Technical Contents

Engineering Guide: Egg Crate Foam Insulation

Engineering Insight: Material Selection in Egg Crate Foam Insulation

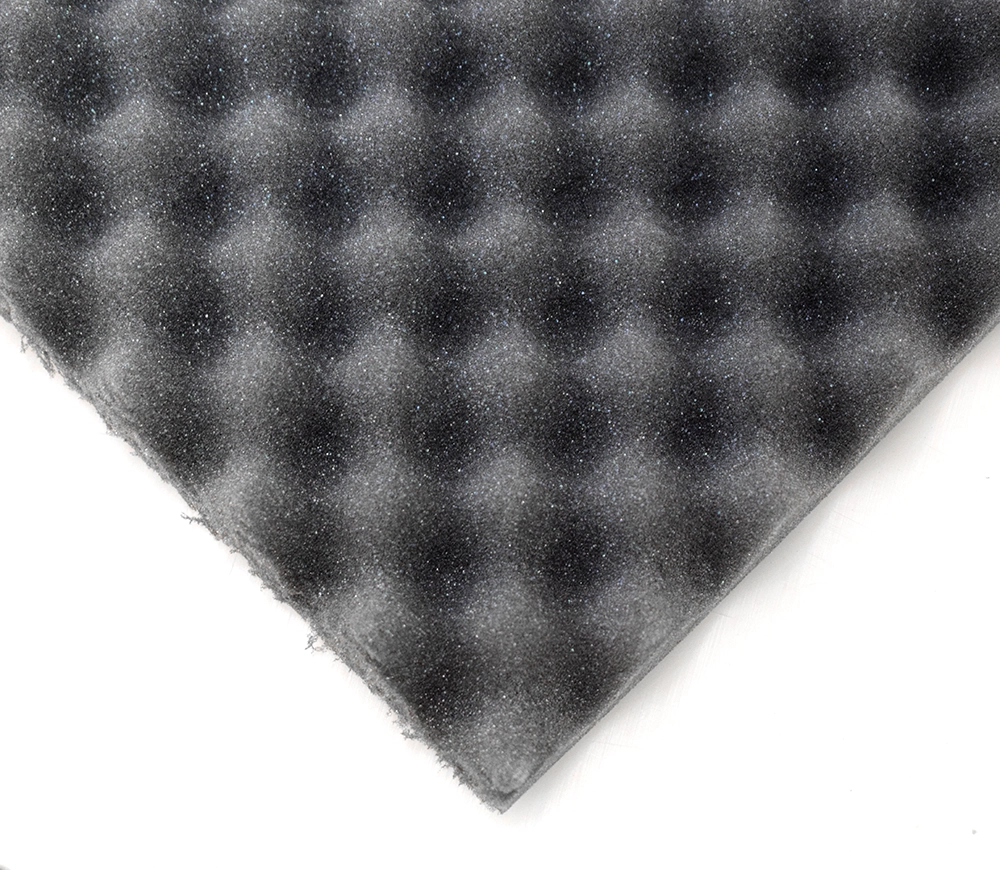

In industrial applications, egg crate foam insulation is frequently deployed for vibration damping, acoustic attenuation, and thermal management. While its geometric structure contributes significantly to performance, the underlying material selection is the decisive factor in long-term reliability. Off-the-shelf solutions often fail because they prioritize cost and availability over application-specific engineering requirements. At Suzhou Baoshida Trading Co., Ltd., we emphasize that standardized foams—typically made from low-density polyethylene (LDPE) or generic EVA—are ill-suited for demanding environments where temperature fluctuation, mechanical stress, or chemical exposure are present.

Material properties directly influence compression set resistance, tensile strength, and resilience. For example, a foam used in automotive under-hood insulation must withstand prolonged exposure to engine oils and temperatures exceeding 120°C. Standard foams degrade under such conditions, leading to loss of structural integrity and reduced insulation efficiency. Similarly, in industrial machinery enclosures, UV exposure and ozone can cause embrittlement in non-formulated elastomers, resulting in premature cracking and failure.

The core issue with generic egg crate foams lies in their homogenized formulation. They are designed for broad consumer use—such as packaging or light-duty padding—where performance margins are less critical. In contrast, engineered rubber solutions require precise control over polymer base, cross-linking density, and additive packages. Closed-cell nitrile rubber (NBR), for instance, offers superior oil resistance and thermal stability compared to LDPE. Chloroprene (CR) provides excellent flame retardancy and weather resistance, making it ideal for outdoor or transit applications.

At Baoshida, our approach begins with application mapping: identifying operational temperature ranges, load cycles, and environmental stressors. This enables us to tailor compound formulations that meet exact performance thresholds. Custom vulcanization processes enhance cell structure uniformity, improving both acoustic damping and compression recovery. Furthermore, we integrate anti-microbial agents and flame-retardant additives when required, ensuring compliance with industrial safety standards.

Below is a comparative analysis of common foam materials used in egg crate insulation, highlighting key performance metrics relevant to industrial use.

| Material | Density (kg/m³) | Temp Range (°C) | Compression Set (%) | Oil Resistance | Flame Retardancy (UL94) |

|---|---|---|---|---|---|

| LDPE | 25–35 | -40 to 80 | 25–35 | Poor | HB |

| EVA | 30–45 | -50 to 90 | 20–30 | Fair | HB |

| NBR | 40–60 | -40 to 120 | 15–20 | Excellent | V-1 |

| CR (Neoprene) | 50–70 | -40 to 130 | 10–18 | Good | V-0 |

Selecting the correct material is not a secondary consideration—it is foundational. Off-the-shelf foams may offer short-term savings, but they compromise system durability and increase total cost of ownership. Precision-engineered rubber solutions, developed through rigorous material science, ensure sustained performance in critical industrial environments.

Material Specifications

Material Specifications for Egg Crate Foam Insulation

Egg crate foam insulation requires precise material selection to ensure optimal performance in demanding industrial sealing and thermal management applications. The geometric structure of egg crate profiles imposes unique stress distribution and compression set requirements, necessitating elastomers with tailored physical and chemical resistance properties. At Suzhou Baoshida Trading Co., Ltd., we engineer Viton, Nitrile, and Silicone compounds specifically for egg crate foam manufacturing, prioritizing cell structure integrity, rebound resilience, and environmental stability. Each material addresses distinct operational challenges, from extreme temperature exposure to aggressive chemical contact.

Viton fluorocarbon rubber delivers exceptional resistance to high temperatures, fuels, and synthetic lubricants. Its molecular stability ensures minimal compression set degradation in continuous service up to 200°C, making it ideal for aerospace and automotive under-hood applications where thermal cycling and oil exposure are critical failure points. Viton-based egg crate foams maintain sealing integrity in jet engine insulation and fuel system gaskets, though higher material costs necessitate strategic application targeting.

Nitrile butadiene rubber (NBR) offers a cost-effective solution for moderate-temperature environments with significant exposure to petroleum-based fluids. With a functional range of -30°C to 100°C, NBR egg crate foams excel in hydraulic systems, marine gasketing, and industrial machinery seals. Its superior abrasion resistance and low gas permeability prevent fluid ingress in dynamic sealing interfaces, though ozone and weathering resistance remain limited without specialized additives.

Silicone rubber provides unmatched flexibility across extreme temperatures (-60°C to 230°C) and outstanding resistance to UV, ozone, and water. Silicone egg crate foams are preferred for medical device insulation, LED lighting thermal management, and outdoor electronic enclosures where dimensional stability under thermal shock is non-negotiable. While exhibiting lower tensile strength than hydrocarbon rubbers, its inertness and flame retardancy comply with stringent safety standards like UL 94 V-0.

The following table details critical specifications for egg crate foam insulation compounds:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Hardness (Shore A) | 50–80 | 40–70 | 30–60 |

| Temp Range (°C) | -20 to 200 | -30 to 100 | -60 to 230 |

| Density (kg/m³) | 350–550 | 300–500 | 300–400 |

| Key Chemical Resistance | Fuels, acids, oils | Petroleum oils, water | Ozone, UV, water |

| Compression Set (%) | ≤25 (200°C/70h) | ≤30 (100°C/70h) | ≤20 (200°C/70h) |

Material selection directly impacts egg crate foam’s service life in OEM applications. Viton is indispensable for high-temperature chemical exposure, NBR balances economy and oil resistance for general industrial use, and Silicone dominates in wide-temperature or biocompatible scenarios. Suzhou Baoshida’s precision compounding ensures consistent cell morphology and closed-cell structure, preventing moisture ingress and maintaining thermal/acoustic performance. All compounds undergo rigorous ASTM D2000 and ISO 3302 validation to guarantee dimensional repeatability in high-volume production tooling. Partnering with our engineering team ensures optimal material alignment with your operational parameters and regulatory requirements.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of industrial rubber solutions, delivering high-performance materials and engineered components tailored to the rigorous demands of modern manufacturing. Our Engineering Capability division is anchored by a dedicated team of 5 Mould Engineers and 2 specialized Formula Engineers, enabling us to offer comprehensive OEM (Original Equipment Manufacturer) services for advanced applications such as egg crate foam insulation. This integrated technical team ensures precision from concept to production, maintaining strict control over material formulation, mold design, and process optimization.

Our Formula Engineers possess deep expertise in polymer chemistry, focusing on custom elastomer formulations that meet exact thermal, mechanical, and environmental performance criteria. For egg crate foam insulation, this translates into closed-cell or open-cell rubber foams engineered for superior thermal resistance, acoustic damping, and compression recovery. By tailoring base polymers such as EPDM, NBR, or CR with specific cross-linking agents, blowing agents, and stabilizers, we achieve consistent cell structure and density profiles critical for insulation efficiency. These formulations are validated through accelerated aging, thermal cycling, and compression set testing to ensure long-term reliability in industrial and automotive environments.

Complementing material science capabilities, our Mould Engineering team specializes in precision tooling for complex foam geometries. The egg crate profile—characterized by its repetitive pyramidal or sinusoidal structure—requires exact control over draft angles, venting, and cavity symmetry to ensure uniform expansion and dimensional stability during molding. Our engineers utilize 3D CAD modeling and mold flow simulation to optimize tool design, minimizing defects such as voids, shrinkage, or surface imperfections. All molds are fabricated using high-grade tool steel with surface treatments to extend service life and maintain release performance under repeated thermal cycling.

We support full OEM integration, providing end-to-end development from prototype to high-volume production. Clients benefit from design for manufacturing (DFM) reviews, material selection guidance, and rapid prototyping using in-house molding presses and laboratory testing facilities. Our quality management system adheres to ISO 9001 standards, with traceability maintained at every stage of production.

The table below outlines key technical specifications achievable for egg crate foam insulation through our engineering platform:

| Parameter | Typical Range | Test Standard |

|---|---|---|

| Density | 40–120 kg/m³ | ASTM D3574 |

| Hardness (Shore A) | 15–45 A | ASTM D2240 |

| Compression Set (22h, 70°C) | ≤ 20% | ASTM D3574 |

| Thermal Conductivity | 0.035–0.042 W/(m·K) | ASTM C518 |

| Tensile Strength | 0.8–2.0 MPa | ASTM D412 |

| Elongation at Break | 150–300% | ASTM D412 |

| Cell Structure | Open-cell or Closed-cell | Microscopy Analysis |

This combination of material innovation and precision engineering positions Suzhou Baoshida as a trusted partner for industrial clients requiring mission-critical insulation solutions. Our OEM framework supports customization, scalability, and technical accountability across global supply chains.

Customization Process

Customization Process for Egg Crate Foam Insulation

At Suzhou Baoshida Trading Co., Ltd., our egg crate foam insulation customization adheres to a rigorously defined sequence to ensure technical precision and industrial reliability. This process transforms client specifications into high-performance rubber solutions through four critical phases, each governed by ASTM and ISO standards.

Drawing Analysis

Initial engagement begins with exhaustive CAD drawing evaluation. Our engineering team scrutinizes dimensional tolerances, cell structure geometry, and application-specific load requirements. We cross-reference client schematics against material behavior databases to identify potential stress points or thermal expansion risks. This phase includes feasibility assessment for complex contours, ensuring manufacturability without compromising structural integrity. All annotations are validated against ISO 2768-mK general tolerance standards, with deviations flagged for collaborative resolution prior to formulation.

Formulation

Material science drives our proprietary compound development. Based on thermal conductivity targets, chemical exposure, and compression set requirements from the drawing analysis, we select base polymers—typically EPDM for extreme weather resistance or NBR for oil/fuel applications. Critical additives include closed-cell stabilizers to maintain uniform egg crate topology and flame retardants meeting UL 94 V-0. Each formulation undergoes Durometer testing (Shore A 15–45 range) and thermal aging simulations at 100°C for 72 hours to validate long-term resilience.

Prototyping

Physical validation occurs through iterative prototyping. Using precision CNC-machined molds, we produce samples for ASTM D3574 compression deflection testing and ISO 844 thermal conductivity verification. Clients receive detailed performance dossiers including force-deflection curves and dimensional stability reports under 50% compression. This phase includes 3–5 revision cycles with real-time data sharing, ensuring alignment with operational parameters before tooling sign-off.

Mass Production

Transition to volume manufacturing leverages automated continuous vulcanization lines with SPC-monitored curing parameters. Each batch undergoes 100% visual inspection for cell uniformity and automated dimensional scanning against CAD benchmarks. Statistical process control tracks critical metrics like density variation (±0.02 g/cm³) and compression recovery (≥90% at 23°C). Final shipment includes traceable material certificates and batch-specific performance validation per ISO 188 aging tests.

Key Performance Specifications

| Parameter | Standard Range | Test Method | Industrial Application Threshold |

|---|---|---|---|

| Density | 0.08–0.15 g/cm³ | ASTM D3574 | ≤0.12 g/cm³ for HVAC ducts |

| Compression Deflection | 15–45% at 2.5 kPa | ASTM D3574 | ≥30% for vibration damping |

| Thermal Conductivity | 0.032–0.045 W/m·K | ISO 8301 | ≤0.038 W/m·K for cryogenic use |

| Temperature Resistance | -50°C to +150°C | ISO 188 | Sustained +135°C for automotive |

| Compression Set (22h) | ≤20% | ASTM D395 | ≤15% for sealing applications |

This structured methodology guarantees that every egg crate foam component meets exacting industrial demands, from initial concept to certified volume production. Suzhou Baoshida’s integration of material science and process control eliminates performance variability, delivering insulation solutions engineered for operational longevity.

Contact Engineering Team

For industrial manufacturers seeking high-performance egg crate foam insulation solutions, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in advanced rubber material engineering. Our expertise in closed-cell and open-cell rubber foams enables us to deliver tailored thermal, acoustic, and vibration-damping insulation products that meet the rigorous demands of automotive, aerospace, HVAC, and industrial equipment sectors. Engineered for dimensional stability, moisture resistance, and long-term durability, our egg crate foam profiles are precision-manufactured to ensure consistent cell structure and optimal surface contact for superior insulation performance.

Egg crate foam insulation is distinguished by its unique geometric surface pattern, which increases surface area and creates air pockets that enhance thermal resistance and sound absorption. At Suzhou Baoshida, we optimize this structure using proprietary compounding techniques and advanced foaming processes, ensuring each batch meets exact OEM specifications. Whether you require NBR, EPDM, silicone, or custom-blend rubber foams, our formulations are designed to withstand extreme temperatures, UV exposure, and chemical environments without degradation.

Our manufacturing capabilities include continuous vulcanization, precision die-cutting, lamination, and custom density control, allowing us to produce egg crate foam insulation in a wide range of thicknesses, hardness levels, and compression set characteristics. Each product is subjected to stringent quality control protocols, including ASTM D3574 for cellular rubber and ISO 9001-compliant testing procedures, to guarantee repeatability and compliance across large-volume production runs.

The following table outlines the standard technical specifications for our most commonly requested egg crate foam insulation profiles:

| Property | Test Method | Value Range |

|---|---|---|

| Material Type | – | NBR, EPDM, Silicone, CR |

| Density | ASTM D3574 | 60–180 kg/m³ |

| Hardness (Shore A) | ASTM D2240 | 30–80 |

| Tensile Strength | ASTM D412 | 1.5–4.0 MPa |

| Elongation at Break | ASTM D412 | 150–400% |

| Compression Set (22h, 70°C) | ASTM D395 | ≤35% |

| Temperature Range | – | -40°C to +150°C (up to +300°C for silicone) |

| Flame Resistance | UL 94, FMVSS 302 | HB to V-0 ratings available |

| Closed Cell Content | ASTM D2031 | ≥85% (closed-cell variants) |

All specifications can be customized based on application requirements, including conductive or anti-static additives, adhesive backing, or multi-layer composite structures.

To discuss your specific egg crate foam insulation needs, contact Mr. Boyce, OEM Manager and Rubber Formula Engineer at Suzhou Baoshida Trading Co., Ltd. With over 15 years of experience in industrial rubber solutions, Mr. Boyce leads technical consultations, material selection, and product development for global clients. He ensures seamless integration of our foam insulation products into your manufacturing workflow, from prototype to full-scale production.

For engineering support, sample requests, or quotation inquiries, reach out directly via email at [email protected]. Our team responds to all technical inquiries within 24 business hours and offers bilingual (English/Chinese) project coordination to support international supply chain integration. Partner with Suzhou Baoshida for precision-engineered rubber foam solutions that deliver measurable performance and reliability in demanding industrial environments.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).