Technical Contents

Engineering Guide: Entryways Doormats

Engineering Insight: The Critical Role of Material Selection in Industrial Entryway Doormats

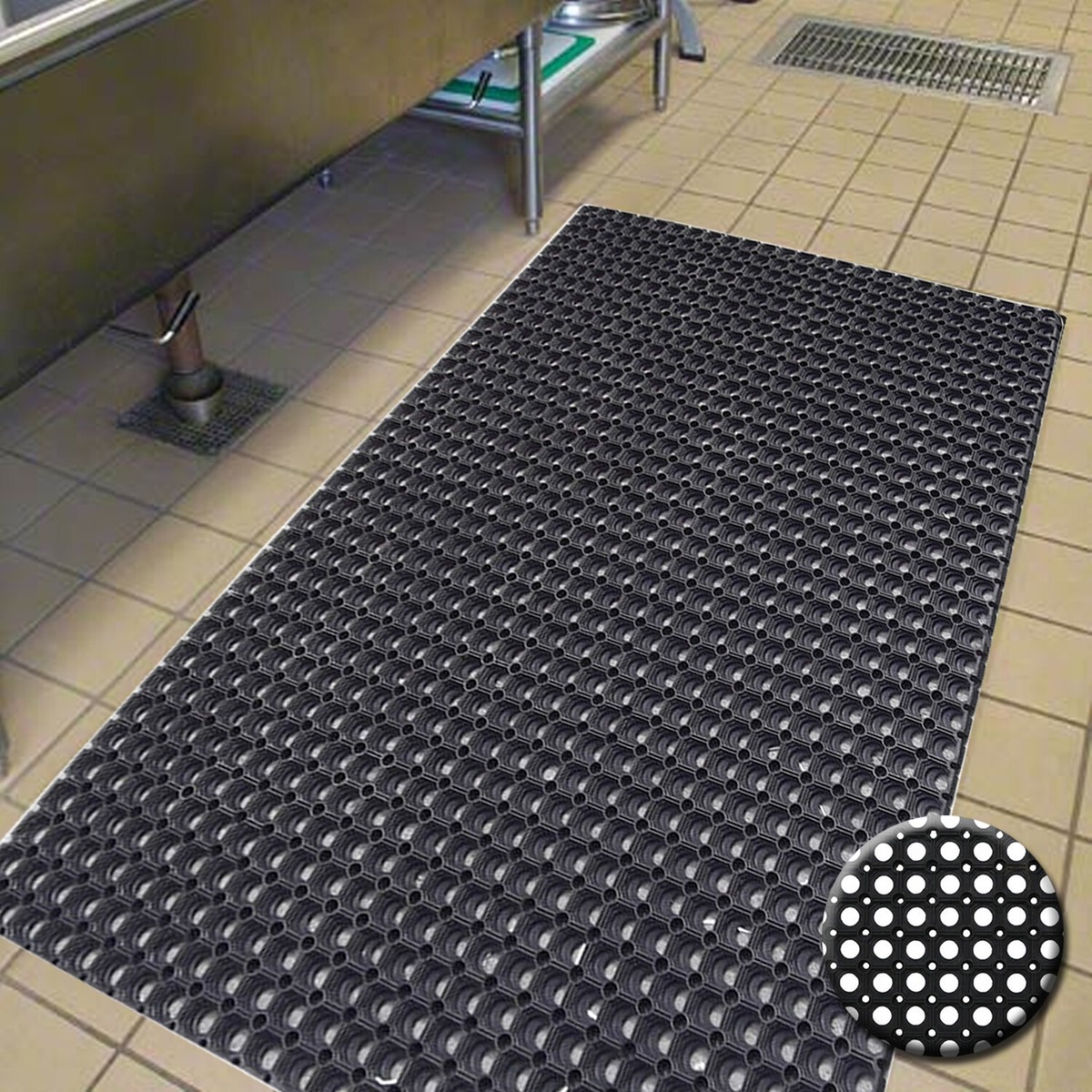

In industrial and commercial environments, entryway doormats are not merely aesthetic or functional accessories—they are engineered components designed to manage contamination, ensure safety, and extend the lifespan of interior flooring systems. Off-the-shelf solutions, while cost-attractive initially, often fail under sustained operational demands due to inadequate material selection and suboptimal engineering design. At Suzhou Baoshida Trading Co., Ltd., we emphasize that performance-driven rubber doormats must be precision-formulated to meet the mechanical, chemical, and environmental challenges of real-world applications.

Standard consumer-grade doormats typically employ natural rubber or low-grade synthetic compounds with minimal reinforcement. These materials degrade rapidly when exposed to oils, UV radiation, temperature extremes, or heavy foot and wheeled traffic. In industrial settings—such as manufacturing plants, warehouses, or food processing facilities—these conditions are not exceptions; they are the norm. As a result, premature cracking, delamination, and loss of traction become common, increasing slip hazards and maintenance costs.

The failure of generic mats stems from a fundamental oversight: treating doormats as commodities rather than engineered systems. High-performance entryway solutions require elastomers with tailored properties. For instance, nitrile butadiene rubber (NBR) offers superior resistance to petroleum-based fluids, making it ideal for automotive or mechanical workshops. Ethylene propylene diene monomer (EPDM) provides exceptional weathering and ozone resistance, suitable for exterior entrances in variable climates. Furthermore, incorporating reinforcing fillers such as carbon black or silica enhances tensile strength and abrasion resistance, directly extending service life.

At the core of our industrial rubber solutions is a material-first design philosophy. Each doormat is developed based on site-specific variables, including traffic load, contaminant type, cleaning protocols, and installation environment. This approach ensures dimensional stability, consistent grip, and long-term resilience.

The table below outlines key performance characteristics of common rubber compounds used in industrial doormat applications.

| Material | Tensile Strength (MPa) | Elongation at Break (%) | Hardness (Shore A) | Key Resistance Properties |

|---|---|---|---|---|

| Natural Rubber (NR) | 18–25 | 400–600 | 40–60 | Abrasion, impact |

| Nitrile Rubber (NBR) | 10–20 | 250–400 | 50–70 | Oil, fuel, grease |

| EPDM | 7–15 | 300–500 | 50–80 | UV, ozone, weathering |

| Neoprene (CR) | 10–17 | 250–400 | 50–75 | Flame, oil, sunlight |

| SBR (Styrene-Butadiene) | 15–25 | 400–700 | 50–70 | Wear, tearing |

Selecting the appropriate compound is only the first step. Engineering features such as cleated profiles, drainage channels, and embedded grit coatings must be integrated in alignment with material behavior. A high-hardness NBR mat with deep tread patterns, for example, can simultaneously resist fluid absorption and provide aggressive scraping action at entry points.

In conclusion, industrial entryway doormats demand the same rigor in material science and design as any other engineered component. Off-the-shelf products, constrained by generic formulations and mass production, lack the specificity required for demanding environments. By prioritizing material integrity and application-specific engineering, Suzhou Baoshida delivers doormat solutions that perform reliably under stress—ensuring safety, reducing lifecycle costs, and supporting operational continuity.

Material Specifications

Material Specifications for Industrial Entryway Doormats

Selecting the optimal elastomer is critical for commercial and industrial entryway doormats subjected to heavy foot traffic, chemical exposure, and extreme environmental conditions. At Suzhou Baoshida Trading Co., Ltd., we engineer rubber compounds to meet rigorous OEM performance standards, prioritizing longevity, safety, and functional resilience. Viton (FKM), Nitrile (NBR), and Silicone each offer distinct advantages based on application demands. Viton excels in high-temperature and aggressive chemical environments, such as semiconductor manufacturing facilities or chemical processing plants, where resistance to acids, fuels, and ozone is non-negotiable. Its molecular stability ensures dimensional integrity between -20°C and +230°C, though higher material costs necessitate targeted deployment. Nitrile remains the industry benchmark for general industrial use due to its exceptional abrasion resistance and cost efficiency. With a Shore A hardness range of 60–90, it withstands constant scraping from footwear debris while resisting oils, greases, and mild solvents common in automotive workshops or warehouses. Operating effectively from -30°C to +120°C, NBR provides optimal traction and wear life for high-traffic zones. Silicone delivers unmatched flexibility in extreme cold and high-purity requirements, making it ideal for pharmaceutical cleanrooms or food processing entrances. Its biocompatibility and resistance to steam sterilization support compliance with FDA and EU 1935/2004 standards, though lower abrasion resistance requires careful application assessment.

The following table details key technical specifications for OEM selection:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone |

|---|---|---|---|

| Temperature Range | -20°C to +230°C | -30°C to +120°C | -60°C to +200°C |

| Shore A Hardness Range | 60–90 | 50–95 | 30–80 |

| Tensile Strength (MPa) | 12–20 | 10–25 | 4–12 |

| Abrasion Resistance | Moderate | Excellent | Good |

| Chemical Resistance | Acids, fuels, oils | Oils, greases | Water, steam |

| Ozone Resistance | Excellent | Good | Excellent |

| Primary Industrial Use | Chemical plants | Warehouses, garages | Cleanrooms, labs |

Material selection directly impacts lifecycle cost and safety compliance. Viton is reserved for niche applications with severe chemical exposure due to its premium pricing. Nitrile dominates 80% of industrial doormat production at Suzhou Baoshida, balancing durability, chemical tolerance, and economic viability for standard commercial entrances. Silicone is specified where thermal extremes or regulatory purity standards override abrasion concerns. All compounds undergo ASTM D2000 validation for compression set, tensile retention, and colorfastness per OEM technical drawings. We collaborate with clients to validate material suitability against site-specific contaminants, traffic volume (measured in ASTM F609 cycles), and regional climate profiles. Precision in compound formulation ensures each doormat meets ISO 9001-certified production tolerances, eliminating premature failure in critical entryway infrastructure.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of industrial rubber engineering, delivering precision-engineered solutions tailored to the functional and aesthetic demands of entryway doormats. Our in-house engineering team comprises five dedicated mould engineers and two specialized rubber formula engineers, forming a multidisciplinary unit capable of end-to-end product development from concept to mass production. This integrated capability ensures that every doormat we manufacture meets exacting performance standards while aligning with OEM partner specifications.

Our mould engineers possess extensive expertise in precision steel tooling, 3D CAD modeling, and injection moulding dynamics. They utilize advanced simulation software to optimize flow, cooling, and ejection parameters, minimizing cycle times and maximizing part consistency. With a focus on durability and repeatability, our tooling solutions support high-volume production runs with tight tolerances, critical for maintaining the intricate surface textures and dimensional stability required in commercial and residential entryway applications. Each mould is rigorously tested and refined to ensure longevity exceeding 500,000 cycles under industrial operating conditions.

Complementing our mould engineering strength is our advanced rubber compounding capability. Our two formula engineers specialize in elastomer science, focusing on optimizing material performance for abrasion resistance, compression set, slip resistance, and environmental durability. We formulate custom EPDM, SBR, and recycled rubber compounds tailored to specific application requirements such as outdoor weathering, indoor traction, or high-traffic commercial use. These formulations are developed in-house using controlled batch testing, ensuring consistency across production lots and compliance with international standards for hardness, density, and aging resistance.

Our OEM service model is built on technical collaboration. Clients provide functional or design inputs, and our engineering team delivers fully validated prototypes within 15–20 working days. We support low-volume pilot runs and rapid tooling iterations, enabling swift time-to-market. All formulations and mould designs remain proprietary to the client, with strict IP protection protocols in place.

The following table outlines key technical capabilities and performance benchmarks achievable through our integrated engineering approach:

| Parameter | Capability Range | Testing Standard |

|---|---|---|

| Shore A Hardness | 45–85 | ASTM D2240 |

| Tensile Strength | Up to 12 MPa | ASTM D412 |

| Elongation at Break | 250–450% | ASTM D412 |

| Compression Set (22h, 70°C) | ≤ 20% | ASTM D395 |

| Abrasion Loss (Taber, 1000 rev) | ≤ 80 mg | ASTM D1044 |

| Operating Temperature Range | -40°C to +100°C | ISO 1817 |

| Mould Tolerance | ±0.1 mm | ISO 2768 |

| Production Cycle Time | 45–90 seconds per unit | In-house monitoring |

This convergence of mould and material engineering enables Suzhou Baoshida to deliver doormat solutions that are not only functionally robust but also scalable and cost-optimized for global OEM partners.

Customization Process

Customization Process for Industrial Entryway Doormats

At Suzhou Baoshida Trading Co., Ltd., our customization process for industrial rubber entryway doormats integrates rigorous material science with precision manufacturing. This ensures optimal performance under high-traffic commercial environments while meeting exact client specifications. The four-phase workflow—Drawing Analysis, Formulation, Prototyping, and Mass Production—eliminates guesswork and guarantees repeatability.

Drawing Analysis initiates the process. Our engineering team conducts a granular review of client-provided CAD files or technical sketches, focusing on critical dimensions, surface texture patterns, and structural reinforcements. We validate tolerances against ISO 2768-mK standards and assess manufacturability for extrusion or compression molding. Key considerations include drainage channel depth (minimum 3.5 mm), edge stability under cyclic loading, and compatibility with anti-slip additives. Any geometric conflicts are resolved via collaborative engineering feedback within 72 hours.

Formulation follows, where our rubber chemists develop a bespoke compound. Leveraging 15+ years of OEM experience, we select base polymers (SBR, EPDM, or recycled rubber blends) and optimize filler ratios, vulcanizing agents, and performance enhancers. Shore hardness is calibrated between 55–85 A per ASTM D2240, balancing durability against pedestrian comfort. Critical additives include silica for abrasion resistance, zinc oxide for UV stability, and antimicrobial agents for hygiene-critical zones like hospitals. All formulations undergo accelerated aging tests per ISO 188 before approval.

Prototyping validates the design and material synergy. Using client-approved molds, we produce 5–10 units under controlled vulcanization parameters (150–165°C, 10–15 MPa pressure). Each prototype undergoes destructive and non-destructive testing: tensile strength (ASTM D412), tear resistance (ASTM D624), and real-world grit retention trials. We document surface wear after 5,000 simulated footsteps and perform root-cause analysis for any dimensional deviations. Client sign-off requires ≤0.3 mm tolerance variance across all critical features.

Mass Production commences only after prototype validation. We deploy automated batching systems with ±0.5% ingredient accuracy and inline rheometers to monitor cure kinetics. Every 500th unit undergoes spot-checking for Shore hardness consistency and visual defects. Final products are packaged with traceability codes linking to batch-specific formulation logs and test certificates. Our lean manufacturing framework ensures 98.5% on-time delivery for orders exceeding 5,000 units.

Material Performance Specifications

| Property | Standard Formulation | Custom Formulation Range | Test Standard |

|---|---|---|---|

| Shore A Hardness | 60–70 | 55–85 | ASTM D2240 |

| Tensile Strength (MPa) | ≥12.0 | 10.0–18.0 | ASTM D412 |

| Abrasion Loss (mm³) | ≤120 | 80–200 | DIN 53516 |

| Tear Resistance (kN/m) | ≥45 | 35–65 | ASTM D624 |

| Operating Temperature (°C) | -30 to +80 | -40 to +100 | ISO 188 |

This structured approach ensures Suzhou Baoshida delivers entryway solutions that withstand 10+ years of commercial use while adhering to global safety and environmental regulations. All phases are documented under ISO 9001:2015 for full audit transparency.

Contact Engineering Team

For industrial-grade entryway doormats that meet the rigorous demands of commercial, institutional, and high-traffic environments, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in engineered rubber solutions. Our expertise lies in the development and manufacturing of high-performance rubber doormats designed to maximize durability, improve safety, and enhance cleanliness at building entrances. As a leading OEM supplier, we specialize in custom formulations, precision extrusion, and scalable production to meet the exact specifications of global distributors, facility managers, and architectural product designers.

Our rubber entryway systems are formulated using advanced polymer blends that resist abrasion, weathering, and chemical exposure while maintaining structural integrity under continuous foot and wheeled traffic. Whether your application requires aggressive dirt-scraping profiles, moisture-wicking channel designs, or color-stable surfaces for aesthetic integration, Suzhou Baoshida delivers tailored solutions backed by material science and manufacturing precision.

We invite technical buyers, procurement managers, and product development teams to engage directly with our engineering and sales leadership to discuss integration, compliance, and volume supply capabilities. For immediate technical consultation or quotation requests, contact Mr. Boyce, our designated OEM Manager and Rubber Formula Engineer, who oversees material specifications, performance validation, and client collaboration from concept to production.

Mr. Boyce brings over a decade of experience in industrial elastomer formulation and can guide your team through critical selection parameters such as Shore hardness, tensile strength, UV resistance, and slip coefficient optimization. With direct access to our R&D lab and production floor in Suzhou, he ensures rapid prototyping, material testing, and seamless scale-up for long-term contracts.

To initiate a technical discussion, request samples, or submit a project brief, please reach out via email at [email protected]. We respond to all inquiries within 12 business hours and offer virtual or on-site meetings for strategic partnerships.

Below are key technical specifications representative of our standard commercial entryway mat series. Custom modifications are available across all parameters to meet regional safety standards, design requirements, or environmental conditions.

| Property | Test Method | Typical Value |

|---|---|---|

| Material Base | Visual/FTIR | Styrene-Butadiene Rubber (SBR) or EPDM |

| Shore A Hardness | ASTM D2240 | 65 ± 5 |

| Tensile Strength | ASTM D412 | ≥ 10 MPa |

| Elongation at Break | ASTM D412 | ≥ 250% |

| Abrasion Loss (Taber, 1000 cycles) | ASTM D1044 | ≤ 80 mg |

| Slip Resistance (COF, wet) | ASTM F2913 | ≥ 0.6 |

| Temperature Range | ISO 188 | -40°C to +100°C |

| UV Resistance | ASTM G154 | Pass (2000 hrs QUV) |

| Fire Rating (UL 94) | UL 94 | HB or V-0 (custom) |

Partner with Suzhou Baoshida to transform your entryway performance through scientifically optimized rubber matting systems. Contact Mr. Boyce today at [email protected] to begin the engineering dialogue.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).