Technical Contents

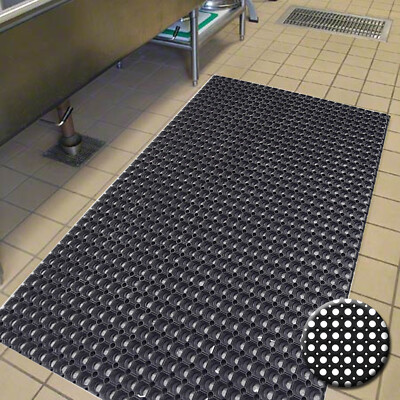

Engineering Guide: Double Door Doormat

Engineering Insight: Material Science Imperatives for Double-Door Doormats

Double-door configurations impose unique mechanical stresses fundamentally different from single-door applications. Standard commercial doormats, often designed for low-traffic residential use, catastrophically fail in industrial or high-traffic commercial settings due to inadequate material formulation. The critical flaw lies in the inability of off-the-shelf solutions to withstand the combined cyclical compression at the central seam, abrasive wear from concentrated foot traffic, and environmental exposure. Generic mats typically utilize high percentages of post-consumer recycled rubber (70-85%) with minimal virgin polymer content and insufficient reinforcing agents. This results in poor resilience, rapid permanent deformation under door weight, and surface degradation when subjected to repeated impact and abrasion. The central seam, constantly compressed as doors swing closed, experiences concentrated stress exceeding 1.5 MPa in high-use scenarios. Low-grade recycled compounds lack the necessary polymer chain integrity and cross-link density to recover elastically, leading to permanent crushing, seam separation, and eventual structural failure within 6-12 months. Simultaneously, inadequate filler dispersion and low tensile strength cause accelerated surface wear, creating trip hazards and reducing contaminant-scraping efficacy.

Chemical resistance is another frequent oversight. Industrial cleaning agents, oils, and de-icing salts prevalent in commercial environments aggressively attack poorly vulcanized compounds. Off-the-shelf mats often exhibit swelling, softening, or surface tackiness upon exposure, compromising dimensional stability and slip resistance. This degradation accelerates mechanical failure modes. Material selection is not merely a cost factor; it is a structural engineering requirement. Industrial-grade doormats demand precision-engineered compounds balancing Shore hardness, tensile strength, elongation, and chemical resistance to maintain functional integrity under dynamic load cycles.

The following table contrasts critical material properties between generic off-the-shelf solutions and engineered industrial formulations:

| Property | Generic Off-the-Shelf Mat | Engineered Industrial Mat (Baoshida Specification) |

|---|---|---|

| Shore A Hardness | 45-55 | 65-75 |

| Tensile Strength (MPa) | 5.0 – 8.0 | ≥ 15.0 |

| Elongation at Break (%) | 250 – 350 | 400 – 550 |

| Compression Set (B) (%) | 35 – 50 (22h/70°C) | ≤ 18 (22h/70°C) |

| Chemical Resistance | Poor (Swelling in oils) | Excellent (Resistant to oils, salts, cleaners) |

Suzhou Baoshida’s engineered solution utilizes a proprietary SBR/NR blend with optimized silica and carbon black reinforcement, achieving a precise 68-72 Shore A hardness. This formulation provides the essential balance: sufficient surface firmness for effective dirt scraping, adequate resilience to recover from door compression cycles exceeding 10,000 repetitions, and high tensile strength to resist tearing at stress points. The enhanced cross-link density from precision vulcanization ensures minimal permanent set (<15%) and superior resistance to common industrial contaminants. Material science is the non-negotiable foundation for double-door doormat longevity; compromising on compound specification guarantees premature failure and increased lifecycle costs. Precision rubber formulation transforms a simple mat into a durable, functional component of facility infrastructure.

Material Specifications

Material selection is a critical factor in the performance and longevity of industrial rubber components, particularly for applications such as double door doormats used in commercial and industrial environments. These doormats must withstand repeated mechanical stress, exposure to oils, greases, moisture, and fluctuating temperatures while maintaining structural integrity and sealing efficiency. At Suzhou Baoshida Trading Co., Ltd., we specialize in high-performance rubber formulations tailored to meet the rigorous demands of industrial applications. Our primary material offerings for double door doormats include Viton (FKM), Nitrile (NBR), and Silicone (VMQ), each with distinct chemical, thermal, and mechanical properties.

Viton is a fluorocarbon-based synthetic rubber known for its exceptional resistance to high temperatures, oils, fuels, and a broad range of chemicals. With a continuous service temperature range up to 200°C and excellent ozone and UV resistance, Viton is ideal for harsh industrial environments where exposure to aggressive media is common. Its low gas permeability and high elasticity retention under stress make it a premium choice for critical sealing applications, although it comes at a higher material cost.

Nitrile rubber, or Buna-N, is a copolymer of acrylonitrile and butadiene, offering outstanding resistance to aliphatic hydrocarbons, oils, and fuels. It is one of the most widely used elastomers in industrial sealing due to its balance of performance and cost-effectiveness. Nitrile performs well in temperature ranges from -30°C to 105°C and exhibits good abrasion resistance, making it suitable for heavy-duty doormat applications in manufacturing plants, garages, and transportation facilities. However, its performance degrades under prolonged exposure to ozone, UV light, and polar solvents.

Silicone rubber provides superior thermal stability, operating effectively from -60°C to 200°C, and demonstrates excellent resistance to UV radiation and ozone. While it does not match Nitrile in oil resistance or mechanical strength, Silicone excels in extreme temperature environments and applications requiring high purity and flexibility. It is often selected for indoor industrial settings where thermal cycling and weathering are primary concerns.

The following table summarizes the key material properties for informed selection:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 | -30 to 105 | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–8 |

| Elongation at Break (%) | 200–300 | 250–500 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Oil Resistance | Excellent | Excellent | Poor |

| Ozone/UV Resistance | Excellent | Fair | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

| Common Applications | Chemical processing, aerospace | Automotive, machinery | HVAC, electronics, indoor industrial |

Each material offers unique advantages, and selection should be based on the specific operational environment and performance requirements of the double door doormat application.

Manufacturing Capabilities

Engineering Capability: Precision Rubber Solutions for Double Door Doormats

Suzhou Baoshida Trading Co., Ltd. leverages deep expertise in industrial rubber formulation and precision moulding to deliver superior double door doormats meeting rigorous commercial and institutional demands. Our core strength resides in the integrated collaboration between dedicated mould engineering and advanced rubber chemistry teams. Five specialized mould engineers possess extensive experience in designing complex, high-cavitation tooling capable of achieving micron-level dimensional accuracy and exceptional surface replication for intricate double door profiles. This precision ensures consistent mat geometry, critical for optimal sealing against drafts, debris, and moisture ingress across dual entry points. Complementing this, our two in-house rubber formula engineers apply fundamental polymer science to develop bespoke elastomeric compounds. They meticulously engineer formulations balancing Shore A hardness (typically 65-85), tensile strength, tear resistance, and controlled compression set to withstand the unique dual-point pressure cycles and heavy foot traffic inherent in double door applications, while maintaining effective scraping functionality.

Material performance is non-negotiable for high-traffic entrances. Our formula engineers optimize vulcanization systems and filler packages to achieve exceptional abrasion resistance (ASTM D5963) and resilience, directly translating to extended service life and reduced maintenance costs for facility managers. Crucially, formulations are tailored for environmental stability, resisting degradation from ozone, UV exposure, common oils, and temperature extremes (-40°C to +100°C) encountered in diverse climates. This scientific approach ensures the mat maintains structural integrity and functional performance throughout its lifecycle, preventing premature hardening, cracking, or loss of scraping efficiency. The synergy between precise mould design and advanced compound development guarantees mats that fit perfectly, perform reliably under dual-door stress, and deliver consistent dirt and moisture capture.

Key performance characteristics of our standard and custom double door doormat compounds are summarized below:

| Property | Standard Compound | Custom High-Performance Compound | Test Method |

|---|---|---|---|

| Shore A Hardness | 70 ± 5 | 75 ± 3 (Adjustable) | ASTM D2240 |

| Tensile Strength (MPa) | ≥ 10.0 | ≥ 14.0 | ASTM D412 |

| Elongation at Break (%) | ≥ 300 | ≥ 350 | ASTM D412 |

| Abrasion Loss (mm³) | ≤ 120 | ≤ 80 | ASTM D5963 |

| Compression Set (%), 22h | ≤ 25 | ≤ 18 | ASTM D395, Method B |

| Operating Temperature | -30°C to +90°C | -40°C to +100°C | Internal Validation |

Our OEM capabilities provide seamless integration for partners requiring branded or specification-specific double door solutions. We manage the entire process: from initial CAD analysis and tolerance review of customer drawings, through iterative mould design validation (including flow simulation), compound development and certification, to rigorous production validation against dimensional and physical property specifications. Prototyping utilizes production-intent tooling for accurate performance prediction. Full traceability, adherence to ISO 9001 quality management, and flexible production scaling ensure reliable delivery of mats meeting exact functional and aesthetic requirements. Suzhou Baoshida transforms technical specifications into durable, high-performance rubber entrance solutions through applied engineering science and disciplined manufacturing execution.

Customization Process

Drawing Analysis

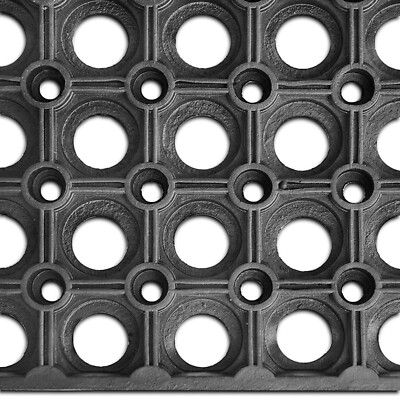

The customization process for industrial double door doormats begins with rigorous drawing analysis. At Suzhou Baoshida Trading Co., Ltd., engineering teams evaluate customer-provided technical drawings or CAD models to confirm dimensional accuracy, surface profile requirements, and structural integrity. This phase ensures compatibility with installation environments such as commercial entrances, cleanrooms, or high-traffic industrial facilities. Critical parameters including groove depth, edge chamfering, and drainage channel geometry are verified against OEM standards. Tolerance analysis is performed to meet ISO 2768-mK or customer-specific benchmarks. Any discrepancies or optimization opportunities are communicated through formal engineering change proposals (ECPs), ensuring alignment before material development commences.

Formulation Development

Following drawing validation, our rubber formulation engineers design a compound tailored to the doormat’s operational demands. The base polymer selection—typically SBR, EPDM, or recycled rubber granulate—is determined by environmental exposure, abrasion resistance needs, and color stability requirements. Additives such as sulfur for vulcanization, carbon black for UV resistance, and processing oils for extrusion efficiency are precisely metered. For double door applications requiring anti-slip performance, high-durometer nitrile or TPE blends may be incorporated. All formulations adhere to REACH and RoHS compliance standards. Material batches undergo Mooney viscosity testing, hardness (Shore A) calibration, and aging resistance evaluation in climatic chambers to ensure long-term durability under thermal cycling and moisture exposure.

Prototyping and Validation

Once the compound is finalized, a prototype run is executed using precision compression or injection molding techniques. Prototypes are assessed for dimensional conformity, surface finish quality, and functional performance. Key tests include load deflection behavior, coefficient of friction measurement (ASTM D2047), and accelerated wear simulation. Customers receive physical samples alongside material test reports (MTRs) for approval. Feedback is integrated into mold adjustments or formulation tweaks, with a maximum of two revision cycles included in standard service. This iterative process ensures the final design meets both aesthetic and mechanical specifications prior to scale-up.

Mass Production Readiness

Upon prototype approval, the project transitions to mass production. Automated batching systems ensure formulation consistency across large volumes. Each doormat is molded under controlled temperature and pressure profiles, with real-time monitoring of cure time and press tonnage. Post-molding operations such as trimming, surface texturing, and labeling are performed in-line. Final inspection includes 100% visual checks and statistical sampling for dimensional verification. Products are packaged in stackable, moisture-resistant wrapping suitable for export logistics.

Typical Technical Specifications for Custom Double Door Doormats

| Parameter | Standard Value | Test Method |

|---|---|---|

| Material | SBR/EPDM/Recycled Rubber | ISO 1431 |

| Hardness (Shore A) | 60–75 | ASTM D2240 |

| Tensile Strength | ≥8 MPa | ASTM D412 |

| Elongation at Break | ≥250% | ASTM D412 |

| Compression Set (24h, 70°C) | ≤25% | ASTM D395 |

| Operating Temperature | -30°C to +80°C | ISO 188 |

| Coefficient of Friction | ≥0.6 (dry), ≥0.45 (wet) | ASTM D2047 |

| Dimensional Tolerance | ±1.5 mm | ISO 2768-mK |

Contact Engineering Team

Contact Suzhou Baoshida for Precision Rubber Doormat Manufacturing

Suzhou Baoshida Trading Co., Ltd. stands as your definitive partner for engineered industrial rubber solutions, specifically tailored for high-performance double door doormat applications. Our technical expertise transcends standard manufacturing, integrating advanced polymer science with rigorous OEM protocols to deliver products that meet exacting operational demands. In environments where durability, chemical resistance, and dimensional stability are non-negotiable—such as automotive facilities, pharmaceutical cleanrooms, or heavy machinery assembly plants—our doormats perform as critical infrastructure components. We recognize that substandard rubber compounds lead to premature wear, inconsistent traction, and costly facility downtime. Our formulations, developed through iterative lab testing and real-world validation, ensure optimal Shore A hardness, tensile strength, and resistance to ozone, UV degradation, and industrial contaminants. This scientific approach guarantees that every doormat maintains structural integrity and functional efficacy across extended service cycles, directly supporting your operational continuity and safety compliance.

Our OEM process begins with a collaborative technical assessment. Mr. Boyce, our dedicated OEM Manager, will engage directly with your engineering team to dissect performance requirements, environmental stressors, and dimensional tolerances. We do not offer generic solutions; instead, we formulate bespoke rubber compounds using premium synthetic elastomers and reinforcing fillers calibrated to your specific load profiles and exposure conditions. Whether you require enhanced cut-resistance for high-traffic logistics hubs or specialized anti-static properties for electronics manufacturing zones, our R&D pipeline translates your technical specifications into validated production outputs. All components undergo stringent in-house quality control per ISO 9001 standards, including accelerated aging tests, abrasion resistance cycles, and dimensional metrology checks to ensure batch-to-batch consistency. This precision engineering minimizes field failures and extends product lifecycle, delivering measurable ROI through reduced replacement frequency and maintenance overhead.

The table below summarizes critical performance metrics achievable through our custom formulation process, benchmarked against generic industrial alternatives:

| Specification | Suzhou Baoshida Standard | Generic Industrial Alternative | Test Standard |

|---|---|---|---|

| Shore A Hardness | 65 ± 3 | 55–75 (inconsistent) | ASTM D2240 |

| Tensile Strength | ≥ 18 MPa | ≥ 12 MPa | ASTM D412 |

| Abrasion Loss (vol%) | ≤ 120 | ≤ 250 | ASTM D5963 |

| Oil Resistance (Δ vol%) | ≤ +15 | ≤ +35 | ASTM D471 |

| Operating Temp Range | -40°C to +120°C | -20°C to +80°C | ISO 188 |

Partnering with Suzhou Baoshida means securing a supply chain ally committed to technical excellence and responsive engineering support. We manage end-to-end production—from raw material sourcing to final packaging—ensuring seamless scalability for global distribution without compromising on precision. For double door systems requiring exacting dimensional accuracy and uncompromised material performance, our solutions eliminate the guesswork inherent in off-the-shelf products. Contact Mr. Boyce directly at [email protected] to initiate a technical consultation. Provide your application parameters, volume requirements, and performance targets, and we will deliver a validated compound specification and production timeline within 72 business hours. Do not settle for doormats that degrade your facility’s operational standards; engage with engineers who treat rubber formulation as a science, not a commodity. Your next-generation entrance solution begins with a single, precise technical dialogue.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).