Technical Contents

Engineering Guide: Eptfe Gasket

Engineering Insight: ePTFE Gasket – The Critical Role of Material Selection

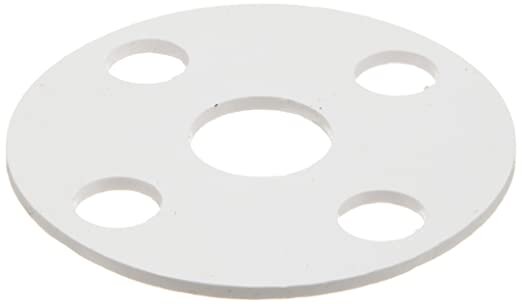

In high-performance sealing applications, expanded polytetrafluoroethylene (ePTFE) has emerged as a premier material due to its exceptional chemical resistance, thermal stability, and low compression set. However, despite its inherent advantages, the failure of ePTFE gaskets in industrial environments is not uncommon—particularly when off-the-shelf solutions are selected without rigorous engineering evaluation. The root cause often lies not in the material itself, but in the mismatch between standardized gasket designs and the unique operational demands of the application.

ePTFE is engineered through a specialized expansion process that creates a microporous structure, offering superior conformability and resilience compared to traditional PTFE. This structure enables the gasket to seal effectively over irregular flange surfaces and maintain integrity under dynamic thermal cycling. Yet, this performance is highly dependent on precise material formulation, density control, and reinforcement integration—parameters that are frequently overlooked in generic, mass-produced gasket offerings.

Off-the-shelf ePTFE gaskets are typically manufactured to meet broad industry standards rather than site-specific conditions. They often lack the tailored reinforcement (e.g., fiberglass, stainless steel core, or elastomeric inserts) needed to resist blowout under high pressure or thermal degradation in extreme environments. Furthermore, standard-grade ePTFE may exhibit higher cold flow tendencies or reduced recovery characteristics, leading to premature seal failure in cyclic operations.

Material selection must therefore be driven by a comprehensive understanding of the operating environment. Key factors include chemical exposure, temperature range, pressure fluctuations, flange type, and required service life. For instance, in aggressive chemical processing applications involving strong acids or solvents at elevated temperatures, only fully stabilized, high-density ePTFE with appropriate backing support will ensure long-term reliability.

At Suzhou Baoshida Trading Co., Ltd., we emphasize application-specific engineering for every ePTFE gasket solution. Our technical team collaborates with OEMs to analyze system dynamics and select the optimal ePTFE variant—balancing compressibility, recovery, creep resistance, and chemical compatibility.

The following table outlines key performance specifications of engineered ePTFE gasket materials versus standard off-the-shelf equivalents:

| Property | Engineered ePTFE Gasket | Standard Off-the-Shelf ePTFE |

|---|---|---|

| Density (g/cm³) | 0.7 – 1.2 (adjustable) | ~0.7 (fixed) |

| Tensile Strength (MPa) | 15 – 30 | 8 – 12 |

| Temperature Range (°C) | -260 to +327 | -200 to +260 |

| Compression Set (%), 24h @ 200°C | <15% | 25 – 40% |

| Chemical Resistance | Full spectrum, including halogens and amines | Limited in strong oxidizers |

| Reinforcement Options | Custom (metal, fiber, rubber core) | None or minimal |

| Recovery Rate (%) | >85% | 60 – 70% |

Selecting the right ePTFE gasket is not a commodity decision—it is an engineering imperative. Generic solutions may reduce initial costs but invariably increase total cost of ownership through unplanned downtime, leakage risks, and safety hazards. Precision in material selection ensures reliability, safety, and operational continuity in critical sealing applications.

Material Specifications

Material Specifications for ePTFE Gasket Applications

Expanded polytetrafluoroethylene (ePTFE) gaskets represent the pinnacle of chemical inertness and thermal stability in critical sealing applications. At Suzhou Baoshida Trading Co., Ltd., we engineer ePTFE formulations to withstand aggressive media—including strong acids, bases, and solvents—where conventional elastomers fail. Operating continuously from -200°C to +260°C, ePTFE maintains structural integrity without swelling, hardening, or outgassing. Its micro-porous structure ensures low creep relaxation and exceptional recovery, vital for flange sealing under cyclic thermal loads. Unlike solid PTFE, ePTFE’s expanded matrix provides optimal compression set resistance (typically <10% per ASTM F36), minimizing bolt load degradation in high-pressure systems.

Material selection must align with operational parameters. While ePTFE excels in extreme chemical environments, traditional elastomers like Viton, Nitrile, and Silicone remain cost-effective for less demanding scenarios. Viton offers superior resistance to hydrocarbons and moderate heat but degrades in ketones and amines. Nitrile provides excellent oil/fuel resistance yet suffers below -30°C and above 120°C. Silicone delivers broad temperature flexibility (-60°C to 230°C) but lacks tensile strength in dynamic seals and swells in non-polar solvents. Crucially, none match ePTFE’s non-stick surface properties or purity for semiconductor or pharmaceutical processes where particle generation is unacceptable.

The following comparison details key performance metrics for common gasket materials against ePTFE. Data reflects industry-standard test conditions per ASTM D2000 and ISO 3601.

| Property | ePTFE | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|---|

| Temperature Range (°C) | -200 to +260 | -20 to +230 | -40 to +120 | -60 to +230 |

| Tensile Strength (MPa) | 15–25 | 10–18 | 10–20 | 5–10 |

| Compression Set (%) | <10 (at 200°C) | 20–40 (at 200°C) | 30–50 (at 100°C) | 20–35 (at 200°C) |

| Acid Resistance | Excellent | Good | Poor | Fair |

| Base Resistance | Excellent | Poor | Poor | Good |

| Hydrocarbon Resistance | Excellent | Excellent | Excellent | Poor |

| Outgassing Rate (mg/cm²) | 0.01 | 0.5–1.0 | 0.8–1.5 | 0.3–0.7 |

Suzhou Baoshida prioritizes material compatibility validation for each OEM project. ePTFE’s inertness eliminates cross-contamination risks in ultra-high-purity systems, though its higher initial cost is justified by extended service life in corrosive environments. For applications below 150°C with non-aggressive media, Nitrile or Silicone may offer economic advantages—but only after rigorous chemical exposure testing. Viton remains suitable for aerospace fuel systems yet requires supplemental testing for amine-based fluids. Always consult our engineering team to model stress relaxation under your specific pressure-temperature profile.

ePTFE gaskets are not universally optimal; they demand precise flange surface finishes (125–250 μin Ra) and controlled bolt torquing. However, for mission-critical seals in chemical processing, LNG, or semiconductor fabrication, ePTFE’s performance envelope is unmatched. Suzhou Baoshida’s OEM division provides ASTM F104-compliant material certifications and custom density formulations to meet ASME B16.20 or EN 1514 standards. Partner with us to transform material science into reliable sealing solutions.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our core strength in manufacturing precision ePTFE gaskets lies in the integration of advanced material science and precision engineering. With a dedicated team of five certified mould engineers and two specialized rubber formula engineers, we maintain full in-house control over the entire development cycle—from compound formulation to final gasket production. This vertical integration ensures rapid prototyping, consistent quality, and tailored solutions for demanding industrial applications.

Our formula engineers focus on optimizing the chemical resistance, thermal stability, and mechanical integrity of expanded polytetrafluoroethylene (ePTFE) composites. By fine-tuning filler dispersion, fiber reinforcement integration, and surface treatment protocols, we produce formulations that meet exact OEM performance benchmarks. Whether operating in aggressive chemical environments, high-temperature processes, or ultra-high vacuum systems, our ePTFE gaskets maintain reliable sealing performance over extended service life.

The mould engineering team applies precision design principles to develop tooling with micron-level tolerances. Utilizing 3D modeling software and CNC-machined steel molds, we ensure dimensional accuracy and repeatability across production batches. This capability is critical for complex geometries and thin-profile seals used in semiconductor, pharmaceutical, and chemical processing equipment. Our engineers perform mold flow analysis and stress simulation to preempt defects and optimize compression set behavior during curing.

We support full OEM partnerships, offering confidential co-development, intellectual property protection, and scalable production. Our facility is equipped for low-volume prototyping and high-volume manufacturing, with traceability systems compliant with ISO 9001 standards. Clients benefit from direct access to both formula and mould engineering teams, enabling real-time collaboration on design for manufacturability (DFM) and total cost optimization.

The following table outlines key engineering specifications and performance parameters for our standard ePTFE gasket materials:

| Parameter | Standard ePTFE | Reinforced ePTFE (Fiber-Enhanced) | High-Purity ePTFE (Semiconductor Grade) |

|---|---|---|---|

| Temperature Range | -200°C to +260°C | -200°C to +280°C | -200°C to +260°C |

| Tensile Strength (ASTM D4811) | ≥20 MPa | ≥35 MPa | ≥18 MPa |

| Compression Set (22h, 200°C) | ≤25% | ≤20% | ≤30% |

| Chemical Resistance | Excellent (all common media) | Excellent (incl. strong acids/bases) | Ultra-high purity, low extractables |

| Density | 0.7–0.9 g/cm³ | 0.8–1.0 g/cm³ | 0.65–0.85 g/cm³ |

| Thickness Tolerance | ±0.05 mm (≤3 mm) | ±0.05 mm | ±0.03 mm |

| Custom Molding Capability | Yes (flat, shaped, jointed) | Yes (multi-cavity, insert molding) | Yes (cleanroom assembly available) |

Through the synergy of formula innovation and precision tooling, Suzhou Baoshida delivers engineered ePTFE gasket solutions that meet the most stringent industrial requirements. Our technical team is available for direct consultation on material selection, sealing design, and OEM integration.

Customization Process

ePTFE Gasket Customization Process: From Specification to Serial Production

At Suzhou Baoshida Trading Co., Ltd., our ePTFE gasket customization adheres to a rigorously defined engineering workflow to ensure dimensional precision, material integrity, and application-specific performance. This process eliminates guesswork and accelerates time-to-market for critical sealing applications in chemical processing, semiconductor, and aerospace sectors.

Drawing Analysis initiates the engagement. Our engineering team conducts a comprehensive review of client-provided technical drawings against ISO 3601 and ASME B16.21 standards. We validate critical parameters including groove dimensions, surface finish requirements (Ra ≤ 0.8 μm), compression set limits, and flange load specifications. Finite element analysis (FEA) simulates stress distribution under operational conditions—accounting for thermal cycling, pressure spikes, and chemical exposure—to preempt design flaws. Any deviations from manufacturable tolerances (±0.05 mm for critical faces) are flagged for collaborative resolution with the client prior to material selection.

Formulation leverages our proprietary material science database. ePTFE’s base polymer structure is modified through controlled sintering temperature profiles and filler integration to meet exact service demands. For aggressive chemical environments, we incorporate 15–25% graphite or ceramic micro-fillers to enhance creep resistance without compromising purity. In high-vacuum applications, conductive carbon-loaded ePTFE (volume resistivity < 10⁴ Ω·cm) prevents electrostatic discharge. Every formulation undergoes accelerated aging tests per ASTM F146 to validate long-term stability against target media at 150% of rated pressure/temperature conditions.

Prototyping employs CNC-machined tooling for sub-100 unit batches, avoiding costly steel molds for validation runs. Each prototype undergoes:

Helium leak testing per SEMI F57 (≤ 1 × 10⁻⁹ atm·cc/sec)

Compression-deflection curve analysis at 25%, 50%, and 75% load

In-situ thermal cycling from -200°C to +327°C

Client feedback on dimensional conformity and sealing efficacy triggers iterative refinements, typically within 10 business days.

Mass Production transitions validated designs to automated lines with statistical process control (SPC). We implement real-time monitoring of sintering oven temperature gradients (±2°C tolerance) and laser micrometry for cross-sectional consistency. Every production lot includes certified material test reports (MTRs) with traceable batch numbers, dimensional certificates, and full compliance documentation for AS9100 or ISO 13485 frameworks as required.

Material performance specifications are summarized below for common ePTFE grades:

| Material Grade | Density Range (g/cm³) | Max Continuous Temp (°C) | Tensile Strength (MPa) | Key Applications |

|---|---|---|---|---|

| Standard ePTFE | 0.70–0.80 | 260 | 15–20 | General chemical flanges |

| Graphite-Reinforced | 0.85–0.95 | 300 | 25–30 | High-pressure reactors |

| Conductive ePTFE | 0.75–0.85 | 260 | 12–18 | Semiconductor vacuum chambers |

This structured approach ensures Suzhou Baoshida delivers ePTFE gaskets that exceed OEM performance expectations while minimizing total cost of ownership through optimized material utilization and failure-proof validation. All stages are governed by our IATF 16949-certified quality management system, providing end-to-end accountability from CAD file to certified shipment.

Contact Engineering Team

Contact Suzhou Baoshida for High-Performance ePTFE Gaskets

At Suzhou Baoshida Trading Co., Ltd., we specialize in precision-engineered rubber seals and advanced polymeric solutions tailored for demanding industrial environments. Our expertise in expanded polytetrafluoroethylene (ePTFE) gasket technology ensures unmatched performance in chemical resistance, thermal stability, and sealing integrity across a wide range of critical applications. Whether you are operating in semiconductor manufacturing, pharmaceutical processing, chemical transfer systems, or high-purity fluid handling, our ePTFE gaskets are designed to meet stringent OEM and regulatory requirements.

We understand that reliability and consistency are non-negotiable in high-stakes industrial operations. That is why our ePTFE gaskets are manufactured under strict quality controls, ensuring dimensional accuracy, low outgassing, and long-term resilience under fluctuating temperatures and aggressive media exposure. Our formulations are optimized for compatibility with acids, bases, solvents, and steam, making them ideal for use in cleanrooms, reactors, pumps, valves, and flanged connections.

To support your specific engineering needs, we offer custom fabrication services, including die-cutting, water-jet cutting, and CNC machining, allowing for precise geometries and tight tolerances. Our technical team collaborates directly with OEMs and system integrators to develop sealing solutions that enhance system uptime, reduce maintenance cycles, and ensure compliance with international standards such as FDA, USP Class VI, and ISO 10993.

When you choose Suzhou Baoshida, you are partnering with a trusted supplier known for technical depth, responsive service, and consistent product quality. We maintain an agile supply chain to support both prototyping and high-volume production runs, with fast turnaround times and global logistics coordination.

For expert consultation or to request technical documentation, pricing, or samples, contact Mr. Boyce, our dedicated OEM Account Manager. With extensive experience in polymer material science and industrial sealing applications, Mr. Boyce provides personalized support to help you select the optimal ePTFE gasket configuration for your operational demands.

Reach out today via email at [email protected] to discuss your project requirements. We respond promptly to all technical inquiries and are committed to delivering engineered solutions that exceed expectations.

ePTFE Gasket Technical Specifications

| Property | Value |

|---|---|

| Material | Expanded PTFE (ePTFE) |

| Density | 0.7–0.8 g/cm³ |

| Tensile Strength | ≥20 MPa |

| Elongation at Break | ≥150% |

| Operating Temperature Range | -260°C to +260°C |

| Chemical Resistance | Excellent against acids, bases, solvents, and oxidizers |

| Permeability | Extremely low gas and liquid permeation |

| Compression Set | <10% (after 24h at 200°C) |

| Electrical Resistivity | >1×10¹⁶ Ω·cm |

| Compliance | FDA 21 CFR 177.1550, USP Class VI, RoHS |

Partner with Suzhou Baoshida and leverage our precision rubber sealing expertise to enhance your system’s reliability and performance. Contact Mr. Boyce directly to begin the conversation.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).