Technical Contents

Engineering Guide: Delkor Systems – Headquarters

Engineering Insight: Material Selection in Industrial Rubber Applications

In industrial environments, the performance of rubber components is not solely determined by design or manufacturing precision—material selection is the cornerstone of reliability and longevity. At Suzhou Baoshida Trading Co., Ltd., we emphasize that off-the-shelf rubber solutions often fail under real-world operational stress because they are engineered for generality, not specificity. Standard formulations may meet baseline requirements in controlled conditions but falter when exposed to dynamic variables such as temperature extremes, chemical exposure, mechanical fatigue, or abrasive wear.

The failure of generic rubber components typically stems from mismatched elastomer properties. For example, a standard nitrile (NBR) seal may suffice in light-duty hydraulic systems but will degrade rapidly in high-temperature environments exceeding 120°C or when exposed to aggressive oils and solvents. Similarly, ethylene propylene diene monomer (EPDM), while excellent for ozone and weather resistance, lacks compatibility with hydrocarbon-based fluids, leading to swelling and loss of mechanical integrity.

Delkor Systems – Headquarters operates within demanding sectors including mining, mineral processing, and heavy industrial automation, where equipment downtime carries significant financial consequences. In such contexts, the rubber components interfacing with slurry pumps, vibratory screens, and sealing systems must be tailored to the exact chemical, thermal, and mechanical profile of the application. A one-size-fits-all approach compromises efficiency, safety, and total cost of ownership.

Custom material formulation allows for optimization of key performance indicators such as tensile strength, elongation at break, compression set, and abrasion resistance. By analyzing the operational environment—fluid media, temperature range, pressure cycles, and dynamic loading—we engineer compounds that deliver sustained performance. For instance, hydrogenated nitrile (HNBR) offers superior thermal stability and mechanical strength for high-speed rotary seals, while fluorocarbon (FKM) provides unmatched resistance to aromatic hydrocarbons and high-temperature degradation.

The following table illustrates comparative performance characteristics of common industrial elastomers relevant to Delkor Systems’ operational demands:

| Material | Temperature Range (°C) | Fluid Resistance | Abrasion Resistance | Compression Set | Typical Use Case |

|---|---|---|---|---|---|

| NBR | -30 to +120 | Good (oils, water) | Moderate | Moderate | Hydraulic seals, O-rings |

| HNBR | -40 to +150 | Excellent | High | Low | High-performance seals, mining pumps |

| FKM | -20 to +200 | Exceptional | Moderate | Low | Chemical exposure seals |

| EPDM | -50 to +150 | Poor (hydrocarbons) | Low | Low | Weather seals, water systems |

| Natural Rubber | -50 to +80 | Poor | Very High | High | High-abrasion liners |

Material selection is not a secondary consideration—it is a primary engineering decision. Suzhou Baoshida Trading Co., Ltd. partners with Delkor Systems to ensure that every rubber component is engineered for mission-critical performance, avoiding the hidden costs of premature failure. Through precise material science and application-specific design, we deliver solutions that outperform, outlast, and optimize industrial operations.

Material Specifications

Material Specifications for Critical Sealing Applications

Suzhou Baoshida Trading Co., Ltd. provides engineered rubber solutions tailored to the rigorous demands of industrial OEM partners like Delkor Systems. As your dedicated Rubber Formula Engineer and OEM Manager, we emphasize precise material selection to ensure longevity, safety, and operational efficiency in fluid handling systems. This section details three core elastomers—Viton (FKM), Nitrile (NBR), and Silicone (VMQ)—validated against ASTM D2000 standards and optimized for performance in dynamic sealing environments.

Viton fluoroelastomers deliver exceptional resistance to aggressive chemicals, including hydrocarbons, acids, and high-temperature steam. Operating effectively from -20°C to 230°C, Viton maintains integrity in fuel injection systems, chemical processing valves, and aerospace hydraulic seals where exposure to jet fuels or synthetic lubricants occurs. Its molecular stability minimizes swelling in aromatic solvents, though cost considerations necessitate strategic deployment in critical zones. Mechanical properties include 70–90 Shore A hardness and tensile strength of 15–20 MPa, with compression set resistance below 25% after 70 hours at 200°C.

Nitrile butadiene rubber remains the industry benchmark for cost-sensitive applications involving petroleum derivatives. With a functional range of -40°C to 120°C (extended to 150°C for peroxide-cured variants), NBR excels in hydraulic O-rings, pump seals, and fuel line gaskets. It withstands mineral oils, greases, and water-based fluids but degrades in ozone-rich or chlorinated solvent environments. Typical formulations achieve 50–90 Shore A hardness, 10–25 MPa tensile strength, and compression set values of 15–30% after 70 hours at 100°C. Its abrasion resistance and low compression set under oil immersion make it ideal for mobile equipment seals.

Silicone rubber offers unparalleled thermal stability from -60°C to 200°C, with specialty grades enduring brief excursions to 300°C. Preferred for food, pharmaceutical, and high-purity fluid systems, it resists water, ozone, and UV radiation but exhibits poor resistance to petroleum oils and low tensile strength (5–12 MPa). Silicone’s biocompatibility and electrical insulation properties suit it for diaphragm pumps, medical device seals, and semiconductor manufacturing components. Hardness typically ranges from 30–80 Shore A, though tear strength remains a limitation requiring careful design compensation.

The comparative analysis below summarizes critical performance parameters for informed material selection:

| Material | Temperature Range (°C) | Key Resistances | Primary Limitations | Typical Applications |

|---|---|---|---|---|

| Viton (FKM) | -20 to 230 | Hydrocarbons, acids, steam, ozone | Poor ketone/amine resistance; high cost | Fuel systems, chemical valves, aerospace seals |

| Nitrile (NBR) | -40 to 120 (150) | Petroleum oils, water, alcohols | Poor ozone/weathering resistance | Hydraulic seals, automotive gaskets, industrial pumps |

| Silicone (VMQ) | -60 to 200 (300) | Water, ozone, UV, biocompatibility | Poor oil/fuel resistance; low tear strength | Medical devices, food processing, high-temp diaphragms |

Material selection must balance chemical exposure, thermal profiles, mechanical loads, and lifecycle costs. Suzhou Baoshida’s OEM partnership includes application-specific compound customization, rigorous batch traceability, and ASTM-compliant validation testing. We recommend Viton for extreme chemical resilience, NBR for cost-effective oil sealing, and Silicone for thermal stability in non-hydrocarbon environments. Contact our engineering team to optimize your sealing solution for Delkor Systems’ operational requirements.

Manufacturing Capabilities

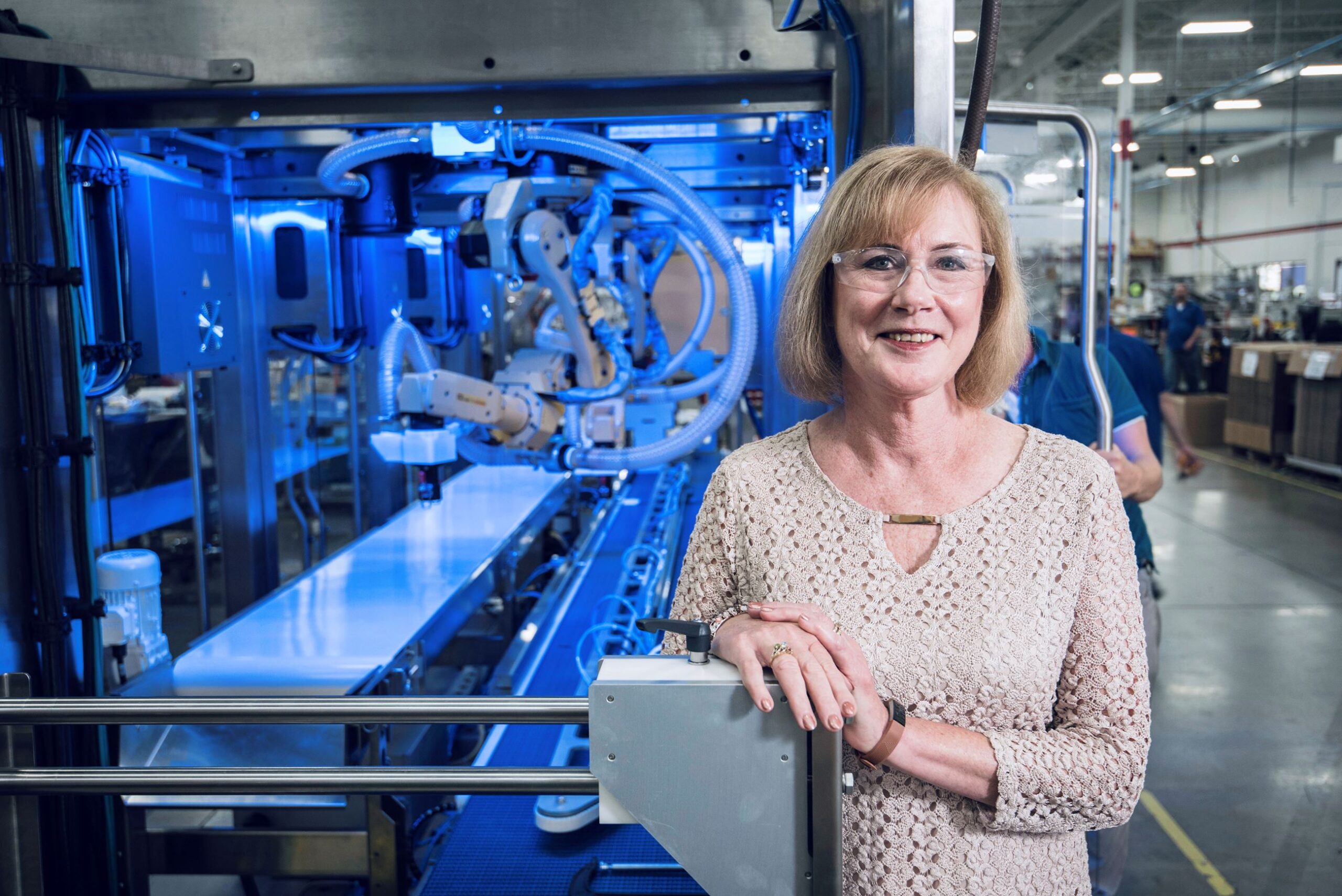

Suzhou Baoshida Trading Co., Ltd. delivers precision-engineered rubber solutions tailored for industrial OEM applications. Our Engineering Capability forms the core of our value proposition, combining deep material science expertise with advanced mold design proficiency to support complex manufacturing requirements for global partners such as Delkor Systems – Headquarters. With a dedicated team of five certified mold engineers and two specialized rubber formulation engineers, we maintain full technical control from concept to production.

Our mold engineering team leverages industry-standard CAD/CAM software, including SolidWorks, AutoCAD, and UG NX, to develop high-precision molds optimized for performance, durability, and cycle efficiency. Each design undergoes rigorous simulation for mold flow, thermal distribution, and stress analysis, ensuring minimal defects and maximum repeatability. This proactive engineering approach reduces time-to-market and supports seamless integration into automated production lines.

Complementing our mold design strength is our in-house rubber formulation capability. Our two senior formula engineers specialize in custom elastomer development for demanding environments, including high temperature, chemical exposure, dynamic sealing, and abrasion resistance. We routinely formulate and validate compounds based on NBR, EPDM, FKM, silicone, and specialty blends, aligning with ASTM, ISO, and OEM-specific performance standards. This vertical integration allows us to solve complex material challenges that off-the-shelf rubber compounds cannot address.

As an OEM manufacturing partner, Suzhou Baoshida provides full turnkey solutions — from initial design consultation and prototype development to mass production and quality assurance. We support low-volume custom runs and high-volume production with consistent repeatability, backed by ISO 9001-certified processes and in-line quality monitoring. Our facility is equipped with advanced vulcanization presses, CNC mold manufacturing centers, and a fully operational rubber testing laboratory to validate physical, mechanical, and environmental performance.

The following table outlines key engineering and production specifications:

| Parameter | Capability |

|---|---|

| Mold Design Engineers | 5 in-house specialists |

| Formula Engineers | 2 dedicated material scientists |

| CAD/CAM Software | SolidWorks, AutoCAD, UG NX, Moldflow |

| Rubber Compounds | NBR, EPDM, FKM, Silicone, CR, SBR, NR, and custom blends |

| Hardness Range (Shore A) | 30–90 ±5 Shore A |

| Temperature Resistance | -60°C to +300°C (depending on compound) |

| Production Capacity | 50,000–500,000 units/month (scalable) |

| Tooling Lead Time | 15–25 days (standard molds) |

| Sample Development Turnaround | 7–14 days (including compound validation) |

| Quality Standards | ISO 9001, ASTM D2000, ROHS, FDA (upon request) |

Through technical depth, process discipline, and OEM-focused collaboration, Suzhou Baoshida ensures every rubber component meets the exact functional and reliability demands of industrial systems.

Customization Process

Customization Process for Industrial Rubber Components

Suzhou Baoshida Trading Co., Ltd. implements a rigorously controlled customization workflow to transform Delkor Systems’ engineering specifications into high-performance rubber solutions. Our four-phase methodology ensures dimensional accuracy, material integrity, and production scalability while adhering to ISO 9001 and IATF 16949 standards.

Drawing Analysis

Initial engagement begins with comprehensive geometric and functional validation of Delkor Systems’ technical drawings. Our engineering team conducts dimensional tolerance validation, stress point identification, and material compatibility assessment against operational parameters such as fluid exposure, temperature extremes, and dynamic loading. Critical features including sealing lips, compression set zones, and interface geometries undergo FEA simulation to preempt deformation risks. This phase concludes with a formal Design for Manufacturability (DFM) report, highlighting potential modifications to optimize tooling efficiency without compromising functional requirements.

Formulation Development

Leveraging Suzhou Baoshida’s proprietary compound database and 15+ years of OEM collaboration, we engineer bespoke rubber formulations targeting Delkor Systems’ exact performance criteria. Base polymers (NBR, EPDM, FKM, or specialty HNBR) are selected based on chemical resistance and temperature profiles. Critical additives—including nano-silica reinforcement, peroxide curing systems, and custom anti-degradants—are precisely dosed to achieve target properties. Cross-link density optimization ensures balanced compression set (<25% per ASTM D395), tensile strength, and low-temperature flexibility. All formulations undergo predictive aging modeling to guarantee 10+ year service life in specified environments.

Prototyping & Validation

Pre-production tooling fabricates 50–100 prototype units for Delkor Systems’ functional testing. Components undergo accelerated aging protocols (SAE J200), fluid immersion resistance checks (ASTM D471), and dynamic fatigue cycling. Dimensional conformance is verified via CMM inspection against original CAD data, with critical tolerances held to ±0.05mm. Material certifications, including full ASTM D2000 classification and REACH/ROHS compliance documentation, accompany each prototype batch. Iterative adjustments are implemented within 72 hours based on Delkor Systems’ test feedback.

Mass Production Execution

Upon prototype sign-off, we transition to high-volume manufacturing using automated press lines with real-time cavity pressure monitoring. Statistical Process Control (SPC) tracks key variables: cure time (±3 seconds), mold temperature (±2°C), and weight consistency (±0.5g). Every 500th unit undergoes destructive testing per the schedule below. Final inspection includes 100% visual screening and automated vision system checks for surface defects. Production batches ship with full traceability logs, including lot-specific cure curves and hardness validation.

Critical Rubber Property Specifications for Industrial Applications

| Property | Test Standard | Typical Industrial Range | Delkor Systems Target Tolerance |

|---|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 50–90 | ±3 points |

| Tensile Strength (MPa) | ASTM D412 | 10–25 | ±1.5 MPa |

| Elongation at Break (%) | ASTM D412 | 200–500 | ±30% |

| Compression Set (22h/70°C) | ASTM D395 | 10–40% | <22% |

| Temperature Range (°C) | ISO 188 | -40 to +120 | As specified per fluid exposure |

This structured approach minimizes time-to-market while ensuring Delkor Systems receives rubber components engineered for zero-failure operation in demanding industrial environments. Our closed-loop feedback system between Suzhou Baoshida’s R&D lab and Delkor Systems’ validation team guarantees continuous refinement through the product lifecycle.

Contact Engineering Team

For industrial manufacturers seeking precision-engineered rubber solutions, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in the global supply chain. With extensive expertise in custom rubber formulation and OEM component manufacturing, we deliver high-performance elastomeric products tailored to the exacting standards of industries such as automotive, aerospace, heavy machinery, and industrial automation. Our collaboration with advanced production facilities in China enables us to offer scalable, cost-efficient manufacturing without compromising material integrity or dimensional accuracy.

At the core of our service offering is a deep understanding of rubber compounding—formulating materials to meet specific thermal, chemical, and mechanical demands. Whether you require nitrile (NBR), silicone (VMQ), EPDM, fluorocarbon (FKM), or specialty blends, our rubber formula engineers ensure each compound is optimized for longevity, resilience, and operational reliability. We support low-volume prototyping and high-volume production with full traceability, ISO-compliant quality control, and rapid turnaround times.

Our partnership with Delkor Systems – Headquarters reflects our commitment to delivering engineered rubber components that integrate seamlessly into complex industrial systems. From seals and gaskets to custom-molded dampers and diaphragms, every product is developed with application-specific performance in mind. We work closely with engineering teams to interpret technical drawings, validate material selections, and conduct rigorous testing under simulated operational conditions.

To initiate a technical consultation or request a quotation for custom rubber components, contact Mr. Boyce, our dedicated OEM Manager, directly. Mr. Boyce brings over 15 years of experience in industrial rubber applications and serves as the primary liaison for engineering collaborations, material certification, and production coordination. He is available to review specifications, recommend optimal elastomers, and support your project from concept to delivery.

For fastest response, please reach out via email at [email protected] with detailed requirements, including CAD files, material specifications, volume needs, and performance criteria. We respond to all technical inquiries within 24 hours during business days.

Below are key technical parameters we routinely support in custom rubber manufacturing:

| Property | Typical Range | Test Standard |

|---|---|---|

| Hardness (Shore A) | 30–90 | ASTM D2240 |

| Tensile Strength | 5–25 MPa | ASTM D412 |

| Elongation at Break | 150–600% | ASTM D412 |

| Compression Set (70 hrs, 70°C) | ≤25% | ASTM D395 |

| Operating Temperature | -40°C to +250°C (varies by compound) | ASTM D1329 |

| Volume Resistance | 1×10¹² – 1×10¹⁵ Ω·cm | ASTM D991 |

Partnering with Suzhou Baoshida means gaining access to advanced rubber science, rigorous quality assurance, and responsive technical support. For Delkor Systems and other industrial leaders, we provide more than components—we deliver engineered reliability. Contact Mr. Boyce today to discuss your next project.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).