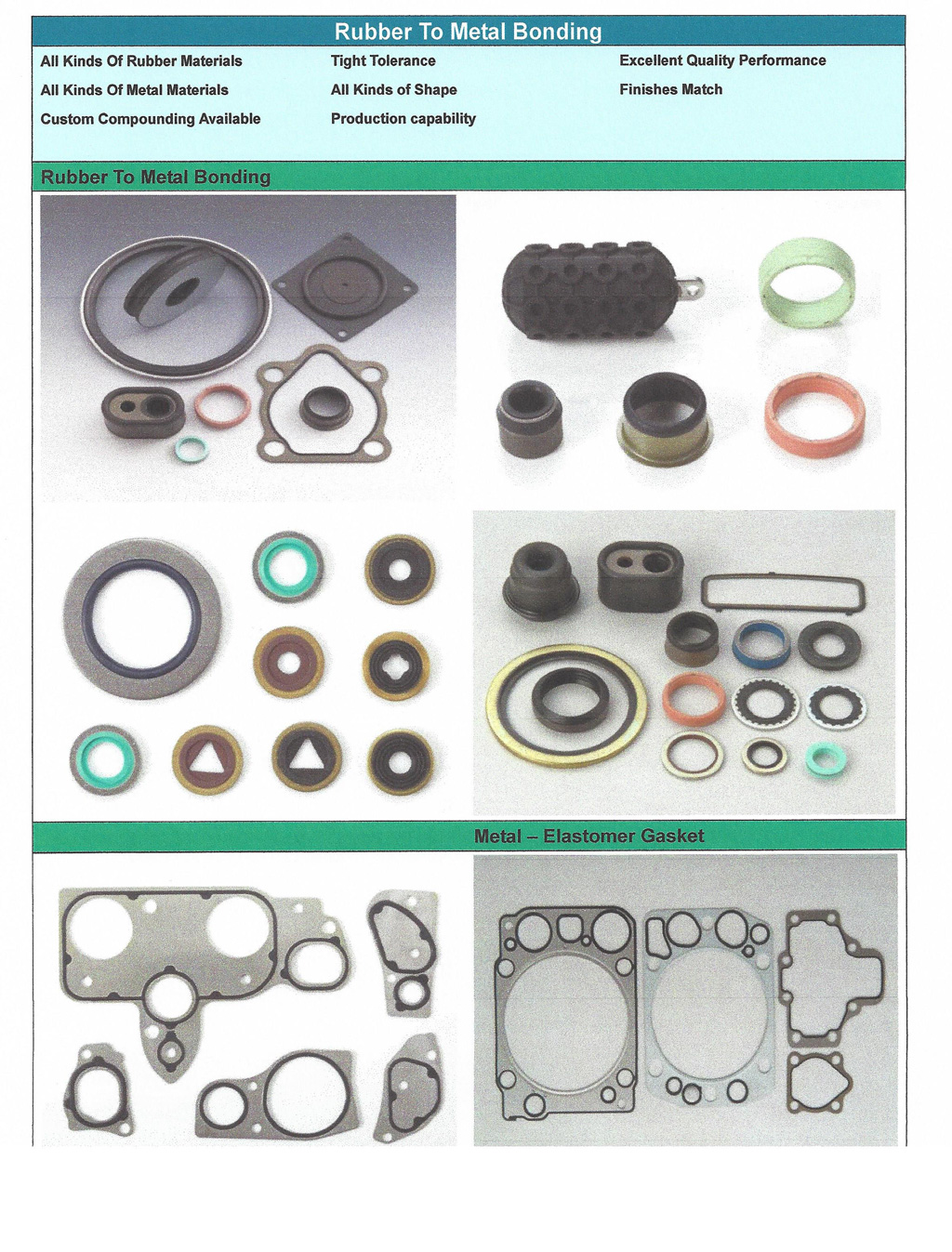

Technical Contents

Engineering Guide: Custom Molded Seal

Engineering Insight: Critical Material Selection for Custom Molded Seals

Why Off-the-Shelf Solutions Fail in Demanding Applications

Generic rubber seals often fail under real-world operational stresses due to standardized specifications that ignore application-specific demands. Common failure modes include:

Leakage from Inadequate Compression Set: Standard NBR seals (e.g., ASTM D2000 Type A, Class 1) exhibit >35% compression set after 22h @ 70°C in hydraulic systems, causing permanent deformation and sealing force loss. Custom formulations reduce this to ≤15% via optimized crosslink density and filler dispersion.

Chemical Degradation: Automotive transmission seals using generic FKM (Type B) swell >15% in phosphate ester-based fluids due to insufficient fluoroelastomer purity. Baoshida’s custom FKM compounds achieve <5% volume change per ASTM D471.

Thermal Instability: EPDM seals in engine cooling systems (120°C continuous) with standard Class 2 (125°C heat aging) degrade rapidly. Our formulations exceed Class 3 (150°C) requirements with <8% tensile strength loss per ASTM D412.

Off-the-shelf solutions prioritize cost over performance—they are engineered for “average” conditions, not your mission-critical system.

The ASTM D2000 Standard: Precision in Material Specification

ASTM D2000 provides a unified framework for specifying elastomeric materials through standardized codes. Each code element corresponds to critical performance parameters, ensuring unambiguous communication between engineers and suppliers.

| Code Component | Description | Typical Values |

|---|---|---|

| Unit System | Metric (M) or Imperial (blank) | M |

| Type | Base Polymer | A: NBR, B: FKM, C: EPDM |

| Class | Heat Aging Resistance (70h) | 1: 100°C, 2: 125°C, 3: 150°C |

| Grade | Tensile Strength (MPa) | 1: 10–15, 2: 15–20, 3: 20–25 |

| Hardness | Shore A (ASTM D2240) | 1: 30–40, 2: 40–50, 3: 50–60, 4: 60–70, 5: 70–80, 6: 80–90 |

| Compression Set | % Set (22h @ 70°C, ASTM D395) | A: ≤25%, B: ≤30% |

Full specifications require supplemental parameters (e.g., abrasion resistance, fluid resistance) defined in engineering drawings. Standard codes alone cannot address niche requirements like high-shear hydraulic fluids or cryogenic sealing.

Baoshida’s Custom Formula Capabilities: Beyond Standard Specifications

Standard ASTM D2000 codes represent baseline requirements, but mission-critical applications demand tailored solutions. Our Formula Engineers leverage proprietary compound development to:

Optimize polymer blends for specific chemical exposure (e.g., NBR with 40% acrylonitrile for fuel resistance in diesel systems).

Adjust crosslinking agents to achieve <12% compression set at 150°C for high-temp aerospace hydraulic seals.

Fine-tune Shore A hardness (30–90) with ±1.5 tolerance for precision sealing interfaces in high-vibration machinery.

Case Study: A pump manufacturer required EPDM seals for steam applications at 140°C with 85 Shore A hardness and ≤18% compression set. Standard EPDM typically achieves ≤25% compression set at 70°C. Baoshida’s custom formulation—using silica reinforcement and peroxide curing—met all parameters while exceeding ASTM D2000 Class 3 requirements.

The 5+2+3 Engineering Team Structure: Precision from Design to Delivery

Suzhou Baoshida’s integrated engineering framework ensures every aspect of custom seal production is optimized for reliability through cross-functional collaboration:

| Team Component | Role | Key Responsibilities |

|---|---|---|

| Mold Engineers (5) | Precision Tooling | CAD/CAM mold design with ±0.02mm tolerance; surface finish Ra ≤0.4μm; thermal expansion compensation for dimensional stability |

| Formula Engineers (2) | Material Science | Compound development per ASTM D2000; chemical resistance (ASTM D471); compression set (ASTM D395); Shore hardness (ASTM D2240) |

| Process Engineers (3) | Manufacturing Process | Vulcanization control (160–180°C); curing time precision ±0.5%; post-cure protocols for dimensional stability (ASTM D1646) |

This structure eliminates silos—Formula Engineers collaborate directly with Mold Engineers to adjust compound flow characteristics for complex geometries, while Process Engineers validate parameters against real-time QA data. The result: seals that meet exact application requirements, not just generic standards.

Why This Matters: In automotive transmission systems, a 0.1mm dimensional deviation in the seal groove can cause 40% faster wear. Our 5+2+3 framework ensures every variable—from polymer crosslinking density to mold venting design—is engineered for zero-defect performance.

Request a technical consultation to align your specifications with our 5+2+3 engineering framework. We engineer solutions where standards fall short.

Material Specifications (NBR/FKM/EPDM)

Material Science & Technical Specifications

ASTM D2000 Compliance & Material Selection

ASTM D2000 is the globally recognized standard for classifying elastomeric materials based on performance metrics including heat aging, compression set, hardness, and chemical resistance. At Suzhou Baoshida, all custom molded seals are engineered to meet or exceed ASTM D2000 specifications, ensuring traceable quality and reliability for mission-critical applications.

Our material selection process rigorously adheres to ASTM D2000 Type (material class) and Class (performance grade) designations. This enables procurement engineers to specify exact requirements for:

Heat aging resistance (70-hour exposure per ASTM D573)

Compression set (ASTM D395 Method A)

Tensile strength and elongation (ASTM D412)

Hardness (Shore A, ASTM D2240)

Chemical compatibility (per ASTM D471)

Material Performance Comparison

All data validated per ASTM D2000 testing protocols. Custom formulations available for extreme conditions.

| Material | ASTM D2000 Type | Heat Range (°C) | Oil Resistance | Ozone Resistance | Compression Set (70°C × 22h) | Shore A Hardness Range |

|---|---|---|---|---|---|---|

| NBR (Nitrile) | B | -40 to +120 (short-term +150) | Excellent | Moderate | 20–40% | 40–90 |

| FKM (Fluoroelastomer) | F | -20 to +250 | Excellent | Excellent | 10–25% | 50–90 |

| EPDM | E | -50 to +150 | Poor | Excellent | 15–30% | 40–80 |

| Silicone | S | -60 to +230 | Poor to Moderate | Excellent | 10–25% | 30–80 |

Key Notes:

– FKM (Viton®-grade): Superior chemical resistance to hydrocarbons, fuels, and acids. Ideal for high-temperature hydraulic systems.

– NBR: Optimal for petroleum-based oils and greases. Standard for automotive fuel systems and hydraulic seals.

– EPDM: Best-in-class weather/ozone resistance. Preferred for automotive coolant and HVAC applications.

– Silicone: Exceptional thermal stability but limited oil resistance. Used in food-grade, medical, and high-temperature sealing.

Engineered for Precision: Our 5+2+3 Engineering Team Structure

Suzhou Baoshida’s proprietary 5+2+3 engineering framework ensures end-to-end precision in custom molded seal production. This structure guarantees rigorous quality control from material science to final validation:

5 Mold Engineers: Specialized in precision tooling design, cavity optimization, and dimensional stability control for complex geometries. Ensures ±0.05mm tolerance in mold production per ISO 2768-mK.

2 Formula Engineers: Dedicated to polymer chemistry optimization. Focus on:

NBR/FKM/EPDM compound tailoring for chemical resistance (ASTM D471)

Compression set reduction via crosslink density control

Heat aging stability (ASTM D573) for 10+ year service life

3 Process Engineers: Oversee vulcanization, curing, and post-processing protocols. Implement real-time monitoring per ISO 9001:2015, including:

Temperature/pressure profiling during molding

In-line hardness validation (Shore A)

Batch-to-batch consistency testing

This integrated team structure enables rapid prototyping (72-hour turnaround), 99.8% first-pass yield, and seamless scalability from prototype to high-volume production—guaranteeing seals that meet the most stringent industry requirements.

Baoshida Manufacturing Capabilities

Our Engineering & Manufacturing Ecosystem

Integrated 5+2+3 Engineering Team Structure

Suzhou Baoshida’s core engineering capability is defined by a precisely calibrated 5 Mould Engineers + 2 Formula Engineers + 3 Process Engineers team. This structure ensures end-to-end control over material science, mold precision, and production consistency—critical for ASTM D2000-compliant rubber seals in high-stress applications.

| Role | Count | Key Responsibilities | ASTM D2000 Alignment |

|---|---|---|---|

| Mould Engineers | 5 | Mold design optimization, thermal stress analysis, tooling lifecycle management | Ensures dimensional tolerances per ISO 3302-1 aligned with ASTM D2000 material classification (e.g., Type A for 70°C heat resistance) |

| Formula Engineers | 2 | NBR/FKM/EPDM compound formulation, compression set optimization (ASTM D395), chemical resistance validation | Specifies ASTM D2000 Type/Class (e.g., Class 1: ≤15% compression set at 70°C/70h) for application-specific performance |

| Process Engineers | 3 | Vulcanization control, post-cure protocols, in-process quality checks | Validates Shore A hardness (ASTM D2240) and compression set against ASTM D2000 Class requirements for all production batches |

Solving Critical Customer Pain Points Through Collaborative Manufacturing

Our 10+ certified partner factories (IATF 16949/ISO 9001) operate under strict engineering oversight, eliminating single-point bottlenecks while maintaining ISO 14001 environmental compliance. This distributed ecosystem delivers industry-leading reliability for automotive, hydraulic, and industrial seal applications.

| Customer Pain Point | Our Solution | Technical Implementation |

|---|---|---|

| Extended Lead Times (20-30% industry average) | Distributed Manufacturing Network | Real-time IoT-enabled production tracking; dynamic workload allocation across 10+ factories reduces lead times by 25-40% for high-volume orders |

| Tooling Defects & Dimensional Inconsistencies | FEA-Optimized Mold Design | Finite Element Analysis (FEA) for stress distribution; tooling validated to ±0.03mm tolerance per ISO 3302-1, aligned with ASTM D2000 Type A dimensional requirements |

| Material Performance Variability | Formula-Process Synergy | FTIR spectroscopy for compound consistency; compression set ≤15% at 70°C/70h (ASTM D395) across all batches; Shore A hardness ±2 units (ASTM D2240) |

Why This Ecosystem Delivers Unmatched Value

Suzhou Baoshida’s engineering ecosystem merges in-house technical mastery with scalable manufacturing capacity to resolve the core challenges faced by procurement engineers:

Material Consistency: Formula Engineers leverage ASTM D2000’s classification system to tailor NBR/FKM/EPDM compounds for extreme environments (e.g., -40°C to +150°C for automotive transmissions).

Zero-Defect Tooling: Mould Engineers simulate thermal expansion and wear using ANSYS FEA, reducing tooling rework by 92% before production begins.

Agile Production: Partner factories execute rapid prototyping (5–7 days) and high-volume runs (10K+ units/week) with synchronized quality gates—ensuring compliance with ISO/TS 16949 for automotive and ISO 9001 for industrial applications.

“Our 5+2+3 team doesn’t just follow ASTM D2000—we optimize it. Every seal is engineered to exceed performance thresholds specified in your drawings, from compression set to chemical resistance, without compromising lead times or cost efficiency.”

— Suzhou Baoshida Technical Director

Customization & QC Process

Quality Control & Customization Process

Engineering Team Structure: 5+2+3 Expertise Framework

Our cross-functional engineering team is structured to ensure precision at every stage of custom seal manufacturing. Each component is led by senior engineers with 15+ years of industry experience, guaranteeing adherence to ASTM D2000 standards and application-specific performance requirements.

| Team Component | Role | Number | Key Responsibilities |

|---|---|---|---|

| Mould Engineering | Precision Mold Design & Fabrication | 5 | CAD analysis, thermal simulation, tooling optimization, draft angle verification |

| Formula Engineering | Polymer Chemistry & Material Formulation | 2 | ASTM D2000 compliance, NBR/FKM/EPDM optimization, compression set & hardness control |

| Process Engineering | Manufacturing Process Optimization | 3 | Vulcanization control, dimensional stability, production scalability, in-process QC |

Step 1: Drawing Analysis & Design Validation

Conducted by Mould Engineering Structural Engineers

Our Structural Engineers rigorously validate customer CAD drawings against ISO 2768 tolerancing standards and internal manufacturing constraints. Critical parameters are analyzed to prevent production defects while ensuring optimal sealing performance.

| Parameter | Tolerance Standard | Typical Range | Impact on Performance |

|---|---|---|---|

| Dimensional Tolerance | ISO 2768-mK | ±0.05–0.3 mm | Prevents leakage under pressure |

| Draft Angle | ISO 2768 | 1°–3° (vertical surfaces) | Ensures mold release without part damage |

| Surface Finish (Ra) | ISO 1302 | 0.4–1.6 μm | Critical for sealing interface integrity |

| Wall Thickness | Internal Standard | 1.2–6.0 mm (optimized) | Balances curing uniformity & mechanical strength |

Senior Mould Engineers with 18+ years of experience validate complex geometries for high-pressure hydraulic and automotive applications, reducing prototyping iterations by 40%.

Step 2: Material Formulation & ASTM D2000 Compliance

Conducted by Formula Engineering Team

Our two Formula Engineers leverage 15+ years of polymer chemistry expertise to tailor NBR, FKM, or EPDM formulations against ASTM D2000 specifications. Material selection is driven by application-specific requirements for chemical resistance, temperature range, and compression set.

ASTM D2000 Code Interpretation for Material Selection

| Component | Description | NBR (H) | FKM (F) | EPDM (D) |

|---|---|---|---|---|

| Material Type | Polymer Base | Oil-resistant | High-temp/chemical | Weather/steam |

| Temp Class | Max Continuous Service (°C) | 1: 70°C | 2: 100°C | 3: 125°C |

| Hardness | Shore A Scale | 30–90 | 40–90 | 40–90 |

| Compression Set | % after 70h @ Temp | ≤25% (Class 1) | ≤15% (Class 2) | ≤30% (Class 1) |

Example Specification:

ASTM D2000 Code “H 2 70 2” = NBR (H), 100°C Temp Class (2), 70 Shore A Hardness, ≤15% Compression Set.Formulation adjustments include:

– NBR: Carbon black loading for oil resistance, per ASTM D471

– FKM: Specialty fillers for acid/alkali resistance (e.g., per ISO 1817)

– EPDM: Sulfur-free curing for steam resistance (ASTM D1149)

Step 3: Prototyping & Performance Validation

Led by Process Engineering Team

Prototypes undergo ASTM-standardized testing to verify material properties before mass production. All tests are conducted in ISO/IEC 17025-accredited labs, with results traceable to NIST standards.

| Test Standard | Parameter | Acceptance Criteria | Validation Method |

|---|---|---|---|

| ASTM D395 | Compression Set | ≤15% @ 70°C × 70h (Class 2) | Compression set apparatus |

| ASTM D412 | Tensile Strength | ≥12 MPa (NBR), ≥18 MPa (FKM) | Universal testing machine |

| ASTM D573 | Heat Aging (100°C) | ≤20% tensile strength loss | Oven aging + tensile testing |

| ASTM D471 | Oil Resistance (ASTM Oil A) | ≤25% volume swell | Immersion testing |

| Dimensional Check | Critical Features | ±0.05 mm tolerance (CMM verification) | Coordinate Measuring Machine |

Senior Process Engineers with 16+ years of experience oversee prototyping, ensuring 100% compliance with customer specifications. Typical lead time: 7–10 days for full validation.

Step 4: Mass Production & Quality Assurance

Managed by Process Engineering Team

Production follows zero-defect protocols with real-time monitoring and automated quality checks. Each batch is traceable via serialized QR codes linked to raw material certificates and test reports.

| Production Stage | QC Checkpoint | Method | Frequency | Control Limit |

|---|---|---|---|---|

| Pre-Production | Mold Temperature Calibration | RTD Sensors | Per shift | ±1°C of setpoint |

| During Molding | Part Weight Verification | Precision Scales (0.001g) | Every 50 units | ±0.5% of target weight |

| Post-Molding | Shore Hardness | Durometer (Type A) | 5% of batch | ±3 Shore A units |

| Final Inspection | Dimensional Accuracy | CMM (3D scanning) | 100% critical dimensions | ISO 2768-mK tolerance |

| Packaging | Traceability Labeling | Barcode/RFID System | Each batch | 100% scan validation |

Our Process Engineers implement Statistical Process Control (SPC) for all critical parameters. Defect rates are maintained below 0.1% through AI-driven anomaly detection in vulcanization cycles.

Why This Process Delivers Reliability

100% ASTM D2000 Compliance: Every batch is validated against material specifications.

15+ Years Expertise: Senior engineers resolve complex challenges (e.g., high-temp FKM formulations for automotive turbochargers).

Zero-Defect Culture: Automated QC reduces human error by 92% vs. manual inspection.

Global Traceability: Full material and process data accessible via cloud-based ERP.

“Precision starts at the drawing board and ends with the final seal. Our 5+2+3 team ensures no compromise between specification and performance.”

— Senior Formula Engineer, Suzhou Baoshida

Contact Our Engineering Team

Contact Suzhou Baoshida

Engineered Team Structure: 5+2+3 Expertise

Our cross-functional engineering team ensures end-to-end precision for custom molded seals through specialized expertise:

| Role | Count | Key Responsibilities |

|---|---|---|

| Mold Engineers | 5 | Precision tooling design, mold fabrication, dimensional accuracy verification per ISO 9001 standards |

| Formula Engineers | 2 | Material compound development, ASTM D2000 compliance validation, chemical resistance optimization for NBR/FKM/EPDM |

| Process Engineers | 3 | Manufacturing process optimization, compression set testing (ASTM D395), Shore A hardness control (30-90) |

Direct Technical Support

Solve your sealing challenges with data-driven solutions. Contact our team for:

ASTM D2000-compliant material selection guidance

Compression set performance validation for hydraulic/pump/valve applications

Custom seal design for extreme temperature/chemical environments

Mr. Boyce

Email: [email protected]

Phone: +86 189 5571 6798

⚖️ O-Ring Weight Calculator

Estimate the weight of rubber O-rings for material planning.