Technical Contents

Engineering Guide: Expanded Ptfe Gasket

Engineering Insight: The Critical Role of Material Selection in Expanded PTFE Gaskets

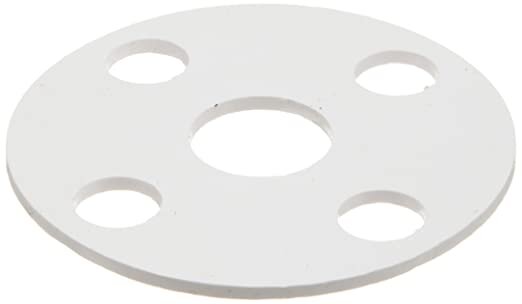

In precision sealing applications, expanded polytetrafluoroethylene (ePTFE) gaskets are often specified for their exceptional chemical resistance, thermal stability, and low creep relaxation. However, despite their widespread availability as off-the-shelf components, many industrial failures stem from improper material selection and inadequate understanding of operational stressors. At Suzhou Baoshida Trading Co., Ltd., we emphasize that successful gasket performance is not guaranteed by material class alone—engineering context determines suitability.

Standard ePTFE gaskets are manufactured using a process that expands the PTFE structure into a microporous matrix, enhancing conformability and sealing efficiency. While this structure provides advantages over conventional PTFE, it also introduces sensitivity to compression load, surface finish, and long-term stress conditions. Off-the-shelf gaskets are typically produced with generic formulations optimized for cost and broad compatibility, not for the specific mechanical, thermal, or chemical environment of critical applications. This one-size-fits-all approach frequently leads to premature seal failure, leakage, or unplanned downtime.

Material selection must account for dynamic variables such as flange type, bolt load consistency, thermal cycling, and exposure to aggressive media. For example, in high-vacuum or ultra-pure semiconductor processing, even trace outgassing from a standard ePTFE formulation can compromise system integrity. Similarly, in cryogenic applications, unmodified ePTFE may exhibit embrittlement, leading to microcracking under thermal shock. These failure modes are not inherent to ePTFE as a material but arise from mismatched specifications.

Custom-engineered ePTFE gaskets incorporate fillers, density gradients, or surface treatments to meet precise OEM requirements. At Baoshida, we collaborate with clients to analyze service conditions and tailor material properties accordingly. This includes adjusting porosity, incorporating reinforcement layers, or modifying the molecular orientation to enhance recovery and resilience under sustained load.

The following table outlines key performance parameters for standard versus engineered ePTFE gaskets under demanding conditions:

| Parameter | Standard ePTFE Gasket | Engineered ePTFE Gasket |

|---|---|---|

| Density (g/cm³) | 0.7 – 0.8 | 0.6 – 1.2 (adjustable) |

| Tensile Strength (MPa) | 10 – 15 | 18 – 25 |

| Compression Recovery (%) | 75 – 80 | 90 – 95 |

| Max Continuous Temp (°C) | 260 | 260 (with thermal stabilizers) |

| Permeation Resistance | Moderate | High (with barrier layer) |

| Chemical Compatibility | Broad | Custom-optimized |

| Outgassing (at 200°C, TGA) | 0.8% mass loss | <0.2% mass loss |

Selecting the correct ePTFE gasket is not a commodity decision—it is an engineering imperative. At Suzhou Baoshida Trading Co., Ltd., we provide OEMs with material intelligence and precision manufacturing to ensure sealing solutions perform reliably under real-world conditions. Relying on off-the-shelf products risks system performance; engineered solutions ensure long-term success.

Material Specifications

Material Specifications for Expanded PTFE Gaskets

Expanded polytetrafluoroethylene (ePTFE) represents the critical substrate for high-performance gasketing solutions requiring exceptional chemical inertness and thermal stability. At Suzhou Baoshida Trading Co., Ltd., our ePTFE gaskets are manufactured from virgin PTFE resin expanded into a microporous structure, achieving densities between 0.5–0.8 g/cm³. This process yields compressibility of 15–25% at 3.4 MPa and recovery exceeding 60%, ensuring reliable sealing under dynamic flange conditions. Continuous service temperature spans -200°C to +260°C, with intermittent peaks up to 300°C. Per ASTM F1387, ePTFE demonstrates zero fluid absorption and resistance to virtually all industrial chemicals, including concentrated acids, bases, and solvents. Density and fiber orientation are precisely controlled during expansion to meet OEM torque retention specifications, minimizing cold flow under sustained load.

While ePTFE serves as the benchmark substrate, elastomeric alternatives like Viton, Nitrile, and Silicone remain relevant for specific non-ePTFE applications. The following table details comparative performance parameters essential for material selection in demanding sealing environments.

| Material Property | Expanded PTFE (ePTFE) | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|---|

| Temperature Range (°C) | -200 to +260 | -20 to +230 | -30 to +120 | -60 to +200 |

| Tensile Strength (MPa) | 15–25 | 10–20 | 10–25 | 5–12 |

| Compression Set (%) | <15 (at 200°C) | 15–30 (at 200°C) | 20–40 (at 100°C) | 20–50 (at 200°C) |

| Chemical Resistance | Exceptional | Excellent | Good (oils/fuels) | Poor (solvents) |

| Pressure Limit (MPa) | 40 | 30 | 20 | 15 |

| Key Limitation | Creep under load | Cost, low-temp | Ozone degradation | Low tensile strength |

ePTFE’s unparalleled chemical compatibility makes it indispensable for semiconductor, pharmaceutical, and aggressive chemical processing applications where elastomer degradation risks contamination. Viton offers a cost-effective balance for high-temperature hydrocarbon exposure but suffers in low-temperature flexibility and ketone resistance. Nitrile remains prevalent in hydraulic and fuel systems below 120°C but fails against polar solvents and ozone. Silicone provides wide-temperature flexibility yet lacks mechanical robustness for high-pressure gasketing.

Suzhou Baoshida rigorously tests all materials per ASTM F37, F471, and ISO 3601 standards. Our ePTFE formulations achieve purity levels exceeding 99.98% fluorine content, with trace metal concentrations below 1 ppm—critical for ultra-high-purity (UHP) systems. When elastomers are specified, we prioritize custom compound adjustments: hydrogenated NBR for enhanced ozone resistance, peroxide-cured Viton for low-temperature flexibility, and phenyl-modified silicone for jet fuel compatibility. Material selection must align with fluid media, thermal cycling profiles, and flange surface finish to prevent extrusion or stress relaxation. Consult our engineering team for OEM-specific validation data against MIL-G-24441, ASME B16.20, or customer-defined protocols. Precision in material specification directly dictates gasket service life in critical industrial assemblies.

Manufacturing Capabilities

Engineering Excellence in Expanded PTFE Gasket Development

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our leadership in precision rubber seals, particularly in the development and production of expanded PTFE gaskets. With a dedicated team of five mould engineers and two specialized rubber formula engineers, we integrate material science with precision manufacturing to deliver high-performance sealing solutions tailored to the exacting demands of industrial applications.

Our formula engineers possess deep expertise in polymer chemistry, with a focused understanding of polytetrafluoroethylene (PTFE) microstructure and expansion dynamics. This enables precise control over porosity, density, tensile strength, and chemical resistance—critical parameters in expanded PTFE performance. By optimizing the expansion process and post-treatment protocols, we ensure consistent cell structure and mechanical integrity across all production batches. This scientific approach allows us to customize gasket materials for extreme environments, including high-temperature, high-pressure, and corrosive media applications.

Complementing our material expertise, our five mould engineers bring advanced capabilities in tooling design, process simulation, and dimensional precision. They utilize CAD/CAM systems and finite element analysis (FEA) to model gasket behavior under operational stress, enabling predictive optimization of compression set, recovery, and sealing force. This ensures that every expanded PTFE gasket meets stringent OEM specifications for fit, form, and function.

We operate as a full-service OEM partner, supporting clients from concept to mass production. Our engineering team collaborates directly with client R&D departments to co-develop gasket solutions that meet unique application requirements—whether in semiconductor manufacturing, chemical processing, or aerospace systems. From prototype tooling to full-scale compression molding and skiving lines, our in-house capabilities reduce lead times and ensure intellectual property security.

Our expanded PTFE gaskets are manufactured under ISO 9001-certified processes, with rigorous QC protocols at every stage. We maintain full traceability of raw materials and process parameters, ensuring repeatability and compliance with international standards.

The following table outlines key technical specifications achievable with our expanded PTFE gasket materials:

| Property | Typical Value | Test Method |

|---|---|---|

| Density | 0.7–0.85 g/cm³ | ASTM D792 |

| Tensile Strength | ≥15 MPa | ASTM D4894 |

| Elongation at Break | ≥150% | ASTM D4894 |

| Operating Temperature | -200°C to +260°C | ASTM D149 |

| Compression Recovery (24h) | ≥50% | ASTM F36 |

| Permeation Resistance (He) | <0.1 cm³/cm²·day·atm | ASTM E493 |

By combining advanced material formulation, precision engineering, and OEM agility, Suzhou Baoshida delivers expanded PTFE gaskets that exceed performance expectations in critical sealing applications.

Customization Process

Expanded PTFE Gasket Customization Process: Precision Engineering from Concept to Production

At Suzhou Baoshida Trading Co., Ltd., our expanded PTFE (ePTFE) gasket customization process is engineered for absolute precision and reliability in demanding industrial sealing applications. We strictly adhere to a four-phase methodology ensuring seamless translation from client specifications to high-performance, mass-produced components. This structured approach minimizes risk and guarantees optimal seal integrity under operational stress.

Drawing Analysis initiates the process. Our engineering team conducts a rigorous review of client-provided technical drawings, focusing on critical geometric tolerances per ASME Y14.5 standards, surface finish requirements, and functional interface conditions. We meticulously assess groove dimensions, flange types, and potential misalignment factors. Simultaneously, we evaluate the specified operating environment—chemical exposure, temperature extremes (-268°C to +315°C), and pressure differentials—to determine baseline material suitability. Any ambiguities or potential conflict points in the drawing are resolved collaboratively with the client before progression, ensuring absolute alignment on performance expectations and manufacturability constraints.

Formulation Development leverages our proprietary material science database. Based on the validated environmental and mechanical requirements from the drawing analysis, our rubber formula engineers select the optimal ePTFE microstructure. This involves precise control over expansion ratio, node-fibril morphology, and potential filler integration (e.g., graphite for enhanced thermal conductivity or ceramic for abrasion resistance). We tailor density, porosity, and compression characteristics to achieve the required creep resistance, recovery rate, and sealing force. Material certifications (ASTM D4894 compliance) and traceability are embedded at this stage, ensuring full documentation for critical applications.

Prototyping & Validation employs rapid, precision machining of ePTFE sheets using CNC or die-cutting techniques. Prototypes undergo rigorous validation protocols per ASTM F1384 standards, including compression set testing at elevated temperatures, chemical immersion resistance checks, and simulated service condition trials. Leak rate measurements under dynamic pressure cycles are critical. Client feedback on prototype performance is integrated iteratively; minor formulation or dimensional adjustments are made until all performance metrics are consistently met. This phase typically requires 2-3 validation cycles for complex seals.

Mass Production commences only after formal client sign-off on validated prototypes. Our ISO 9001-certified production line implements strict in-process controls: 100% dimensional verification via optical comparators, batch traceability through serialized material logs, and real-time monitoring of sintering parameters. Final gaskets undergo comprehensive QA checks against the approved drawing, including surface defect inspection and batch sampling for critical physical properties. Consistent output is ensured through controlled raw material inventory and calibrated tooling, delivering gaskets ready for immediate installation in critical OEM systems.

Key ePTFE material specifications achievable through our customization process include:

| Parameter | Standard Range | Customizable Range | Test Standard |

|---|---|---|---|

| Density (g/cm³) | 0.5 – 0.7 | 0.35 – 0.85 | ASTM D792 |

| Tensile Strength (MPa) | 15 – 30 | 10 – 40 | ASTM D4894 |

| Compression @ 15% (MPa) | 1.5 – 3.0 | 0.8 – 5.0 | ASTM F36 |

| Recovery Rate (%) | 70 – 85 | 60 – 95 | ASTM F36 |

| Max. Temp. (°C) | Continuous: 260 | Continuous: 315 | ASTM D149 |

| Min. Temp. (°C) | -268 | -268 | ASTM D746 |

This disciplined workflow, combining material science expertise with stringent process control, ensures Suzhou Baoshida delivers ePTFE gaskets that meet the exacting demands of aerospace, semiconductor, and chemical processing industries, every time.

Contact Engineering Team

For industrial manufacturers and engineering teams seeking high-performance sealing solutions, expanded PTFE gaskets represent a critical component in ensuring system integrity under extreme conditions. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision rubber seals engineered to meet the rigorous demands of chemical processing, pharmaceutical, semiconductor, and high-vacuum applications. Our expanded PTFE gaskets are manufactured using a proprietary expansion process that enhances molecular alignment, resulting in superior compressibility, resilience, and chemical inertness compared to standard PTFE materials.

Expanded PTFE (ePTFE) offers distinct advantages over conventional sealing materials. Its microstructure consists of a node-fibril architecture that provides excellent sealing performance across fluctuating temperatures and pressures. This material maintains sealing force over time, resists cold flow, and exhibits minimal outgassing—making it ideal for use in ultra-clean environments. Whether you require custom die-cut gaskets, sheet stock, or complex molded forms, Suzhou Baoshida ensures dimensional accuracy, batch traceability, and compliance with international material standards.

We understand that every industrial application presents unique sealing challenges. Our engineering team works closely with OEMs and maintenance departments to evaluate operating parameters such as media exposure, temperature cycles, surface finish, and flange design. This collaborative approach allows us to recommend or develop a tailored ePTFE gasket solution that optimizes service life, reduces downtime, and enhances safety.

Below are the standard technical specifications for our expanded PTFE gasket material:

| Property | Value | Test Method |

|---|---|---|

| Density | 0.70–0.80 g/cm³ | ASTM D792 |

| Tensile Strength (MD) | ≥ 3.5 MPa | ASTM D1457 |

| Compressibility | 20–35% | ASTM F36 |

| Recovery | ≥ 50% | ASTM F36 |

| Maximum Continuous Use Temperature | 260°C (500°F) | — |

| Minimum Use Temperature | -200°C (-328°F) | — |

| Permeability (He) | < 0.05 cm³/cm²·day | ASTM E96 |

| pH Range | 0–14 | — |

All materials are free from fillers, plasticizers, and extractables, ensuring compatibility with aggressive acids, bases, solvents, and high-purity fluids. Custom formulations with controlled dielectric properties or enhanced creep resistance are available upon request.

To discuss your specific sealing requirements or request a technical datasheet, contact Mr. Boyce at Suzhou Baoshida Trading Co., Ltd. Direct correspondence ensures rapid response, technical validation, and sample provisioning for qualification testing. Email Mr. Boyce at [email protected] to initiate a consultation. Include details such as operating conditions, flange dimensions, required certifications, and target volume to expedite the evaluation process.

Suzhou Baoshida is committed to advancing sealing technology through precision manufacturing and responsive engineering support. Partner with us to resolve persistent leakage issues, extend maintenance intervals, and achieve reliable performance in the most demanding industrial environments. Your application’s success begins with the right material—contact us today.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).