Technical Contents

Engineering Guide: Eco Foam Insulation

Engineering Insight: Material Selection in eco foam Insulation

The performance and longevity of eco foam insulation in industrial applications are fundamentally determined by material selection. While the market offers numerous off-the-shelf foam solutions marketed as “eco-friendly” or “high-performance,” these generic products frequently fail to meet the rigorous demands of industrial environments. The root cause lies in a one-size-fits-all formulation approach that neglects application-specific variables such as thermal cycling, chemical exposure, mechanical stress, and long-term environmental stability.

At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered material solutions tailored to the operational parameters of the end-use environment. Standard foam insulations often utilize base polymers with inadequate cross-link density, leading to compression set, reduced thermal resistance, and premature degradation. For instance, conventional EVA or LDPE foams may exhibit acceptable initial insulation values but suffer significant performance decay under continuous exposure to elevated temperatures or UV radiation.

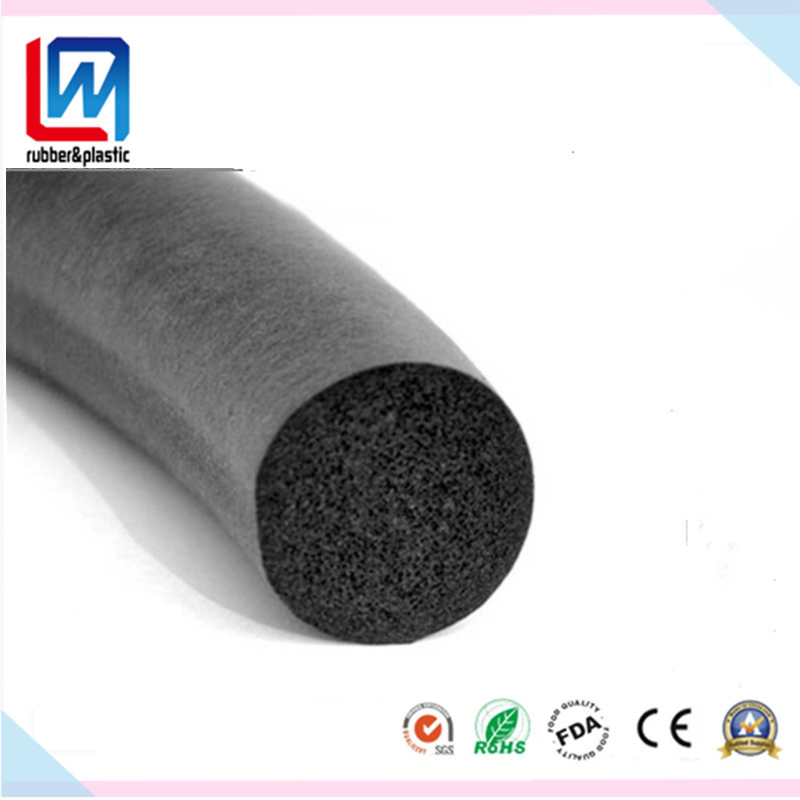

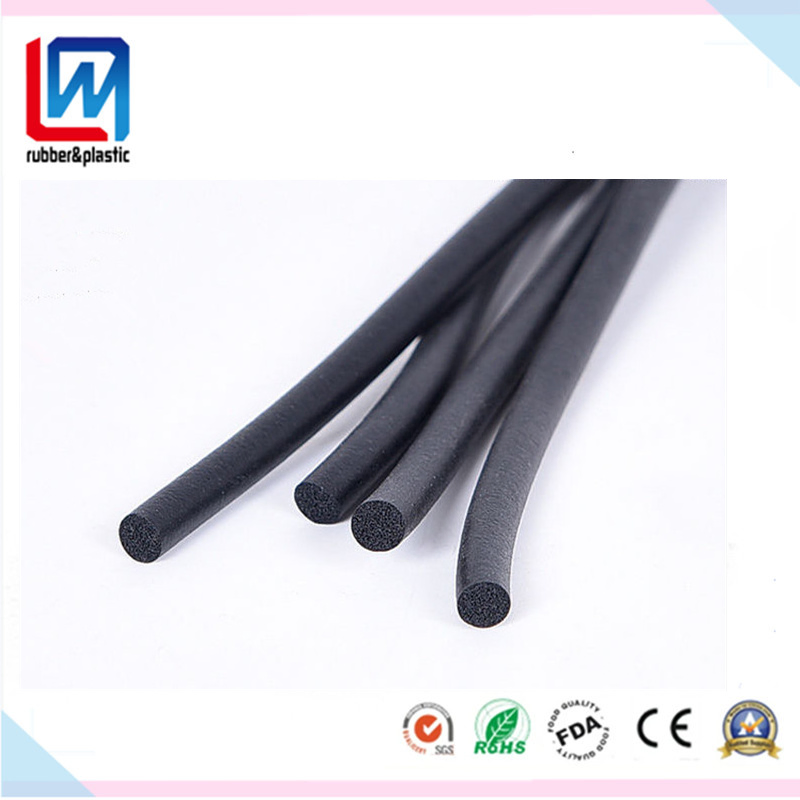

True eco foam insulation integrates sustainability with engineering precision. Our formulations leverage advanced closed-cell nitrile rubber (NBR) and polyolefin blends, engineered for optimal cell structure uniformity and gas retention. This results in consistent thermal conductivity (k-value) over time, critical for maintaining energy efficiency in HVAC, refrigeration, and industrial piping systems. Moreover, these materials are compounded with non-halogenated flame retardants and low-VOC additives, aligning with environmental regulations without compromising fire safety or indoor air quality.

A key differentiator is resistance to fluid absorption. Off-the-shelf foams often exhibit high water vapor transmission rates (WVT), leading to condensation within the cell matrix and a sharp decline in insulating performance. Our engineered eco foams achieve ultra-low permeability through precise control of cross-linking and cell membrane integrity, ensuring dimensional stability and preventing microbial growth in humid conditions.

Mechanical resilience is another area where standard solutions fall short. Industrial installations demand materials capable of withstanding vibration, abrasion, and repeated thermal expansion/contraction cycles. Generic foams, typically with lower tensile strength and elongation at break, crack or delaminate under such stress. Our formulations are designed to maintain elasticity and structural integrity across a wide temperature range, from -40°C to +125°C.

The following table outlines the comparative performance metrics between standard off-the-shelf foam and our engineered eco foam insulation:

| Property | Standard Off-the-Shelf Foam | Baoshida Engineered eco Foam |

|---|---|---|

| Thermal Conductivity (k-value, W/m·K) | 0.038–0.042 | 0.034–0.036 |

| Water Vapor Transmission Rate (ng/Pa·s·m²) | 50–80 | 20–30 |

| Compression Set (22h at 70°C, %) | 25–35 | 10–15 |

| Tensile Strength (MPa) | 0.8–1.2 | 1.8–2.3 |

| Elongation at Break (%) | 180–250 | 350–450 |

| Operating Temperature Range (°C) | -20 to +90 | -40 to +125 |

| Flame Spread Index (ASTM E84) | 25–35 | ≤20 |

| VOC Emissions | Moderate to High | Low (compliant with ISO 16000) |

Material selection is not a commodity decision—it is a critical engineering parameter. At Suzhou Baoshida, we reject generic formulations in favor of scientifically validated, application-driven designs that ensure durability, efficiency, and compliance. For industrial OEMs, this precision translates into reduced lifecycle costs, enhanced system reliability, and alignment with global sustainability targets.

Material Specifications

Material Specifications for Eco Foam Insulation Base Polymers

Suzhou Baoshida Trading Co., Ltd. provides precision-engineered rubber compounds as base polymers for closed-cell eco foam insulation systems. These materials are formulated to balance thermal performance, chemical resilience, and environmental responsibility for industrial applications. Our Viton, Nitrile, and Silicone formulations undergo rigorous QC protocols to ensure consistency in density, cell structure integrity, and long-term service life. Each polymer is optimized for specific operational demands, reducing lifecycle waste through extended durability and compatibility with low-GWP blowing agents.

Viton fluoroelastomers deliver exceptional resistance to extreme temperatures and aggressive chemicals, making them ideal for high-stakes insulation in petrochemical or aerospace conduits. Continuous service spans -20°C to +200°C with peak excursions to 230°C. They maintain structural stability against hydrocarbon derivatives, acids, and steam, preventing permeation-induced degradation. Nitrile butadiene rubber (NBR) offers cost-effective resilience for HVAC and automotive applications, operating reliably from -40°C to +120°C. Its superior resistance to mineral oils, greases, and water ensures consistent thermal barrier performance in dynamic environments. Silicone rubber provides unmatched flexibility and wide-temperature adaptability (-60°C to +200°C), critical for architectural seals and renewable energy infrastructure. Its inherent flame resistance and UV stability support sustainable building standards without halogenated additives.

The comparative analysis below details critical performance parameters for informed material selection:

| Material | Temperature Range (°C) | Chemical Resistance Profile | Density (g/cm³) | Tensile Strength (MPa) | Elongation at Break (%) | Compression Set (70h/100°C) | Key Eco Credentials |

|---|---|---|---|---|---|---|---|

| Viton | -20 to +200 | Hydrocarbons, acids, steam | 1.82 ± 0.02 | 12.5 min | 200 min | ≤ 25% | High durability reduces replacement frequency |

| Nitrile | -40 to +120 | Mineral oils, water, aliphatics | 1.35 ± 0.03 | 10.0 min | 250 min | ≤ 30% | Optimized for low-VOC foam processing |

| Silicone | -60 to +200 | Ozone, UV, water, mild chemicals | 1.15 ± 0.02 | 6.0 min | 400 min | ≤ 20% | Recyclable backbone; halogen-free formulation |

Selection hinges on operational parameters: Viton for extreme chemical exposure, Nitrile for cost-driven oil-resistant applications, and Silicone for ultra-low temperature flexibility. All compounds are engineered with reduced extractables to meet ISO 188 and ASTM D2000 standards, ensuring minimal environmental impact during service. Our OEM customization capability allows tailoring of compression set, flame ratings (UL 94 HF-1), and thermal conductivity (0.032–0.045 W/m·K) to project-specific sustainability targets. Suzhou Baoshida guarantees batch-to-batch repeatability through ISO 9001-certified production, enabling seamless integration into automated foam extrusion lines while adhering to global eco-regulations like REACH and RoHS. This precision engineering minimizes material waste and maximizes insulation efficiency across the product lifecycle.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Rubber Solutions for eco Foam Insulation

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the development and production of high-performance eco foam insulation. With a dedicated team comprising five experienced mould engineers and two specialized rubber formula engineers, we deliver technically advanced, application-specific insulation products tailored to the rigorous demands of global OEMs.

Our mould engineering team brings over 60 combined years of expertise in precision tooling design and manufacturing. Each engineer is proficient in CAD/CAM software including SolidWorks, AutoCAD, and UG NX, enabling rapid prototyping and seamless integration with client design inputs. Moulds are engineered for optimal flow dynamics, dimensional stability, and extended service life, ensuring consistent part quality across high-volume production runs. We specialize in multi-cavity and family moulds, supporting complex geometries required in HVAC, automotive, and building insulation applications.

Complementing our mould expertise, our two in-house rubber formula engineers focus exclusively on material science innovation for eco foam insulation. Leveraging deep knowledge of elastomer chemistry, they formulate closed-cell and open-cell rubber foams with enhanced thermal resistance, low water absorption, and superior flexibility. Our formulations are halogen-free, REACH and RoHS compliant, and optimized for low environmental impact without compromising performance. These eco-conscious compounds exhibit excellent aging resistance and UV stability, making them ideal for both indoor and outdoor applications.

Our integrated engineering workflow enables seamless collaboration between formula development and mould design. This synergy ensures that material behavior during curing and foaming is accurately predicted and accommodated in the tooling phase, minimizing trial iterations and accelerating time-to-market. All formulations undergo rigorous in-house testing for compression set, thermal conductivity, tensile strength, and flame retardancy prior to production release.

We operate as a certified OEM partner, offering full design-for-manufacturability (DFM) support, intellectual property protection, and scalable production from prototype to mass output. Our clients benefit from a single-source solution where material, mould, and process are engineered in unison for maximum efficiency and performance.

The following table outlines key technical specifications achievable through our engineered eco foam insulation systems:

| Property | Typical Value | Test Standard |

|---|---|---|

| Density | 45–85 kg/m³ | ISO 845 |

| Thermal Conductivity (25°C) | ≤0.036 W/(m·K) | ISO 8301 |

| Compression Set (70°C, 22h) | ≤15% | ISO 1856 |

| Water Absorption (7d) | ≤0.2% by volume | ASTM C272 |

| Tensile Strength | ≥0.8 MPa | ISO 1798 |

| Elongation at Break | ≥200% | ISO 1798 |

| Flame Spread Index (ASTM E84) | ≤25 | ASTM E84 |

| Smoke Developed Index (ASTM E84) | ≤50 | ASTM E84 |

By combining advanced material science with precision engineering, Suzhou Baoshida delivers eco foam insulation solutions that meet the highest industrial standards, supporting sustainability and performance in equal measure.

Customization Process

Customization Process for Eco Foam Insulation Solutions

Precision customization of eco foam insulation begins with rigorous drawing analysis to translate client specifications into actionable manufacturing parameters. Our engineering team conducts dimensional validation against CAD files, verifying critical features such as cell structure density, thickness tolerances, and edge sealing requirements. This phase identifies potential production constraints early, including mold flow challenges or thermal expansion variables inherent to sustainable polymer blends. We prioritize compatibility with global standards like ISO 9001 and ASTM C518, ensuring geometric integrity aligns with thermal performance targets. Client feedback loops are integrated at this stage to resolve ambiguities in sealing interfaces or substrate adhesion points before material development commences.

Formulation engineering follows, leveraging our proprietary database of bio-based elastomers and blowing agents. We optimize compound recipes to balance eco-compliance with mechanical resilience, adjusting ratios of renewable polyols, recycled rubber content, and non-halogenated flame retardants. Key variables include closed-cell percentage for moisture resistance and crosslink density for compression recovery. Each formulation undergoes predictive modeling for thermal conductivity stability across -40°C to 120°C operational ranges. Critical adjustments address client-specific demands such as reduced VOC emissions or enhanced UV resistance without compromising the foam’s R-value. All materials are screened for REACH and RoHS compliance, with full traceability documentation provided.

Prototyping employs CNC-machined aluminum molds for rapid validation of complex geometries. We produce 3-5 sample batches under controlled vulcanization conditions, measuring dimensional accuracy via CMM (Coordinate Measuring Machine) and conducting accelerated aging tests per ASTM D395. Thermal performance is validated using guarded hot-plate apparatus to confirm lambda values. Clients receive comprehensive test reports including compression set data at 50% deflection and flammability ratings per UL 94. Iterative refinements occur within 72 hours based on empirical results, ensuring the prototype meets both functional and sustainability KPIs before tooling sign-off.

Mass production transitions seamlessly using statistical process control (SPC) protocols. Each batch undergoes real-time monitoring of density gradients and cell homogeneity via inline X-ray imaging. We maintain ±0.5mm thickness tolerance through servo-hydraulic press calibration and implement 100% visual inspection for surface defects. Final validation includes third-party laboratory certification of thermal conductivity and environmental impact metrics. Suzhou Baoshida guarantees batch-to-batch consistency through material lot tracking and annual requalification of all eco-foam formulations, supporting OEMs with scalable production from 5,000 to 500,000 units monthly.

Eco Foam Insulation Customization Specifications

| Parameter | Standard Range | Customizable Range | Testing Standard |

|————————-|———————-|————————|———————|

| Density (kg/m³) | 30-120 | 20-150 | ASTM D1622 |

| Thermal Conductivity (W/m·K) | 0.032-0.038 | 0.028-0.040 | ASTM C518 |

| Compression Set (%) | ≤15 (25% deflection) | ≤10 (client-specified) | ASTM D395 |

| Tensile Strength (kPa) | 80-200 | 50-300 | ASTM D412 |

| Flame Rating | UL 94 HF-1 | UL 94 V-0 achievable | UL 94 |

Contact Engineering Team

For industrial partners seeking high-performance eco foam insulation solutions, Suzhou Baoshida Trading Co., Ltd. stands as a trusted leader in advanced rubber material engineering. Specializing in sustainable, closed-cell rubber foam formulations, we deliver precision-engineered insulation products tailored to meet the rigorous demands of HVAC, refrigeration, transportation, and industrial equipment applications. Our eco foam insulation is developed using proprietary low-emission elastomer blends that combine thermal efficiency, moisture resistance, and long-term durability—without compromising environmental responsibility.

At Suzhou Baoshida, we understand that performance consistency and regulatory compliance are critical in industrial procurement. Our eco foam insulation products are manufactured under ISO 9001-certified processes, ensuring batch-to-batch uniformity, dimensional accuracy, and adherence to international standards including RoHS, REACH, and ASTM C534. Each formulation is optimized for low thermal conductivity, high tensile strength, and exceptional resistance to mold, UV exposure, and chemical degradation. Whether you require customized sheeting, pre-slit rolls, or die-cut components, our technical team works directly with OEMs and system integrators to align material specifications with application requirements.

To support seamless integration into your production workflow, we offer comprehensive technical documentation, material safety data sheets (MSDS), and third-party test reports upon request. Our R&D division continuously evaluates new polymer architectures and blowing agents to reduce global warming potential (GWP) and enhance lifecycle performance—ensuring our clients remain at the forefront of sustainable manufacturing.

Partnering with Suzhou Baoshida means gaining access to not only superior materials but also deep technical expertise in rubber compounding and industrial supply chain logistics. We serve clients across Europe, North America, and Southeast Asia with reliable lead times, container-load scalability, and full export documentation support.

For immediate technical consultation or sample requests, contact Mr. Boyce, Rubber Formula Engineer and OEM Manager, directly at [email protected]. Mr. Boyce leads client-specific formulation development and is available to discuss custom density profiles, flame-retardant additives, colored compound options, and compliance strategies for regional market entry.

Below are key technical specifications for our standard eco foam insulation product line:

| Property | Test Method | Typical Value |

|---|---|---|

| Density | ASTM D3574 | 45–65 kg/m³ |

| Thermal Conductivity (23°C) | ISO 8301 | ≤0.034 W/(m·K) |

| Water Vapor Transmission | ASTM E96 | ≤5.0 ng/(Pa·m·s) |

| Tensile Strength | ASTM D412 | ≥0.8 MPa |

| Elongation at Break | ASTM D412 | ≥180% |

| Compression Set (22h, 70°C) | ASTM D395 | ≤20% |

| Flame Spread Index | ASTM E84 | <25 |

| Smoke Developed Index | ASTM E84 | <50 |

| Operating Temperature Range | — | -40°C to +105°C |

Initiate your project with scientifically validated, industrially proven eco foam insulation. Contact Mr. Boyce today at [email protected] to schedule a technical briefing or request application-specific data.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).