Technical Contents

Engineering Guide: Eva Block Foam

Engineering Insight: EVA Block Foam – The Critical Role of Material Selection in Industrial Applications

In industrial rubber solutions, EVA (ethylene-vinyl acetate) block foam is frequently selected for its resilience, lightweight structure, and excellent shock absorption. However, despite its widespread availability and apparent uniformity, off-the-shelf EVA block foam often fails to meet the rigorous demands of precision manufacturing environments. The root cause lies not in the material itself, but in the lack of engineered specificity during selection. Standard commercial-grade EVA foams are formulated for consumer goods—such as footwear, packaging, or sports equipment—where performance tolerances are broad and environmental exposure is minimal. When deployed in industrial contexts—sealing, gasketing, vibration damping, or thermal insulation—these generic materials quickly degrade, compress permanently, or fail under thermal and chemical stress.

Material selection must be driven by application-specific engineering parameters. Off-the-shelf EVA foams typically lack the necessary cross-linking density, closed-cell structure integrity, or additive packages required for long-term stability in dynamic or harsh conditions. For instance, exposure to UV radiation, ozone, or industrial oils can lead to surface cracking, embrittlement, or swelling in non-formulated grades. Similarly, repeated compression cycles in machinery mounting or damping applications demand precise control over hardness, recovery rate, and creep resistance—properties that vary significantly across EVA formulations.

At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered material matching over commodity substitution. Our EVA block foam solutions are developed in collaboration with OEMs to align density, hardness, temperature range, and chemical resistance with operational requirements. This approach ensures not only prolonged service life but also system reliability and reduced maintenance downtime.

The following table outlines key performance characteristics of engineered EVA block foam versus standard commercial-grade alternatives:

| Property | Engineered EVA Block Foam | Standard Commercial EVA Foam |

|---|---|---|

| Density (kg/m³) | 120–300 | 60–150 |

| Hardness (Shore A) | 30–80 | 20–50 |

| Compression Set (22h @ 70°C) | ≤ 20% | 30–50% |

| Temperature Range (°C) | -40 to +100 | -20 to +70 |

| Tensile Strength (MPa) | 0.8–2.0 | 0.3–0.8 |

| Elongation at Break (%) | 180–400 | 120–250 |

| Closed Cell Content (%) | ≥ 95 | 80–90 |

| Oil Resistance | Moderate to High | Low |

These distinctions underscore why material selection cannot be reduced to cost or availability. In critical applications, the performance delta between engineered and generic EVA foam directly impacts system integrity. Suzhou Baoshida Trading Co., Ltd. provides technical consultation to ensure that each EVA block foam specification is optimized for the intended service environment—delivering not just material, but engineered reliability.

Material Specifications

Material Specifications for EVA Block Foam Applications

EVA block foam serves as a critical base material in industrial sealing, gasketing, and cushioning solutions due to its closed-cell structure, resilience, and chemical inertness. At Suzhou Baoshida Trading Co., Ltd., we engineer EVA formulations to meet exacting tolerances for density (0.03–0.35 g/cm³), hardness (15–90 Shore A), and compression set (<30% per ASTM D3574). However, the performance envelope of EVA-based assemblies is significantly influenced by elastomeric sealing components. Viton, Nitrile, and Silicone remain the dominant elastomers paired with EVA foam in demanding environments. Each material offers distinct thermal, chemical, and mechanical properties that must align with operational parameters. Misalignment risks premature failure, leakage, or reduced service life. Our OEM partnerships prioritize precise elastomer-EVA synergy to ensure system integrity under dynamic stress.

Viton (FKM) delivers exceptional resistance to aggressive chemicals, fuels, and high temperatures, making it indispensable for aerospace and chemical processing applications. Its tensile strength (15–25 MPa) and thermal stability (–20°C to +230°C continuous) withstand extreme conditions but at a premium cost. Nitrile (NBR) provides optimal balance for oil and fuel exposure in automotive and hydraulics, with tensile strength of 10–20 MPa and a practical range of –30°C to +100°C. While cost-effective, it degrades under ozone or ketone exposure. Silicone (VMQ) excels in biocompatibility and wide-temperature resilience (–60°C to +200°C), supporting medical and food-grade EVA assemblies, though its lower tensile strength (5–8 MPa) requires design compensation for high-stress zones.

The comparative analysis below details critical specifications for informed material selection. All values reflect standard test methods (ASTM D2000, ISO 37) and represent typical commercial grades.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Tensile Strength (MPa) | 15–25 | 10–20 | 5–8 |

| Elongation at Break (%) | 150–300 | 200–400 | 200–600 |

| Hardness Range (Shore A) | 60–90 | 50–90 | 30–80 |

| Continuous Temp Range | –20°C to +230°C | –30°C to +100°C | –60°C to +200°C |

| Key Resistance | Acids, fuels, ozone | Oils, aliphatic hydrocarbons | Extreme temps, steam, biocompatibility |

| Typical Applications | Jet engine seals, chemical valves | Fuel hoses, O-rings | Medical device gaskets, food processing seals |

Selection must account for fluid compatibility, dynamic load profiles, and regulatory requirements. For instance, NBR’s vulnerability to brake fluids necessitates Viton substitution in high-performance braking systems, while Silicone’s low compression set suits reusable medical EVA foam components. Suzhou Baoshida’s formulation team validates material pairings through accelerated aging tests per ISO 188 and fluid immersion protocols. We emphasize that EVA foam’s cellular structure must complement the elastomer’s durometer to prevent extrusion or stress relaxation. Partnering with our OEM division ensures tailored solutions where material science meets manufacturing precision, minimizing field failures and optimizing lifecycle costs for industrial clients.

Manufacturing Capabilities

Engineering Capability in EVA Block Foam Manufacturing

At Suzhou Baoshida Trading Co., Ltd., our engineering expertise in EVA block foam production is anchored in a dedicated team of 5 specialized mould engineers and 2 advanced rubber formula engineers. This integrated technical team enables us to deliver high-precision, application-specific EVA foam solutions tailored to the demanding requirements of industrial clients across automotive, construction, electronics, and consumer goods sectors. Our engineering capability is not limited to manufacturing—it spans material science, mould design, process optimization, and full-cycle OEM development.

Our formula engineers possess deep knowledge in polymer chemistry, specializing in ethylene-vinyl acetate (EVA) compounding. They design custom formulations to achieve precise physical properties such as compression set resistance, density control, thermal stability, and closed-cell structure integrity. By adjusting vinyl acetate (VA) content, crosslinking agents, blowing agents, and additives, we produce EVA block foams with Shore A hardness ranging from 15 to 80, densities from 0.15 g/cm³ to 0.60 g/cm³, and exceptional resilience under dynamic loading conditions. These formulations are validated through in-house testing for aging, UV resistance, and low-temperature flexibility, ensuring compliance with international standards.

Complementing material development, our 5 mould engineers focus on precision tooling and process engineering. They utilize CAD/CAM software to design high-tolerance mould cavities optimized for uniform foam expansion, minimal flash, and consistent cell structure. Their expertise ensures dimensional accuracy within ±0.3 mm and smooth surface finishes suitable for direct assembly or secondary bonding. Moulds are fabricated from high-grade steel or aluminum, with temperature-controlled channels to support repeatable curing cycles in continuous press foaming systems.

Our OEM capabilities are built on this dual foundation of material and mechanical engineering. Clients benefit from full design-for-manufacturability (DFM) support, rapid prototyping, and scalable production from 500 to 50,000 units per month. We manage tooling, formulation validation, and quality assurance in-house, reducing lead times and ensuring IP protection. Whether developing gasketing blocks, shock-absorbing pads, or insulation cores, we align material performance with functional requirements at every stage.

The following table outlines key technical specifications achievable with our EVA block foam engineering platform:

| Property | Range / Value | Test Standard |

|---|---|---|

| Density | 0.15 – 0.60 g/cm³ | ASTM D3574 |

| Hardness (Shore A) | 15 – 80 | ASTM D2240 |

| Tensile Strength | 1.5 – 4.0 MPa | ASTM D412 |

| Elongation at Break | 150% – 400% | ASTM D412 |

| Compression Set (22h, 70°C) | ≤ 30% | ASTM D395 |

| Cell Structure | Closed-cell (>90%) | Microscopic Analysis |

| Operating Temperature | -40°C to +80°C | ISO 188 |

| Custom Colors | Available (Pantone Matching) | — |

This technical depth positions Suzhou Baoshida as a strategic partner in industrial rubber solutions, where precision, consistency, and innovation define our EVA block foam manufacturing excellence.

Customization Process

EVA Block Foam Customization Process: Precision Engineering from Concept to Volume

Suzhou Baoshida Trading Co., Ltd. executes a rigorous, science-driven customization pathway for EVA block foam, ensuring industrial clients receive materials meeting exact functional and dimensional specifications. Our process eliminates guesswork through systematic engineering validation at every stage, directly translating client requirements into reliable production outcomes. This methodology minimizes time-to-market while guaranteeing performance consistency under demanding operational conditions.

Drawing Analysis & Requirement Definition

The foundation is meticulous technical drawing review against ASTM D3574 and ISO 1798 standards. Our engineering team dissects GD&T callouts, critical tolerances (±0.1mm achievable), and environmental exposure parameters. We identify potential manufacturability conflicts early, such as wall thickness ratios affecting cell structure uniformity or complex geometries challenging demolding. Client application context—load-bearing requirements, chemical exposure, temperature cycles—is quantified into material property targets before formulation begins. This phase includes feasibility assessment and collaborative refinement of specifications.

Advanced Formulation Development

Leveraging proprietary polymer science, our rubber formula engineers design bespoke EVA compounds. Key variables include VA content (18%-40% range), crosslinking density (peroxide vs. azo systems), and additive packages for flame retardancy (UL94 HF-1), UV stability, or static dissipation. Melt flow index is precisely tuned for optimal mold filling without knit lines. Every formulation undergoes predictive modeling for compression set (ASTM D395) and resilience, ensuring the base chemistry aligns with the mechanical behavior demanded by the final part geometry and service environment.

Prototyping & Performance Validation

Physical prototypes are produced using production-intent tooling under controlled process parameters. Dimensional accuracy is verified via CMM against the original CAD model. Critical physical properties undergo third-party certified testing as shown in the comparative specification table below. Accelerated aging tests simulate 5+ years of service exposure. Client feedback on prototype functionality triggers iterative formulation or process adjustments—typically 1-2 cycles—until all KPIs are met with statistical confidence (CpK >1.33).

| Critical Parameter | Standard EVA Range | Baoshida Custom Range | Test Standard |

|---|---|---|---|

| Density (kg/m³) | 25-150 | 18-200 | ASTM D3574 |

| Hardness (Shore A) | 10-90 | 5-95 | ASTM D2240 |

| Compression Set (%) | ≤50% | ≤25% (70°C/22h) | ASTM D3574 Method B |

| Tensile Strength (MPa) | 0.1-2.0 | 0.05-3.5 | ASTM D412 |

| Elongation at Break (%) | 100-700 | 80-900 | ASTM D412 |

Controlled Mass Production Transition

Upon prototype sign-off, we implement full statistical process control (SPC) for volume manufacturing. Each production lot undergoes in-process checks for melt viscosity consistency and final inspection per AQL 1.0 standards. Our Suzhou facility utilizes closed-loop temperature and pressure monitoring during continuous slabstock foaming, ensuring batch-to-batch repeatability. Dedicated OEM production lines prevent cross-contamination, with traceability down to raw material lot numbers. Clients receive comprehensive material certifications and production data packages, enabling seamless integration into their supply chain with zero quality escapes. This disciplined transition guarantees that the validated prototype performance scales identically to high-volume output.

Contact Engineering Team

For industrial manufacturers seeking high-performance EVA block foam materials, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in the global supply chain. As a specialized provider of engineered rubber and polymer solutions, we deliver precision-manufactured EVA (ethylene-vinyl acetate) block foam products tailored to meet the rigorous demands of automotive, electronics, medical devices, packaging, and industrial equipment sectors. Our commitment to material consistency, dimensional accuracy, and technical support ensures that your production processes remain efficient and reliable.

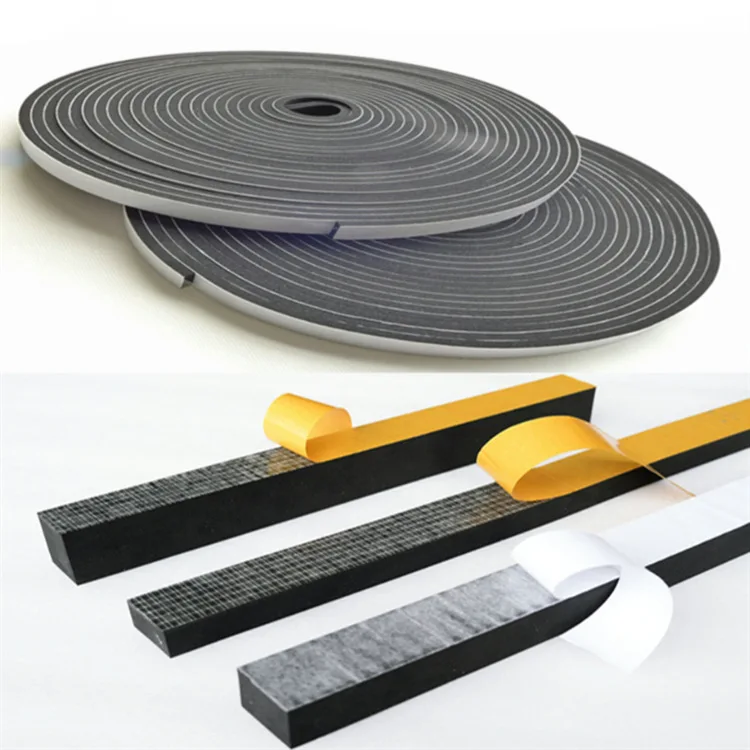

EVA block foam is renowned for its excellent cushioning properties, resilience, and resistance to moisture, chemicals, and UV exposure. At Suzhou Baoshida, we produce EVA foam in customizable densities, hardness levels, and cell structures to match your application requirements. Whether you need shock absorption in transportation packaging, sealing performance in gasketing, or ergonomic padding in protective gear, our formulations are engineered for optimal functionality and long-term durability.

We understand that industrial procurement decisions hinge on both technical performance and supply chain stability. That is why our manufacturing processes adhere to ISO-certified quality controls, and our R&D team collaborates directly with clients to refine material specifications. From prototype development to high-volume production runs, we ensure batch-to-batch uniformity and on-time delivery to support your operational timelines.

Below are standard technical specifications for our most commonly supplied EVA block foam grades. Custom modifications are available upon request.

| Property | Test Method | Value Range |

|---|---|---|

| Density | ASTM D3574 | 0.15–0.60 g/cm³ |

| Hardness (Shore A) | ASTM D2240 | 20–80 |

| Tensile Strength | ASTM D412 | 1.5–6.0 MPa |

| Elongation at Break | ASTM D412 | 150–450% |

| Compression Set (22h, 70°C) | ASTM D395 | ≤ 30% |

| Closed Cell Content | ASTM D2856 | ≥ 90% |

| Operating Temperature Range | — | -40°C to +80°C |

| Color Options | — | Black, White, Gray, Custom |

| Customization | — | Density, Hardness, Additives (anti-static, flame retardant, etc.) |

To discuss your specific EVA block foam requirements, contact Mr. Boyce, OEM Account Manager at Suzhou Baoshida Trading Co., Ltd. With extensive experience in industrial rubber solutions and international supply logistics, Mr. Boyce provides technical guidance and commercial support to ensure your project’s success. We offer sample submissions, material data sheets, and full traceability documentation to facilitate your evaluation and integration process.

Reach out today via email at [email protected] to initiate a technical consultation or request a quotation. Our team responds promptly to all inquiries and is prepared to assist with material selection, compliance needs, and volume pricing strategies. Partner with Suzhou Baoshida for precision-engineered EVA block foam solutions backed by technical expertise and global manufacturing reliability.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).