Technical Contents

Engineering Guide: Double Acting Valve

Engineering Insight: The Critical Role of Material Selection in Double Acting Valves

In the design and deployment of double acting valves within industrial fluid control systems, material selection is not merely a component of engineering—it is the foundation of performance, longevity, and system reliability. At Suzhou Baoshida Trading Co., Ltd., our expertise in industrial rubber solutions underscores a critical observation: off-the-shelf valve materials frequently fail under real-world operational demands due to inadequate compatibility with media, pressure cycles, and environmental conditions.

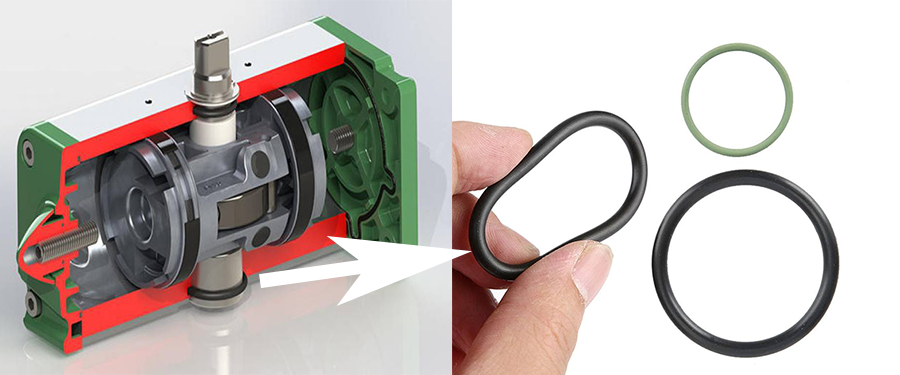

Double acting valves operate by utilizing pressurized fluid or air on both sides of the piston or diaphragm, enabling precise bidirectional control. This dynamic operation subjects internal sealing elements—particularly rubber components such as O-rings, diaphragms, and piston seals—to repeated mechanical stress, cyclic compression, and exposure to aggressive media. Standard elastomers like NBR (nitrile butadiene rubber) or generic silicone compounds, commonly used in mass-produced valves, often degrade prematurely when exposed to oils, ozone, elevated temperatures, or chemical contaminants. This leads to swelling, cracking, extrusion, or loss of elastic recovery, ultimately resulting in leakage, control failure, or unplanned downtime.

The failure of off-the-shelf solutions stems from a one-size-fits-all approach that neglects application-specific variables. For instance, a valve functioning in a hydraulic system with phosphate ester-based fire-resistant fluid requires fluoroelastomer (FKM) seals to resist chemical attack. Conversely, a valve in a food-grade pneumatic system demands FDA-compliant EPDM or platinum-cured silicone to ensure safety and regulatory compliance. Generic materials lack the tailored resistance needed for such specialized environments.

Furthermore, dynamic sealing in double acting valves demands elastomers with high tensile strength, low compression set, and excellent resilience. Materials such as hydrogenated nitrile (HNBR) or perfluoroelastomer (FFKM) offer superior performance under high cycling frequencies and extreme temperatures, but are rarely found in standard valve assemblies due to cost considerations. However, the total cost of ownership—factoring in maintenance, replacement, and system inefficiencies—often favors engineered rubber solutions over cheaper, short-lived alternatives.

At Suzhou Baoshida, we prioritize material science in every valve solution. By analyzing operating pressure, media chemistry, temperature range, and cycle life, we specify elastomers that align precisely with application demands. This engineering-first approach ensures reliability, reduces lifecycle costs, and prevents the systemic risks associated with premature seal failure.

Below is a comparative overview of common elastomers used in double acting valve applications:

| Material | Temperature Range (°C) | Key Media Resistance | Typical Use Case | Compression Set Resistance |

|---|---|---|---|---|

| NBR | -30 to +100 | Oil, water, hydraulic fluids | General industrial | Moderate |

| EPDM | -50 to +150 | Steam, water, alkalis | Food & beverage, HVAC | High |

| FKM (Viton®) | -20 to +200 | Fuels, acids, oils | Petrochemical, aerospace | Excellent |

| HNBR | -40 to +150 | Oils, refrigerants, high-pressure fluids | Automotive, oil & gas | Very High |

| Silicone | -60 to +200 | Ozone, UV, water | Medical, electronics | Low to Moderate |

Material Specifications

Material Specifications for Double-Acting Valve Sealing Elements

Selection of elastomeric sealing materials for double-acting valves requires rigorous evaluation of thermal stability, chemical compatibility, and dynamic sealing performance under bidirectional pressure cycles. Suzhou Baoshida Trading Co., Ltd. emphasizes material integrity to prevent extrusion, compression set, and premature failure in critical industrial systems. Viton fluorocarbon rubber (FKM) delivers exceptional resistance to aggressive media including synthetic hydraulic fluids, acids, and hydrocarbons at temperatures up to 200°C. Its low gas permeability and superior compression set resistance after prolonged heat exposure make it ideal for high-pressure aerospace and chemical processing valves where seal longevity is non-negotiable. Viton formulations cured via peroxide chemistry further enhance low-temperature flexibility down to -20°C while maintaining ASTM D2000 classification for stringent OEM validation.

Nitrile butadiene rubber (NBR) remains a cost-effective solution for petroleum-based hydraulic systems operating below 120°C. High-acrylonitrile variants (48% ACN) provide robust resistance to mineral oils, greases, and aliphatic hydrocarbons but exhibit vulnerability to ozone, ketones, and polar solvents. NBR’s moderate compression set performance necessitates careful groove design in double-acting configurations to avoid leakage during rapid pressure reversals. This material is frequently specified for industrial machinery and mobile hydraulic valves where budget constraints intersect with moderate chemical exposure.

Silicone rubber (VMQ) excels in extreme-temperature applications spanning -60°C to 200°C but demonstrates poor resistance to petroleum derivatives and steam. Its high purity and biocompatibility align with FDA 21 CFR 177.2600 standards for pharmaceutical and food-grade valves, though mechanical strength limitations require reinforced composite structures in high-pressure double-acting designs. Silicone’s inherent low surface friction reduces stiction during valve actuation but mandates secondary sealing elements when exposed to hydraulic oils.

Critical performance parameters are summarized below for informed material selection against operational demands.

| Material | Temperature Range (°C) | Key Chemical Resistances | Compression Set (22 hrs, 150°C) | Typical Valve Applications |

|---|---|---|---|---|

| Viton (FKM) | -20 to 200+ | Fuels, acids, hydraulic fluids, chlorinated solvents | ≤20% (per ASTM D395) | Chemical processing, aerospace hydraulics, offshore oil & gas |

| Nitrile (NBR) | -30 to 120 | Mineral oils, greases, water, aliphatic hydrocarbons | 25-40% (per ASTM D395) | Industrial machinery, mobile equipment, general hydraulics |

| Silicone (VMQ) | -60 to 200 | Water, alcohols, mild acids, ozone | 15-30% (per ASTM D395) | Pharmaceutical, food processing, cryogenic systems (non-oil) |

Material choice must align with fluid media, temperature transients, and cycle frequency. Viton is irreplaceable for aggressive chemical environments despite higher cost, while NBR offers optimal value in standard oil-based systems. Silicone serves niche cryogenic or high-purity roles but requires exclusion from petroleum exposure. Suzhou Baoshida Trading Co., Ltd. validates all compounds per ISO 3601 flange standards and provides OEM-specific formulation adjustments to ensure zero leakage in double-acting valve assemblies under ISO 15848 fugitive emissions criteria. Consult our engineering team for application-specific compound certification data.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. maintains a robust engineering framework specifically tailored to meet the rigorous demands of industrial rubber component manufacturing, particularly for precision applications such as double acting valves. Our in-house engineering team comprises five dedicated mould engineers and two specialized rubber formula engineers, enabling us to deliver fully integrated OEM solutions from concept to production. This multidisciplinary structure ensures that both the physical design and material science aspects of rubber components are optimized in parallel, reducing development cycles and enhancing product reliability.

Our mould engineers possess extensive experience in designing high-precision steel and aluminum tooling for complex rubber parts, including sealing elements, diaphragms, and valve actuators used in double acting valve systems. Utilizing advanced CAD/CAM software and CNC machining protocols, they develop moulds with tight tolerances, optimal flow channels, and extended service life. Each design undergoes rigorous simulation for material flow and compression behavior, ensuring dimensional stability and repeatability across large production batches.

Complementing the mould design expertise, our two rubber formula engineers focus on developing custom elastomer compounds tailored to the operational requirements of double acting valves. These include resistance to high pressure, temperature extremes, and exposure to aggressive media such as hydraulic fluids, gases, and industrial chemicals. By formulating proprietary blends using NBR, EPDM, FKM, and silicone base polymers, we achieve performance characteristics that surpass standard material offerings. Our formulation process includes iterative testing for compression set, tensile strength, hardness, and aging behavior, ensuring long-term sealing integrity.

OEM collaboration is central to our engineering philosophy. We work directly with clients to reverse-engineer existing components, improve failure modes, or co-develop new solutions optimized for specific valve architectures. Our facility supports low-volume prototyping and rapid tooling, enabling clients to validate designs before full-scale production. All formulations and mould designs are documented and maintained under strict confidentiality, ensuring intellectual property protection.

The following table outlines typical performance specifications for rubber components used in double acting valves, reflecting our standard engineering capabilities:

| Property | Test Method | Typical Value Range |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 50–90 ±5 |

| Tensile Strength | ASTM D412 | 8–20 MPa |

| Elongation at Break | ASTM D412 | 200–500% |

| Compression Set (22 hrs, 70°C) | ASTM D395 | ≤25% |

| Operating Temperature Range | — | -30°C to +200°C (FKM) |

| Fluid Resistance (Hydraulic Oil) | ASTM D471 | Volume Swell <15% after 70 hrs |

Through the synergy of advanced tooling design and precision material engineering, Suzhou Baoshida delivers high-performance rubber solutions that meet the exacting standards of industrial valve manufacturers worldwide.

Customization Process

Double-Acting Valve Customization Process: Precision Rubber Engineering

At Suzhou Baoshida Trading Co., Ltd., our double-acting valve customization adheres to a rigorously defined engineering workflow, ensuring optimal performance in demanding industrial applications. This process transforms client specifications into high-integrity rubber components through four critical phases, each governed by ISO 9001 protocols and material science expertise.

Drawing Analysis

We initiate with comprehensive technical drawing dissection, focusing on dimensional tolerances, sealing surface geometries, and dynamic stress points. Our engineering team cross-references ASME B16.10 and ISO 5211 standards to identify critical features such as stem clearance, seat contact angles, and pressure cavity integrity. Finite element analysis (FEA) simulations predict elastomer deformation under operational loads, enabling preemptive mitigation of extrusion risks or compression set failure. Client-provided CAD models undergo GD&T validation to confirm compatibility with mating metal components, ensuring zero interface leakage paths.

Formulation Development

Based on fluid media, temperature extremes, and cyclic fatigue requirements, our rubber chemists design bespoke polymer matrices. We prioritize compound stability across the full operational spectrum, selecting base polymers like HNBR for sour gas resistance or FKM for jet fuel compatibility. Critical additives—including nano-silica for tear strength and特种填料 for low-temperature flexibility—are dosed to ±0.5% precision. All formulations undergo accelerated aging tests per ASTM D2000, with dynamic mechanical analysis (DMA) verifying storage modulus retention at -40°C to +200°C. Material datasheets explicitly define compression set limits (<20% at 150°C/72h) and fluid swell thresholds (<15% in ISO standard fluids).

Prototyping & Validation

Prototypes are manufactured using client-specified tooling or Baoshida’s rapid prototyping presses, with real-time cure monitoring via rheometer-integrated sensors. Each sample undergoes multi-axis functional testing: 10,000+ cycle endurance runs under 150% rated pressure, helium leak checks to 1×10⁻⁶ atm·cc/sec, and thermal shock validation per NORSOK M-710. Third-party lab reports detail friction coefficients, rebound resilience, and dynamic compression set. Client feedback loops refine geometry or compound adjustments before final sign-off, typically within 15 business days.

Mass Production Assurance

Serial production leverages automated molding cells with in-line vision systems for dimensional conformance. Every batch includes traceable material certificates (Mill Test Reports), real-time cure curve documentation, and 100% visual inspection per ISO 3302-1. Statistical process control (SPC) tracks critical parameters like durometer (±3 Shore A) and weight variation (±0.5g). Finished valves undergo batch-level hydrostatic testing at 1.5x working pressure, with full documentation archived for 10+ years.

Key Rubber Compound Specifications for Double-Acting Valves

| Compound Type | Hardness (Shore A) | Temperature Range (°C) | Key Properties |

|---|---|---|---|

| High-Purity FKM | 70 ± 5 | -25 to +230 | Jet fuel resistance, low permeation |

| Peroxide-Cured EPDM | 65 ± 5 | -50 to +150 | Steam tolerance, NSF 61 compliance |

| Carboxylated NBR | 80 ± 5 | -30 to +120 | Abrasion resistance, H₂S stability |

| Specialty HNBR | 75 ± 5 | -40 to +175 | Dynamic fatigue life >500k cycles |

This end-to-end methodology guarantees valves meeting API 6D and ISO 5208 Class VI leakage standards. Suzhou Baoshida’s integration of polymer science with precision manufacturing delivers mission-critical sealing solutions, reducing client downtime through engineered reliability. All processes are co-validated with OEM partners to ensure seamless integration into final assemblies.

Contact Engineering Team

For industrial manufacturers seeking high-performance sealing solutions, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in the development and supply of precision rubber components for critical applications. Our expertise in industrial rubber technology, particularly in valve sealing systems, positions us as a strategic supplier for double acting valve manufacturers requiring durability, chemical resistance, and long service life under dynamic operating conditions.

Double acting valves demand sealing elements that can withstand bidirectional pressure, frequent cycling, and exposure to aggressive media such as oils, gases, and industrial fluids. At Suzhou Baoshida, we engineer custom elastomeric seals using advanced compounding techniques, ensuring optimal performance across a broad range of temperatures and pressures. Our formulations are tailored to meet specific OEM requirements, including resistance to compression set, extrusion, and thermal degradation—key factors in maintaining valve integrity and operational safety.

We specialize in manufacturing seals from a variety of high-grade rubber materials, including Nitrile (NBR), Ethylene Propylene Diene Monomer (EPDM), Fluoroelastomer (FKM/Viton®), and Silicone (VMQ), each selected based on application-specific needs. Our production processes adhere to strict quality control standards, with full traceability and compliance with international certifications, including ISO 9001:2015. Whether you require prototype development, small-batch customization, or large-scale production, our team ensures consistent dimensional accuracy and material performance.

Below is a representative specification table for a standard double acting valve seal manufactured by Suzhou Baoshida, illustrating our technical capabilities:

| Parameter | Specification |

|---|---|

| Material | FKM (Viton® 7075) |

| Hardness (Shore A) | 75 ± 5 |

| Temperature Range | -20°C to +230°C |

| Maximum Pressure | 35 MPa |

| Media Resistance | Hydraulic oils, fuels, steam, acids (dilute) |

| Compression Set (22 hrs, 150°C) | ≤ 20% |

| Tensile Strength | ≥ 15 MPa |

| Elongation at Break | ≥ 150% |

| Color | Black |

| Standard Compliance | ASTM D2000, ISO 3601 |

Partnering with Suzhou Baoshida means gaining access to deep technical knowledge, responsive engineering support, and a commitment to on-time delivery. We work closely with OEMs and system integrators to optimize seal design, reduce maintenance intervals, and enhance overall valve reliability.

For technical inquiries, material selection guidance, or to request a quotation for custom rubber components, contact Mr. Boyce, OEM Manager, directly at [email protected]. Our team is prepared to support your project with data sheets, sample submissions, and collaborative design reviews. Let Suzhou Baoshida be your preferred supplier for high-integrity rubber solutions in double acting valve applications. Reach out today to discuss how we can meet your performance and production requirements with precision and reliability.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).