Technical Contents

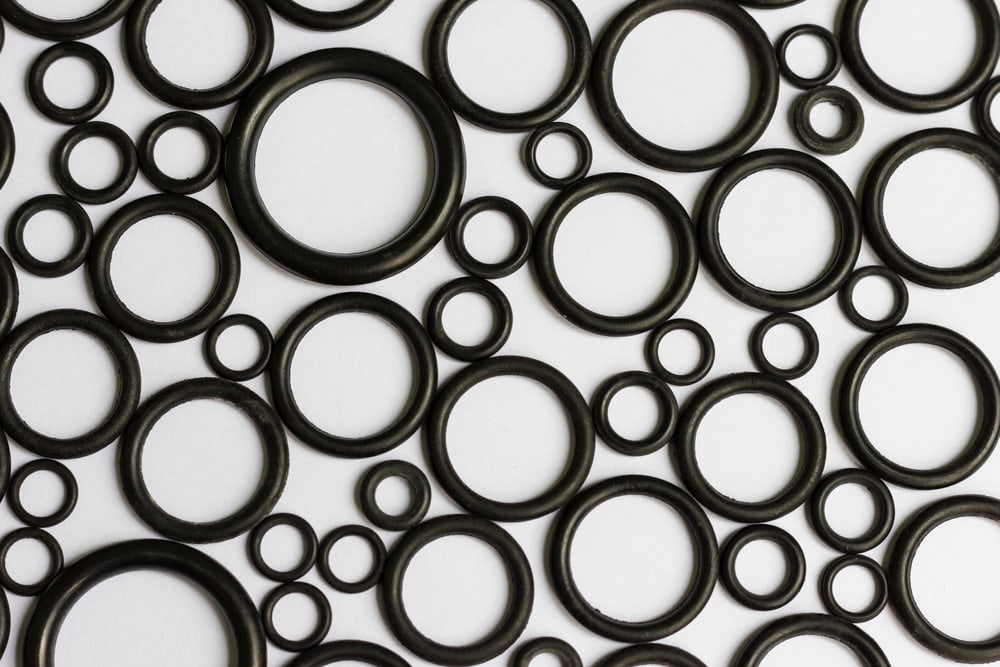

Engineering Guide: Custom Molded O Rings

Engineering Insight: Custom Molded O Rings – The Critical Role of Material Selection

In the realm of precision rubber seals, material selection is not merely a design consideration—it is the foundation of performance, longevity, and system reliability. Off-the-shelf O rings, while convenient, are engineered for generalized applications and often fail under the specific thermal, chemical, and mechanical demands of industrial environments. This limitation underscores the necessity of custom molded O rings, where material properties are precisely aligned with operational parameters.

Standard O rings are typically manufactured from common elastomers such as Nitrile (NBR) or Silicone (VMQ), selected for cost-efficiency and broad compatibility. However, when exposed to aggressive media like strong acids, chlorinated solvents, or high-pressure steam, these materials degrade rapidly. Swelling, compression set, and loss of tensile strength compromise the seal, leading to leakage, system downtime, and potential safety hazards. In dynamic applications involving reciprocating motion or frequent thermal cycling, the mismatch between generic material behavior and actual service conditions accelerates failure.

Custom molded O rings address these shortcomings through tailored elastomer formulation. At Suzhou Baoshida Trading Co., Ltd., we prioritize material science in every custom solution. By analyzing the application’s temperature range, fluid exposure, pressure profile, and dynamic load, we select or compound elastomers that deliver optimal resistance and resilience. For example, Fluorocarbon (FKM) is deployed in high-temperature fuel systems due to its exceptional resistance to hydrocarbons and thermal stability up to 250°C. For applications involving ozone or UV exposure, Ethylene Propylene Diene Monomer (EPDM) provides unmatched durability. In food and pharmaceutical environments, peroxide-cured silicone ensures compliance with FDA and USP Class VI standards.

The table below illustrates key performance characteristics of common elastomers used in custom O ring manufacturing:

| Elastomer | Temperature Range (°C) | Key Chemical Resistances | Typical Applications |

|---|---|---|---|

| NBR (Nitrile) | -30 to +120 | Oils, fuels, aliphatic hydrocarbons | Hydraulic systems, automotive seals |

| FKM (Viton®) | -20 to +250 | Aromatic hydrocarbons, acids, fuels | Aerospace, chemical processing |

| EPDM | -50 to +150 | Water, steam, alkalis, oxygenated solvents | HVAC, sterilization equipment |

| Silicone (VMQ) | -60 to +200 | Ozone, UV, water, weak acids | Medical devices, food processing |

| FFKM (Perfluoroelastomer) | -15 to +327 | Aggressive chemicals, plasma | Semiconductor, ultra-high-purity systems |

Material selection directly influences compression set resistance, elastic recovery, and long-term sealing force. A custom approach allows for the integration of specialty fillers, cure systems, and polymer blends that enhance performance beyond off-the-shelf capabilities. Furthermore, precise molding processes ensure dimensional accuracy and repeatability, critical in high-integrity sealing applications.

In conclusion, the failure of standard O rings in demanding environments is not a flaw of design but of material misalignment. Custom molded O rings, engineered with application-specific elastomers, provide a scientifically sound solution to ensure reliability, safety, and operational efficiency in precision sealing systems.

Material Specifications

Material Specifications for Custom Molded O-Rings

Selecting the optimal elastomer is critical for O-ring performance in demanding industrial applications. At Suzhou Baoshida Trading Co., Ltd., we engineer custom molded O-rings using rigorously tested compounds to ensure seal integrity under specific operational stresses. Material choice directly impacts chemical compatibility, temperature resilience, compression set resistance, and service life. Our primary formulations—Viton® (FKM), Nitrile (NBR), and Silicone (VMQ)—address distinct environmental challenges. Each compound undergoes stringent ASTM D2000 and ISO 3601 validation to meet OEM specifications.

Viton® fluorocarbon rubber delivers exceptional resistance to high temperatures, aggressive chemicals, and fuels. It maintains functionality from -20°C to +230°C continuous service, with short-term peaks up to 300°C. This material excels in aerospace, semiconductor, and oilfield applications where exposure to aromatic hydrocarbons, acids, and steam is prevalent. Viton® exhibits low gas permeability and outstanding resistance to compression set, ensuring long-term sealing in critical static joints. However, it is less effective against ketones, esters, and phosphate ester hydraulic fluids.

Nitrile rubber (NBR) remains the industry standard for cost-sensitive applications involving petroleum-based oils and hydraulic fluids. With a standard temperature range of -40°C to +120°C (extended formulations reach +150°C), NBR offers robust abrasion resistance and tensile strength. Its compatibility with aliphatic hydrocarbons, water, and silicone oils makes it ideal for automotive fuel systems, hydraulics, and general industrial machinery. Limitations include poor ozone resistance and vulnerability to polar solvents like acetone or chlorinated hydrocarbons.

Silicone (VMQ) provides unmatched flexibility across extreme temperatures (-60°C to +200°C), coupled with excellent resistance to oxidation and UV exposure. Its biocompatibility and low toxicity support FDA 21 CFR 177.2600 compliance for food, beverage, and medical applications. Silicone demonstrates superior electrical insulation properties but exhibits lower tensile strength and tear resistance compared to NBR or Viton®. It is incompatible with concentrated acids, alkalis, and most hydrocarbon fuels, restricting use in dynamic sealing scenarios.

The comparative specifications below guide material selection based on operational parameters. All values represent typical cured compound properties per ASTM standards.

| Material | Temperature Range (°C) | Key Chemical Resistances | Key Chemical Vulnerabilities | Tensile Strength (MPa) | Hardness Range (Shore A) | Primary Applications |

|---|---|---|---|---|---|---|

| Viton® (FKM) | -20 to +230 | Aromatic hydrocarbons, acids, fuels, steam | Ketones, esters, amines, hot hydroxides | 10–18 | 50–90 | Aerospace seals, oil/gas downhole tools, semiconductor manufacturing |

| Nitrile (NBR) | -40 to +120 (+150 ext.) | Aliphatic hydrocarbons, water, silicone oils | Ozone, ketones, esters, phosphate esters | 15–25 | 40–90 | Automotive fuel systems, hydraulic cylinders, industrial pumps |

| Silicone (VMQ) | -60 to +200 | Oxygen, ozone, UV, water, alcohols | Concentrated acids, hydrocarbons, fuels | 5–10 | 30–80 | Medical devices, food processing, HVAC thermal seals |

Material selection must align with fluid media, temperature cycles, and mechanical loads. Suzhou Baoshida Trading Co., Ltd. provides OEM engineering support to validate compound suitability through accelerated aging tests and finite element analysis. Incorrect material specification accounts for 78% of premature seal failures; our technical team ensures your custom O-rings meet exacting performance criteria. Contact our engineering department for application-specific compound recommendations and certification documentation.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Development for Custom Molded O-Rings

At Suzhou Baoshida Trading Co., Ltd., our engineering capability is anchored in a team of highly specialized professionals dedicated to delivering technically superior custom molded O-rings for demanding industrial applications. Our in-house technical team comprises five experienced mold engineers and two dedicated rubber formula engineers, enabling full vertical control from material formulation to precision tooling and production. This integrated approach ensures that every O-ring we manufacture meets exacting performance, durability, and dimensional accuracy requirements.

Our mold engineers bring over a decade of cumulative experience in precision tool design for rubber compression, transfer, and injection molding processes. Utilizing advanced CAD/CAM software, they develop optimized mold geometries that ensure consistent part quality, minimal flash, and repeatability across production batches. Each mold design undergoes rigorous validation through simulation and prototype testing to confirm flow dynamics, venting efficiency, and part ejection reliability. This precision-focused methodology reduces time-to-market and enhances long-term tool life, critical for high-volume OEM programs.

Complementing our mold expertise is our proprietary rubber compounding capability. Our two formula engineers specialize in developing custom elastomer formulations tailored to specific environmental and mechanical demands. Whether the application requires resistance to extreme temperatures, aggressive chemicals, dynamic compression, or ultra-low outgassing, our team formulates compounds based on silicone, FKM, EPDM, NBR, HNBR, and other specialty rubbers. Each formulation is tested in-house for tensile strength, elongation, compression set, hardness, and aging characteristics per ASTM and ISO standards. This ensures that the final product performs reliably under real-world operating conditions.

Our OEM capabilities are built on a foundation of technical collaboration. We work closely with clients during the design phase to review application parameters, suggest material improvements, and optimize part geometry for manufacturability. This proactive engineering engagement minimizes design iterations and reduces total project cost. From low-volume prototypes to high-volume production runs, our facility supports seamless scale-up with consistent quality control and traceability.

The following table outlines our core engineering and production specifications:

| Parameter | Capability |

|---|---|

| Mold Design Software | SolidWorks, AutoCAD, UG NX |

| Mold Manufacturing Tolerance | ±0.01 mm |

| Standard Materials | NBR, EPDM, FKM, Silicone, HNBR, ACM, AEM, CR |

| Hardness Range (Shore A) | 30 to 90 |

| Temperature Resistance | -60°C to +300°C (depending on compound) |

| Custom Formulation Lead Time | 7–14 days (including lab testing) |

| Prototype Production | 5–10 days for first article samples |

| OEM Documentation | Material Certifications (RoHS, REACH), PPAP, IMDS, Test Reports |

By combining deep materials science expertise with precision mold engineering, Suzhou Baoshida delivers custom O-ring solutions that meet the highest standards of industrial performance and reliability. Our engineering team is not just a supplier resource — it is a technical partner in solving sealing challenges.

Customization Process

Custom Molded O-Ring Manufacturing Process: Precision Engineering from Concept to Volume

At Suzhou Baoshida Trading Co., Ltd., our custom molded O-ring production adheres to a rigorously defined engineering workflow, ensuring dimensional accuracy, material integrity, and functional reliability for demanding industrial applications. This structured process eliminates guesswork and guarantees seamless transition from client specifications to certified production.

Drawing Analysis & Feasibility Assessment

Initial engagement commences with meticulous scrutiny of client-provided technical drawings against ISO 3601 and AS568 standards. Our engineering team performs comprehensive geometric dimensioning and tolerancing (GD&T) validation, verifying critical parameters including cross-section tolerance (±0.05mm achievable), inner diameter limits, and surface finish requirements. We conduct tolerance stack-up analysis to identify potential molding conflicts early, assessing cavity pressure distribution and parting line implications. Material compatibility with specified media and temperature ranges is cross-referenced against our formulation database, providing actionable feedback within 72 hours if design modifications are necessary for manufacturability.

Material Formulation & Compound Development

Based on verified application parameters—fluid exposure, temperature extremes (-55°C to +230°C), and dynamic/static sealing requirements—our rubber chemists select the optimal base polymer. Critical performance characteristics are engineered through precise control of crosslink density, filler dispersion, and additive packages. The table below outlines key material properties for common elastomers we formulate in-house:

| Material | Tensile Strength (MPa) | Compression Set (70h/100°C) | Fluid Resistance (ASTM 1) | Operating Temp Range (°C) |

|---|---|---|---|---|

| NBR | 15-25 | ≤25% | Excellent (Oils, Fuels) | -30 to +120 |

| FKM | 12-20 | ≤20% | Exceptional (Aggressive Chem) | -20 to +230 |

| EPDM | 10-18 | ≤30% | Superior (Water, Steam) | -55 to +150 |

Each compound undergoes stringent QC per ASTM D2000, with Durometer hardness held to ±2 Shore A tolerance. Traceable batch records document all raw material lots and mixing parameters.

Prototyping & Validation

Precision tooling cuts are executed for prototype cavities using hardened P20 steel. We produce 50-100 units per iteration under controlled molding conditions (temperature ±2°C, cure time ±3 seconds). Every prototype batch undergoes metrology verification via optical comparators and coordinate measuring machines (CMM), alongside application-specific testing: compression set per ASTM D395, fluid immersion per ISO 1817, and leakage rate validation. Client approval of physical samples and test reports is mandatory before tooling sign-off.

Mass Production & Quality Assurance

Full-scale production leverages multi-cavity molds with real-time cavity pressure monitoring and automated demolding. Statistical Process Control (SPC) charts track critical dimensions and physical properties hourly. Each production lot includes full material traceability from raw polymer to finished goods, with certificates of conformance detailing hardness, tensile strength, and compression set results. Final inspection employs AQL 1.0 sampling per ISO 2859, ensuring only defect-free O-rings meeting all client specifications ship from our ISO 9001:2015 certified facility. This end-to-end control guarantees consistent performance across volumes from 1,000 to 1,000,000+ units.

Contact Engineering Team

Contact Suzhou Baoshida for Custom Molded O-Rings – Precision Sealing Solutions Engineered to Perform

When it comes to high-performance sealing applications in demanding industrial environments, the quality, consistency, and precision of rubber components are non-negotiable. At Suzhou Baoshida Trading Co., Ltd., we specialize in the design, formulation, and manufacturing of custom molded O-rings tailored to meet exact OEM specifications and application requirements. Our engineering-led approach ensures that every seal we produce delivers optimal compression set resistance, thermal stability, chemical compatibility, and mechanical integrity across a broad range of operating conditions.

We understand that off-the-shelf solutions often fall short in critical applications. Whether you are working in automotive hydraulics, semiconductor processing, oil and gas exploration, or medical device manufacturing, our team collaborates directly with your engineers to develop O-rings that align precisely with your functional, regulatory, and environmental demands. From material selection and durometer optimization to custom tooling and volume production, Suzhou Baoshida provides end-to-end support with a commitment to dimensional accuracy and repeatability.

Our manufacturing process integrates advanced rubber compounding, precision molding technologies, and rigorous quality control protocols, including ISO 9001-compliant inspection and traceability systems. We work with a comprehensive range of elastomers, including Nitrile (NBR), EPDM, Silicone (VMQ), Fluorocarbon (FKM), Neoprene (CR), and specialty compounds such as FFKM and AEM for extreme environments.

To ensure seamless integration into your production workflow, we offer rapid prototyping, DFM analysis, and scalable production runs—from low-volume pilot batches to high-volume continuous supply. All custom O-rings are manufactured to meet or exceed international standards, including ASTM D2000, ISO 3601, and SAE AS568, with full material certification available upon request.

Below is a summary of key technical capabilities for custom molded O-rings at Suzhou Baoshida:

| Specification | Range / Capability |

|---|---|

| Inner Diameter (ID) | 3 mm to 500 mm |

| Cross Section (CS) | 1.0 mm to 12.0 mm |

| Hardness Range (Shore A) | 30 to 90 ±5 |

| Temperature Resistance | -60°C to +325°C (depending on compound) |

| Tolerance Grade | ISO 3302-1:2019, Class M1/M2 |

| Standard Materials | NBR, EPDM, FKM, VMQ, CR, ACM, AEM, FFKM |

| Custom Compounds | FDA, UL, NSF, MIL-SPEC, low outgassing, conductive, flame retardant |

| Production Volume | Prototype to 5 million units/month |

| Lead Time (Prototype) | 10–15 working days |

| Quality Standards | ISO 9001, RoHS, REACH compliant |

Partnering with Suzhou Baoshida means gaining access to a technical team deeply experienced in rubber science and industrial sealing challenges. We don’t just manufacture O-rings—we engineer reliable, long-term sealing performance.

For immediate assistance with your custom molded O-ring requirements, contact Mr. Boyce directly at [email protected]. He will coordinate technical evaluation, material recommendations, and quotation based on your drawings, samples, or performance criteria. Let us help you achieve leak-free, durable sealing solutions built to your exact needs.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).