Technical Contents

Engineering Guide: Estate Doormat

Engineering Insight: Material Selection in Estate Doormat Manufacturing

In the domain of industrial rubber applications, the estate doormat represents a critical interface between architectural aesthetics and functional durability. While often perceived as a simple floor covering, its performance under sustained environmental and mechanical stress demands rigorous material engineering. Off-the-shelf solutions typically fail in premium residential and commercial estate applications due to inadequate consideration of polymer composition, cross-link density, and environmental resistance profiles.

Standard doormats, commonly fabricated from recycled rubber or low-grade EPDM, exhibit premature degradation when exposed to UV radiation, moisture, and temperature fluctuations. These materials lack the molecular stability required for long-term resilience, leading to surface cracking, color fading, and loss of tensile integrity. In high-traffic estate environments—such as gated communities, luxury villas, or corporate lobbies—such failures not only compromise safety but also reflect poorly on facility maintenance standards.

At Suzhou Baoshida Trading Co., Ltd., our approach begins with virgin-grade synthetic rubber compounds, primarily high-saturation EPDM and nitrile butadiene rubber (NBR), selected for their superior ozone resistance, thermal stability, and mechanical strength. These polymers are engineered with precise sulfur-based vulcanization systems to optimize cross-linking, enhancing abrasion resistance and dimensional stability. Additives such as UV stabilizers, anti-aging agents, and mineral fillers are incorporated to extend service life under extreme climatic conditions.

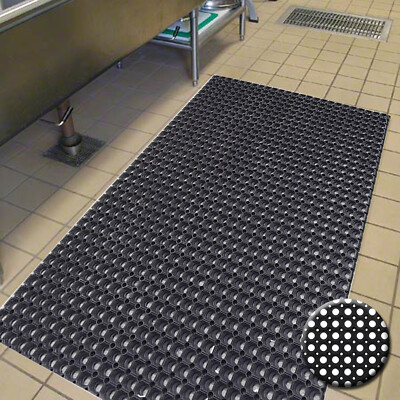

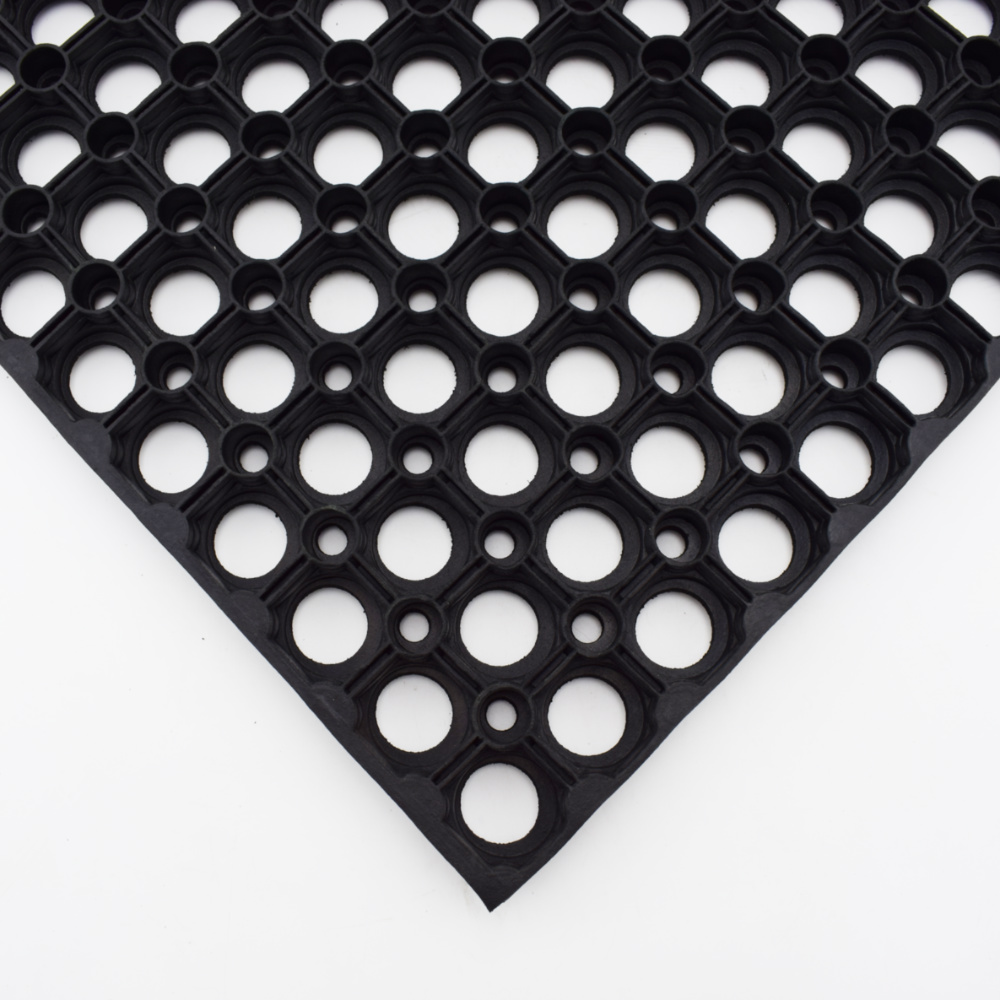

Another critical factor is surface texture design, which must balance dirt-scraping efficiency with slip resistance. Generic mats often use shallow, uniform patterns that quickly clog with debris. Our engineered profiles utilize deep-channel treads and directional grooves, molded under high-pressure vulcanization to maintain structural fidelity over time. This ensures consistent particulate removal and water drainage, reducing indoor contamination and slip hazards.

Below is a comparative specification table highlighting key performance metrics between standard off-the-shelf mats and Baoshida-engineered estate doormats:

| Property | Off-the-Shelf Mat (Typical) | Baoshida Engineered Estate Mat |

|---|---|---|

| Base Material | Recycled rubber / low-grade EPDM | Virgin high-saturation EPDM / NBR blend |

| Tensile Strength | 7–10 MPa | 15–18 MPa |

| Elongation at Break | 200–250% | 350–400% |

| Shore A Hardness | 55–60 | 65–70 |

| UV Resistance (ASTM G154) | Poor (cracking in 500 hrs) | Excellent (no degradation at 2,000 hrs) |

| Operating Temperature Range | -10°C to +70°C | -40°C to +120°C |

| Abrasion Loss (DIN 53516) | ≤ 180 mm³ | ≤ 90 mm³ |

| Molded Tread Depth | 3–4 mm | 8–10 mm |

The data underscores a fundamental principle: performance is not an add-on but a result of intentional material science. Off-the-shelf products prioritize cost reduction over lifecycle value, whereas engineered solutions from Baoshida deliver long-term reliability, safety, and aesthetic consistency. For estate managers and architectural specifiers, the choice is not merely between products—but between failure and engineered assurance.

Material Specifications

Material Specifications for Premium Estate Doormat Manufacturing

Selecting the optimal elastomer for estate-grade doormats requires rigorous evaluation of environmental exposure, mechanical stress, and longevity expectations. At Suzhou Baoshida Trading Co., Ltd., our OEM engineering team prioritizes material science precision to ensure mats withstand foot traffic, UV degradation, moisture ingress, and chemical exposure inherent in high-end residential applications. Viton, Nitrile, and Silicone represent three critical polymer families, each offering distinct performance profiles for discerning architectural specifications.

Viton fluorocarbon rubber (FKM) delivers unparalleled resistance to extreme conditions, making it ideal for luxury estates with heated entryways or coastal locations. Its molecular stability ensures operational integrity from -20°C to 250°C per ASTM D2000 standards, with exceptional resistance to ozone, UV radiation, and petroleum-based contaminants. While Viton’s formulation cost is higher, its compression set resistance below 25% after 70 hours at 150°C guarantees dimensional stability under constant load, preventing permanent deformation in high-traffic zones. This material is recommended for bespoke installations where failure is not an option, though standard estate applications may not justify its premium.

Nitrile rubber (NBR) remains the industrial benchmark for cost-effective performance in general-purpose doormats. Our optimized NBR compounds achieve Shore A hardness of 65–75, balancing abrasion resistance with comfortable underfoot compliance. Validated per ISO 188, NBR maintains functionality between -30°C and 120°C and exhibits strong resilience against water, aliphatic hydrocarbons, and mild acids. Its tensile strength of 15–20 MPa (ASTM D412) ensures durability against scraping and grit abrasion. For estates prioritizing value without compromising core functionality, NBR provides optimal lifecycle economics with minimal formulation complexity.

Silicone rubber (VMQ) excels in aesthetic and thermal versatility for designer-focused projects. Its biocompatible composition supports vibrant color retention and smooth surface finishes, critical for visible entryway elements. Silicone operates reliably from -60°C to 230°C (per ASTM D1229) and demonstrates superior UV stability, preventing yellowing in sun-exposed porticos. While tensile strength (6–8 MPA) is lower than NBR, its exceptional flexibility at low temperatures and non-toxic profile suit estates with stringent environmental standards. Compression set values below 20% ensure long-term resilience against mat flattening.

The following comparative analysis details critical parameters for informed material selection:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +250 | -30 to +120 | -60 to +230 |

| Shore A Hardness | 70–80 | 65–75 | 50–70 |

| Tensile Strength (MPa) | 12–18 | 15–20 | 6–8 |

| Compression Set (%) | ≤25 (150°C/70h) | ≤30 (100°C/22h) | ≤20 (200°C/22h) |

| Key Resistance | Ozone, fuels, acids | Water, oils, abrasion | UV, extreme cold |

| Primary Estate Application | Heated/coastal entries | Standard high-traffic | Architectural/design-focused |

Suzhou Baoshida’s OEM division tailors compound formulations to exact project demands, leveraging decades of rubber chemistry expertise. Material choice must align with site-specific stressors—Viton for extreme chemical exposure, NBR for balanced economics, or Silicone for aesthetic permanence. Our engineering team provides full technical validation data to ensure seamless integration into luxury estate supply chains.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Rubber Solutions for Estate Doormat Manufacturing

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the development and production of high-performance estate doormats. With a dedicated team comprising five specialized mould engineers and two advanced formula engineers, we deliver technically superior, application-specific rubber products that meet the rigorous demands of modern architectural and environmental standards.

Our mould engineering team leverages over a decade of cumulative experience in precision tooling design and rapid prototyping. Each engineer is proficient in CAD/CAM software suites including SolidWorks, AutoCAD, and UG NX, enabling seamless translation of client concepts into manufacturable, high-tolerance moulds. The team specializes in multi-cavity steel and aluminum moulds optimized for high-volume extrusion and compression molding, ensuring dimensional accuracy, surface consistency, and long service life—critical for estate doormats exposed to heavy foot traffic and outdoor elements.

Complementing our mould expertise is our in-house rubber formulation capability. Our two formula engineers focus on material science tailored to functional performance. They design proprietary EPDM, SBR, and recycled rubber blends engineered for superior abrasion resistance, UV stability, water drainage efficiency, and anti-slip characteristics. By controlling the formulation process from raw compound selection to vulcanization parameters, we ensure consistent Shore A hardness (typically 60–75), extended product lifecycle, and compliance with environmental regulations including RoHS and REACH.

This integrated approach—combining mould design and material formulation under one technical roof—enables us to offer comprehensive OEM services. Clients benefit from end-to-end development support, from initial sketch to mass production. We support custom branding, dimensional customization, texture patterning (e.g., geometric, logo embossing), and color matching (Pantone or RAL standards). Our OEM process includes DFM (Design for Manufacturability) analysis, sample validation, and lifecycle testing under simulated weathering and mechanical stress.

All formulations and mould designs undergo rigorous performance validation in our on-site testing lab, where we simulate real-world conditions such as thermal cycling (-30°C to +70°C), abrasion cycles, and slip resistance (DIN 51130 ramp test). This ensures that every estate doormat not only meets aesthetic expectations but also delivers long-term functional reliability in residential and commercial environments.

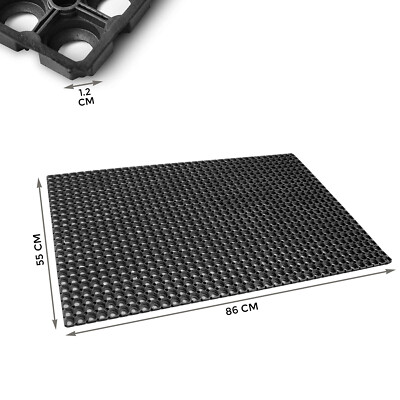

Below is a summary of our standard technical specifications for estate doormat production:

| Parameter | Specification |

|---|---|

| Material Options | EPDM, SBR, Recycled Rubber, Custom Blends |

| Hardness (Shore A) | 60–75 (adjustable per application) |

| Density | 1.1–1.3 g/cm³ |

| Tensile Strength | ≥8 MPa |

| Elongation at Break | ≥250% |

| Operating Temperature | -30°C to +70°C |

| UV Resistance | 1,000+ hours (QUV accelerated testing) |

| Mould Tolerance | ±0.2 mm |

| Production Lead Time | 25–35 days (including tooling and sampling) |

| OEM Customization Support | Full (design, mold, compound, branding) |

Our engineering synergy ensures that every estate doormat produced meets the highest benchmarks in durability, safety, and design fidelity—making Suzhou Baoshida a trusted partner in industrial rubber manufacturing.

Customization Process

Customization Process for Premium Estate Doormats

Suzhou Baoshida Trading Co., Ltd. implements a rigorous engineering workflow to transform client specifications into high-performance rubber doormats for luxury residential and commercial estates. Our process ensures dimensional accuracy, material resilience, and brand alignment while meeting stringent industrial standards.

Drawing Analysis

Initial technical review focuses on critical geometric parameters and functional requirements. We validate CAD drawings against ASTM D2000 standards for rubber products, scrutinizing groove depth tolerance (±0.3mm), edge radius consistency, and anti-slip pattern geometry. Key considerations include load-bearing capacity (min. 500kg/m²) and drainage channel efficiency to prevent water retention. Any deviations from manufacturable tolerances trigger collaborative engineering feedback within 72 hours, ensuring design integrity without compromising production viability.

Formulation Engineering

Based on environmental exposure analysis, our rubber compounding team develops proprietary blends. For estate applications, we prioritize UV resistance (ASTM G154), ozone stability (ASTM D1149), and abrasion resistance (ASTM D5963). Standard formulations utilize 60-70 Shore A EPDM rubber with 30-40% carbon black reinforcement for outdoor durability. Premium variants incorporate nano-silica fillers to enhance tensile strength (20-25 MPa) and thermal stability (-40°C to 120°C operational range). All compounds undergo accelerated aging tests per ISO 188 before approval.

Prototyping & Validation

Precision compression molding produces functional prototypes using client-approved tooling. Each sample undergoes:

Dimensional verification via CMM (Coordinate Measuring Machine)

Slip resistance testing (ASTM F2913, DCOF ≥0.42 wet)

Embedded logo clarity assessment under 500 lux illumination

Salt spray corrosion testing (ASTM B117) for metallic inserts

Client feedback integrates within 5 business days, with material adjustments made at the molecular level if performance thresholds are unmet.

Mass Production Protocol

Upon prototype sign-off, we initiate ISO 9001-certified production with real-time statistical process control. Each batch undergoes:

In-line Shore hardness checks (every 30 minutes)

Tensile strength validation (ASTM D412) on sacrificial coupons

Color consistency measurement (ΔE ≤1.5 via spectrophotometer)

Final inspection for surface defects under ISO 2859-1 AQL 1.0 standards

Typical lead time from order confirmation to shipment is 25-30 days for 5,000-unit batches, with full traceability via lot-numbered material certificates.

Material Performance Specifications

| Parameter | Standard EPDM Formulation | Premium Nano-Enhanced | Test Method |

|————————–|—————————|————————|——————|

| Hardness (Shore A) | 65 ± 3 | 68 ± 3 | ASTM D2240 |

| Tensile Strength (MPa) | 18.5 min | 23.0 min | ASTM D412 |

| Abrasion Loss (mm³) | ≤120 | ≤85 | ASTM D5963 |

| UV Resistance (2000h) | Grade 3 | Grade 1 | ASTM G154 |

| Operating Temperature | -30°C to 110°C | -40°C to 120°C | ISO 188 |

This systematic approach guarantees estate doormats that withstand extreme weather, heavy foot traffic, and maintain aesthetic precision throughout their service life, directly supporting our clients’ brand reputation for quality and safety. All formulations are REACH-compliant with full material disclosure available upon request.

Contact Engineering Team

For industrial-grade estate doormat manufacturing, precision engineering and material integrity are non-negotiable. At Suzhou Baoshida Trading Co., Ltd., we specialize in high-performance rubber formulations tailored for commercial and residential exterior applications. Our engineered rubber solutions provide superior durability, slip resistance, and weather resilience—critical attributes for estate-grade entrance systems exposed to continuous foot traffic and harsh environmental conditions.

We invite architects, OEMs, and construction supply manufacturers to engage directly with our technical team to co-develop custom doormat solutions that meet exact dimensional, textural, and performance criteria. Whether your requirement involves deep-tread patterns for maximum debris capture, UV-stabilized EPDM compounds for long-term color retention, or Shore A hardness tuning for optimal flexibility and wear resistance, our R&D team ensures material science aligns with functional design.

Partnering with Suzhou Baoshida means access to ISO-compliant production lines, scalable extrusion and molding capabilities, and rigorous quality control protocols. We support low-volume prototyping and high-volume production runs with consistent batch-to-batch repeatability. All rubber compounds are tested for abrasion resistance, compression set, and low-temperature flexibility to ensure compliance with international building and safety standards.

To initiate a technical consultation or request material samples, contact Mr. Boyce, Rubber Formula Engineer and OEM Manager, directly at [email protected]. Mr. Boyce leads client-facing formulation development and oversees technical integration from concept to delivery. He will coordinate material data sheets, lead time estimates, and regulatory documentation upon request.

Below are standard technical specifications for our premium estate doormat rubber profiles. Custom modifications are available upon engineering review.

| Property | Test Method | Typical Value |

|---|---|---|

| Material Type | — | EPDM / SBR Blend |

| Hardness (Shore A) | ASTM D2240 | 65 ± 5 |

| Tensile Strength | ASTM D412 | ≥ 10 MPa |

| Elongation at Break | ASTM D412 | ≥ 250% |

| Compression Set (22 hrs, 70°C) | ASTM D395 | ≤ 20% |

| Abrasion Loss (Taber, 1000 cycles) | ASTM D1044 | ≤ 80 mg |

| Operating Temperature Range | — | -40°C to +100°C |

| Density | ASTM D297 | 1.25 ± 0.05 g/cm³ |

| Slip Resistance (DIN 51130, R9) | DIN 51130 | Compliant |

All products are manufactured in Suzhou, China, under strict environmental and occupational health standards. We support REACH, RoHS, and FDA-compliant formulations depending on application needs.

For technical collaboration, quoting inquiries, or CAD model integration support, reach out to Mr. Boyce. Let us apply industrial rubber science to elevate your next estate doormat project.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).