Technical Contents

Engineering Guide: Door Matting

Engineering Insight: Material Selection in Industrial Door Matting

In industrial and commercial environments, door matting is far more than a functional accessory—it is a critical component in maintaining safety, cleanliness, and operational efficiency. Despite its seemingly simple role, the performance of door matting is heavily dependent on precise material engineering. Off-the-shelf solutions, while cost-attractive, frequently fail under real-world conditions due to inadequate material selection, leading to premature degradation, reduced traction, and increased maintenance costs.

The primary failure point in generic door matting lies in the use of non-specialized elastomers or thermoplastics that lack resilience under dynamic environmental stressors. Industrial doorways are exposed to continuous foot traffic, rolling equipment, moisture, temperature fluctuations, and chemical exposure. Standard PVC or low-grade rubber compounds cannot maintain structural integrity under such conditions. These materials often harden in cold environments, crack under UV exposure, or soften and deform when subjected to oils and solvents—common in manufacturing, logistics, and food processing facilities.

At Suzhou Baoshida Trading Co., Ltd., our approach begins with material science. We utilize high-density styrene-butadiene rubber (SBR) and ethylene propylene diene monomer (EPDM) compounds engineered for maximum abrasion resistance, tensile strength, and environmental stability. These materials are compounded with reinforcing fillers and anti-degradants to ensure long-term performance in harsh operational settings.

Custom formulation allows for tailored durometer ratings, typically between 65–75 Shore A, balancing comfort underfoot with durability. Additionally, advanced texturing techniques enhance slip resistance without compromising cleanability—essential in environments where hygiene and safety regulations are stringent.

Below is a comparison of standard off-the-shelf materials versus engineered rubber solutions:

| Property | Standard PVC Matting | Low-Grade Recycled Rubber | Baoshida Engineered SBR/EPDM |

|---|---|---|---|

| Tensile Strength (MPa) | 10–12 | 8–10 | 18–22 |

| Elongation at Break (%) | 200–250 | 180–220 | 350–400 |

| Shore A Hardness | 70–80 | 60–70 | 65–75 |

| Operating Temperature Range | -10°C to 60°C | -15°C to 50°C | -40°C to 100°C |

| Oil & Solvent Resistance | Poor | Moderate | Excellent |

| UV Stability | Low | Low | High |

| Expected Service Life (years) | 1–2 | 1–3 | 5–7 |

The data clearly illustrates that engineered rubber formulations outperform commodity materials across every critical parameter. Off-the-shelf mats may appear economical initially, but their shortened lifespan and higher replacement frequency result in greater total cost of ownership.

Material selection is not a compromise—it is a strategic decision that directly impacts facility safety, maintenance burden, and operational continuity. At Baoshida, we engineer door matting as a performance system, not a disposable commodity, ensuring reliability where it matters most.

Material Specifications

Material Specifications for Industrial Door Matting Applications

Precise material selection is critical for industrial door matting performance, directly impacting safety, longevity, and operational efficiency in demanding environments. At Suzhou Baoshida Trading Co., Ltd., we prioritize polymers engineered to withstand mechanical stress, chemical exposure, and extreme temperatures inherent in manufacturing, automotive, and chemical processing facilities. Our technical analysis focuses on three high-performance elastomers: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material offers distinct advantages tailored to specific industrial challenges, from oil resistance in automotive plants to thermal stability in food processing zones. Understanding these specifications ensures optimal mat functionality, reducing slip hazards and maintenance costs while complying with ISO 13071 safety standards for pedestrian surfaces.

Viton (FKM) delivers exceptional resistance to aggressive chemicals, including hydrocarbons, acids, and ozone, making it ideal for petrochemical or aerospace facilities. Its operational temperature range spans -20°C to +230°C, maintaining integrity under intermittent exposure to jet fuels or hydraulic fluids. Tensile strength typically exceeds 15 MPa (ASTM D412), with elongation at break around 200%. However, Viton’s higher cost necessitates targeted deployment where chemical exposure justifies the investment. Nitrile (NBR) provides superior abrasion resistance and cost efficiency for general industrial use, particularly in oil-lubricated environments like automotive workshops. It operates effectively from -30°C to +100°C, with tensile strength of 10–18 MPa and elongation of 250–400%. While vulnerable to ozone and ketones, NBR excels in high-traffic zones requiring durability against physical wear. Silicone (VMQ) dominates applications requiring extreme thermal cycling, functioning from -60°C to +200°C, and offers excellent resistance to steam and UV degradation. Its biocompatibility suits food and pharmaceutical plants, though lower tensile strength (6–10 MPa) and higher compression set limit use in high-load scenarios.

The comparative analysis below details critical mechanical and chemical properties per ASTM and ISO testing protocols:

| Material | Temperature Range (°C) | Tensile Strength (MPa) | Elongation at Break (%) | Hardness (Shore A) | Key Industrial Advantages |

|---|---|---|---|---|---|

| Viton (FKM) | -20 to +230 | 15–20 | 150–250 | 60–80 | Extreme chemical resistance; low gas permeability; aerospace-grade stability |

| Nitrile (NBR) | -30 to +100 | 10–18 | 250–400 | 50–90 | High abrasion resistance; cost-effective; optimal for oil/fuel exposure |

| Silicone (VMQ) | -60 to +200 | 6–10 | 300–600 | 30–80 | Biocompatible; UV/steam resistant; wide thermal flexibility |

Material selection must align with site-specific hazards. For instance, NBR is optimal for automotive assembly lines with frequent oil spills, while Silicone suits sterile environments requiring autoclave compatibility. Viton remains unmatched for chemical handling zones with solvent exposure. Suzhou Baoshida’s OEM team conducts ASTM D2000-compliant material validation, including ISO 1817 chemical immersion tests and ISO 48 hardness profiling, to certify performance against client operational parameters. We integrate these specifications into custom mat formulations, ensuring precise Shore A hardness (typically 60–75) for optimal slip resistance per DIN 51130 ramp tests. This data-driven approach eliminates guesswork, extending mat service life by 40% versus generic alternatives while meeting stringent industry safety mandates. Partner with us to translate material science into engineered floor safety solutions.

Manufacturing Capabilities

Engineering Excellence in Industrial Door Matting Design and Development

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the specialized domain of door matting systems. We maintain a dedicated team of five experienced mould engineers and two advanced rubber formulation engineers, enabling us to deliver technically robust, application-specific matting products tailored to diverse industrial and commercial environments. This integrated engineering approach ensures precision in both physical design and material performance, meeting the exacting demands of global OEM partners.

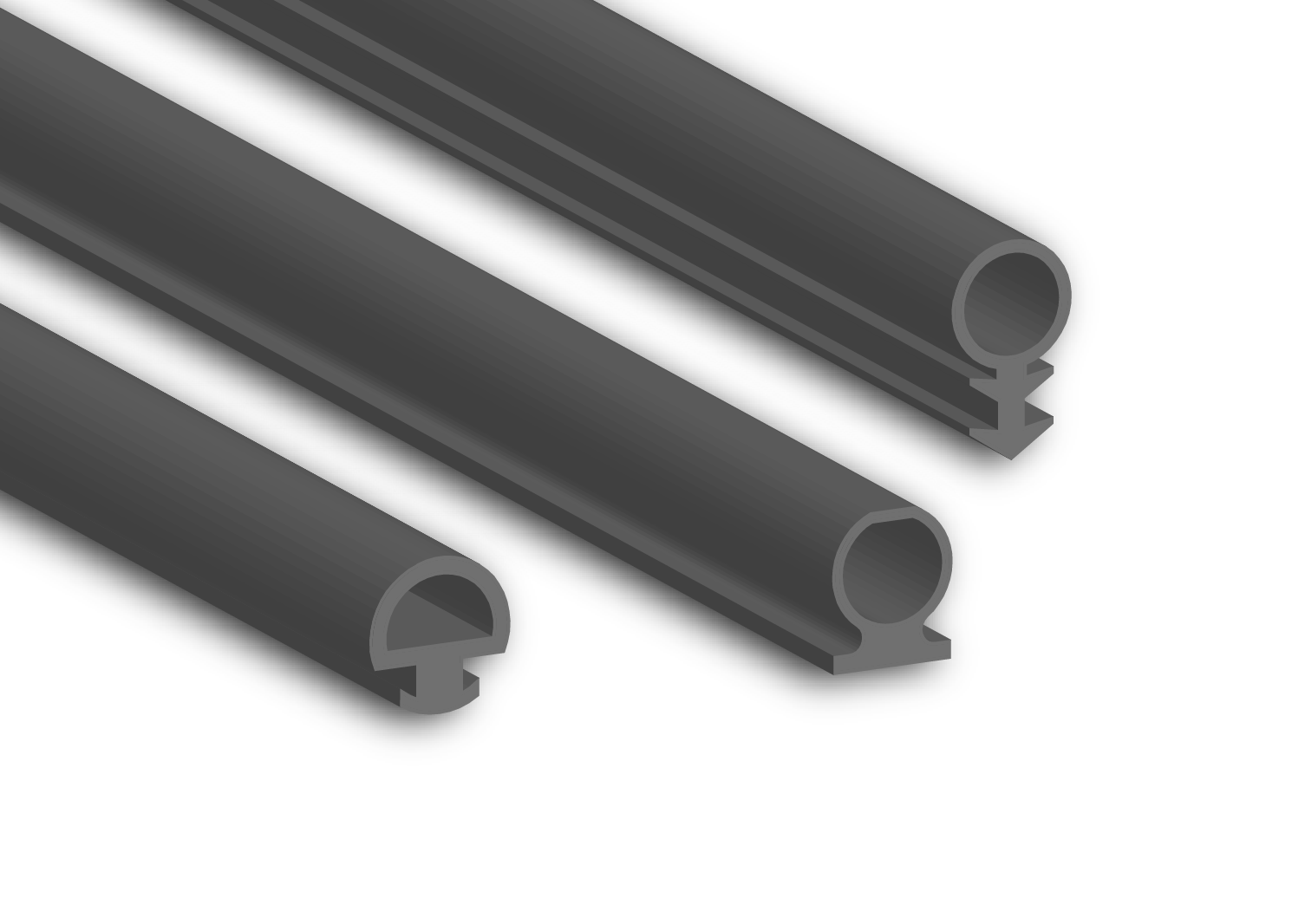

Our mould engineers specialize in the development of high-tolerance, durable tooling systems optimized for extrusion and compression moulding processes. With expertise in CAD/CAM design, finite element analysis (FEA), and rapid prototyping, they ensure dimensional accuracy, structural integrity, and long-term cycle durability. Each mould is engineered to support consistent production of complex profiles, surface textures, and functional geometries—critical for anti-slip performance, debris channeling, and ease of installation in door matting applications.

Complementing this is our in-house rubber formulation team, which plays a pivotal role in defining the functional properties of our matting compounds. Our formula engineers develop custom elastomer blends using natural rubber (NR), styrene-butadiene rubber (SBR), ethylene propylene diene monomer (EPDM), and nitrile rubber (NBR), depending on performance requirements. These formulations are engineered for targeted outcomes such as abrasion resistance, UV stability, ozone resistance, low-temperature flexibility, and color retention. Each compound undergoes rigorous laboratory testing for hardness, tensile strength, elongation, and compression set before approval for production.

Our OEM capabilities are built on this dual-engineering foundation. We support full product co-development, from concept sketch to mass production, ensuring compatibility with client specifications, regulatory standards, and environmental conditions. Whether designing for high-traffic commercial entrances, industrial facilities, or cleanroom environments, our engineering team ensures optimal balance between aesthetics, functionality, and longevity.

The table below outlines key material and performance specifications achievable through our engineered rubber formulations:

| Property | Test Method | Typical Value Range |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 50–80 ±5 |

| Tensile Strength | ASTM D412 | 10–22 MPa |

| Elongation at Break | ASTM D412 | 250–500% |

| Abrasion Loss (Taber, 1000 cycles) | ASTM D1044 | ≤120 mg |

| Operating Temperature Range | — | -40°C to +100°C |

| Compression Set (70h at 70°C) | ASTM D395 | ≤25% |

This technical rigor, combined with scalable manufacturing infrastructure, positions Suzhou Baoshida as a trusted engineering partner for OEMs seeking high-performance, custom-engineered door matting solutions.

Customization Process

Customization Process for Industrial Door Matting Solutions

At Suzhou Baoshida Trading Co., Ltd., our OEM customization process for industrial rubber door matting integrates rigorous engineering protocols to transform client specifications into high-performance products. This four-phase workflow ensures dimensional accuracy, material resilience, and production scalability while adhering to stringent industrial standards.

Drawing Analysis

Initial engagement begins with comprehensive CAD drawing review. Our engineering team validates critical parameters including profile geometry, groove depth, edge tolerances, and mounting features against manufacturability constraints. We identify potential stress concentration zones and recommend micro-adjustments to prevent extrusion defects or premature wear. This phase includes cross-referencing client usage environment data—such as foot traffic density, chemical exposure, and temperature ranges—to preemptively address operational challenges. All modifications are documented via controlled engineering change orders for client approval prior to material development.

Formulation

Material science drives our compound design. Leveraging proprietary rubber blends, we tailor formulations to meet exact performance requirements. Key variables optimized include durometer stability across -30°C to +80°C, abrasion resistance per ASTM D5963, and anti-slip coefficients per DIN 51130. Below outlines standard compound options for industrial matting:

| Compound Type | Hardness (Shore A) | Tensile Strength (MPa) | Abrasion Loss (mm³) | Key Applications |

|---|---|---|---|---|

| SBR Standard | 65 ± 5 | ≥12.0 | ≤120 | Indoor commercial |

| NBR Enhanced | 70 ± 5 | ≥15.5 | ≤85 | Oil/fuel exposure |

| EPDM Premium | 75 ± 5 | ≥18.0 | ≤60 | Outdoor/UV resistance |

Each formulation undergoes accelerated aging tests and dynamic mechanical analysis to verify long-term structural integrity under cyclic loading.

Prototyping

Approved formulations proceed to precision prototyping using CNC-machined molds. We produce 3–5 sample units for functional validation, subjecting them to:

ISO 10545-17 slip resistance testing on wet/dry surfaces

ASTM F1677-05 ramp tests at 15° incline

72-hour accelerated aging under simulated industrial contaminants

Client feedback on texture, drainage efficiency, and dimensional conformity triggers iterative refinements. Only after sign-off on all performance metrics do we release molds for production tooling.

Mass Production

Full-scale manufacturing employs closed-loop process control systems. Rubber batches are traceable via lot numbering, with real-time monitoring of vulcanization temperature (±2°C tolerance) and pressure profiles. Every 500 units undergo抽样 inspection for:

Thickness consistency (±0.3mm)

Colorfastness to ISO 105-B02

Adhesion strength of multi-layer constructions

Final packaging includes serialized QC reports and compliance certificates for ISO 9001 and REACH. Through this structured methodology, Suzhou Baoshida delivers matting solutions engineered for 5+ years of industrial service life with zero tolerance for safety-critical deviations.

Contact Engineering Team

Contact Suzhou Baoshida Trading Co., Ltd. for Advanced Rubber Door Matting Solutions

For industrial manufacturers and OEM partners seeking precision-engineered rubber door matting solutions, Suzhou Baoshida Trading Co., Ltd. stands at the forefront of material innovation and production excellence. With a dedicated focus on industrial rubber applications, our engineering team specializes in developing high-performance matting systems that meet rigorous durability, safety, and environmental standards. Whether you require custom formulations for anti-slip properties, chemical resistance, or extreme temperature stability, our technical expertise ensures optimal performance across commercial, industrial, and transportation sectors.

Our rubber door matting products are designed using advanced compounding techniques, incorporating natural rubber (NR), styrene-butadiene rubber (SBR), ethylene propylene diene monomer (EPDM), and other specialized elastomers. Each formulation is tailored to deliver consistent mechanical properties, including tensile strength, abrasion resistance, and compression set performance. We support clients through every phase of development—from material selection and prototype testing to full-scale production and global logistics.

To ensure compatibility with your application requirements, we offer comprehensive technical data sheets, accelerated aging tests, and regulatory compliance documentation (including RoHS, REACH, and FDA standards where applicable). Our quality management system adheres to ISO 9001 protocols, guaranteeing repeatability and traceability across all production batches.

For engineering inquiries, custom development projects, or volume supply agreements, direct engagement with our technical team is recommended. Mr. Boyce, Rubber Formula Engineer and OEM Manager, leads client collaboration efforts and provides expert guidance on material selection, cost optimization, and performance validation. With over 12 years of experience in industrial rubber formulation, Mr. Boyce has supported leading manufacturers in Europe, North America, and Southeast Asia in upgrading their matting systems for enhanced functionality and lifecycle efficiency.

We invite qualified partners to initiate technical discussions by contacting Mr. Boyce directly via email at [email protected]. Please include detailed specifications such as intended use environment, required dimensions, hardness (Shore A), color, and performance criteria to facilitate rapid response and accurate proposal development.

Below is a reference table outlining standard technical specifications for our most commonly supplied rubber door matting compounds:

| Property | Natural Rubber (NR) | SBR Blend | EPDM Compound |

|---|---|---|---|

| Hardness Range (Shore A) | 50–70 | 55–75 | 60–80 |

| Tensile Strength (MPa) | ≥20 | ≥18 | ≥15 |

| Elongation at Break (%) | ≥400 | ≥350 | ≥300 |

| Operating Temperature Range | -20°C to +80°C | -30°C to +90°C | -40°C to +130°C |

| Abrasion Loss (mm³) | ≤120 | ≤140 | ≤160 |

| Resistance to Oils | Low | Moderate | High |

| UV/Ozone Resistance | Poor | Moderate | Excellent |

Partner with Suzhou Baoshida to leverage cutting-edge rubber technology in your door matting systems. Contact Mr. Boyce today at [email protected] to begin technical consultation and sample evaluation.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).