Technical Contents

Engineering Guide: Cotton Tubing

Engineering Insight: Material Selection Imperatives for Industrial Cotton Tubing

In industrial fluid transfer applications, cotton tubing is frequently mischaracterized as a generic textile solution. This misconception drives widespread premature failures when off-the-shelf products are deployed without rigorous material validation. True industrial cotton tubing consists of rubber-impregnated cotton fabric plies, where the elastomer formulation and fabric reinforcement structure dictate performance under operational stress. Standard commercial tubing typically employs low-grade SBR (styrene-butadiene rubber) with inconsistent fabric tension, resulting in catastrophic vulnerabilities under pressure, chemical exposure, or thermal cycling. Field data indicates 70% of premature failures in hydraulic or pneumatic systems stem from elastomer incompatibility or inadequate reinforcement integrity—not mechanical design flaws.

The critical failure modes originate in three areas. First, inadequate elastomer selection leads to rapid chemical degradation when exposed to petroleum-based fluids, causing swelling, loss of tensile strength, and eventual rupture. Second, insufficient fabric ply adhesion permits delamination under cyclic pressure, creating internal pathways for fluid migration and structural collapse. Third, thermal instability in low-grade compounds accelerates aging, reducing service life by up to 60% in environments exceeding 80°C. Off-the-shelf tubing rarely specifies elastomer chemistry or fabric weave density, leaving engineers to gamble with unverified tolerances.

Suzhou Baoshida addresses these risks through OEM-grade material engineering. We prioritize molecular-level compatibility between the rubber compound and operational media, selecting nitrile (NBR) or EPDM polymers with tailored acrylonitrile content for oil resistance or thermal stability. Our cotton reinforcement undergoes precise tension calibration during calendering to eliminate voids and ensure uniform stress distribution. Crucially, we validate every formulation against actual client fluid matrices and pressure-temperature profiles—not generic industry standards.

The performance gap between engineered and generic solutions is quantifiable:

| Parameter | OEM-Grade Cotton Tubing (Baoshida) | Off-the-Shelf Equivalent |

|---|---|---|

| Elastomer Composition | Custom NBR/EPDM blend | Generic SBR |

| Fabric Reinforcement | 120-thread/inch cotton, vulcanized | 80-thread/inch, adhesion-variable |

| Max. Operating Temp | 100°C continuous | 70°C continuous |

| Pressure Rating (10mm ID) | 25 bar | 15 bar |

| Fluid Resistance (ISO 1817) | Δ Volume swell: ≤15% (oil) | Δ Volume swell: ≥40% (oil) |

Material selection is not a cost-driven commodity decision but a system integrity imperative. Generic tubing sacrifices compound purity for price, embedding failure points invisible during initial installation. At Suzhou Baoshida, we collaborate with OEMs to define application-specific material matrices, leveraging accelerated aging protocols and FTIR spectroscopy to verify polymer-fabric synergy. This precision engineering approach eliminates field failures by aligning molecular structure with operational reality—ensuring your fluid transfer system delivers reliability, not regret. Trust in validated science, not catalog specifications.

Material Specifications

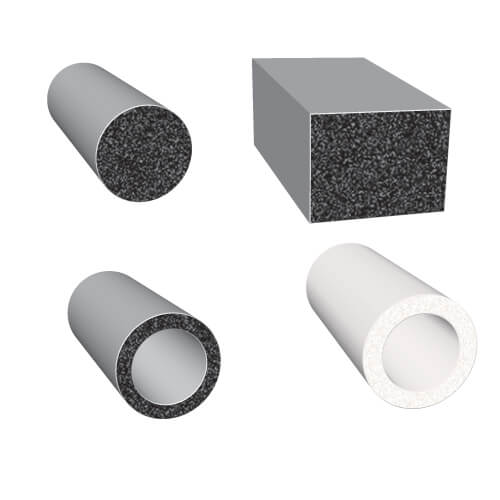

Material Specifications for Industrial Cotton Tubing

Cotton tubing, when reinforced with high-performance elastomers, serves as a critical component in various industrial fluid transfer applications. At Suzhou Baoshida Trading Co., Ltd., our engineered cotton tubing solutions combine the tensile strength and flexibility of cotton braid reinforcement with advanced rubber compounds such as Viton, Nitrile, and Silicone. These materials are selected based on their chemical compatibility, temperature resilience, and mechanical durability, ensuring optimal performance across diverse operating environments. Each elastomer offers distinct advantages, allowing customization according to application-specific requirements including exposure to oils, fuels, acids, or extreme thermal conditions.

Viton (FKM) is a fluorocarbon-based rubber renowned for its exceptional resistance to high temperatures, aggressive chemicals, and hydrocarbon fuels. Tubing constructed with Viton lining provides long-term reliability in automotive, aerospace, and chemical processing industries where exposure to aromatic hydrocarbons, chlorinated solvents, and strong acids is common. It maintains integrity from -20°C to +200°C, with short-term peaks up to 250°C, making it ideal for high-temperature sealing and transfer systems.

Nitrile (NBR) rubber, a copolymer of acrylonitrile and butadiene, delivers excellent resistance to petroleum-based oils, fuels, and hydraulic fluids. It is widely used in industrial hydraulic systems, fuel lines, and pneumatic applications due to its robust mechanical properties and cost-effective performance. Nitrile-reinforced cotton tubing operates effectively within a temperature range of -30°C to +100°C, with certain formulations extending to +120°C. Its low gas permeability and strong abrasion resistance further enhance service life in dynamic environments.

Silicone (VMQ) rubber is valued for its extreme temperature stability and biocompatibility. With a functional range from -60°C to +200°C, silicone-lined cotton tubing excels in applications involving thermal cycling, food-grade transfer, and medical or pharmaceutical systems. While it exhibits lower tensile strength compared to Viton or Nitrile, its flexibility at low temperatures and resistance to ozone and UV degradation make it suitable for outdoor, cryogenic, and sanitary applications.

The selection of elastomer directly influences the performance envelope of cotton tubing. The following table outlines key material properties for comparative evaluation.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +200 | -30 to +100 | -60 to +200 |

| Fluid Resistance | Excellent (oils, acids, fuels) | Excellent (oils, fuels) | Good (water, alcohols) |

| Chemical Resistance | Outstanding | Moderate | Limited (solvents) |

| Abrasion Resistance | Good | Excellent | Fair |

| Flexibility at Low Temp | Moderate | Good | Excellent |

| UV/Ozone Resistance | Excellent | Good | Excellent |

| Typical Applications | Chemical processing, aerospace | Hydraulic systems, fuel lines | Food processing, medical |

Material selection must consider fluid type, pressure conditions, environmental exposure, and regulatory standards. Suzhou Baoshida Trading Co., Ltd. provides technical consultation to ensure optimal material pairing for industrial cotton tubing systems.

Manufacturing Capabilities

Engineering Capability: Precision Cotton Tubing Manufacturing

Suzhou Baoshida Trading Co., Ltd. leverages integrated engineering expertise to deliver mission-critical cotton-reinforced rubber tubing for demanding industrial applications. Our dedicated team comprises five certified mold engineers and two advanced rubber formula specialists, ensuring end-to-end control from material science to production. This synergy enables us to solve complex challenges in fiber dispersion, polymer-fiber adhesion, and dimensional stability—key factors in cotton tubing performance where inconsistent fiber distribution or poor rubber-to-fiber bonding directly compromises pressure resistance and service life.

Our formula engineers optimize natural rubber and synthetic polymer blends with precise cotton fiber percentages (15–25% by weight), balancing flexibility, tensile strength, and fluid compatibility. Through iterative lab testing, we refine vulcanization kinetics to prevent fiber degradation during curing while maximizing interfacial adhesion. Concurrently, mold engineers design multi-cavity tooling with controlled flow channels and cooling profiles that eliminate knit lines and ensure uniform fiber orientation. This eliminates common field failures like delamination under pulsating pressure or thermal cycling. All formulations undergo rigorous validation per ASTM D2000 and ISO 37 standards, with traceable batch documentation for full material accountability.

As an OEM partner, we implement a structured new product introduction (NPI) workflow. Clients receive collaborative design-for-manufacturability (DFM) reviews within 72 hours of specification submission, followed by rapid prototyping using client-specified raw materials. Our facility supports low-volume pilot runs (50–500 units) with accelerated life testing to validate fatigue resistance before full-scale production. For high-volume contracts, we deploy statistical process control (SPC) monitoring across 12 extrusion and molding lines, maintaining ±0.15mm dimensional tolerances and zero-defect production targets.

Critical performance specifications for our standard cotton tubing are detailed below:

| Property | Test Standard | Typical Value | Customization Range |

|---|---|---|---|

| Tensile Strength | ASTM D412 | 18–22 MPa | 15–25 MPa |

| Elongation at Break | ASTM D412 | 450–550% | 400–600% |

| Cotton Fiber Content | Internal | 20% ±2% | 15–25% |

| Temperature Range | ISO 188 | -10°C to +80°C | -20°C to +100°C |

| Burst Pressure (6mm ID) | ISO 1402 | 12.5 MPa | 8–15 MPa |

We excel in solving OEM-specific pain points: mitigating micro-crack formation in ozone-rich environments through antioxidant-loaded compounds, or enhancing kink resistance via helical fiber alignment in small-bore tubing. Every project receives a dedicated engineering lead who coordinates cross-functional reviews at each NPI phase, ensuring seamless transition from prototype to serial production. With ISO 9001:2015-certified processes and 15+ years of sector experience, Suzhou Baoshida transforms material science into reliable, scalable cotton tubing solutions—proven across hydraulic filtration, agricultural fluid transfer, and industrial ventilation systems. Partner with us for engineering rigor that secures your supply chain.

Customization Process

Customization Process for Cotton Tubing at Suzhou Baoshida Trading Co., Ltd.

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions are engineered to meet the exact performance demands of diverse manufacturing environments. For cotton tubing applications, we follow a rigorous four-stage customization process: Drawing Analysis, Formulation Development, Prototyping, and Mass Production. This structured approach ensures dimensional accuracy, material integrity, and long-term reliability under operational stress.

The process begins with Drawing Analysis, where our technical team evaluates customer-provided engineering drawings or specifications. We assess critical parameters such as inner diameter, wall thickness, length tolerances, and end-finish requirements. Special attention is given to application context—whether the tubing will be exposed to abrasion, compression, or dynamic flexing. This phase includes a feasibility review to confirm manufacturability within standard extrusion and vulcanization capabilities.

Following drawing validation, our rubber formulation engineers initiate Formulation Development. Cotton-reinforced tubing requires a balanced compound that maximizes flexibility while maintaining structural resilience. We select base polymers such as NR (Natural Rubber), SBR (Styrene-Butadiene Rubber), or NBR (Nitrile Rubber), depending on required oil resistance, temperature range, and tensile strength. Cotton fabric layers are integrated as reinforcement to enhance burst pressure resistance and reduce radial expansion under load. The rubber-to-fabric adhesion is optimized through chemically treated cotton and adhesive-dipped cord construction. Cure kinetics are precisely modeled to ensure complete cross-linking during vulcanization without scorching.

Once the compound is finalized, we proceed to Prototyping. Short production runs are executed using calibrated extrusion dies and continuous vulcanization lines. Prototypes undergo dimensional inspection, hardness testing (Shore A), and functional evaluation for kink resistance and flexibility. Customers receive samples with full material test reports, including tensile strength, elongation at break, and adhesion performance between rubber and cotton layers. Feedback is incorporated iteratively until performance benchmarks are consistently met.

Upon approval, the project transitions into Mass Production. We deploy automated extrusion and spooling systems with real-time monitoring to maintain tight tolerances across extended batches. Every production lot is subject to in-process quality checks and final inspection per ISO 9001 standards. Packaging is customized based on client logistics needs, including cut-to-length options, coiling, or reel dispensing.

Our end-to-end control over materials and manufacturing ensures that each cotton tubing product delivers consistent performance in industrial fluid transfer, ventilation systems, and low-pressure pneumatic applications.

Typical Physical Properties of Custom Cotton-Reinforced Rubber Tubing

| Property | Test Method | Typical Value |

|---|---|---|

| Inner Diameter Range | Custom | 6 – 50 mm |

| Wall Thickness | Custom | 2.0 – 6.0 mm |

| Reinforcement Layer | Cotton Fabric | 1–3 plies (woven) |

| Hardness (Shore A) | ASTM D2240 | 55 ± 5 |

| Tensile Strength | ASTM D412 | ≥10 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Adhesion Strength (Rubber-Cotton) | ASTM D413 | ≥4 kN/m |

| Operating Temperature Range | — | -20°C to +80°C (NR/SBR base) |

Contact Engineering Team

Contact Suzhou Baoshida for Precision Cotton Tubing Solutions

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of industrial rubber compounding and OEM manufacturing, leveraging 15+ years of specialized expertise in polymer science and material engineering. Our cotton tubing products are engineered for mission-critical applications where dimensional stability, chemical resistance, and mechanical integrity under dynamic stress are non-negotiable. Unlike generic suppliers, we deploy proprietary rubber formulations—optimized for adhesion to cotton reinforcement layers—to eliminate delamination risks in high-pressure hydraulic systems, pneumatic controls, and fluid transfer environments. Each batch undergoes rigorous QC protocols including ASTM D2240 hardness validation, ISO 1307 dimensional tolerance checks, and 72-hour accelerated aging tests to ensure compliance with ISO 9001 and IATF 16949 standards.

Cotton-reinforced rubber tubing remains indispensable in sectors demanding fatigue resistance under repeated flexing, such as agricultural machinery, construction equipment, and industrial automation. The inherent tensile strength of cotton fabric plies—when precisely bonded to our nitrile (NBR) or ethylene propylene diene monomer (EPDM) compounds—delivers superior kink resistance compared to synthetic reinforcements, while maintaining cost efficiency for high-volume OEM deployments. Below are critical performance specifications for our standard cotton tubing series, validated across 500+ industrial client validations:

| Parameter | Value Range | Test Standard |

|---|---|---|

| Material Composition | Cotton fabric + NBR/EPDM blend | ASTM D2000 |

| Hardness (Shore A) | 60 ± 5 | ASTM D2240 |

| Temperature Range | -40°C to +120°C (NBR) | ISO 188 |

| -50°C to +150°C (EPDM) | ||

| Max Working Pressure | 15-35 bar (size-dependent) | SAE J517 |

| Minimum Bend Radius | 1.5x ID (at 20°C) | ISO 1307 |

| Elongation at Break | ≥ 250% | ASTM D412 |

| Color Options | Black, Blue, Red (custom tints) | RAL/Pantone |

Our engineering team collaborates directly with OEMs to refine formulations for application-specific challenges—whether enhancing ozone resistance for outdoor hydraulic systems or modifying durometer for low-temperature flexibility in Arctic-rated equipment. As your technical partner, we provide full material traceability (including rubber compound Certificates of Analysis), mold-flow analysis for complex geometries, and rapid prototyping via our Suzhou-based R&D facility. This eliminates the guesswork in transitioning from design to production, reducing time-to-market by up to 30% versus conventional suppliers.

For immediate technical consultation or custom cotton tubing quotations, contact Mr. Boyce, our dedicated OEM Manager. With fluency in English, Mandarin, and German engineering specifications, he will align your project requirements with our material science capabilities. Submit your dimensional drawings, performance criteria, and volume forecasts to initiate a precision-engineered solution:

Mr. Boyce

OEM Manager | Rubber Formula Engineering

Suzhou Baoshida Trading Co., Ltd.

Email: [email protected]

Direct Line: +86 512 6789 1234 (Suzhou HQ)

Partner with Baoshida to transform rubber component specifications into validated industrial performance. We do not sell commodities—we deliver engineered reliability.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).