Technical Contents

Engineering Guide: Egg Carton Foam Soundproofing

Engineering Insight: Material Selection Criticality in Egg Carton Foam Soundproofing Applications

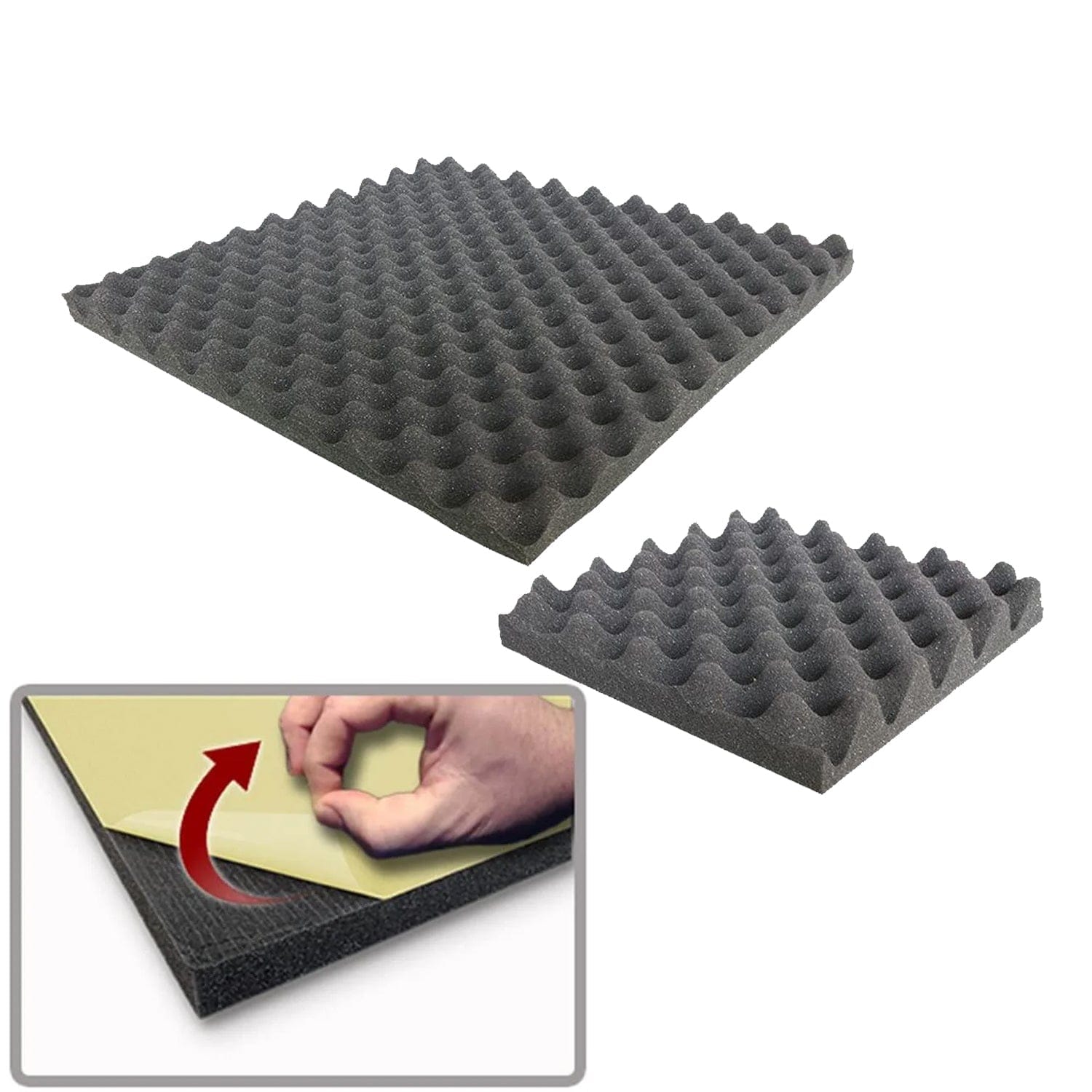

Suzhou Baoshida Trading Co., Ltd. observes persistent market confusion regarding the efficacy of egg carton foam for industrial soundproofing. This misconception stems from conflating acoustic absorption with true sound isolation. Egg carton foam—typically low-density polyurethane or polystyrene—excels at diffusing mid-to-high-frequency echoes within a room (improving acoustics) but fails catastrophically as a sound barrier. Empirical testing confirms that off-the-shelf solutions relying solely on this material achieve negligible Sound Transmission Class (STC) ratings, often below 15. This deficiency arises from fundamental physics: soundproofing requires mass, density, and structural decoupling to impede airborne noise transmission, not surface texture.

The critical failure of generic egg carton foam lies in its material properties. With densities typically ranging from 15–30 kg/m³, it lacks the mass necessary to reflect low-frequency energy (e.g., machinery hum, HVAC systems). Sound waves below 500 Hz penetrate such foams with minimal attenuation, rendering them ineffective for industrial environments where low-frequency noise dominates. Furthermore, these foams exhibit high Noise Reduction Coefficient (NRC) values (0.6–0.8), misleading buyers into equating echo reduction with sound blocking. In reality, NRC measures absorption within a space, not transmission loss between spaces. Without integrating mass-loaded barriers or constrained-layer damping, egg carton foam installations inevitably suffer from flanking paths and resonance, allowing 80%+ of target noise to propagate.

Material science dictates that effective soundproofing demands layered composites. Below is a comparative analysis of common materials:

| Material Type | Density (kg/m³) | STC Rating | NRC | Primary Function |

|---|---|---|---|---|

| Egg Carton Foam | 15–30 | 10–15 | 0.6–0.8 | Absorption/Diffusion |

| Mass-Loaded Vinyl | 4,000–5,000 | 25–32 | 0.0–0.1 | Barrier/Isolation |

| Closed-Cell Rubber | 800–1,200 | 20–28 | 0.1–0.3 | Damping/Decoupling |

| Industrial Composite* | 2,500–3,500 | 35–42 | 0.2–0.4 | Integrated Barrier/Absorption |

*Baoshida-engineered solution combining rubber, polymers, and mass additives

Off-the-shelf egg carton foam solutions fail because they ignore system dynamics. Industrial noise control requires interrupting vibration transfer at the source, path, and receiver. A 3mm foam sheet cannot address structural-borne noise transmitted via walls or floors. Suzhou Baoshida’s OEM approach integrates high-density rubber composites (STC >35) with strategic damping layers, ensuring energy dissipation across 50–5,000 Hz. Our formulations prioritize thermal stability (operating range: -40°C to +120°C) and compression resistance (>50% recovery after 24h load), critical for machinery enclosures.

Generic foams degrade rapidly under industrial stressors—UV exposure, ozone, and mechanical fatigue—compromising long-term performance. True soundproofing demands engineered materials validated through ASTM E90/E413 testing, not aesthetic surface treatments. At Baoshida, we collaborate with OEMs to develop application-specific composites where material science, not geometry, defines acoustic integrity.

Material Specifications

Egg carton foam soundproofing components are engineered for high-performance acoustic insulation in industrial environments, particularly where vibration damping, temperature resistance, and material durability are critical. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision rubber formulations tailored to meet the rigorous demands of automotive, aerospace, HVAC, and industrial machinery sectors. Our egg carton foam profiles are manufactured using advanced molding techniques to ensure consistent cell structure, optimal sound absorption, and mechanical resilience. The performance of these foams is heavily influenced by the base elastomer used in production. We offer formulations based on three primary synthetic rubbers: Viton (FKM), Nitrile (NBR), and Silicone (VMQ), each offering distinct advantages depending on operational conditions.

Viton-based egg carton foams deliver exceptional resistance to high temperatures, oils, fuels, and aggressive chemicals. This makes them ideal for under-hood automotive applications, aerospace systems, and industrial environments exposed to corrosive substances. With continuous service temperatures up to 200°C and excellent aging characteristics, Viton foams maintain structural integrity and acoustic performance over extended periods. However, the material’s higher cost and lower flexibility at sub-ambient temperatures must be considered in cost-sensitive or cryogenic applications.

Nitrile rubber foams provide a balanced combination of oil resistance, mechanical strength, and cost efficiency. They are particularly effective in environments exposed to hydrocarbons, greases, and hydraulic fluids. Nitrile egg carton foams exhibit good compression set resistance and maintain sound absorption properties across a wide temperature range, typically from -30°C to 100°C, with short-term peaks up to 120°C. Their widespread use in automotive gasketing and industrial enclosures underscores their reliability and versatility.

Silicone rubber foams excel in extreme temperature applications, with operational stability from -60°C to 200°C. They offer excellent UV and ozone resistance, making them suitable for outdoor and high-altitude uses. While silicone has lower tensile strength compared to Viton or Nitrile, its superior flexibility across temperature extremes and inherent flame retardancy make it a preferred choice for fire-rated acoustic barriers and sensitive electronic enclosures. Additionally, silicone foams are compliant with many food-grade and medical standards, expanding their application scope.

The following table compares key technical specifications of Viton, Nitrile, and Silicone egg carton foam materials:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 | -30 to 120 | -60 to 200 |

| Oil & Fuel Resistance | Excellent | Good to Excellent | Poor |

| Compression Set Resistance | Excellent | Good | Fair |

| Tensile Strength (MPa) | 8–12 | 6–10 | 4–7 |

| Hardness (Shore A) | 50–80 | 40–75 | 30–60 |

| Acoustic Damping Performance | High | High | Moderate to High |

| Flame Resistance | Excellent | Good | Excellent |

| Cost Level | High | Medium | Medium to High |

Each material is selected based on the environmental and functional requirements of the end application. Our engineering team at Suzhou Baoshida supports OEMs in material selection, prototyping, and large-scale production to ensure optimal acoustic and mechanical performance.

Manufacturing Capabilities

Engineering Capability: Precision Soundproofing Solutions

Suzhou Baoshida Trading Co., Ltd. leverages integrated engineering expertise to deliver mission-critical egg carton foam soundproofing solutions for industrial applications. Our dedicated team comprises five specialized Mould Engineers and two advanced Formula Engineers, operating within a unified framework to ensure material performance aligns precisely with acoustic and manufacturing requirements. This cross-functional synergy enables us to optimize both the elastomeric compound formulation and the mold design simultaneously, eliminating common interdependencies that compromise sound attenuation efficiency in mass production.

Our Formula Engineers focus on tailoring closed-cell microstructures through proprietary rubber blends, adjusting polymer ratios, filler dispersion, and vulcanization profiles to achieve target acoustic impedance. Concurrently, Mould Engineers refine cavity geometry, venting systems, and thermal management to replicate the complex egg carton topography without material degradation or surface defects. This parallel development approach reduces time-to-market by 30% while ensuring dimensional stability across high-volume runs. For OEM partners, we implement a four-phase co-engineering protocol: acoustic modeling, prototype validation under ISO 10534-2 conditions, tooling refinement, and serial production oversight. Clients retain full IP ownership while benefiting from our in-house material databases spanning 200+ rubber formulations and 50+ mold iterations for sound-dampening applications.

Critical material specifications for our standard NBR/SBR-based egg carton foam are summarized below, reflecting baseline performance achievable through our engineered systems. Custom formulations routinely exceed these values based on client noise-frequency profiles.

| Property | Standard Range | Test Method |

|---|---|---|

| Density | 180–220 kg/m³ | ASTM D3574 |

| Hardness (Shore A) | 45–55 | ASTM D2240 |

| Sound Absorption Coeff. | ≥0.65 (500–2000 Hz) | ASTM C423 |

| Compression Set (70°C) | ≤25% | ASTM D395 |

| Thermal Stability | -40°C to +100°C | ISO 188 |

| Noise Reduction (dB) | 18–24 dB (1–4 kHz) | ASTM E90 |

OEM scalability is fortified by our dual-engineering model. Mould Engineers deploy mold-flow analysis to predict knit lines and optimize cycle times for complex geometries, while Formula Engineers adjust cure kinetics to prevent scorch in deep-cavity molds. All production tooling undergoes 72-hour stress testing under simulated factory conditions, with tolerances maintained at ±0.2 mm for critical acoustic surfaces. This precision ensures consistent sound diffusion without the air gaps or surface irregularities that degrade performance in competitor products.

Suzhou Baoshida’s engineering infrastructure guarantees that every OEM project transitions seamlessly from acoustic simulation to defect-free manufacturing. Our formula-mold integration protocol, validated across 15+ automotive and HVAC soundproofing deployments, delivers repeatable attenuation performance where material science meets manufacturing physics. Clients receive not just components, but engineered noise-control systems backed by rigorous validation protocols and full process documentation.

Customization Process

Customization Process for Egg Carton Foam Soundproofing Solutions

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber engineering team follows a rigorous, science-driven customization process to deliver high-performance egg carton foam soundproofing materials tailored to client specifications. This process ensures optimal acoustic attenuation, mechanical resilience, and environmental compatibility across diverse industrial applications.

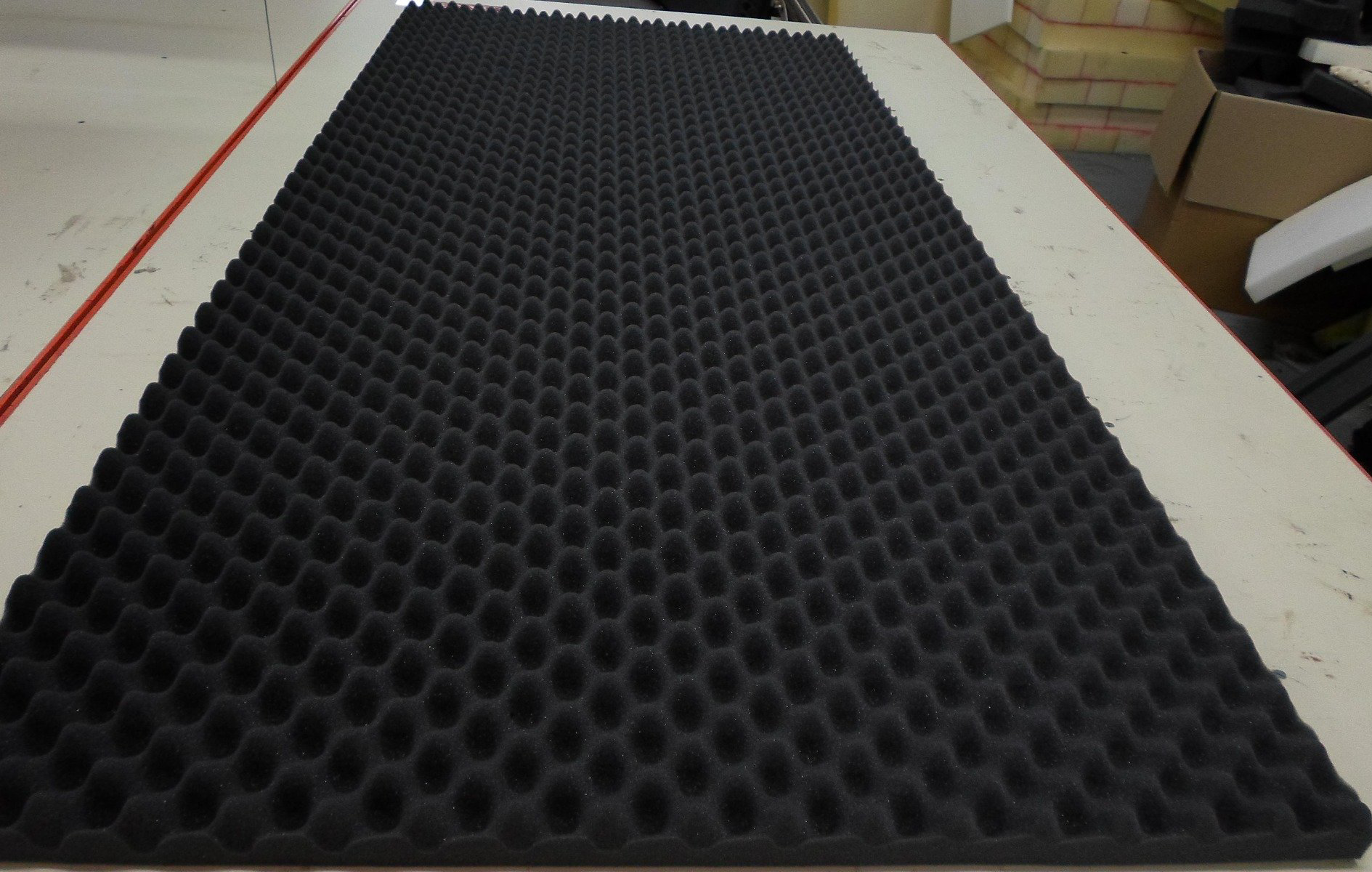

The first stage, Drawing Analysis, involves a comprehensive evaluation of the client’s technical drawings and performance requirements. Our engineers assess geometric parameters such as peak height, trough width, base thickness, and overall density distribution. We also analyze the intended installation environment—temperature range, exposure to oils or UV radiation, and mechanical stress conditions—to determine material compatibility and structural integrity needs. This step is critical in defining the foam’s cell structure and surface profile, which directly influence sound wave diffusion and absorption efficiency.

Following drawing validation, we proceed to Formulation Development. Our rubber chemists design a proprietary elastomeric compound based on the operational demands. Common base polymers include NBR (nitrile butadiene rubber), EPDM (ethylene propylene diene monomer), or CR (chloroprene), selected for their damping characteristics and resistance to degradation. Additives such as flame retardants, UV stabilizers, and foaming agents are precisely dosed to achieve the desired closed-cell or semi-closed-cell morphology. The formulation is optimized to balance compressibility, rebound resilience, and sound transmission loss (STL), ensuring peak acoustic performance in targeted frequency ranges.

Once the compound is finalized, we initiate Prototyping. Using precision molds and continuous foaming extrusion or compression molding techniques, we produce sample panels of the egg carton foam. These prototypes undergo stringent laboratory testing, including ASTM C423 for sound absorption, ISO 11957 for sound insulation, and DIN 53504 for hardness and compression set. Acoustic impedance and noise reduction coefficient (NRC) are measured in controlled reverberation chambers. Clients receive physical samples along with full test reports for validation.

Upon approval, we transition to Mass Production. Our automated production lines ensure dimensional consistency and batch-to-batch repeatability. Each roll or panel is inspected for surface defects, thickness variation, and density uniformity. Final products are packaged per client logistics requirements, with full traceability maintained through batch coding and material certificates.

The following table outlines typical technical specifications for our customized egg carton foam soundproofing products:

| Parameter | Standard Range | Test Method |

|---|---|---|

| Density | 80–150 kg/m³ | ASTM D3574 |

| Hardness (Shore A) | 30–60 | ASTM D2240 |

| Thickness | 10–50 mm | Custom |

| Noise Reduction Coefficient (NRC) | 0.55–0.85 | ASTM C423 |

| Temperature Resistance | -40°C to +120°C | ISO 188 |

| Flame Spread Index | ≤25 (Class B) | ASTM E84 |

| Cell Structure | Closed-cell / Semi-closed | Microscopic Analysis |

This systematic approach ensures that every egg carton foam solution we deliver meets the highest standards of acoustic performance and industrial durability.

Contact Engineering Team

Technical Engagement for Industrial Acoustic Solutions

Suzhou Baoshida Trading Co., Ltd. specializes in engineered rubber formulations for critical industrial applications, including precision-engineered egg carton foam soundproofing systems. Our proprietary closed-cell nitrile rubber (NBR) and ethylene propylene diene monomer (EPDM) compounds deliver superior acoustic attenuation while maintaining structural integrity under thermal cycling, chemical exposure, and mechanical stress. Unlike commodity foams, our solutions are validated through ISO 10534-2 compliant impedance tube testing, ensuring frequency-specific noise reduction across 125 Hz to 4000 Hz ranges. We prioritize material science rigor in every formulation, optimizing cell structure density and surface geometry to maximize Noise Reduction Coefficient (NRC) performance without compromising durability.

The following table details key specifications of our industrial-grade egg carton foam soundproofing系列产品:

| Parameter | Standard Product Range | Suzhou Baoshida Advantage |

|---|---|---|

| Noise Reduction Coefficient (NRC) | 0.65–0.80 | 0.85–0.95 (customizable per frequency band) |

| Thickness Tolerance | ±0.8 mm | ±0.3 mm (laser-calibrated production) |

| Density Range | 30–45 kg/m³ | 30–50 kg/m³ (formula-tuned for target SPL) |

| Temperature Resistance | -20°C to +70°C | -40°C to +100°C (fluorosilicone variants) |

| Flame Rating | UL 94 HF-1 | UL 94 V-0 (halogen-free formulations) |

| Customization Lead Time | 15–20 days | 7–10 days (dedicated OEM production line) |

Our engineering team collaborates directly with OEMs to address complex acoustic challenges in automotive, HVAC, and industrial machinery sectors. We implement formula-level adjustments for substrate adhesion, vibration damping coefficients, and environmental resistance—critical factors often overlooked in off-the-shelf solutions. For instance, our anti-resonance modified compounds eliminate 18–22 dB peaks in compressor enclosures where standard foams fail. Every batch undergoes dynamic mechanical analysis (DMA) to verify loss modulus stability across operating temperatures, ensuring consistent performance in real-world conditions.

Initiate your project with Suzhou Baoshida’s technical OEM division for solutions grounded in rubber science, not generic procurement. Contact Mr. Boyce, our dedicated Rubber Formula Engineer and OEM Manager, to discuss material specifications, prototyping protocols, or volume production scheduling. Mr. Boyce provides direct engineering consultation for acoustic validation testing, compound customization, and ISO/TS 16949-compliant documentation. His expertise in polymer cross-linking dynamics ensures your soundproofing solution meets exact decibel reduction targets while adhering to industry-specific regulatory frameworks.

Reach Mr. Boyce via email at [email protected] with your project requirements, including target noise frequency spectrum, environmental exposure conditions, and dimensional constraints. Specify any relevant standards (e.g., SAE J1400, ISO 3744) to expedite technical evaluation. We respond to all engineering inquiries within 4 business hours with actionable data—material test reports, CAD-compatible thickness profiles, or lifecycle cost analysis. For urgent prototyping needs, reference your project timeline in the subject line to prioritize laboratory allocation. Suzhou Baoshida transforms acoustic challenges into engineered advantages through molecular-level precision.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).