Technical Contents

Engineering Guide: Collar Pipe Fittings

Material Selection in Collar Pipe Fittings: Engineering for Industrial Longevity

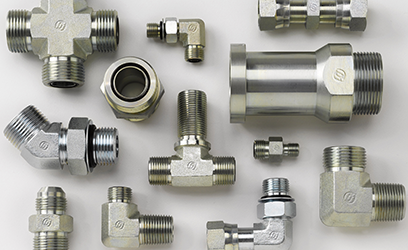

In industrial fluid transfer systems, collar pipe fittings serve as critical junctions that ensure leak-free connections, structural integrity, and resistance to dynamic operational stresses. While often perceived as standard components, the performance of these fittings is profoundly influenced by material selection—a factor frequently underestimated in procurement decisions. Off-the-shelf collar pipe fittings, typically manufactured from generic elastomers or low-grade polymers, are prone to premature failure under real-world conditions such as high pressure, temperature extremes, chemical exposure, and mechanical fatigue. This underscores the necessity of engineered material solutions tailored to specific application parameters.

The failure of generic fittings commonly manifests through swelling, cracking, compression set, or extrusion under pressure. These issues arise when the base elastomer lacks compatibility with the conveyed media. For example, nitrile rubber (NBR), while cost-effective and widely used, degrades rapidly in the presence of ozone, aromatic hydrocarbons, or high-temperature steam. Similarly, silicone-based fittings may offer wide temperature tolerance but exhibit poor resistance to petroleum-based fluids, leading to volumetric expansion and seal degradation.

At Suzhou Baoshida Trading Co., Ltd., we emphasize application-specific material engineering. Our collar pipe fittings utilize high-performance elastomers such as EPDM, FKM (Viton®), and HNBR, selected based on fluid compatibility, thermal range, and mechanical demand. EPDM demonstrates exceptional resistance to hot water, steam, and polar solvents, making it ideal for HVAC and sanitary process lines. FKM offers superior performance in aggressive chemical environments, including exposure to acids, fuels, and chlorinated hydrocarbons, with operational stability up to 200°C. HNBR bridges the gap between NBR and FKM, offering enhanced thermal resistance and tensile strength while maintaining good oil resistance—suitable for demanding automotive and industrial hydraulics.

Beyond chemical resistance, mechanical properties such as tensile strength, elongation at break, and compression set are critical in dynamic sealing applications. Poorly formulated materials exhibit permanent deformation under continuous load, leading to loss of sealing force and eventual leakage. Our formulations are optimized to maintain elastic recovery and dimensional stability over extended service cycles, ensuring long-term reliability.

The following table outlines key material properties for common elastomers used in industrial collar pipe fittings:

| Material | Temperature Range (°C) | Key Chemical Resistances | Key Limitations | Typical Applications |

|---|---|---|---|---|

| NBR | -30 to +100 | Aliphatic oils, water, hydraulic fluids | Poor ozone and aromatic solvent resistance | General-purpose hydraulics |

| EPDM | -50 to +150 | Steam, water, alkalis, ketones | Poor oil and fuel resistance | HVAC, water treatment |

| FKM (Viton®) | -20 to +200 | Acids, fuels, aromatic hydrocarbons | Poor resistance to ketones, brake fluids | Petrochemical, aerospace |

| HNBR | -40 to +170 | Oils, hot water, mild acids | Limited steam resistance | Automotive, industrial machinery |

Material selection is not a commodity decision—it is a precision engineering requirement. Standardized fittings fail because they assume uniform operating conditions, which rarely exist in industrial environments. At Baoshida, we partner with OEMs to analyze fluid composition, pressure cycles, and environmental exposure, enabling the deployment of collar pipe fittings engineered for reliability, safety, and extended service life.

Material Specifications

Material Specifications for Collar Pipe Fittings in Industrial Applications

Selecting the appropriate elastomer for collar pipe fittings is critical to ensuring long-term sealing integrity, chemical compatibility, and operational safety within demanding industrial fluid handling systems. At Suzhou Baoshida Trading Co., Ltd., our engineering expertise focuses on matching material properties precisely to the specific environmental stresses encountered in OEM applications. The three primary rubber compounds utilized for high-performance collar fittings are Viton (FKM), Nitrile (NBR), and Silicone (VMQ), each offering distinct advantages and limitations. Understanding these characteristics is fundamental for optimal component selection and system reliability.

Viton fluorocarbon rubber represents the premium solution for extreme chemical and thermal resistance. Engineered for harsh environments, Viton collar fittings consistently perform across a broad temperature spectrum from -20°C to +250°C. They exhibit exceptional resistance to a wide array of aggressive media including aromatic and chlorinated hydrocarbons, strong acids, jet fuels, and hydraulic fluids. This makes Viton the definitive choice for aerospace, chemical processing, and high-temperature automotive underhood applications where failure is not an option. While offering superior performance, Viton commands a higher material cost and demonstrates lower flexibility at very low temperatures compared to alternatives.

Nitrile butadiene rubber remains the most widely specified material for general industrial collar pipe fittings due to its excellent balance of performance and cost-effectiveness. NBR formulations provide robust resistance to petroleum-based oils, greases, aliphatic hydrocarbons, and water, operating effectively within a temperature range of -40°C to +120°C. Its good abrasion resistance and mechanical strength suit it well for hydraulic systems, fuel lines, and standard pneumatic applications. Limitations include poor resistance to ozone, weathering, and polar solvents like ketones or esters, necessitating protective measures or alternative materials in such environments. Nitrile offers the best value proposition for medium-temperature oil and fuel handling.

Silicone rubber excels in applications requiring extreme temperature flexibility and biocompatibility. Collar fittings molded from silicone maintain sealing integrity from -60°C to +230°C, demonstrating outstanding resistance to oxidation, ozone, and weathering. They are inherently resistant to water and steam and meet stringent FDA and USP Class VI requirements for food, beverage, and medical applications. However, silicone possesses lower tensile strength and abrasion resistance compared to Viton or Nitrile and exhibits poor resistance to concentrated acids, alkalis, and most hydrocarbon oils and fuels. Its primary use cases are in high-purity fluid transfer, extreme cold environments, and applications demanding wide thermal stability without chemical aggression.

The following table provides a concise technical comparison of these critical elastomer properties for informed collar fitting material selection.

| Material | Temperature Range (°C) | Key Resistances | Key Limitations | Primary Applications |

|---|---|---|---|---|

| Viton (FKM) | -20 to +250 | Aromatic hydrocarbons, acids, jet fuels, hydraulic fluids, steam | High cost, poor ketone resistance, limited low-temp flexibility | Aerospace, chemical processing, high-temp automotive |

| Nitrile (NBR) | -40 to +120 | Petroleum oils, greases, aliphatic hydrocarbons, water | Poor ozone/weathering, ketone/solvent sensitivity | General hydraulics, fuel systems, industrial pneumatics |

| Silicone (VMQ) | -60 to +230 | Ozone, weathering, steam, water, high/low temp stability | Low oil/fuel resistance, poor abrasion strength, moderate tensile | Food & beverage, medical, extreme temp seals, high-purity |

Suzhou Baoshida Trading Co., Ltd. leverages deep material science expertise to guide OEM partners in selecting the optimal elastomer formulation for collar pipe fittings. Our technical team evaluates specific fluid media, temperature profiles, pressure cycles, and regulatory requirements to ensure the chosen compound delivers maximum service life and system safety, avoiding costly field failures through precise material engineering.

Manufacturing Capabilities

Engineering Excellence in Industrial Rubber Solutions

At Suzhou Baoshida Trading Co., Ltd., our engineering capabilities form the backbone of our industrial rubber solutions, particularly in the design and production of high-performance collar pipe fittings. With a dedicated team of five certified mould engineers and two specialized rubber formula engineers, we maintain full in-house control over the entire product development lifecycle—from concept and material formulation to precision tooling and final validation. This integrated technical approach ensures superior product consistency, accelerated time-to-market, and unmatched customization for OEM partners.

Our mould engineers bring over 15 cumulative years of experience in precision rubber component manufacturing, specializing in complex geometries required for sealing integrity in demanding environments. Utilizing advanced CAD/CAM software and CNC machining, they design and refine moulds to meet exact dimensional tolerances, ensuring repeatable performance across high-volume production runs. Each collar pipe fitting is engineered to withstand mechanical stress, thermal cycling, and chemical exposure, making them ideal for automotive, HVAC, and industrial fluid systems.

Complementing our tooling expertise, our two rubber formula engineers focus on material science innovation tailored to application-specific requirements. They formulate custom elastomer compounds using NR, EPDM, NBR, and silicone, optimizing for properties such as compression set resistance, ozone stability, and low-temperature flexibility. These formulations are rigorously tested in-house for physical, dynamic, and environmental performance, ensuring compliance with ISO, ASTM, and OEM-specific standards. This dual expertise—mould design and material formulation—enables us to solve complex sealing challenges with scientifically validated solutions.

We operate as a full-service OEM partner, offering end-to-end development support. Clients provide performance specifications or application conditions, and our engineering team delivers functional prototypes within 15–20 days. We support both small-batch custom orders and large-scale serial production, backed by ISO 9001-certified quality systems. Our collaborative engineering process includes Design for Manufacturability (DFM) reviews, finite element analysis (FEA) for stress simulation, and iterative prototyping to ensure fit, form, and function.

The following table outlines key technical capabilities and performance parameters for our collar pipe fittings:

| Parameter | Specification |

|---|---|

| Material Types | NR, EPDM, NBR, Silicone, CR, ACM |

| Hardness Range (Shore A) | 40–90 ±5 |

| Temperature Range | -40°C to +150°C (up to +300°C for silicone) |

| Tensile Strength | 8–25 MPa (dependent on compound) |

| Elongation at Break | 200–600% |

| Compression Set (70h at 100°C) | ≤25% |

| Mould Tolerance (ISO 3302) | Class M3–M2 |

| Production Capacity | 500,000 pcs/month (standard sizes) |

| OEM Customization Lead Time | 15–20 days (prototype), 30–45 days (mass production) |

Through precise engineering, scientific material development, and scalable OEM manufacturing, Suzhou Baoshida delivers collar pipe fittings that meet the highest industrial standards. Our technical team stands ready to co-develop solutions that enhance performance, durability, and cost efficiency for global industrial clients.

Customization Process

Customization Process for Industrial Collar Pipe Fittings

Suzhou Baoshida Trading Co., Ltd. implements a rigorous, science-driven customization pathway for industrial collar pipe fittings, ensuring optimal performance under demanding operational conditions. This structured methodology mitigates risk and guarantees precise alignment with client specifications and environmental requirements. The process commences with comprehensive Drawing Analysis. Our engineering team meticulously reviews client-provided technical schematics, focusing on dimensional tolerances per ISO 3601, sealing surface geometries, groove specifications, and critical interface points. We verify all ASTM D2000 line callouts, fluid compatibility requirements, and pressure/temperature ratings. This phase identifies potential manufacturability conflicts or performance vulnerabilities early, enabling collaborative refinement before material commitment. Ambiguities are resolved through direct technical consultation, establishing a definitive baseline for subsequent stages.

Material Formulation follows, leveraging our core competency in advanced elastomer science. Based on the validated application parameters—exposure media (hydraulic fluids, fuels, chemicals), temperature extremes, dynamic stress cycles, and regulatory constraints—we select and engineer the optimal compound. This involves precise balancing of polymer base (e.g., NBR, EPDM, FKM), reinforcement fillers, curatives, and specialty additives to achieve target properties. Critical performance metrics are non-negotiable: compression set resistance per ASTM D395, tensile strength, elongation, and fluid immersion stability must meet or exceed project thresholds. The final formulation is documented with full traceability to raw material batch records.

Prototyping executes the engineered solution using production-intent tooling. We fabricate initial samples under controlled process parameters (temperature, pressure, cure time) mirroring mass production conditions. Rigorous first-article inspection validates dimensional conformity against the approved drawing using calibrated CMM equipment. Functional validation includes pressure testing per SAE J514 standards, leakage checks under thermal cycling, and dynamic fatigue assessment simulating real-world vibration. Accelerated aging per ASTM D573 confirms long-term stability. Client feedback on prototype performance is integrated for final validation prior to tool sign-off.

Mass Production initiates only after successful prototype approval. We deploy statistical process control (SPC) across all critical stages—mixing, molding, trimming, and inspection—to maintain ±0.05mm dimensional tolerances and consistent material properties. Each production batch undergoes stringent lot-release testing, including durometer verification (Shore A), visual inspection per ISO 3601-3, and抽样 fluid compatibility checks. Full documentation, including material certificates and test reports, accompanies every shipment, ensuring complete supply chain transparency and compliance with OEM quality management systems.

Key Material Performance Specifications for Collar Fittings

| Material Type | Temperature Range (°C) | Typical Shore A Hardness | Key Fluid Resistance | Compression Set (70h/100°C) % max |

|---|---|---|---|---|

| Nitrile (NBR) | -40 to +120 | 60-90 | Mineral oils, fuels | 25 |

| EPDM | -50 to +150 | 50-80 | Water, steam, brake fluid | 20 |

| Fluorocarbon (FKM) | -20 to +230 | 65-85 | Aggressive chemicals, synthetic oils | 15 |

Contact Engineering Team

Contact Suzhou Baoshida for Premium Collar Pipe Fittings and Industrial Rubber Solutions

At Suzhou Baoshida Trading Co., Ltd., we specialize in delivering high-performance industrial rubber solutions tailored to the rigorous demands of modern manufacturing, automotive, and fluid transfer systems. As a trusted OEM partner, we combine material science expertise with precision engineering to produce collar pipe fittings that ensure leak-free connections, long service life, and compatibility across diverse operating environments. Our focus on quality, consistency, and technical support makes us the preferred supplier for global industrial clients seeking reliable elastomeric components.

Collar pipe fittings play a critical role in maintaining system integrity under dynamic pressure, vibration, and temperature fluctuations. Our engineered rubber collars are designed to provide secure hose retention, reduce assembly time, and prevent disengagement in high-vibration applications. Whether you require standard configurations or custom-molded solutions, Suzhou Baoshida offers full technical collaboration—from material selection to dimensional validation—to meet your exact performance requirements.

We utilize advanced compounding techniques to formulate rubber compounds based on EPDM, NBR, silicone, and FKM, ensuring optimal resistance to oils, ozone, steam, and extreme temperatures. Each collar undergoes stringent quality control, including tensile strength testing, compression set analysis, and dimensional inspection, to guarantee compliance with international standards such as ISO 9001 and ASTM D2000.

For OEMs and industrial procurement teams, partnering with Suzhou Baoshida means access to scalable production capacity, rapid prototyping, and responsive supply chain management. Our technical team supports clients through every phase—from initial design consultation to batch traceability and after-sales service.

To discuss your collar pipe fitting requirements or request material certifications, performance data, or samples, contact Mr. Boyce directly. As the dedicated OEM Manager, Mr. Boyce provides personalized technical guidance and commercial support to ensure seamless integration of our rubber solutions into your manufacturing workflow.

| Specification | Details |

|---|---|

| Material Options | EPDM, NBR, Silicone, FKM, Neoprene |

| Hardness Range (Shore A) | 50–80 ±5 |

| Temperature Resistance | -40°C to +200°C (depending on compound) |

| Pressure Rating | Up to 3.0 MPa (custom configurations available) |

| Color Options | Black, red, blue, green, or custom |

| Standards Compliance | ISO 9001, ASTM D2000, ROHS |

| Production Lead Time | 15–30 days (based on order volume) |

| Packaging | Industrial cartons with moisture protection |

Reach out today to optimize your fluid system performance with engineered rubber collar fittings from Suzhou Baoshida. For technical inquiries, quotations, or sample requests, email Mr. Boyce at [email protected]. We respond to all inquiries within 24 hours on business days. Let us help you achieve superior sealing performance, reduced maintenance cycles, and enhanced system reliability.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).