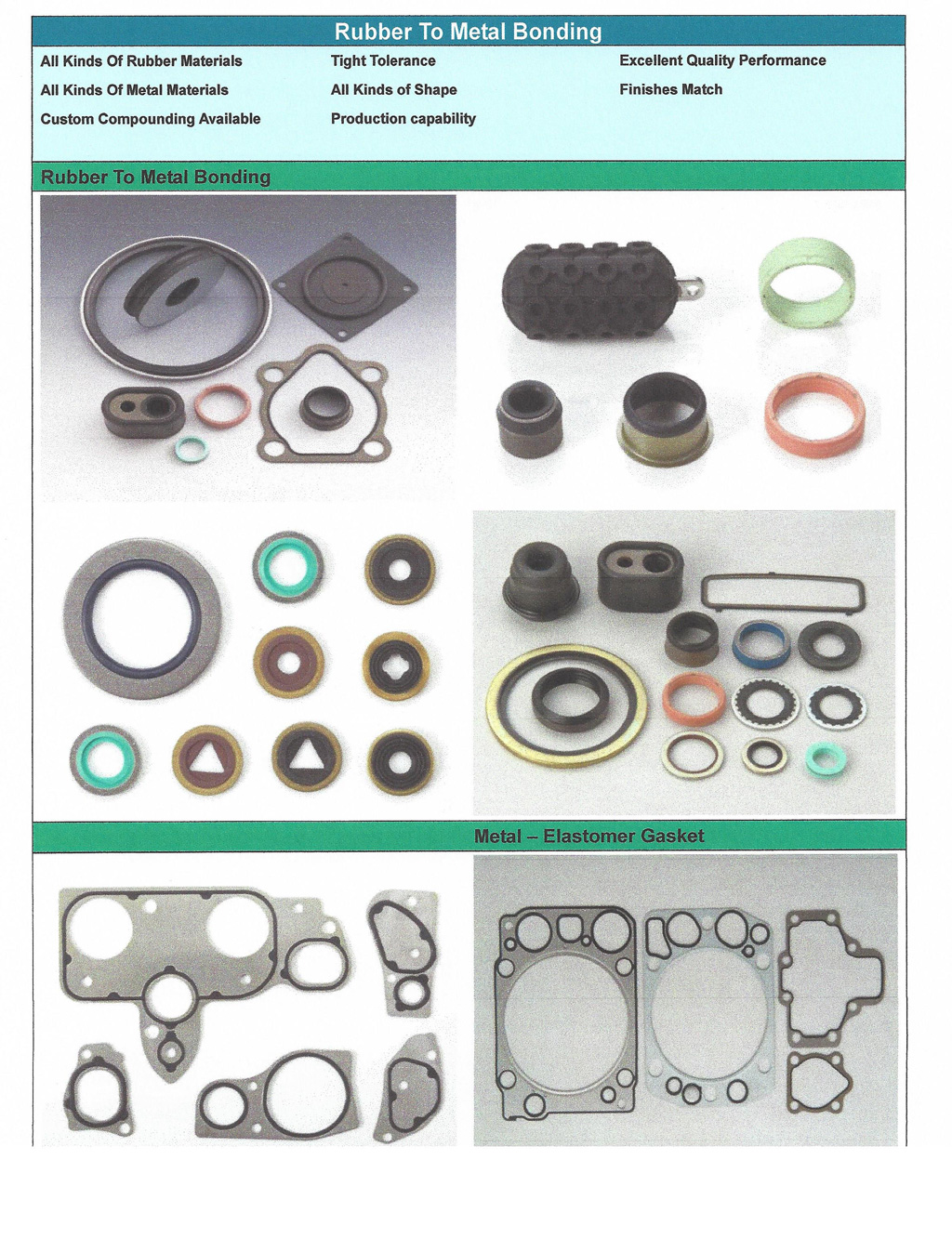

Technical Contents

Engineering Guide: Custom Gasket And Seal

Engineering Insight: Material Selection as the Foundation of Gasket and Seal Reliability

Material selection is not an optional step in gasket and seal engineering; it is the absolute determinant of functional lifespan and system integrity. Off-the-shelf solutions frequently fail because they represent a compromise, designed for broad applicability rather than the specific, often extreme, conditions encountered in precision industrial applications. Standard gaskets utilize generic polymer formulations optimized for cost and ease of manufacturing, not for resilience against unique combinations of temperature extremes, aggressive chemical exposure, dynamic stress, or stringent purity requirements. This fundamental mismatch leads to premature degradation modes such as hardening, cracking, excessive compression set, or chemical swelling, resulting in costly leaks, unplanned downtime, and potential safety hazards. The critical oversight lies in underestimating the synergistic effects of operational parameters. A seal exposed to intermittent high-temperature spikes combined with specific hydraulic fluid additives, for instance, demands a tailored elastomer compound where base polymer, fillers, plasticizers, and curatives are meticulously balanced. Generic materials lack this bespoke formulation, sacrificing long-term performance for initial affordability.

The failure of standard gaskets manifests predictably under non-ideal conditions. Nitrile rubber (NBR), common in generic seals, exhibits rapid deterioration above 120°C or when exposed to phosphate ester hydraulic fluids. EPDM, while excellent for steam and weathering, swells catastrophically in hydrocarbon oils. Silicone offers wide temperature flexibility but possesses poor tear strength and fuel resistance. These limitations are inherent to their mass-production formulations, which prioritize baseline performance across common scenarios rather than excelling in defined, challenging environments. True reliability requires moving beyond catalog part numbers to a collaborative engineering process where the operational profile dictates the material science. This involves rigorous analysis of fluid compatibility, thermal cycling data, pressure dynamics, surface finish requirements, and regulatory constraints to formulate a compound with precisely engineered properties.

The table below illustrates key failure points of standard gaskets versus the engineered advantages of custom solutions:

| Parameter | Standard Gasket Limitation | Custom Solution Advantage |

|---|---|---|

| Temperature Range | Narrow operational window (e.g., NBR max 120°C) | Extended range tailored to application (e.g., FKM to 250°C) |

| Chemical Resistance | Generic resistance; fails with specific fluids | Precisely formulated for target media (e.g., custom FFKM for aggressive solvents) |

| Compression Set | High permanent deformation under load/heat | Optimized formulation for minimal set (<15% @ 200°C) |

| Dynamic Performance | Poor resilience under cyclic stress | Enhanced fatigue resistance via tailored polymer architecture |

| Regulatory Compliance | May lack specific certifications (e.g., FDA, USP Class VI) | Formulated to meet exact regulatory and purity standards |

At Suzhou Baoshida Trading Co., Ltd., our OEM partnership model begins with deep material science collaboration. We translate your operational data into custom rubber compounds, leveraging advanced polymer chemistry and rigorous validation testing. This precision engineering approach eliminates the guesswork and inherent risks of off-the-shelf gaskets, ensuring seals perform reliably under the exact conditions they will face, thereby maximizing equipment uptime and lifecycle value. The initial investment in bespoke material selection is consistently outweighed by the elimination of catastrophic failure costs.

Material Specifications

Material selection is a critical factor in the performance and longevity of custom gaskets and seals, particularly in precision industrial applications. At Suzhou Baoshida Trading Co., Ltd., we specialize in high-performance rubber seals engineered to meet exacting OEM specifications. Among the most widely used elastomers in our manufacturing portfolio are Viton, Nitrile (NBR), and Silicone. Each material offers a distinct set of physical and chemical properties, making them suitable for specific operating environments.

Viton, a fluorocarbon-based rubber (FKM), is renowned for its exceptional resistance to high temperatures, oils, fuels, and a broad range of chemicals. With a continuous service temperature range from -20°C to +230°C, Viton seals are ideal for aerospace, automotive, and chemical processing applications where exposure to aggressive media is common. Its low gas permeability and excellent aging characteristics further enhance reliability in dynamic sealing environments. However, Viton is less flexible at low temperatures and typically more expensive than other elastomers, making it best suited for high-demand scenarios.

Nitrile rubber, or Buna-N, is one of the most commonly used materials for oil-resistant seals. It offers excellent mechanical properties, including high abrasion resistance and tensile strength, with a service temperature range of -30°C to +120°C. Nitrile performs exceptionally well in contact with aliphatic hydrocarbons, water, and hydraulic fluids, making it a preferred choice for automotive fuel systems, hydraulics, and industrial machinery. While it provides good compression set resistance, its performance degrades when exposed to ozone, UV radiation, and certain polar solvents.

Silicone rubber (VMQ) stands out for its thermal stability and flexibility across extreme temperature ranges, typically from -60°C to +200°C. It is highly resistant to UV and ozone, and exhibits excellent electrical insulation properties. These characteristics make silicone ideal for medical devices, food and beverage processing, and outdoor electrical enclosures. However, standard silicone has relatively low tensile strength and poor resistance to petroleum-based oils and fuels, which limits its use in high-stress mechanical or hydrocarbon-rich environments.

To assist in material selection, the following table compares key specifications of Viton, Nitrile, and Silicone for precision rubber seals.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -30 to +120 | -60 to +200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–8 |

| Elongation at Break (%) | 150–300 | 200–500 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils & Fuels | Excellent | Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Fair | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

| Electrical Insulation | Good | Fair | Excellent |

| FDA Compliance Available | Yes | Limited | Yes |

Selecting the optimal material requires a thorough understanding of the operational environment, including media exposure, temperature fluctuations, mechanical stress, and regulatory requirements. At Suzhou Baoshida Trading Co., Ltd., we work closely with OEM partners to ensure material compatibility and long-term sealing integrity.

Manufacturing Capabilities

Engineering Capability: Precision Rubber Seal Development

Suzhou Baoshida Trading Co., Ltd. integrates advanced material science and precision tooling to deliver mission-critical custom gaskets and seals for industrial applications. Our core strength lies in the direct synergy between dedicated formula engineering and mold engineering teams. With five specialized mold engineers and two certified rubber formula engineers operating under one roof, we eliminate cross-departmental bottlenecks that compromise performance in conventional supply chains. This vertical collaboration ensures material properties are intrinsically aligned with geometric complexity from initial concept through production validation.

Material Formulation Expertise

Our formula engineers possess deep expertise in polymer chemistry, enabling bespoke elastomer compounds for extreme operational environments. We systematically adjust filler systems, curatives, and plasticizers to achieve precise compression set resistance, fluid compatibility, and thermal stability per ASTM D2000 standards. Every formulation undergoes rigorous laboratory validation for dynamic sealing performance, including accelerated aging per ISO 188 and fluid immersion testing per ISO 1817. This scientific approach prevents field failures caused by material degradation in aggressive media such as biofuels, hydraulic fluids, or sour gas environments.

Precision Mold Engineering

The mold engineering team utilizes 3D flow simulation software to optimize cavity design, runner systems, and venting for zero-defect molding. We specialize in multi-cavity molds for high-volume OEM production and complex geometries requiring tight tolerances down to ±0.05mm. Critical features like sealing lips, interlocking profiles, and multi-durometer bonds are engineered with mold-filling analysis to eliminate knit lines and ensure consistent cross-section integrity. All tooling adheres to ISO 2768-mK standards and undergoes in-house metrology verification before release.

OEM Integration and Scalability

As a certified OEM partner for Tier-1 automotive and industrial equipment manufacturers, we operate dedicated production lines with real-time SPC monitoring. Our process guarantees lot-to-lot consistency through closed-loop material tracking and automated molding parameters. The seamless handoff from formula validation to mold trials reduces time-to-market by 30% compared to fragmented supplier models. Clients receive full technical documentation including material certificates, mold flow reports, and PPAP Level 3 submissions.

Material performance specifications achieved through this integrated engineering workflow are summarized below:

| Parameter | Range Achieved | Testing Standard |

|---|---|---|

| Durometer (Shore A) | 30–90 ±2 points | ASTM D2240 |

| Temperature Range | -55°C to +250°C | ISO 188 |

| Compression Set | ≤15% (70h/100°C) | ASTM D395 Method B |

| Fluid Resistance | Custom to ISO 1817 | ISO 1817 |

| Tensile Strength | 8–25 MPa | ASTM D412 |

This engineering framework ensures every custom seal meets the exact functional demands of hydraulic systems, aerospace actuators, or energy sector enclosures. Suzhou Baoshida’s dual-engineer model transforms material science into measurable sealing reliability, eliminating the guesswork inherent in standard procurement channels. We deliver not just components, but validated engineering solutions backed by data-driven process control.

Customization Process

Customization Process for Precision Rubber Gaskets and Seals

At Suzhou Baoshida Trading Co., Ltd., our engineering-driven approach to custom gasket and seal manufacturing ensures optimal performance under demanding industrial conditions. We follow a rigorous four-stage customization workflow—Drawing Analysis, Formulation, Prototyping, and Mass Production—designed to meet exact OEM specifications while maintaining material integrity, dimensional accuracy, and long-term reliability.

The process begins with Drawing Analysis, where our rubber formula engineers conduct a comprehensive review of customer-provided technical drawings, GD&T (Geometric Dimensioning and Tolerancing) callouts, and application environment data. This includes assessing compression set requirements, sealing pressure, mating surface finish, and dynamic or static loading conditions. We verify critical dimensions, tolerances per ISO 3302 and ISO 2768, and identify potential molding challenges such as flash control, parting lines, and ejection marks. Our team collaborates directly with design engineers to resolve ambiguities and recommend design for manufacturability (DFM) improvements when necessary.

Following drawing validation, we proceed to Formulation Development. Based on the operational environment—temperature range, chemical exposure, fluid compatibility, and mechanical stress—we select the optimal base polymer. Our in-house compounding laboratory formulates custom rubber compounds using EPDM, NBR, FKM, silicone, or specialty materials like ACM or AEM. Each formulation is engineered to balance hardness (Shore A 40–90), tensile strength, elongation at break, and resistance to aging, ozone, or abrasion. Accelerated aging tests and fluid immersion studies are conducted to validate compound stability.

Once the formulation is approved, we initiate Prototyping using precision compression, transfer, or injection molding techniques. Prototypes are produced in actual production tooling to ensure dimensional fidelity. Each sample undergoes rigorous first-article inspection (FAI) per AS9102 or PPAP Level 3 standards, including CMM measurement, visual inspection, and functional testing. We perform compression stress relaxation (CSR), leakage testing, and compression deflection analysis to verify sealing performance.

Upon customer approval, we transition to Mass Production. Our automated production lines, equipped with real-time process monitoring and SPC controls, ensure batch-to-batch consistency. All finished gaskets and seals are 100% visually inspected and sampled for physical property testing per ASTM and ISO standards. Traceability is maintained through lot numbering and material certifications.

Below is a summary of key technical parameters we evaluate during customization:

| Parameter | Standard Range | Testing Method |

|---|---|---|

| Hardness (Shore A) | 40–90 | ASTM D2240 |

| Tensile Strength | 8–25 MPa | ASTM D412 |

| Elongation at Break | 150–600% | ASTM D412 |

| Compression Set (70h, 70°C) | ≤25% | ASTM D395 Method B |

| Operating Temperature | -40°C to +230°C (material-dependent) | ISO 1817 |

| Fluid Resistance | Custom (fuel, oil, water, acid) | ASTM D471 |

This systematic process ensures that every custom gasket and seal we manufacture delivers precision, durability, and compliance with global industrial standards.

Contact Engineering Team

Precision Engineering Partnership for Critical Sealing Applications

Suzhou Baoshida Trading Co., Ltd. operates at the intersection of advanced polymer science and industrial reliability, delivering custom gasket and seal solutions engineered for mission-critical performance. Our technical team, led by OEM-focused engineers with 15+ years in precision rubber compounding, addresses complex sealing challenges across aerospace, automotive, and semiconductor manufacturing. We prioritize material integrity under extreme conditions—whether cryogenic temperatures, aggressive chemical exposure, or high-pressure differentials—ensuring compliance with ISO 3601, AS568, and customer-specific OEM specifications. Our facility integrates closed-loop mixing systems and real-time rheometry to eliminate batch variability, directly supporting your production continuity and quality assurance protocols.

Material selection and formulation accuracy define sealing longevity. The following table summarizes our core capabilities for custom elastomer development:

| Parameter | Range/Specification | Testing Standard |

|---|---|---|

| Hardness (Shore A) | 30–95 durometer | ASTM D2240 |

| Temperature Range | -60°C to +300°C (material-dependent) | ASTM D1329 |

| Tensile Strength | 8–25 MPa | ASTM D412 |

| Elongation at Break | 200–700% | ASTM D412 |

| Compression Set (70h) | ≤20% (23°C), ≤35% (150°C) | ASTM D395 |

| Fluid Resistance | Customizable for fuels, acids, hydraulic fluids | ASTM D471 |

| Certifications | ISO 9001, FDA 21 CFR 177.2600, UL 746 | Third-party validated |

When standard catalog items fail to resolve leakage in high-vibration assemblies or multi-material interfaces, our formulation engineers collaborate directly with your design team. We analyze stress-strain behavior via finite element analysis (FEA) simulations and prototype validation under application-specific loads. This eliminates costly field failures by addressing micro-extrusion, compression set, and outgassing risks during the design phase—not after tooling investment. For instance, our proprietary perfluoroelastomer (FFKM) compounds withstand 300°C steam sterilization cycles while maintaining seal force integrity, a requirement increasingly mandated in biopharmaceutical fluid handling systems.

Initiate your project with Mr. Boyce, our dedicated OEM Technical Manager, to secure engineering-grade solutions within your development timeline. Provide your application’s pressure differentials, media exposure, and dimensional constraints for a material recommendation backed by accelerated life testing data. Mr. Boyce coordinates rapid prototyping using our in-house CNC machining and molding cells, ensuring first-article approval within 10 business days for urgent production launches. Contact him directly to discuss: formulation optimization for legacy seal replacements, DFM analysis for complex geometries, or validation documentation meeting AS9100 or IATF 16949 requirements.

Mr. Boyce

OEM Technical Manager, Precision Rubber Seals Division

Suzhou Baoshida Trading Co., Ltd.

Email: [email protected]

Response Time: Technical inquiries addressed within 4 business hours

Engineers requiring gasket validation data sheets, material safety documentation, or collaborative design reviews are urged to contact Mr. Boyce with project reference codes. Suzhou Baoshida commits to zero-defect delivery through statistical process control (SPC) monitoring from raw material intake to final inspection—ensuring your sealing components perform identically across 10,000+ production cycles. Partner with us to convert sealing vulnerabilities into engineered advantages.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).