Technical Contents

Engineering Guide: Dog Crate Grate Floor

Engineering Insight: The Critical Role of Material Selection in Dog Crate Grate Floor Performance

In industrial and commercial animal housing applications, the dog crate grate floor is a critical structural and functional component. It must endure continuous mechanical loading, exposure to biological fluids, aggressive cleaning agents, and wide temperature fluctuations. Despite its apparent simplicity, the long-term performance of a grate floor is fundamentally determined by material selection—a factor frequently overlooked in favor of cost or availability. Off-the-shelf solutions, often fabricated from generic polymers or low-grade recycled materials, routinely fail under operational stress due to inadequate chemical resistance, poor fatigue strength, and dimensional instability.

Standard polyethylene or polypropylene gratings, while economical, exhibit pronounced creep under sustained load, leading to warping and structural deformation within months of service. These materials also degrade rapidly when exposed to common disinfectants such as quaternary ammonium compounds, sodium hypochlorite, and peracetic acid. Surface microcracking develops, creating harborage points for pathogens and compromising hygiene—a critical failure in regulated environments.

At Suzhou Baoshida Trading Co., Ltd., we engineer dog crate grate floors using high-performance thermoplastic elastomers (TPE) and reinforced polyamide composites, specifically formulated for durability in high-moisture, high-sanitation environments. Our proprietary compounds integrate UV stabilizers, antimicrobial additives, and glass-fiber reinforcement to achieve optimal balance between flexibility, impact resistance, and chemical inertness. Unlike brittle alternatives, our materials maintain integrity after repeated thermal cycling and resist abrasion from animal movement and cleaning equipment.

The failure of generic solutions often stems from a one-size-fits-all approach. Industrial canine facilities vary significantly in usage intensity—kennels in breeding operations, veterinary isolation units, and police/military training centers impose different mechanical and environmental demands. A material that performs adequately in a low-traffic facility may catastrophically fail in a high-throughput shelter. Custom formulation based on application-specific stress profiles is not a luxury—it is a necessity.

Below is a comparative specification table highlighting the performance gap between standard and engineered materials used in dog crate grate floors.

| Property | Standard Polyethylene | Reinforced Polyamide (Baoshida) | Test Standard |

|---|---|---|---|

| Tensile Strength | 25 MPa | 140 MPa | ISO 527 |

| Flexural Modulus | 1.1 GPa | 9.8 GPa | ISO 178 |

| Chemical Resistance (NaOCl 500ppm) | Poor (cracking at 30 days) | Excellent (no degradation at 180 days) | ASTM C581 |

| Impact Strength (Izod, notched) | 3 kJ/m² | 18 kJ/m² | ISO 180 |

| Service Temperature Range | -20°C to +60°C | -40°C to +120°C | ISO 11359 |

| Antimicrobial Additive | None | Silver-ion based (ISO 22196 compliant) | ISO 22196 |

Material selection directly influences lifecycle cost, sanitation efficacy, and animal welfare. Facilities using engineered grate floors report up to 60% longer service life, reduced maintenance downtime, and improved compliance with biosecurity protocols. At Baoshida, we prioritize performance-driven formulation, ensuring our rubber and polymer solutions meet the exacting demands of modern animal housing infrastructure.

Material Specifications

Material Specifications for Dog Crate Grate Floor Applications

Selecting the optimal elastomer for dog crate grate floors requires rigorous evaluation of chemical exposure, mechanical stress, and thermal stability. At Suzhou Baoshida Trading Co., Ltd., we prioritize formulations that withstand urine, cleaning agents, and constant abrasion while ensuring structural integrity under dynamic loads. Viton (FKM), Nitrile (NBR), and Silicone (VMQ) represent our core industrial solutions, each engineered for specific operational demands.

Viton fluorocarbon rubber delivers exceptional resistance to aggressive chemicals, including concentrated acids, oils, and ozone. Its molecular stability ensures minimal swelling when exposed to veterinary disinfectants or ammonia-based cleaners common in kennel environments. Operating effectively from -20°C to +230°C, Viton maintains hardness retention under prolonged UV exposure. However, its premium cost necessitates deployment only in high-exposure scenarios where standard elastomers fail. Compression set values remain below 25% after 70 hours at 150°C, critical for grate floors requiring decades of cyclic loading resilience.

Nitrile butadiene rubber offers the optimal balance for standard canine facility applications. With Shore A hardness adjustable from 55 to 90, NBR formulations resist animal fats, hydraulic fluids, and diluted acids encountered during routine sanitation. Its tensile strength (15–25 MPa) and abrasion resistance exceed silicone, making it ideal for high-traffic grate surfaces. NBR operates reliably between -40°C and +120°C but exhibits vulnerability to ketones and strong oxidizing agents. Cost efficiency and rapid cure kinetics position NBR as our most specified material for commercial dog crate flooring.

Silicone rubber provides unmatched flexibility across extreme temperatures (-60°C to +200°C) and complies with FDA 21 CFR 177.2600 for indirect food contact—essential for pet hygiene. Though inferior in tensile strength (5–8 MPa) compared to NBR, its biocompatibility prevents skin irritation from prolonged paw contact. Silicone’s hydrophobic nature repels organic contaminants but requires reinforcement to mitigate tearing under sharp claw impact. Limited resistance to concentrated acids necessitates careful chemical compatibility assessment.

The following comparative analysis details critical performance parameters per ASTM D2000 standards:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Hardness Range (Shore A) | 60–90 | 55–90 | 30–80 |

| Tensile Strength (MPa) | 8–15 | 15–25 | 5–8 |

| Temp Range (°C) | -20 to +230 | -40 to +120 | -60 to +200 |

| Compression Set (%) | ≤25 (150°C/70h) | ≤30 (100°C/22h) | ≤20 (200°C/22h) |

| Key Chemical Resistance | Acids, Oils, Ozone | Fats, Aliphatic Hydrocarbons | Steam, Alcohols |

| Primary Limitation | Cost, Low-Temp Flex | Ketones, Ozone | Tensile Strength |

Optimal material selection hinges on quantifiable exposure profiles. For standard kennel operations, NBR provides the most economical durability. Viton becomes indispensable in veterinary clinics using aggressive sterilants, while silicone suits facilities prioritizing thermal cycling during autoclave sanitation. Suzhou Baoshida’s OEM engineering team conducts application-specific validation testing to eliminate field failure risks, ensuring every grate floor specification aligns with operational reality. All compounds undergo ISO 188 aging and ASTM D471 fluid immersion protocols prior to release.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. maintains a robust engineering infrastructure tailored to the rigorous demands of industrial rubber manufacturing, particularly in specialized applications such as dog crate grate flooring. Our in-house engineering team comprises five dedicated mould engineers and two advanced rubber formula engineers, enabling complete vertical control from concept to production. This integrated capability ensures that every product meets exact functional, durability, and compliance standards required in commercial and industrial animal housing environments.

Our mould engineers specialize in precision tooling design for high-cycle rubber compression and transfer moulding processes. Utilizing 3D CAD software and finite element analysis (FEA), they optimize flow dynamics, venting, and ejection systems to minimize defects and maximize part consistency. Each mould is engineered for long service life under continuous thermal and mechanical stress, with hardened steel construction and surface treatments to resist corrosion from cleaning agents and animal waste exposure. This attention to detail ensures uniformity across large production runs, critical for OEM partners requiring batch-to-batch reliability.

Complementing the mould design team, our two rubber formula engineers focus on material science tailored to the operational environment of dog crate floors. These grates are subjected to constant load, impact, chemical exposure, and temperature fluctuations. Our formulations are developed using SBR, EPDM, and nitrile rubber bases, customized for optimal hardness (typically 60–70 Shore A), tensile strength, and resistance to ozone and microbial growth. Through iterative compound testing, we achieve a balance between flexibility for animal comfort and rigidity for structural support. All formulations are free from harmful plasticizers and meet international standards for indoor emissions and animal safety.

We offer full OEM services, including custom geometry development, branding integration, and packaging specification. Clients provide performance requirements or application constraints, and our team delivers a validated solution within 4–6 weeks, including prototype sampling and performance validation under simulated service conditions. This rapid development cycle is supported by on-site testing facilities for compression set, abrasion resistance, and chemical exposure.

The following table outlines the standard technical specifications for our dog crate grate floor product line, which can be further customized based on OEM requirements:

| Property | Test Method | Typical Value |

|---|---|---|

| Material Base | — | EPDM / SBR Blend |

| Hardness (Shore A) | ASTM D2240 | 65 ± 5 |

| Tensile Strength | ASTM D412 | ≥ 12 MPa |

| Elongation at Break | ASTM D412 | ≥ 250% |

| Compression Set (22 hrs, 70°C) | ASTM D395 | ≤ 20% |

| Tear Resistance | ASTM D624 | ≥ 25 kN/m |

| Operating Temperature Range | — | -40°C to +100°C |

| Slip Resistance (DIN 51130) | — | R10 Rating |

| Chemical Resistance | Immersion in 10% NaOH, 7 days | No cracking or swelling |

With a disciplined engineering approach and deep expertise in both rubber compounding and precision tooling, Suzhou Baoshida delivers high-performance, scalable solutions for industrial-grade dog crate grate flooring. Our OEM partnerships benefit from technical transparency, rapid iteration, and consistent quality control across all production phases.

Customization Process

Customization Process for Industrial Rubber Dog Crate Grate Floors

At Suzhou Baoshida Trading Co., Ltd., our customization process for dog crate grate floors integrates material science with precision manufacturing to deliver OEM solutions meeting stringent industrial and biological demands. This four-phase workflow ensures optimal performance in high-moisture, high-load canine environments while adhering to veterinary hygiene standards.

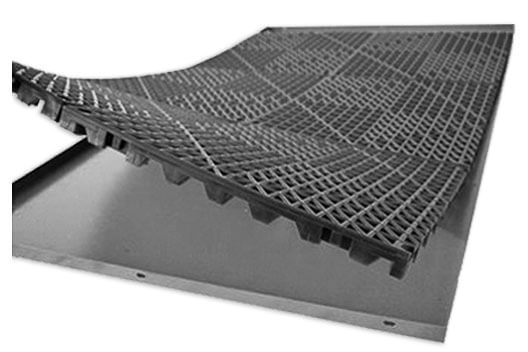

Drawing Analysis initiates the process with rigorous technical validation of client-provided CAD files. Our engineering team assesses structural integrity factors including load distribution points, rib thickness tolerances (±0.2mm), and drainage channel geometry. Critical attention is given to canine paw ergonomics and urine flow dynamics, verifying that slope angles exceed 3° to prevent fluid pooling. Finite element analysis (FEA) simulations predict deflection under 150kg dynamic loads, ensuring no permanent deformation occurs at stress concentrations.

Formulation leverages our proprietary rubber compounding expertise to address biological and mechanical requirements. We select between EPDM and SBR base polymers based on the operational environment: EPDM for UV/ozone resistance in outdoor crates, SBR for superior abrasion resistance in high-traffic facilities. Key additives include zinc oxide for vulcanization control, silica for tear strength enhancement, and antimicrobial agents (silver-ion based) to inhibit bacterial growth from organic contaminants. Shore A hardness is precisely calibrated between 65–75 to balance paw comfort with structural rigidity. The following table summarizes critical formulation parameters:

| Property | Standard Range | Test Method |

|---|---|---|

| Shore A Hardness | 65–75 | ASTM D2240 |

| Tensile Strength | ≥18 MPa | ASTM D412 |

| Elongation at Break | ≥350% | ASTM D412 |

| Compression Set (70°C) | ≤25% | ASTM D395 |

| Urine Resistance | No swelling (72h) | ISO 1817 |

Prototyping employs CNC-machined aluminum molds for first-article production. Each prototype undergoes accelerated lifecycle testing: 10,000 cycles of 100kg impact loading, 168-hour immersion in synthetic urine (pH 5.5), and thermal cycling from -30°C to +70°C. Dimensional verification via CMM (Coordinate Measuring Machine) confirms all features remain within ISO 2768-mK tolerances. Client feedback on drainage efficiency and paw traction directly informs final adjustments to surface micro-texturing.

Mass Production commences only after formal client sign-off on validation reports. Our Suzhou facility utilizes 500-ton hydraulic presses with ±1.5°C temperature control for consistent vulcanization. In-process quality checks occur at 30-minute intervals: hardness verification, visual inspection for porosity, and load testing of random samples. Every batch receives traceability coding linked to raw material certificates and process parameters. Final inspection includes full-spectrum spectrometry to confirm antimicrobial agent distribution uniformity before bulk shipment.

This systematic approach guarantees grate floors withstand 10+ years of veterinary/commercial use while meeting ISO 9001:2015 production standards. Our closed-loop feedback between prototyping and mass production eliminates field failure risks inherent in commodity rubber products.

Contact Engineering Team

For industrial manufacturers seeking high-performance rubber components tailored to demanding applications, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in advanced rubber engineering. Specializing in precision-molded rubber products for heavy-duty environments, we deliver engineered solutions that meet rigorous functional and durability standards. Among our specialized offerings is the rubber grate floor system designed specifically for dog crates—where hygiene, structural integrity, and animal safety are non-negotiable.

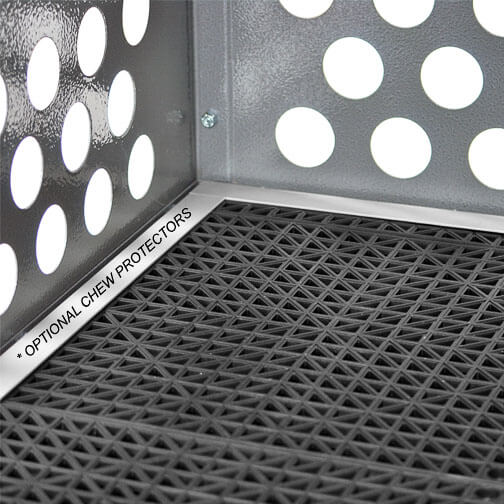

Our dog crate grate floor solutions are not generic rubber mats. They are engineered using industrial-grade EPDM and SBR compounds, selected for their exceptional resistance to abrasion, UV exposure, chemical degradation, and extreme temperatures. Each grate is compression-molded to exact dimensional tolerances, ensuring uniform load distribution, long-term deflection resistance, and seamless integration into standard and custom crate designs. The surface texture is optimized to provide secure footing for animals while facilitating rapid drainage and ease of cleaning—critical factors in commercial breeding facilities, veterinary clinics, transport units, and shelter operations.

Suzhou Baoshida operates at the intersection of material science and industrial application. Our engineering team collaborates directly with OEMs and system integrators to refine product specifications, validate performance under real-world conditions, and ensure compliance with regional safety and sanitation regulations. Whether you require a standard configuration or a fully customized grate profile—adjustable thickness, load rating, color coding, or antimicrobial additive integration—we provide end-to-end technical support from prototype to mass production.

We invite manufacturers, distributors, and design engineers to contact Mr. Boyce, our dedicated OEM Manager and Rubber Formula Engineer, to discuss your specific requirements. Mr. Boyce leads our technical client engagement, bringing over 12 years of experience in rubber compounding and industrial application design. He will work with you to analyze your operational environment, select the optimal rubber formulation, and deliver samples for validation testing. Our facility in Suzhou is equipped with ISO-certified production lines, in-house quality control labs, and automated molding systems capable of high-volume output with consistent repeatability.

To initiate a technical consultation or request material data sheets, pricing, and sample kits, please reach out directly via email. We respond to all inquiries within 12 business hours.

Contact:

Mr. Boyce

OEM Manager & Rubber Formula Engineer

Suzhou Baoshida Trading Co., Ltd.

Email: [email protected]

Below are representative technical specifications for our standard dog crate grate floor series:

| Property | Value | Test Method |

|---|---|---|

| Material | EPDM / SBR Blend | ASTM D2000 |

| Hardness (Shore A) | 65 ± 5 | ASTM D2240 |

| Tensile Strength | ≥ 12 MPa | ASTM D412 |

| Elongation at Break | ≥ 250% | ASTM D412 |

| Compression Set (22 hrs, 70°C) | ≤ 20% | ASTM D395 |

| Operating Temperature Range | -40°C to +120°C | Internal |

| Dimensions (Standard) | 600 × 400 × 25 mm | Customizable |

| Drainage Open Area | 38% | Design Specification |

| Color | Black, Gray, or Custom | RAL/Pantone Match |

Partner with Suzhou Baoshida to transform your dog crate flooring from a commodity component into a high-performance engineered system. Contact Mr. Boyce today to begin the technical dialogue.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).