Technical Contents

Engineering Guide: Door Frame Seals

Engineering Insight: The Critical Role of Material Selection in Door Frame Seals

In the precision rubber seal industry, door frame seals are more than simple gaskets—they are engineered components designed to deliver long-term performance under dynamic environmental and mechanical conditions. A common misconception among procurement teams and product designers is that door frame seals can be treated as commodity items, where off-the-shelf solutions offer sufficient performance at lower cost. This assumption often leads to premature failure, increased warranty claims, and reputational damage. The root cause lies in improper material selection.

Door frame seals are subjected to a complex combination of compression, UV exposure, temperature cycling, moisture, and chemical contact. Standard rubber compounds such as generic EPDM or low-grade silicone may appear adequate on paper, but they frequently lack the formulation precision required for real-world durability. For instance, a seal exposed to automotive under-hood environments must resist oil mist and elevated temperatures beyond 150°C, while architectural seals in coastal regions must withstand salt spray and prolonged UV radiation. Off-the-shelf materials are rarely optimized for such specific stressors.

At Suzhou Baoshida Trading Co., Ltd., we emphasize application-specific compounding. Our engineering team evaluates the full operational profile—load cycles, mating surface geometry, installation method, and environmental exposure—before recommending a base polymer. High-purity EPDM with controlled diene content offers superior ozone resistance for outdoor applications, while fluorosilicone blends provide the necessary fuel and solvent resistance for transportation sectors. Even within a single polymer family, variations in cure system, filler type, and plasticizer selection can drastically alter compression set, tensile strength, and low-temperature flexibility.

A critical flaw in generic seals is poor batch-to-batch consistency. Commodity manufacturers often prioritize cost over repeatability, resulting in variable crosslink density and filler dispersion. This inconsistency manifests as uneven sealing pressure, extrusion under load, or cracking after minimal cycling. Precision-engineered seals, by contrast, utilize tightly controlled mixing protocols and quality-assured raw materials to ensure uniform performance across production runs.

The following table outlines key material properties for common rubber types used in door frame seals, highlighting why material selection cannot be generalized.

| Material | Temperature Range (°C) | Compression Set (% at 70h, 100°C) | UV Resistance | Fluid Resistance | Typical Application |

|---|---|---|---|---|---|

| Standard EPDM | -40 to +125 | 25–35 | Good | Water, Alkalis | General outdoor enclosures |

| High-Purity EPDM | -50 to +150 | 15–20 | Excellent | Water, Ozone | Coastal architecture, transport |

| Silicone | -60 to +200 | 20–30 | Good | Limited | High-temp interiors |

| Fluorosilicone | -50 to +175 | 18–25 | Moderate | Fuels, oils | Automotive engine compartments |

| Neoprene | -40 to +100 | 30–40 | Fair | Mild oils | Indoor industrial use |

Material selection is not a cost-saving opportunity—it is a risk mitigation strategy. Generic solutions fail because they do not account for the cumulative effect of environmental stressors over time. At Baoshida, we treat every door frame seal as a mission-critical component, backed by material science and field validation.

Material Specifications

Material Specifications for Precision Door Frame Seals

Selecting the optimal elastomer for door frame seals is critical to ensuring long-term sealing integrity, environmental resistance, and operational reliability. At Suzhou Baoshida Trading Co., Ltd., we engineer precision rubber compounds to meet stringent OEM performance criteria across automotive, industrial, and architectural applications. Each material—Viton (FKM), Nitrile (NBR), and Silicone (VMQ)—offers distinct chemical, thermal, and mechanical properties that must align with the seal’s operational environment. Misalignment can lead to premature compression set, fluid degradation, or loss of sealing force, directly impacting product lifecycle costs.

Viton (FKM) delivers exceptional resistance to high temperatures (up to 250°C continuous), aggressive fuels, oils, and ozone. Its molecular stability makes it ideal for under-hood automotive seals exposed to engine fluids and thermal cycling. However, Viton’s high raw material cost and lower flexibility at sub-zero temperatures necessitate careful application assessment. Nitrile (NBR) remains the industry standard for cost-sensitive applications requiring robust resistance to petroleum-based fluids, hydraulic oils, and moderate temperatures (–40°C to 125°C). While NBR offers excellent abrasion resistance and compression set performance, its vulnerability to ozone, weathering, and polar solvents limits use in exterior or chemical-exposure scenarios without protective additives. Silicone (VMQ) excels in extreme temperature ranges (–60°C to 230°C) and maintains flexibility in cryogenic conditions, making it suitable for aviation or refrigeration door seals. Its inherent biocompatibility and UV resistance are advantageous, though poor tear strength and susceptibility to silicone oil migration require formulation adjustments for dynamic sealing applications.

OEMs prioritize cost-per-cycle efficiency, driving our custom compound development. For instance, hydrogenated NBR (HNBR) extends NBR’s temperature and ozone resistance, while fluorosilicone variants enhance Silicone’s fuel compatibility. Below is a comparative analysis of baseline properties per ASTM D2000 standards.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | –20 to +250 | –40 to +125 | –60 to +230 |

| Tensile Strength (MPa) | 10–18 | 15–25 | 5–10 |

| Fluid Resistance | Excellent (fuels, acids) | Excellent (oils, water) | Poor (fuels, oils) |

| Compression Set (70h/150°C) | ≤25% | ≤20% | ≤20% |

| Hardness Range (Shore A) | 60–90 | 50–90 | 30–80 |

| Relative Cost | High | Low | Medium |

Material selection must balance fluid exposure, thermal demands, mechanical stress, and lifecycle economics. Suzhou Baoshida’s OEM engineering team collaborates with clients to refine formulations—such as incorporating peroxide curing for NBR ozone resistance or reinforcing Silicone with fumed silica—ensuring seals exceed 10,000 compression cycles under operational loads. We rigorously validate all compounds per ISO 3302 and SAE J200 to eliminate field failure risks. For mission-critical door frame applications, consult our technical specialists to optimize material performance against your specific environmental stressors and cost targets.

Manufacturing Capabilities

Engineering Excellence in Precision Rubber Seal Development

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our leadership in precision rubber seal manufacturing, particularly in the specialized domain of door frame seals for automotive, construction, and industrial applications. Our technical team comprises five dedicated mould engineers and two advanced rubber formula engineers, enabling us to deliver fully integrated OEM solutions from concept to mass production. This multidisciplinary structure ensures that both physical tooling and material science are optimized in parallel, reducing development cycles and enhancing product performance.

Our mould engineers possess extensive experience in precision steel mould design, utilizing advanced CAD/CAM/CAE platforms such as UG (Siemens NX), SolidWorks, and Moldflow to simulate flow, predict shrinkage, and optimize gating systems. This enables us to produce highly accurate, long-life moulds capable of maintaining dimensional tolerances within ±0.1 mm—critical for consistent sealing performance and aesthetic finish in door frame applications. With in-house CNC, EDM, and wire-cut machining capabilities, we maintain tight control over tooling quality and lead times, supporting rapid prototyping and low-volume trials.

Complementing our tooling expertise, our two rubber formulation engineers specialize in elastomer chemistry, focusing on EPDM, silicone, and thermoplastic vulcanizates (TPV) commonly used in door seals. They develop custom compound formulations tailored to specific environmental and mechanical requirements, including ozone resistance, UV stability, compression set performance, and low-temperature flexibility down to -50°C. Each formulation is validated through rigorous laboratory testing for tensile strength, elongation, hardness, and aging characteristics, ensuring long-term durability under real-world conditions.

We offer full OEM/ODM support, including design validation, material selection, tooling development, and production scaling. Our engineering team collaborates directly with clients to interpret technical drawings, conduct DFM (Design for Manufacturability) reviews, and implement design modifications for optimal manufacturability and cost-efficiency. This end-to-end control allows us to deliver customized sealing solutions that meet exact performance, regulatory (e.g., RoHS, REACH), and aesthetic specifications.

Below is a summary of our core engineering specifications and capabilities relevant to door frame seal production.

| Parameter | Specification |

|---|---|

| Mould Tolerance | ±0.1 mm |

| Material Types | EPDM, Silicone, TPV, CR (Neoprene) |

| Hardness Range (Shore A) | 40–90 ±5 |

| Operating Temperature | -50°C to +150°C (material-dependent) |

| Tensile Strength | ≥8 MPa (EPDM, ASTM D412) |

| Elongation at Break | ≥250% |

| Compression Set (24h, 70°C) | ≤25% |

| Tooling Lead Time | 25–35 days (prototype) |

| Sample Turnaround | 7–10 days after design approval |

| CAD/CAM Systems | Siemens NX, SolidWorks, AutoCAD, Moldflow |

Through the seamless integration of advanced tooling engineering and precision rubber chemistry, Suzhou Baoshida delivers technically superior door frame seals that meet the highest standards of performance, reliability, and manufacturability.

Customization Process

Customization Process for Precision Door Frame Seals

At Suzhou Baoshida Trading Co., Ltd., our customization process for door frame seals integrates material science with rigorous engineering validation to ensure OEM-grade performance. Each project follows a four-stage workflow designed to mitigate failure risks inherent in dynamic sealing applications.

Stage 1: Drawing Analysis

We initiate with granular scrutiny of client technical drawings, focusing on geometric tolerances per ISO 1101 and functional requirements. Critical dimensions such as lip geometry, cross-section variance, and compression limits undergo GD&T validation. Our engineers identify potential stress concentration zones and verify compatibility with assembly line parameters, including door closing force specifications. Any deviations from manufacturable tolerances are flagged for collaborative redesign, preventing costly iterations downstream.

Stage 2: Formulation Development

Based on environmental exposure data (e.g., UV, ozone, temperature extremes), we select base polymers and engineer compound formulations. For automotive door seals, EPDM remains optimal for its ozone resistance and thermal stability (-40°C to +150°C), while specialty TPEs address weight-sensitive applications. Our lab optimizes filler ratios, cure systems, and additive packages to achieve target properties: Shore A hardness within ±3 points, compression set below 25% after 70 hours at 100°C, and adhesion strength exceeding 6 kN/m to metal substrates. All compounds comply with ISO 1817 and ASTM D2000 standards.

Stage 3: Prototyping & Validation

Prototypes are produced via precision extrusion and vulcanization, replicating mass production tooling. We conduct accelerated life testing per SAE J2236, including 50,000+ door cycle simulations, thermal shock cycling (-40°C ↔ +85°C), and water ingress validation at 150 Pa pressure differentials. Dimensional conformity is verified using CMM with 0.01 mm resolution. Client approval requires passing all functional tests, with material certificates and traceability logs provided for audit readiness.

Stage 4: Mass Production

Approved designs transition to our IATF 16949-certified production line. Real-time process control monitors extrusion speed, cure temperature gradients, and post-vulcanization aging. Every batch undergoes inline hardness and density checks, with quarterly full-spec revalidation. We implement lot traceability from raw material batches to final shipment, ensuring zero-defect delivery through SPC-driven quality gates.

Key Performance Specifications for Door Frame Seals

| Property | Test Standard | Target Value | OEM Requirement Threshold |

|---|---|---|---|

| Shore A Hardness | ASTM D2240 | 60 ± 3 | 55–65 |

| Compression Set (22h/100°C) | ASTM D395 | ≤22% | ≤30% |

| Tensile Strength | ASTM D412 | ≥10 MPa | ≥8 MPa |

| Temperature Range | ISO 188 | -40°C to +150°C | -35°C to +130°C |

| Adhesion to Steel | ASTM D429 | ≥7 kN/m | ≥5 kN/m |

This structured approach eliminates guesswork in seal performance, directly addressing OEM pain points like premature hardening, water leakage, and assembly line friction. By anchoring each phase in quantifiable metrics, Baoshida delivers door frame seals that achieve 15+ year service life in demanding automotive environments. All processes are documented for full audit transparency, ensuring seamless integration into client supply chains.

Contact Engineering Team

For manufacturers and OEMs seeking high-performance rubber components, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in the precision rubber sealing industry. Specializing in engineered solutions for demanding applications, we deliver door frame seals that meet exacting standards for durability, compression set resistance, and environmental sealing. Our expertise spans material formulation, mold design, and volume production, ensuring consistent quality across automotive, construction, and industrial sectors.

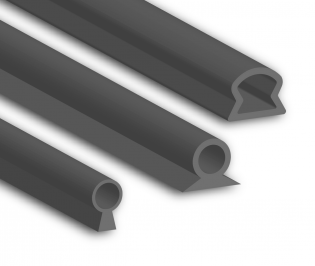

Our door frame seals are manufactured using advanced EPDM, silicone, and thermoplastic vulcanizate (TPV) compounds, each selected for optimal weather resistance, UV stability, and long-term elasticity. Every profile is precision extruded and cured under controlled conditions to maintain dimensional accuracy and mechanical integrity. Whether your application requires low-compression-force geometry, multi-durometer construction, or custom color matching, our engineering team collaborates directly with clients to develop tailored sealing solutions.

We understand that performance in real-world environments is non-negotiable. That’s why our door frame seals undergo rigorous testing for ozone resistance, thermal cycling, and water ingress under simulated operational conditions. All production batches are subject to statistical process control (SPC) monitoring, ensuring conformity to ISO 9001-certified quality management protocols. From prototype to full-scale rollout, Suzhou Baoshida maintains full traceability and documentation support for audit and compliance purposes.

To support global supply chains, we offer flexible packaging, labeling, and logistics coordination, with the capacity to serve Tier 1 suppliers and end-use manufacturers across North America, Europe, and Asia. Our technical team provides on-site and remote support for installation validation, failure mode analysis, and continuous improvement initiatives.

For immediate technical consultation or to initiate a quotation process, contact Mr. Boyce, our dedicated OEM and Engineering Manager. With over 15 years of experience in rubber formulation and sealing system integration, Mr. Boyce leads client engagements with a focus on precision, responsiveness, and long-term reliability. He is available to discuss material selection, performance requirements, and production timelines tailored to your project’s specifications.

Below are typical technical parameters for our standard door frame seal profiles. Custom configurations are available upon request.

| Property | Test Method | Typical Value |

|---|---|---|

| Material | — | EPDM, Silicone, TPV |

| Hardness (Shore A) | ASTM D2240 | 50–80 ±5 |

| Tensile Strength | ASTM D412 | ≥8.0 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Compression Set (22 hrs @ 70°C) | ASTM D395 | ≤25% |

| Operating Temperature Range | — | -40°C to +150°C |

| Color Options | — | Black, Gray, Custom (RAL/Pantone) |

| Standard Tolerances | ISO 3302 | Class M2 or M3 |

Partner with Suzhou Baoshida for door frame seals that combine material science rigor with industrial-scale reliability. Initiate your next project with confidence—contact Mr. Boyce directly at [email protected] to schedule a technical review or request sample submissions.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).