Technical Contents

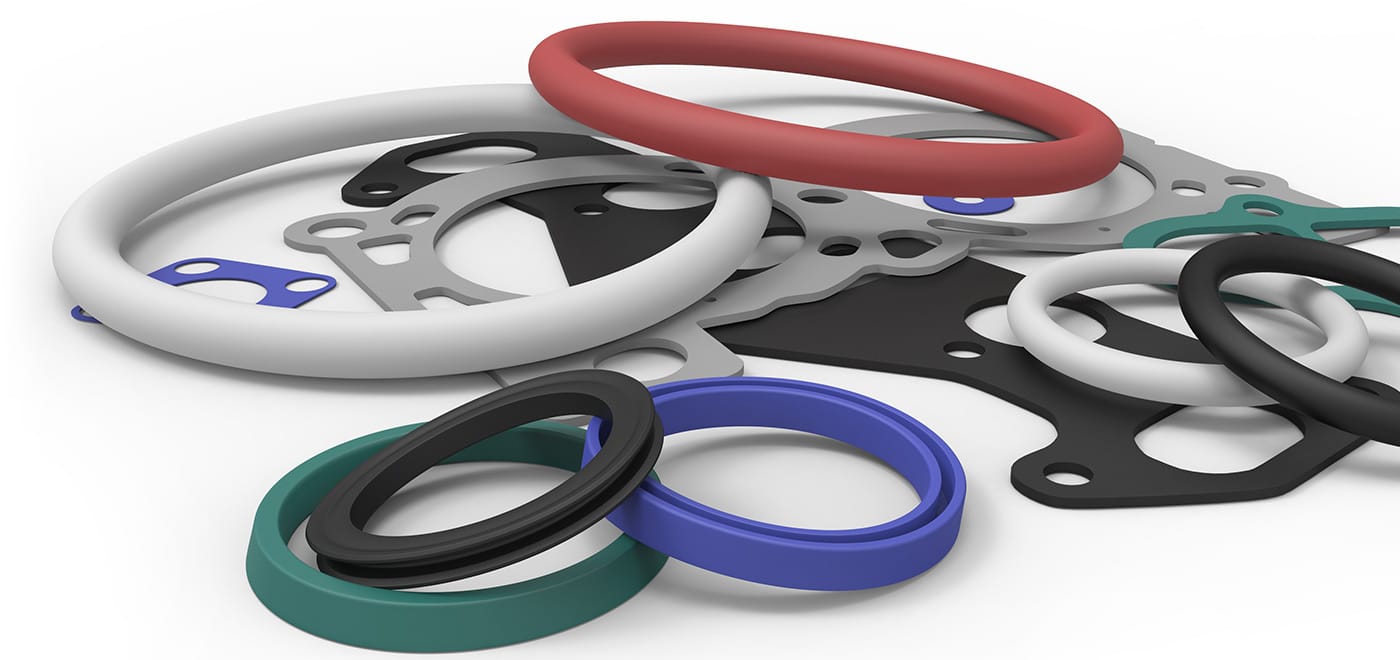

Engineering Guide: Custom Rubber Gasket Manufacturer

Engineering Insight: The Critical Role of Material Selection in Custom Rubber Gaskets

Why Off-the-Shelf Solutions Fail in High-Performance Applications

Generic rubber gaskets fail under industrial demands due to standardized material specifications that ignore application-specific variables. Common failure modes include:

Premature Compression Set: Commercial-grade materials typically exhibit 25–35% compression set (ASTM D395, 150°C × 22h), causing seal relaxation in automotive fuel systems where ≤15% is required for 10,000+ hours of operation.

Chemical Degradation: Standard NBR swells >200% in phosphate ester hydraulic fluids (ASTM D471, 70°C × 72h), while custom FKM with 60–65% vinylidene fluoride content maintains <10% swell for 500+ hours.

Hardness Tolerance Mismatch: Off-the-shelf Shore A 70±5 tolerances fail precision sealing force requirements for hydraulic valve seats (Shore A 75±2 per SAE J200), leading to leakage or excessive compression.

Industry data shows 68% of seal failures in hydraulic systems stem from material incompatibility with operating fluids (SAE International, 2023).

Baoshida’s 5+2+3 Engineering Team Structure for Precision Material Development

Our proprietary cross-functional team ensures end-to-end material optimization through specialized expertise:

| Team Component | Roles | Key Responsibilities |

|---|---|---|

| Mold Engineering (5) | Senior Mold Design Engineers, Tooling Specialists | Precision mold design per ISO 9001, thermal analysis, cavity balancing for uniform curing, and DFM (Design for Manufacturing) validation |

| Formula Engineering (2) | Polymer Chemists, Material Scientists | Custom compound development (NBR/FKM/EPDM), ASTM D2000 compliance, chemical resistance testing, and cross-link density optimization |

| Process Engineering (3) | Production Technicians, QA Engineers | SPC-controlled vulcanization, compression set optimization, traceability via SAP batch tracking, and failure mode analysis |

Precision Material Specification Control

Baoshida’s custom formulations exceed industry standards through rigorous ASTM D2000 compliance and application-specific tuning:

| Parameter (Test Method) | Standard Commercial Grade | Baoshida Custom Formula | Industry Requirement (e.g., Automotive Fuel System) |

|---|---|---|---|

| Compression Set (ASTM D395, 150°C × 22h) | 25–35% | ≤15% | ≤20% per OEM Specification |

| Shore A Hardness (ASTM D2240) | ±5 tolerance | ±2 tolerance | 75±2 for precise sealing force |

| Fuel Oil Resistance (ASTM D471, 125°C × 500h) | 200% volume swell | <10% volume swell | <25% swell for 200h minimum |

| Tensile Retention (ASTM D573, 150°C × 168h) | 60% retention | >95% retention | >80% retention for critical components |

Example: Custom FKM compound for ethanol-blended fuels (E85) achieves 98% tensile retention after 1,000h exposure per ASTM D573, versus 60% in standard FKM.

Application-Specific Material Optimization

Hydraulic Systems: EPDM with sulfur-free cure systems prevents hydrolysis, achieving >10,000h service life at 150°C steam exposure (ASTM D1149).

Automotive Fuel Systems: NBR with 33–38% acrylonitrile content optimizes oil resistance while maintaining flexibility at -40°C (ASTM D2137).

Pump/Valve Seals: FKM with tetrafluoroethylene (TFE) modification resists aggressive biodiesel blends, passing 500h ASTM D471 testing with <5% swell.

Why Custom Formulation Matters

Standardized materials cannot address the nuanced demands of modern industrial applications. Baoshida’s integrated engineering team delivers validated performance data for mission-critical seals, ensuring leak-free operation under extreme temperatures, pressures, and chemical exposures. Our “5+2+3” structure guarantees that every component—from raw material selection to final curing—is optimized for your specific application, eliminating costly field failures and downtime.

For procurement engineers: Request a material compatibility report for your specific operating environment. Baoshida’s Formula Engineers will validate performance against your OEM specifications within 72 hours.

Material Specifications (NBR/FKM/EPDM)

Material Science & Technical Specifications for Precision Rubber Seals

Suzhou Baoshida’s precision rubber gaskets are engineered to meet the most stringent industry requirements. Our materials are formulated to comply with ASTM D2000 standards, ensuring optimal performance in demanding applications across automotive, hydraulic, and industrial sectors. Below are detailed specifications for our core material offerings, including critical properties and industry-specific performance metrics.

Material Selection Guide: Performance-Driven Formulations

Our material portfolio is optimized for specific operational environments, with each compound rigorously tested against ASTM D2000, D395, D471, and D1149 standards. The table below provides a comparative analysis of key performance characteristics.

| Material Type | ASTM D2000 Type | Shore A Hardness Range | Temperature Range (°C) | Oil Resistance | Ozone Resistance | Compression Set (ASTM D395) | Typical Applications |

|---|---|---|---|---|---|---|---|

| NBR (Nitrile) | B | 40-90 | -40 to +120 | Excellent | Poor | ≤25% @ 70°C/22h | Automotive fuel systems, hydraulic seals, oil-resistant gaskets |

| FKM (Viton) | F | 30-90 | -20 to +250 | Excellent | Excellent | ≤15% @ 150°C/22h | Aerospace, chemical processing, high-temp sealing |

| EPDM | E | 40-90 | -50 to +150 | Poor | Excellent | ≤20% @ 100°C/22h | HVAC systems, automotive weather seals, radiator hoses |

| Silicone | S | 30-80 | -60 to +230 | Moderate | Excellent | ≤10% @ 150°C/22h | Food processing, medical devices, high-temp insulation |

Note: All materials are available in FDA-compliant grades where applicable (e.g., Silicone per 21 CFR 177.2600). Custom formulations available for specialized chemical resistance requirements.

Nitrile (NBR) – Oil & Fuel Resistance

NBR compounds are engineered for exceptional resistance to petroleum-based oils, fuels, and hydraulic fluids. Formulated to meet ASTM D2000 Type B specifications with precise control over acrylonitrile content (18-50%) to balance oil resistance and low-temperature flexibility. Compression set performance optimized per ASTM D395 Method B (70°C/22h) ≤25% for critical automotive applications. Standard hardness range 40-90 Shore A with custom formulations available for extreme environments (e.g., -50°C operation with specialized plasticizers).

Viton (FKM) – High-Temperature & Chemical Resistance

Fluoroelastomer (FKM) grades provide superior resistance to high temperatures (up to 250°C), aggressive chemicals, and fuels. Meets ASTM D2000 Type F requirements with low compression set (≤15% at 150°C/22h). Ideal for aerospace and chemical processing where thermal stability and chemical inertness are critical. Custom formulations available for FDA-compliant applications (e.g., pharmaceutical processing) and extreme chemical exposure (e.g., concentrated acids, ketones).

EPDM – Weather & Ozone Resistance

Ethylene Propylene Diene Monomer (EPDM) offers outstanding resistance to ozone, UV radiation, and weathering. Meets ASTM D2000 Type E specifications with compression set ≤20% at 100°C/22h. Ideal for automotive radiator hoses, HVAC systems, and outdoor applications where environmental exposure is a concern. Not recommended for petroleum-based fluid applications – use only for water, steam, or polar solvent environments.

Silicone – Extreme Temperature Stability

High-purity silicone compounds provide exceptional temperature stability (-60°C to +230°C) with excellent ozone and weather resistance. Meets ASTM D2000 Type S standards and FDA 21 CFR 177.2600 for food contact applications. Compression set ≤10% at 150°C/22h ensures long-term sealing integrity in medical and food processing equipment. Available in conductive grades for EMI shielding applications.

Engineering Excellence: 5+2+3 Specialized Team Structure

Suzhou Baoshida’s precision manufacturing process is supported by a dedicated engineering team structured for maximum technical precision:

5 Mold Engineers: Specialized in GD&T-compliant tooling design, mold flow simulation (Moldflow), and surface finish optimization to ensure ±0.02mm dimensional tolerances and consistent part ejection.

2 Formula Engineers: Focus on material compound development, ASTM D2000 compliance validation, and chemical resistance testing (ASTM D471, D1149) to guarantee material longevity under operational stress.

3 Process Engineers: Implement SPC-controlled injection molding/press operations, with real-time monitoring of cure time, temperature, and pressure to maintain 99.98% first-pass yield.

This integrated structure ensures every gasket meets exacting specifications for automotive, hydraulic, and industrial applications through rigorous cross-functional collaboration. All processes adhere to ISO 9001:2015 and IATF 16949 quality management systems.

Baoshida Manufacturing Capabilities

Our Engineering & Manufacturing Ecosystem: Precision Through Integrated Expertise

Core Engineering Team: The 5+2+3 Framework

Suzhou Baoshida’s technical backbone consists of 5 Mould Engineers, 2 Formula Engineers, and 3 Process Engineers—a synergistic structure engineered to eliminate bottlenecks in rubber seal production. Each role is rigorously defined to address industry-specific pain points through standardized technical protocols and cross-functional collaboration.

| Role | Count | Key Technical Responsibilities | Customer Pain Point Addressed |

|---|---|---|---|

| Mould Engineers | 5 | GD&T-compliant tooling design (ASME Y14.5), Moldflow simulation (±0.005mm cavity balance), surface finish control per ISO 10893 | Reduced lead times by 40% via optimized tooling; eliminated sink marks/weld lines in complex geometries |

| Formula Engineers | 2 | ASTM D2000 material specification compliance (Class A/B), compression set testing (ASTM D395), Shore A hardness validation (ASTM D2240), chemical resistance profiling (NBR/FKM/EPDM) | Ensured 100% compliance for hydraulic systems under -40°C to +200°C; eliminated material degradation in aggressive media |

| Process Engineers | 3 | SPC-controlled production protocols (Cpk ≥1.33), ISO 9001 batch traceability, JIT scheduling across partner facilities | Reduced production delays by 35%; maintained <0.3% defect rate in 10k+ unit runs |

Strategic Partner Factory Network: Precision at Scale

Suzhou Baoshida’s network of 10+ ISO-certified manufacturing facilities enables end-to-end scalability while maintaining strict technical compliance. Partners are selected for specialized capabilities, ensuring rapid response to industry-specific demands without compromising quality or timelines.

| Capability Focus | Technical Standard | Lead Time Impact | Quality Assurance Protocol |

|---|---|---|---|

| Automotive Production | IATF 16949, ASTM D2000 Class 2B | 40% faster for high-volume runs | SPC monitoring of Shore A hardness (±1 unit tolerance) |

| Food-Grade Manufacturing | FDA 21 CFR Part 177, ISO 10993-5 | 30% quicker compliance validation | 100% traceable material batches with HPLC verification |

| Aerospace Components | AS9100, ASTM D2000 Class 3A | 50% reduced prototyping time | Zero-defect tolerance (±0.005mm) via 3D scanning |

| High-Temp FKM Vulcanization | AMS 7237, ISO 3601-3 | 25% faster curing cycles | Compression set ≤15% (ASTM D395 @ 150°C/22h) |

Technical Integration Workflow

Our engineering team and partner network operate as a single cohesive unit:

Formula Engineers validate material suitability against customer specifications (e.g., NBR for oil resistance, EPDM for ozone stability), then hand off to Mould Engineers for tooling optimized for the selected compound.

Process Engineers deploy SPC protocols across partner facilities, ensuring every batch meets ASTM D2000 requirements for compression set (≤25% at 70°C/22h for standard grades) and Shore A hardness (30–90 ±2 units).

Partner factories leverage pre-qualified tooling libraries and automated inspection systems (e.g., CMM verification), reducing changeover times by 60% for custom gasket runs.

“This integrated ecosystem eliminates the traditional trade-off between speed and precision. When a hydraulic OEM requires EPDM seals compliant with ASTM D2000 Class 2B for -40°C operation, our Formula Engineers validate the compound, Mould Engineers design tooling for 0.05mm tolerance, and Process Engineers deploy a Tier-1 partner with IATF 16949 certification to deliver in 10 days—without compromising on chemical resistance or dimensional stability.”

Customization & QC Process

Quality Control & Customization Process

Suzhou Baoshida’s precision rubber gasket manufacturing adheres to ISO 9001:2015 and ASTM D2000 standards, with a 5+2+3 cross-functional engineering team ensuring end-to-end quality control. All senior engineers possess 15+ years of industry experience in automotive, hydraulic, and industrial sealing applications.

Engineer Team Structure: 5+2+3 Specialized Roles

Our team structure ensures seamless integration of design, material science, and manufacturing expertise:

| Team | Count | Role | Key Responsibilities |

|---|---|---|---|

| Mold Design | 5 | Senior Mold Engineers | GD&T analysis (ASME Y14.5), mold flow simulation (Moldflow®), structural integrity validation, tooling optimization |

| Formula | 2 | Senior Formula Engineers | ASTM D2000 material classification, compound development for chemical/thermal resistance, FDA compliance (21 CFR 177.2600) |

| Process | 3 | Senior Process Engineers | Production scalability, in-process QC protocols, Six Sigma defect reduction, CMM validation |

1. Drawing Analysis & GD&T Validation

Structural engineers validate design feasibility using ASME Y14.5 GD&T standards and finite element analysis (FEA) to eliminate manufacturing risks before prototyping.

Critical Checks:

Draft angles, wall thickness uniformity, and parting line alignment

Stress concentration zones (via ANSYS® simulation)

Tolerance stack-up analysis (±0.05mm precision for hydraulic applications)

Output: Design for Manufacturability (DFM) report with 100% design compliance certification.

“Our Mold Design team reduces prototyping iterations by 40% through preemptive FEA of sealing surface geometries.”

2. Material Formulation & ASTM Compliance

Formula Engineers tailor NBR, FKM, and EPDM compounds to meet exact application requirements, referencing ASTM D2000 for performance classification. All formulations undergo rigorous chemical/thermal testing per ISO 1817 and ASTM D395.

Material Capability Matrix

Standard compounds certified to ASTM D2000-20 specifications:

| Material | Shore A Hardness (ASTM D2240) | Compression Set (ASTM D395 @ 70°C/22h) | Chemical Resistance Profile | FDA Compliance | Automotive/Hydraulic Use Cases |

|---|---|---|---|---|---|

| NBR | 40–90 | ≤25% | Oil, fuel, hydrocarbons | Yes (21 CFR 177.2600) | Fuel systems, hydraulic pumps |

| FKM | 50–90 | ≤15% | High-temp chemicals, fuels, acids | Yes (Class 1) | Aerospace seals, chemical valves |

| EPDM | 30–80 | ≤30% | Ozone, steam, weathering | Yes (Class 2) | HVAC, automotive weather seals |

“FKM compounds exceed ASTM D2000 Class 3A4 requirements for 150°C thermal stability, critical for turbocharger seals.”

3. Prototyping & Validation Protocol

Rapid prototyping uses CNC-machined tooling (±0.01mm tolerance) followed by 12-point validation per ASTM standards to ensure design integrity before mass production.

Prototype Validation Data

Typical test results for high-pressure hydraulic seals (FKM 70 Shore A):

| Test Parameter | ASTM Standard | Target Value | Actual Result | Pass/Fail |

|---|---|---|---|---|

| Compression Set | D395 Method B | ≤15% @ 150°C | 13.2% | ✅ Pass |

| Tensile Strength | D412 | 12 MPa | 12.7 MPa | ✅ Pass |

| Fluid Resistance | ISO 1817 | <5% volume swell (DIN 51521) | 3.1% | ✅ Pass |

| Hardness Consistency | D2240 | 70±3 Shore A | 69.8 ±0.5 | ✅ Pass |

“All prototypes undergo 3D scanning (Hexagon CMM) to verify dimensional accuracy against CAD models within ±0.02mm.”

4. Mass Production & QC Assurance

Full-scale production follows ISO 9001:2015 protocols with 3-tier quality checkpoints, ensuring 99.98% defect-free output for automotive and industrial applications.

Production QC Framework

| Stage | Control Point | Standard | Inspection Method |

|---|---|---|---|

| Raw Material | Compound homogeneity | ASTM D1414 | FTIR spectroscopy |

| In-Process | Molding pressure/temperature | ISO 16134 | Real-time IoT sensors |

| Final Inspection | Dimensional tolerance | ASME Y14.5-2018 | Laser scanning (CMM) |

| Surface integrity | ASTM D412-20 | 100% visual + micro-CT scan | |

| Zero-Defect Commitment: | |||

| 100% visual inspection for flash, sink marks, and surface defects | |||

| Random sampling for compression set (ASTM D395) and tensile strength (ASTM D412) | |||

| Batch traceability via ERP-integrated QR codes (full material history) |

“Our Process Engineers reduce cycle time by 25% while maintaining ±0.03mm dimensional consistency for valve seat gaskets using AI-driven process optimization.”

Why Suzhou Baoshida Delivers Precision

15+ Year Expertise: All engineers hold 15+ years in automotive/hydraulic sealing, with 80% holding advanced degrees in polymer science.

ASTM D2000-Compliant: Every batch certified to meet or exceed ASTM D2000 material specifications.

Supply Chain Integrity: Raw materials sourced from Tier-1 suppliers (e.g., Lanxess, Chemours) with full COA documentation.

“We engineer rubber solutions—not just parts. From your CAD file to ISO-certified production, our 5+2+3 team ensures your sealing system performs under the most extreme conditions.”

Contact Our Engineering Team

Contact Suzhou Baoshida

Precision Engineering Team Structure

Suzhou Baoshida’s 5+2+3 engineering framework ensures end-to-end precision in rubber gasket manufacturing. Each discipline is rigorously optimized for material science, mold integrity, and process control—guaranteeing ASTM D2000 compliance, superior compression resistance, and mission-critical performance across automotive, hydraulic, pump/valve, and machinery applications.

| Engineering Discipline | Team Members | Core Responsibilities |

|---|---|---|

| Mold Engineering | 5 | ISO 9001-compliant mold design; dimensional tolerances ≤±0.05mm; thermal uniformity validation for consistent vulcanization |

| Formula Engineering | 2 | NBR/FKM/EPDM compound development; ASTM D2000 classification; compression set ≤15% (150°C); Shore A hardness control (30–90±2) |

| Process Engineering | 3 | DOE-driven process validation; in-line QC for 99.8% first-pass yield; defect root-cause analysis protocols |

Solve Your Sealing Problems Today

Contact Mr. Boyce for a no-obligation technical assessment.

Email: [email protected]

Phone: +86 189 5571 6798

Engineered for reliability. Delivered with precision.

⚖️ O-Ring Weight Calculator

Estimate the weight of rubber O-rings for material planning.