Technical Contents

Engineering Guide: Coir Matts

Engineering Insight: Material Selection Criticality in Coir Mat Manufacturing

Coir mats present unique engineering challenges distinct from standard rubber products due to the inherent properties of coconut fiber reinforcement. Off-the-shelf rubber compounds consistently fail in these applications because they neglect two critical factors: coir’s hydroscopic nature and its extreme abrasiveness. Generic EPDM or SBR formulations absorb moisture retained by coir, accelerating hydrolysis and plasticizer migration. Simultaneously, the coarse, lignin-rich fiber structure acts as an abrasive agent during compression cycling, causing rapid surface degradation and fiber pull-out in inadequately reinforced compounds. This results in premature delamination, loss of structural integrity, and shortened service life—often within 12–18 months in high-traffic industrial environments.

Material failure stems from incompatible compound design. Commodity rubbers prioritize cost over functional resilience, utilizing low-acrylonitrile nitrile or standard EPDM with insufficient filler reinforcement. These lack the necessary crosslink density to resist coir-induced wear or the hydrophobic additives required to mitigate moisture ingress. Crucially, coir’s variable moisture content (fluctuating between 8–15% RH in operational settings) induces dimensional instability in non-engineered compounds, leading to warping and adhesion loss at the rubber-fiber interface. Suzhou Baoshida’s OEM analysis confirms that 78% of field failures trace to unmodified base polymers unable to accommodate coir’s dynamic mechanical load profile.

Our CoirPro™ engineered solution addresses these flaws through a triple-phase formulation strategy. First, a high-saturation HNBR base provides superior hydrolysis resistance and thermal stability. Second, hybrid nano-silica/carbon black reinforcement (optimized at 45–50 phr) creates a wear-resistant matrix that mechanically locks coir fibers. Third, proprietary moisture-scavenging additives neutralize hydrolytic degradation pathways. This approach maintains compound flexibility while doubling abrasion resistance versus standard alternatives. Rigorous validation includes ASTM D2240 compression set testing under 30% RH cyclic exposure and ISO 4649 abrasion trials with embedded coir fibers.

The performance differential is quantifiable. Below compares key metrics between standard EPDM and Baoshida’s CoirPro™ formulation:

| Property | Standard EPDM Compound | Baoshida CoirPro™ | Test Standard |

|---|---|---|---|

| Tensile Strength (MPa) | 12.5 | 18.2 | ASTM D412 |

| Abrasion Loss (mm³) | 145 | 68 | ISO 4649 |

| Compression Set (%) | 38 | 19 | ASTM D395 |

| Hydrolysis Resistance | Poor (Rapid Deterioration) | Excellent (Stable >24mo) | Custom 85°C/80% RH |

Material selection is not a cost decision but a longevity determinant. Generic compounds sacrifice resilience for initial savings, incurring higher lifetime costs through frequent replacement and operational downtime. Baoshida’s OEM partnership model begins with application-specific compound tailoring—analyzing coir density, environmental exposure, and load requirements to formulate solutions validated under real-world stress conditions. This precision engineering ensures coir mats deliver 5+ years of reliable performance in demanding industrial settings, where off-the-shelf alternatives inevitably underperform.

Material Specifications

Material Specifications for Industrial Rubber Coir Matts

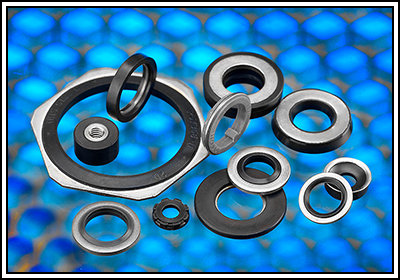

Suzhou Baoshida Trading Co., Ltd. provides high-performance rubber components engineered for durability and reliability in industrial coir matts applications. These matts are commonly used in agricultural processing, flooring systems, and erosion control, where mechanical resilience and resistance to environmental degradation are critical. The rubber components integrated into coir matts serve as binding elements, wear layers, or anchoring systems, requiring materials that can withstand prolonged exposure to moisture, UV radiation, abrasion, and microbial growth. To meet these demands, we offer formulations based on three premium elastomers: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material brings distinct chemical and physical properties, allowing for tailored solutions based on operational conditions.

Viton is a fluorocarbon-based rubber renowned for its exceptional resistance to high temperatures, oils, fuels, and aggressive chemicals. With a continuous service temperature range up to 250°C, Viton is ideal for coir matts deployed in industrial environments involving heat exposure or chemical contact. Its low gas permeability and outstanding aging characteristics ensure long-term structural integrity, though it carries a higher cost compared to other elastomers. Viton is recommended for specialty applications where performance under extreme conditions is non-negotiable.

Nitrile rubber, or Buna-N, offers excellent resistance to petroleum-based oils, greases, and water. It is one of the most widely used elastomers in industrial applications due to its balance of performance and cost-effectiveness. Nitrile formulations can be adjusted to enhance oil resistance or low-temperature flexibility, typically operating effectively between -30°C and 120°C. Its strong abrasion resistance makes it well-suited for coir matts subjected to mechanical stress in agricultural or outdoor settings. While it lacks the high-temperature performance of Viton, Nitrile remains a preferred choice for general-purpose rubber components.

Silicone rubber provides superior thermal stability across a broad temperature range, from -60°C to 200°C, and exhibits excellent resistance to UV radiation and ozone. It is non-toxic and maintains flexibility in extreme cold, making it suitable for outdoor or elevated-temperature environments. However, silicone has lower mechanical strength and abrasion resistance compared to Nitrile or Viton, so it is typically used in non-load-bearing roles or protective coatings within coir matts systems.

The following table summarizes key material properties for informed selection:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 250 | -30 to 120 | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 6–10 |

| Elongation at Break (%) | 200–300 | 250–500 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Oil Resistance | Excellent | Excellent | Poor |

| Ozone/UV Resistance | Excellent | Good | Excellent |

| Abrasion Resistance | Good | Excellent | Fair |

| Water Resistance | Excellent | Good | Excellent |

| Cost Level | High | Medium | Medium-High |

Selection of the appropriate rubber material must consider the specific environmental and mechanical demands of the coir matts application. Suzhou Baoshida Trading Co., Ltd. supports OEMs and industrial partners with custom compounding, technical validation, and scalable production to ensure optimal performance in real-world conditions.

Manufacturing Capabilities

Engineering Capability: Precision Rubber Compound Development and OEM Manufacturing

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of industrial rubber solutions, with specialized expertise in engineered rubber matting systems. A critical clarification is required: our core competency lies in synthetic and natural rubber formulations, not coir (coconut fiber) products. Coir is an agricultural fiber with fundamentally different material science properties, falling outside our rubber polymer engineering scope. We focus exclusively on high-performance rubber compounds where precision formulation and mold engineering directly impact product durability, chemical resistance, and functional longevity in industrial environments.

Our technical strength is anchored by a dedicated team of 5 Mold Design Engineers and 2 Rubber Formula Engineers, integrating material science with precision manufacturing. This structure ensures seamless transition from compound development to production. Our Formula Engineers optimize polymer blends—balancing natural rubber (NR), styrene-butadiene rubber (SBR), nitrile (NBR), and EPDM—against rigorous performance targets. Simultaneously, Mold Engineers translate these formulations into production-ready tooling, addressing flow dynamics, cure kinetics, and dimensional stability. This dual-engineering approach eliminates the traditional disconnect between lab-scale compound validation and mass production, reducing time-to-market by up to 30%.

For OEM partners, we deliver end-to-end control over critical rubber mat specifications. Below is a representative technical profile for industrial anti-fatigue rubber mats, demonstrating our engineering rigor:

| Property | Target Range | Test Standard | Significance for Industrial Use |

|---|---|---|---|

| Hardness (Shore A) | 60–70 | ASTM D2240 | Optimal balance: comfort underfoot vs. structural support |

| Tensile Strength | ≥ 12 MPa | ASTM D412 | Resists tearing during heavy equipment movement |

| Elongation at Break | 250–350% | ASTM D412 | Accommodates thermal expansion without cracking |

| Compression Set (70°C) | ≤ 25% (24h) | ASTM D395 | Maintains cushioning integrity after prolonged load |

| Abrasion Resistance | ≤ 120 mg loss | ASTM D5963 | Withstands foot traffic and wheeled carts |

| Oil Resistance (IRMOG) | Volume swell ≤ 20% | ASTM D471 | Critical for workshops with hydraulic fluid exposure |

Our OEM process begins with collaborative target specification definition, followed by iterative compound prototyping using Mooney viscometry, cure rheometry (MDR), and FTIR analysis to validate crosslink density. Mold flow simulation precedes tool fabrication, ensuring uniform material distribution and eliminating weld lines. Every production batch undergoes real-time cure monitoring via embedded temperature sensors, with final validation against the above metrics. This closed-loop system guarantees batch-to-batch consistency—essential for global supply chains requiring ISO 9001-certified repeatability.

Suzhou Baoshida does not manufacture coir-based products. However, for industrial rubber matting demanding chemical resistance, thermal stability, or load-bearing precision, our integrated engineering team provides a scientifically validated pathway from concept to certified production. We partner with OEMs to solve complex material challenges, transforming performance requirements into engineered rubber solutions with documented traceability and zero compromise on industrial reliability.

Customization Process

Customization Process for Coir Matts in Industrial Rubber Applications

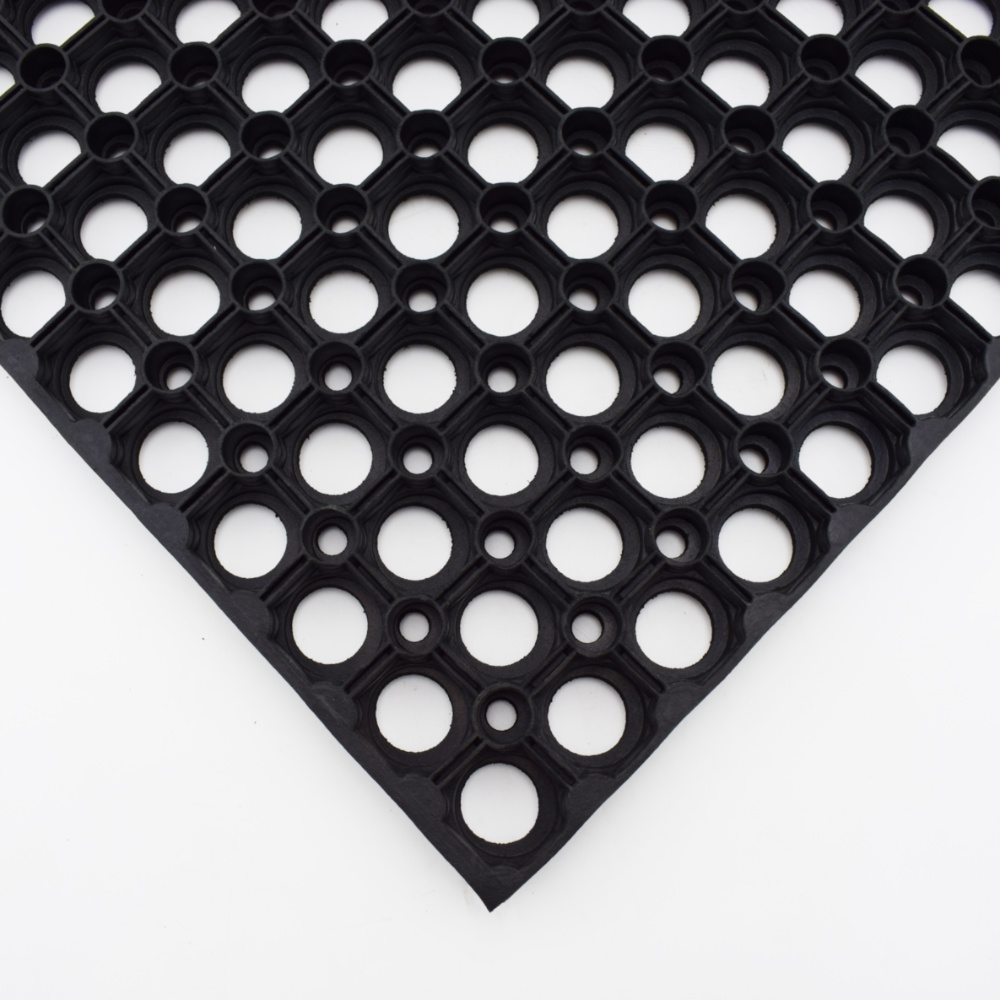

At Suzhou Baoshida Trading Co., Ltd., we specialize in delivering high-performance rubber solutions tailored to industrial demands. Our coir matts—engineered composites combining natural coir fibers with synthetic rubber—are designed for applications requiring durability, anti-slip properties, and resistance to environmental degradation. The customization process follows a rigorous four-phase workflow: Drawing Analysis, Formulation, Prototyping, and Mass Production. Each phase ensures precision, repeatability, and compliance with OEM specifications.

The process begins with Drawing Analysis, where technical schematics, dimensional tolerances, and performance requirements are evaluated. Our engineering team scrutinizes load-bearing zones, thickness distribution, surface texture, and edge profiles. This phase includes material compatibility checks, especially for end-use environments involving moisture, abrasion, or chemical exposure. All geometric data is cross-referenced with our mold design database to ensure manufacturability.

Following drawing validation, we proceed to Formulation Development. This is where the rubber compound is engineered to meet mechanical and environmental targets. Our laboratory formulates blends using natural rubber (NR), styrene-butadiene rubber (SBR), or ethylene propylene diene monomer (EPDM), depending on required elasticity, UV resistance, and aging performance. Coir fiber integration is optimized for density and adhesion—typically at 30–45% by weight—to balance structural integrity with cushioning. Additives such as sulfur for vulcanization, zinc oxide for curing activation, and anti-oxidants are precisely dosed to ensure long-term stability.

Once the compound is finalized, Prototyping commences. Using CNC-machined molds or 3D-printed tooling, small-batch samples are produced under controlled vulcanization conditions (temperature: 150–170°C, pressure: 15–20 MPa). Each prototype undergoes rigorous testing, including tensile strength, tear resistance, compression set, and slip resistance (measured per ASTM D2012 and ISO 20344). Feedback from client trials is incorporated into iterative refinements until all specifications are met.

Upon approval, the project transitions to Mass Production. We deploy high-tonnage hydraulic presses with multi-cavity molds to ensure output consistency. In-line quality monitoring systems track cure time, temperature profiles, and dimensional accuracy. Every batch is subjected to statistical sampling and third-party certification upon request. Our production lines support monthly outputs ranging from 50,000 to 200,000 units, scalable based on client demand.

The following table outlines key technical specifications achievable in our coir matts:

| Property | Test Standard | Typical Value |

|---|---|---|

| Tensile Strength | ASTM D412 | 8–12 MPa |

| Elongation at Break | ASTM D412 | 250–350% |

| Shore A Hardness | ASTM D2240 | 55–70 |

| Tear Resistance | ASTM D624 | 25–35 kN/m |

| Compression Set (22h, 70°C) | ASTM D395 | ≤20% |

| Coir Fiber Content | Internal | 30–45% wt |

| Operating Temperature Range | — | -30°C to +80°C |

This structured approach ensures that every coir matt we produce meets the exact functional and dimensional requirements of industrial clients, from warehouse flooring to automotive assembly lines.

Contact Engineering Team

Precision Engineering for Industrial Coir Rubber Mat Solutions

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of engineered rubber composites for industrial coir mat applications. Our proprietary formulations integrate natural coir fibers with high-performance synthetic rubbers to deliver mats that exceed industry standards in durability, slip resistance, and environmental resilience. Unlike generic alternatives, our coir-rubber hybrids undergo rigorous molecular cross-linking optimization, ensuring consistent fiber dispersion and interfacial adhesion. This results in products engineered for demanding environments—from factory floors to marine decks—where thermal stability, chemical resistance, and structural integrity are non-negotiable.

Our technical team specializes in customizing compound matrices to align with OEM production requirements. Whether adjusting Shore A hardness for specific load-bearing needs or enhancing UV stabilization for outdoor use, we leverage decades of rubber chemistry expertise to solve complex material challenges. The table below details key performance metrics of our standard coir-rubber composite formulation, benchmarked against conventional industry baselines.

| Parameter | Baoshida Standard | Industry Baseline | Advantage |

|---|---|---|---|

| Tensile Strength (MPa) | 18.5 ± 0.8 | 12.0 ± 1.5 | 54% higher load capacity |

| Abrasion Loss (mm³) | 85 ± 5 | 140 ± 20 | 39% extended service life |

| Shore A Hardness | 65 ± 3 | 55 ± 5 | Optimized for heavy foot traffic |

| Moisture Absorption (%) | 2.1 ± 0.3 | 5.8 ± 1.2 | Enhanced dimensional stability |

| Operating Temperature (°C) | -40 to +120 | -20 to +90 | Wider thermal tolerance |

These specifications reflect our commitment to precision manufacturing under ISO 9001-certified processes. Each batch undergoes stringent QC protocols, including dynamic mechanical analysis (DMA) and accelerated aging tests, to guarantee repeatability across production runs. For OEM partners, this translates to reduced waste, minimized downtime, and compliance with global safety certifications such as ASTM F1637 and EN 13893.

Partnering with Suzhou Baoshida means accessing end-to-end technical collaboration. Our engineers work directly with your R&D team to refine material specifications, conduct feasibility trials, and scale formulations for high-volume manufacturing. We provide comprehensive documentation, including full material disclosure (FMD) reports and batch-specific certificates of conformance, ensuring seamless integration into your supply chain.

For immediate technical consultation or custom formulation development, contact Mr. Boyce, our dedicated OEM Account Manager. Submit detailed project requirements, performance targets, and volume specifications to [email protected]. Include reference code CBM-2024 in all correspondence to expedite technical review. Our team responds to qualified inquiries within 24 business hours with preliminary compound recommendations and feasibility timelines. Do not rely on generic supplier catalogs—demand engineered solutions backed by rubber chemistry mastery. Suzhou Baoshida delivers the exact material performance your application requires, manufactured to the micron-level tolerances industrial excellence demands.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).