Technical Contents

Engineering Guide: Door Strips Weather

Engineering Insight: The Critical Role of Material Selection in Door Strip Weather Seals

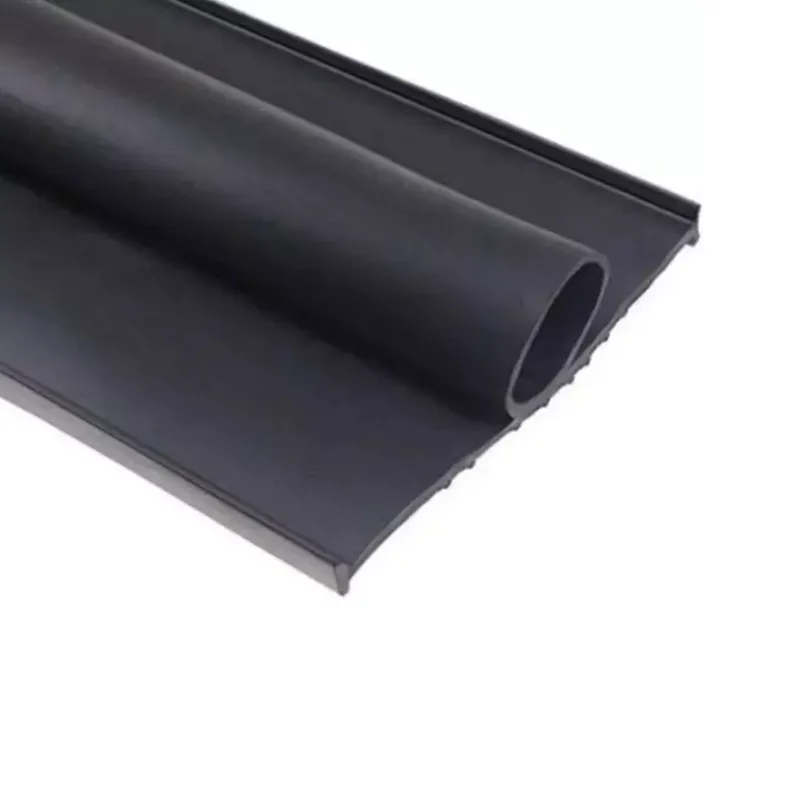

In industrial and commercial applications, door strip weather seals are far more than simple barriers against the elements. They are engineered components designed to maintain environmental integrity, reduce energy loss, and ensure operational reliability under dynamic mechanical and climatic conditions. Despite their apparent simplicity, the failure rate of off-the-shelf weather stripping solutions remains high, primarily due to inappropriate material selection. At Suzhou Baoshida Trading Co., Ltd., we emphasize that precision in rubber formulation is not optional—it is foundational to performance and longevity.

Standard weather strips are typically manufactured using generic EPDM or PVC compounds optimized for cost, not performance. These materials may suffice in mild environments but degrade rapidly under UV exposure, extreme temperatures, or chemical contact. Industrial environments—such as cold storage facilities, automotive manufacturing plants, or coastal infrastructure—demand tailored elastomer solutions that resist compression set, ozone cracking, and thermal cycling. For example, a door seal in a refrigerated warehouse must retain flexibility at -40°C while enduring constant mechanical stress from forklift traffic. Off-the-shelf products often fail under such conditions due to brittle fracture or permanent deformation.

Material selection directly influences key performance metrics: compression deflection force, tensile strength, elongation at break, and resilience. A mismatch in hardness (Shore A) can lead to inadequate sealing pressure or excessive door resistance. Moreover, poor resistance to microbial growth or chemical exposure can compromise hygiene in pharmaceutical or food processing facilities.

At Baoshida, we apply OEM-level engineering to customize rubber compounds based on application-specific stressors. Our formulations integrate high-purity EPDM, silicone, or specialty TPEs with reinforced cross-linking structures to enhance durability. Additives such as anti-oxidants, UV stabilizers, and processing oils are precisely dosed to extend service life without sacrificing elasticity.

The table below outlines comparative performance characteristics of common elastomers used in door strip weather seals:

| Material | Temperature Range (°C) | Shore A Hardness | Tensile Strength (MPa) | Key Resistance Properties |

|---|---|---|---|---|

| Standard EPDM | -40 to +120 | 55–70 | 8–12 | UV, ozone, weathering |

| High-Performance EPDM | -50 to +150 | 60–75 | 14–18 | Enhanced compression set, thermal aging |

| Silicone | -60 to +200 | 40–80 | 6–10 | Extreme temperatures, UV, ozone |

| TPE (Thermoplastic Elastomer) | -30 to +110 | 50–85 | 10–15 | Abrasion, flexibility, recyclability |

| PVC | -10 to +60 | 65–80 | 12–16 | Chemicals, moisture |

Generic solutions often ignore these nuanced trade-offs, leading to premature seal failure, increased maintenance costs, and operational downtime. In contrast, engineered rubber compounds from Baoshida are validated through accelerated aging tests and real-world application trials. By aligning material properties with environmental and mechanical demands, we deliver weather strips that perform reliably over extended service cycles.

Material selection is not a one-size-fits-all decision. It is a science-driven process that defines the boundary between functional reliability and systemic failure. For mission-critical sealing applications, precision-engineered rubber solutions are the only viable choice.

Material Specifications

Material Specifications for Door Strip Weather Seals

Selecting the optimal elastomer for door strip weather seals is critical for OEMs requiring long-term sealing integrity under dynamic environmental stress. At Suzhou Baoshida Trading Co., Ltd., we prioritize material science precision to ensure performance consistency across temperature extremes, chemical exposure, and mechanical compression cycles. Our formulations undergo rigorous ISO 3384 compression set testing and ASTM D2000 classification validation to meet automotive and industrial sector demands.

Viton (FKM) remains the premium choice for high-temperature and aggressive chemical resistance. With a continuous service range of -20°C to +230°C and intermittent peaks up to 300°C, it excels in engine compartment applications where exposure to oils, fuels, and ozone is unavoidable. Its Shore A hardness of 70±5 maintains dimensional stability under compression loads exceeding 50%, though higher material cost necessitates strategic deployment in critical zones. Viton’s low gas permeability also prevents cabin pressure leakage in premium vehicle door seals.

Nitrile (NBR) offers the optimal balance of cost efficiency and functional performance for general-purpose weather stripping. Operating effectively between -40°C and +120°C (with low-temperature variants reaching -55°C), it demonstrates exceptional resistance to water, aliphatic hydrocarbons, and hydraulic fluids. Typical Shore A hardness ranges from 60 to 80, enabling tailored compression force management for door closure dynamics. While inferior to Viton in extreme heat, NBR’s abrasion resistance and 15-25% compression set at 70°C make it the industry standard for mainstream automotive perimeter seals.

Silicone (VMQ) provides unmatched flexibility in cryogenic and high-heat scenarios, with a functional range spanning -60°C to +200°C. Its inherent UV and ozone resistance prevents surface cracking in exterior-exposed seals, while Shore A 40-60 formulations deliver superior low-temperature flexibility for freezer doors or arctic climate vehicles. Limitations include poor tear strength and susceptibility to compression set above 150°C, requiring reinforced compounds for high-cycle applications.

The following table summarizes critical performance parameters for OEM material selection:

| Material | Shore A Hardness | Temperature Range (°C) | Key Resistances | Typical Compression Set (70°C/22h) |

|---|---|---|---|---|

| Viton (FKM) | 70±5 | -20 to +230 | Fuels, Oils, Acids, Ozone | ≤15% |

| Nitrile (NBR) | 60-80 | -40 to +120 | Water, Hydraulic Fluids, Aliphatic Hydrocarbons | 15-25% |

| Silicone (VMQ) | 40-60 | -60 to +200 | UV, Ozone, Extreme Cold | 20-35% |

Suzhou Baoshida implements strict QC protocols per ISO 9001, including batch-specific tensile testing (ASTM D412) and extrusion consistency validation. Our OEM partnerships leverage formulation optimization—such as hydrogenated NBR (HNBR) for enhanced ozone resistance or fluorosilicone blends for fuel compatibility—to address niche application challenges. Material selection must align with SAE J1028 door durability cycle requirements, where compression set below 30% after 500,000 cycles is non-negotiable for warranty compliance. Partner with our engineering team to validate material suitability against your specific environmental stress profiles and lifecycle cost models.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability in the domain of industrial rubber solutions is anchored in deep technical expertise and a structured approach to product development. With a dedicated team comprising five specialized mould engineers and two certified rubber formulation engineers, we maintain full control over the design, material science, and manufacturing lifecycle of door strips weather solutions. This integrated engineering framework enables us to deliver high-performance, application-specific sealing products tailored to the rigorous demands of global OEMs.

Our mould engineers bring over a decade of cumulative experience in precision tooling design for EPDM, TPE, and silicone-based extrusions. Utilizing advanced CAD/CAM systems such as SolidWorks and AutoCAD, they develop robust mould geometries that ensure dimensional accuracy, optimal material flow, and extended tool life. Each design undergoes rigorous simulation for thermal distribution and stress analysis, minimizing defects and ensuring consistent extrusion profiles across production batches. This precision engineering reduces time-to-market and supports rapid prototyping for custom sealing profiles.

Complementing our tooling expertise, our two in-house rubber formulation engineers specialize in polymer chemistry and compound development. They formulate custom rubber blends to meet specific performance criteria such as UV resistance, ozone stability, low-temperature flexibility, and compression set. By controlling the vulcanization system, filler dispersion, and plasticizer integration, they ensure that every compound performs reliably under extreme environmental conditions. This capability is particularly critical for door strips weather applications exposed to temperature cycling, moisture, and mechanical stress over extended service life.

We operate as a full-service OEM partner, offering end-to-end development from concept to mass production. Our clients benefit from confidential formula ownership, traceable batch records, and compliance with international standards including ASTM D2000, ISO 3302, and ISO 2768. Our facility supports co-extrusion, splicing, and automated cutting, enabling complex multi-durometer and multi-material sealing solutions.

The following table outlines key technical specifications we support in door strips weather manufacturing:

| Parameter | Capability Range | Standard Compliance |

|---|---|---|

| Material Types | EPDM, TPE, Silicone, CR | ASTM D2000, ISO 1817 |

| Hardness Range (Shore A) | 40–90 ±5 | ISO 48-4 |

| Temperature Resistance | -50°C to +150°C | ISO 188, ASTM C580 |

| Tensile Strength | ≥8 MPa (EPDM) | ISO 37 |

| Elongation at Break | ≥250% | ISO 37 |

| Compression Set (24h, 70°C) | ≤25% | ISO 815-1 |

| Extrusion Tolerance | ±0.3 mm (standard) | ISO 2768-m |

| Splice Options | Heat, RF, Mechanical | Internal QA-104 |

This technical foundation allows Suzhou Baoshida to consistently exceed OEM expectations in durability, fit, and functional performance. Our engineering team collaborates directly with client R&D departments to co-develop solutions that meet exacting automotive, construction, and transportation industry requirements.

Customization Process

Customization Process for Industrial Door Strip Weatherseals

Suzhou Baoshida Trading Co., Ltd. implements a rigorously defined customization pathway for industrial door strip weatherseals, ensuring optimal performance and client satisfaction. This structured methodology transitions seamlessly from initial concept to high-volume output, grounded in material science and precision manufacturing principles. The process commences with comprehensive Drawing Analysis. Our engineering team meticulously reviews client-provided CAD files or technical sketches, focusing on critical dimensions, sealing interface geometry, installation method, and environmental exposure zones. We assess tolerances against ISO 3302-1 standards for vulcanized rubber, identifying potential stress concentrations or flow limitations during extrusion. Concurrently, we evaluate the operational context—static or dynamic application, expected compression deflection, and adjacent materials—to define precise performance boundaries. This phase often involves collaborative dialogue to refine specifications, ensuring manufacturability without compromising functional intent.

Following dimensional validation, the core Formulation stage begins. Our rubber chemists translate the environmental and mechanical requirements into a tailored polymer compound. Key considerations include base polymer selection (EPDM for ozone/weather resistance, silicone for extreme temperatures, or TPE for recyclability), filler systems for reinforcement and cost optimization, and specialized additives for UV stability, flame retardancy (UL 94), or low-temperature flexibility. The target durometer (Shore A) is precisely engineered, typically ranging from 40 to 80, balancing sealing force with ease of door operation. Critical properties like compression set (ASTM D395 Method B), tensile strength (ASTM D412), and elongation at break are modeled using proprietary databases before laboratory synthesis. This stage culminates in a documented compound specification sheet detailing all raw materials and processing parameters.

Prototyping validates both the formulation and the tooling design. We fabricate initial samples using precision extrusion dies or injection molds, closely monitoring cavity pressure and cure kinetics. Physical samples undergo rigorous in-house testing per ASTM/ISO standards: compression deflection force measurement, accelerated aging (70°C x 168h per ASTM G154), ozone resistance (50 pphm, 40°C), and adhesion verification to common substrates like aluminum or PVC. Dimensional reports using CMM (Coordinate Measuring Machine) confirm adherence to the approved drawing. Client feedback on fit, function, and aesthetics during real-world simulation is integrated, triggering iterative compound or tooling adjustments if necessary. Only upon documented conformance to all performance criteria does the project advance.

Mass Production leverages the validated process under stringent SPC (Statistical Process Control) protocols. Raw material batches undergo incoming inspection per AQL 1.0. Continuous extrusion or molding lines feature real-time monitoring of temperature profiles, line speed, and cure state via dielectric sensors. Every 30 minutes, automated systems extract samples for immediate durometer and visual checks; full physical property testing occurs per ASTM standards on a daily basis. Final inspection includes 100% length verification and surface defect scanning. Traceability is maintained through serialized lot coding, linking each weatherstrip to its specific compound batch and process log. This disciplined approach guarantees consistent, high-integrity weatherseals meeting the exacting demands of industrial door systems.

Key Performance Specifications Comparison

| Property | Standard EPDM Weatherstrip | Custom-Engineered Solution (Typical Range) | Test Standard |

|---|---|---|---|

| Hardness (Shore A) | 60 ± 5 | 40 – 80 (Client-Specified) | ASTM D2240 |

| Compression Set (22h) | ≤ 35% | ≤ 20% (Optimized Formulation) | ASTM D395 Method B |

| Temp. Range (Continuous) | -40°C to +120°C | -60°C to +150°C (Silicone/ Specialty EPDM) | ISO 188 |

| Tensile Strength | ≥ 8.0 MPa | ≥ 10.0 MPa (Reinforced Compound) | ASTM D412 |

| Elongation at Break | ≥ 250% | 300% – 600% (Tailored Flexibility) | ASTM D412 |

| Ozone Resistance | 50 pphm, 200 hrs, No Cracks | 100 pphm, 500 hrs, No Cracks | ASTM D1149 |

Contact Engineering Team

Contact Suzhou Baoshida for Precision Rubber Weather Strips

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of industrial rubber solutions, delivering engineered sealing products that meet the rigorous demands of automotive, construction, and transportation sectors. Our specialty in door strips weather sealing reflects our commitment to durability, precision, and long-term performance under extreme environmental conditions. As a trusted OEM partner, we integrate advanced material science with scalable manufacturing to deliver custom profiles that ensure optimal compression, UV resistance, and thermal stability.

Our door strips are formulated using high-performance elastomers including EPDM, silicone, and thermoplastic vulcanizates (TPV), selected based on application-specific requirements such as temperature range, exposure to chemicals, and mechanical stress. Each profile is designed to maintain consistent sealing force over thousands of cycles, preventing air, water, and dust infiltration. With in-house tooling capabilities and rigorous quality control protocols, Suzhou Baoshida ensures dimensional accuracy to ±0.1 mm and full compliance with international standards such as ISO 9001 and RoHS.

For technical collaboration or sourcing inquiries, direct engagement with our engineering team is essential to align material selection, cross-sectional geometry, and production volume with your operational needs. Mr. Boyce, our designated OEM Manager, leads client integration and technical coordination, ensuring seamless communication from prototype development to mass production.

Below are representative specifications for our standard door strip weather profiles. Custom configurations are available upon request.

| Property | EPDM Rubber | Silicone Rubber | TPV Material |

|---|---|---|---|

| Hardness (Shore A) | 55–75 | 45–80 | 50–70 |

| Temperature Range | -40°C to +135°C | -60°C to +200°C | -30°C to +135°C |

| Tensile Strength | ≥10 MPa | ≥8 MPa | ≥9 MPa |

| Elongation at Break | ≥300% | ≥250% | ≥280% |

| Compression Set (22h, 70°C) | ≤25% | ≤20% | ≤22% |

| UV and Ozone Resistance | Excellent | Excellent | Good |

| Common Applications | Automotive doors, windows, enclosures | High-temp seals, cleanroom doors | Lightweight transport, modular buildings |

All materials undergo accelerated aging tests, dynamic compression analysis, and adhesion verification for metal or plastic substrates. We support co-extrusion, splicing, and automatic application-ready packaging based on production line integration needs.

To initiate a technical discussion or request a sample validation kit, contact Mr. Boyce directly at [email protected]. Include your project specifications, annual volume estimates, and performance requirements to receive a tailored proposal within 48 hours. Our team supports English and Mandarin communications and provides full documentation, including material safety data sheets (MSDS), test reports, and process capability studies (CPK).

Suzhou Baoshida Trading Co., Ltd. operates from the Jiangsu industrial hub, leveraging strategic logistics access to global markets. Our facility is equipped for ISO-compliant batch tracking, just-in-time delivery, and vendor-managed inventory programs for high-volume OEMs.

Partner with us to elevate your sealing performance through engineered rubber solutions built for longevity and precision.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).