramid). Critical parameters such as operating temperature range (-40°C to +150°C), fluid compatibility, and mechanical stress points are cross-referenced with our material database. Non-conformities trigger immediate client consultation to prevent downstream deviations.

Formulation Development follows, leveraging our proprietary rubber compounding expertise. Base polymers (NR, SBR, EPDM, or specialty fluorocarbons) are selected based on the analysis phase. Reinforcing fillers, vulcanizing agents, and protective additives are precisely dosed to achieve target properties. Accelerated aging tests and dynamic mechanical analysis (DMA) validate thermal stability and fatigue resistance. Every formulation undergoes third-party certification for REACH and RoHS compliance, with full material disclosure provided to the client.

Prototyping executes small-batch production under controlled factory conditions. We apply coating via precision calendering or dip-molding, monitoring thickness uniformity (±0.05 mm) and cure kinetics. Each prototype undergoes stringent validation:

Adhesion strength per ASTM D429 Method B

Abrasion resistance via DIN 53516

Fluid immersion testing per SAE J200

Client feedback integrates into final adjustments before sign-off.

Mass Production commences only after prototype approval. Our automated production lines maintain ±1.5% batch-to-batch consistency in critical properties. In-line spectrometry verifies compound homogeneity, while 100% visual inspection and random destructive testing ensure adherence to the agreed specifications. Traceable documentation, including lot-specific certificates of conformance, accompanies all shipments.

The table below summarizes key specification transitions from prototyping to mass production:

| Parameter | Prototype Value | Mass Production Tolerance |

|---|---|---|

| Thickness (mm) | 1.80 | 1.80 ± 0.05 |

| Shore A Hardness | 65 | 65 ± 3 |

| Adhesion Strength (kN/m) | 8.2 | ≥7.5 |

| Tensile Strength (MPa) | 18.5 | 18.5 ± 1.0 |

| Elongation at Break (%) | 320 | 320 ± 25 |

This phased approach eliminates guesswork, reduces time-to-market by 30%, and guarantees that every meter of coated textile meets the exacting demands of industrial applications—from conveyor systems to chemical containment barriers. Suzhou Baoshida’s commitment to precision engineering ensures your OEM partnership delivers zero-defect performance at scale.

Contact Engineering Team

For industrial manufacturers seeking precision-engineered rubber-coated textiles, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in the development and supply of high-performance coated fabrics. Our expertise lies in delivering tailored rubber formulations and coating solutions that meet the rigorous demands of automotive, aerospace, construction, and heavy industrial applications. As a leading provider in the Industrial Rubber Solutions sector, we combine material science innovation with strict quality control to ensure every meter of coated fabric exceeds operational expectations.

Our coated clothes are engineered using advanced compounding techniques, incorporating natural rubber, synthetic elastomers such as NBR, EPDM, and neoprene, and specialized additives to enhance abrasion resistance, thermal stability, and chemical inertness. Each product is manufactured under controlled industrial conditions, ensuring uniform coating thickness, optimal adhesion between fabric substrate and rubber layer, and long-term durability under dynamic stress. Whether you require flame-retardant properties, oil resistance, or low-temperature flexibility, our formulations are customized to your exact performance criteria.

Suzhou Baoshida operates at the intersection of technical precision and scalable manufacturing. We collaborate directly with OEMs and Tier-1 suppliers to develop solutions that align with your production timelines, regulatory standards, and cost structures. Our quality assurance protocols follow ISO-compliant testing procedures, including peel strength analysis, tensile evaluation, and environmental aging tests, guaranteeing consistency across batches and long-term reliability in the field.

To initiate a technical consultation or request a custom formulation proposal, contact Mr. Boyce, our dedicated OEM Manager and Rubber Formula Engineer. With over 15 years of experience in elastomer development and industrial coating systems, Mr. Boyce leads client-driven innovation and ensures seamless integration of our coated fabrics into your manufacturing workflow. He is available to discuss material specifications, performance testing data, and volume production capabilities.

Below are representative technical specifications for our standard rubber-coated fabric series. Custom parameters can be developed upon request.

| Property | Test Method | Value (Typical) |

|---|---|---|

| Coating Thickness | ASTM D3767 | 0.3 – 1.8 mm |

| Tensile Strength | ASTM D412 | 12 – 22 MPa |

| Elongation at Break | ASTM D412 | 250 – 450% |

| Adhesion Strength (Peel) | ASTM D413 | ≥ 80 N/cm |

| Temperature Range | — | -40°C to +120°C |

| Hardness (Shore A) | ASTM D2240 | 50 – 75 |

| Resistance to Oils | ASTM D471 | Excellent (NBR-based) |

| Flame Resistance | UL 94 | HB or V-0 (custom) |

For technical inquiries, quotation requests, or sample submissions, reach out to Mr. Boyce directly at [email protected]. Include your application requirements, performance targets, and volume expectations to receive a targeted solution proposal. Suzhou Baoshida Trading Co., Ltd. is committed to engineering excellence and responsive client support, ensuring your coated fabric needs are met with scientific rigor and industrial precision.

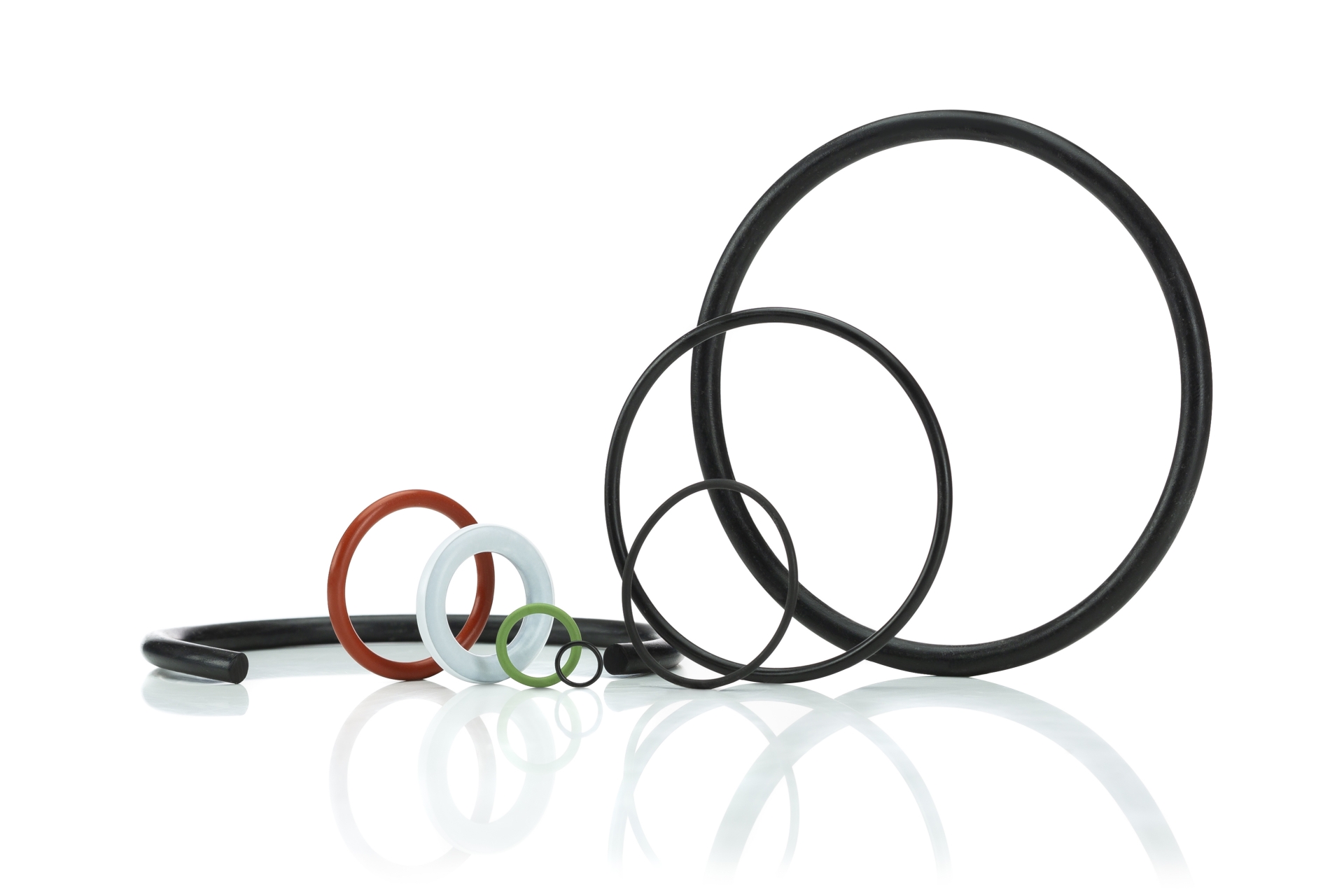

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).