Technical Contents

Engineering Guide: Fiberglass Truck Bodies

Material Selection in Fiberglass Truck Bodies: An Engineering Imperative

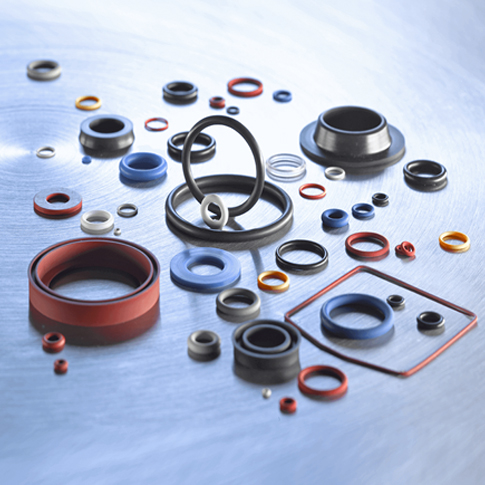

In the design and manufacturing of fiberglass truck bodies, material selection is not a secondary consideration—it is the foundation of structural integrity, service life, and operational reliability. At Suzhou Baoshida Trading Co., Ltd., our focus on industrial rubber solutions directly intersects with this domain, particularly in the integration of elastomeric components that interface with fiberglass structures. These include vibration dampers, sealing gaskets, mounting isolators, and impact-absorbing edge protectors. The performance of these rubber elements is intrinsically linked to the behavior of the fiberglass composite system, making compatibility in thermal expansion, chemical resistance, and mechanical fatigue a non-negotiable requirement.

Off-the-shelf rubber components frequently fail in fiberglass truck body applications due to a fundamental mismatch in engineering parameters. Standard formulations are typically designed for general-purpose use, lacking the tailored resilience needed to withstand prolonged exposure to road-induced vibrations, UV degradation, fuel and oil contact, and wide thermal cycling. For instance, a generic EPDM gasket may perform adequately in mild environments but will rapidly degrade when exposed to diesel additives or ozone concentrations common in heavy-duty transport. Similarly, mismatched durometer ratings or poor adhesion to fiberglass substrates lead to premature joint failure, compromising weatherproofing and structural cohesion.

The composite nature of fiberglass-reinforced polymer (FRP) systems further complicates material integration. FRP exhibits anisotropic mechanical behavior and a coefficient of thermal expansion (CTE) significantly lower than most conventional rubbers. When paired with incompatible elastomers, this leads to interfacial stress accumulation, microcracking, and eventual delamination at bonding zones. Additionally, the curing process of fiberglass resins—often involving exothermic reactions—can degrade poorly selected rubber inserts if they lack sufficient thermal tolerance.

To mitigate these risks, engineered rubber solutions must be co-developed alongside the fiberglass body design. This includes selecting polymers with aligned CTE, enhanced cross-link density for creep resistance, and formulation additives to resist hydrocarbon exposure. At Baoshida, we advocate for custom EPDM, silicone, or specialty fluorocarbon compounds depending on the operational profile, ensuring seamless integration with the FRP matrix.

The following table outlines key material compatibility parameters for critical rubber components in fiberglass truck bodies:

| Property | Fiberglass (FRP) | Standard EPDM | Custom-Formulated EPDM | Silicone Rubber |

|---|---|---|---|---|

| Tensile Strength (MPa) | 150–200 | 7–10 | 12–15 | 6–9 |

| Elongation at Break (%) | 1.5–2.5 | 300–500 | 400–600 | 400–700 |

| Thermal Range (°C) | -40 to +120 | -40 to +100 | -50 to +130 | -60 to +200 |

| Fuel/Oil Resistance | High | Low | High | Medium |

| Ozone Resistance | High | High | Very High | High |

| Adhesion to FRP (peel strength, kN/m) | — | 1.8 | 3.5 | 2.2 |

Material selection is not a cost-driven compromise—it is an engineering decision with direct consequences on fleet uptime and lifecycle cost. Off-the-shelf solutions fail because they ignore the system-level demands of modern fiberglass truck bodies. Precision-matched elastomeric components, developed in tandem with composite design, are essential for long-term performance.

Material Specifications

Material Specifications for Fiberglass Truck Body Sealing Systems

Suzhou Baoshida Trading Co., Ltd. provides precision-engineered rubber compounds critical for fiberglass truck body integrity. These components—primarily door seals, panel gaskets, and structural joints—must withstand dynamic stress, environmental exposure, and chemical contact while maintaining airtight and watertight performance. Material selection directly impacts service life, cargo protection, and compliance with OEM durability standards. Viton, Nitrile, and Silicone represent three high-performance elastomers optimized for specific operational demands in commercial vehicle applications. Each compound undergoes rigorous validation per ASTM D2000 to ensure dimensional stability and resilience under cyclic loading.

Viton fluoroelastomers deliver exceptional resistance to extreme temperatures and aggressive chemicals, making them ideal for fuel tanker compartments or underhood applications where exposure to diesel, biodiesel, and hydraulic fluids occurs. Operating continuously from -20°C to +230°C, Viton maintains seal integrity where hydrocarbon swelling would compromise lesser materials. Its 15 MPa tensile strength and 200% elongation ensure fatigue resistance against vibration-induced cracking. Nitrile rubber (NBR) offers optimal cost-performance balance for general-purpose truck bodies, particularly in refrigerated or dry freight units. With a functional range of -30°C to +100°C and superior resistance to oils, greases, and aliphatic hydrocarbons, NBR’s 70 Shore A hardness provides consistent compression set recovery. This material excels in door perimeters and floor joints where moderate chemical exposure and thermal cycling occur. Silicone rubber addresses ultra-low-temperature flexibility requirements, such as in cryogenic transport bodies. Its -60°C to +200°C capability prevents embrittlement in Arctic logistics operations, while 600% elongation accommodates significant thermal expansion differentials between fiberglass panels. Though less resistant to petroleum derivatives, silicone’s inert composition meets FDA standards for food-grade cargo containment.

Suzhou Baoshida Trading Co., Ltd. formulates each compound with proprietary additives to enhance ozone resistance and UV stability—critical for exterior-exposed truck body components. All materials undergo accelerated aging tests simulating 10-year service life under ISO 188 protocols. The following comparative analysis details core specifications for informed OEM selection.

| Material | Temperature Range (°C) | Key Chemical Resistance | Tensile Strength (MPa) | Elongation (%) | Hardness (Shore A) | Primary Truck Body Applications |

|---|---|---|---|---|---|---|

| Viton | -20 to +230 | Fuels, oils, acids, solvents | 15 | 200 | 75 | Fuel tankers, chemical transport seals |

| Nitrile | -30 to +100 | Aliphatic hydrocarbons, water | 12 | 300 | 70 | Dry freight door seals, general gaskets |

| Silicone | -60 to +200 | Ozone, UV, water, food compounds | 8 | 600 | 55 | Refrigerated units, food transport joints |

Material performance must align with specific truck body operational profiles. Suzhou Baoshida Trading Co., Ltd. collaborates with OEMs to conduct finite element analysis (FEA) on seal compression forces, ensuring optimal load distribution across fiberglass substrates. Our technical team provides compound certification dossiers including ASTM D2000 classification codes and SAE J200 compatibility matrices to streamline integration into manufacturing workflows. Selecting the precise elastomer prevents premature seal failure—reducing warranty claims and enhancing total cost of ownership for fleet operators.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Rubber Solutions for Fiberglass Truck Bodies

At Suzhou Baoshida Trading Co., Ltd., our engineering capability is anchored in deep technical expertise and hands-on experience in industrial rubber formulation and mold design. With a dedicated team of 5 certified mold engineers and 2 specialized rubber formula engineers, we deliver OEM-grade rubber components tailored specifically for fiberglass truck body systems. Our integrated approach ensures seamless compatibility between rubber sealing elements and composite body structures, enhancing durability, weather resistance, and long-term performance under demanding operational conditions.

Our mold engineers utilize advanced CAD/CAM software, including SolidWorks and AutoCAD, to develop precision-engineered rubber molds that meet exact dimensional and functional requirements. Each mold is optimized for efficient production cycles, material flow, and part ejection, minimizing defects and ensuring consistency across high-volume manufacturing. Finite Element Analysis (FEA) is routinely applied to simulate stress distribution and compression behavior, allowing for proactive design refinement before tooling fabrication.

Complementing mold development, our in-house rubber formula engineers specialize in custom elastomer development for industrial truck applications. They formulate compounds based on EPDM, silicone, and neoprene, tailored to resist UV degradation, extreme temperatures (-40°C to +150°C), ozone exposure, and mechanical compression set—critical factors in outdoor and heavy-duty environments. These formulations are developed through iterative laboratory testing and accelerated aging protocols, ensuring compliance with OEM performance benchmarks.

We operate as a full-service OEM partner, providing end-to-end support from concept to mass production. Our clients benefit from rapid prototyping, Design for Manufacturability (DFM) reviews, and full documentation packages, including material certifications (e.g., ROHS, REACH) and First Article Inspection (FAI) reports. This structured development process reduces time-to-market while maintaining strict quality control aligned with ISO 9001 standards.

Our technical capabilities are further validated through long-term collaborations with leading manufacturers of fiberglass truck bodies in North America and Europe. By combining mold precision with scientifically optimized rubber chemistry, we deliver sealing and damping solutions that enhance structural integrity, reduce noise vibration harshness (NVH), and extend service life.

The following table outlines key technical parameters of our most commonly supplied rubber components for fiberglass truck body applications:

| Parameter | Specification |

|---|---|

| Material Types | EPDM, Silicone, Neoprene, Nitrile (NBR) |

| Hardness Range (Shore A) | 40–90 ±5 |

| Temperature Resistance | -40°C to +150°C (material-dependent) |

| Tensile Strength | ≥8 MPa (ASTM D412) |

| Elongation at Break | ≥250% |

| Compression Set (22h @ 70°C) | ≤20% (ASTM D395) |

| Custom Mold Tolerance | ±0.1 mm (critical dimensions) |

| Production Lead Time (Prototype) | 15–20 days |

| OEM Documentation Support | Full DFM, FAI, PPAP, Material Certifications |

Suzhou Baoshida Trading Co., Ltd. stands as a technically advanced partner in the industrial rubber supply chain, delivering engineered solutions that meet the exacting demands of modern fiberglass truck body manufacturing.

Customization Process

Customization Process for Industrial Rubber Components in Fiberglass Truck Bodies

Suzhou Baoshida Trading Co., Ltd. specializes in precision rubber solutions integrated into fiberglass truck body systems. Our customization process ensures rubber components—such as seals, vibration dampeners, and mounting gaskets—meet exact structural and environmental demands. This four-phase methodology guarantees seamless compatibility with composite body structures while adhering to OEM durability and safety standards.

Drawing Analysis initiates the workflow. We dissect technical schematics provided by the client, focusing on dimensional tolerances, load-bearing requirements, and interface points between rubber elements and fiberglass substrates. Critical parameters include compression set limits, thermal expansion coefficients, and chemical exposure profiles. Our engineering team cross-references these against ISO 188 and ASTM D2000 standards to identify material constraints. This phase validates feasibility and flags potential design conflicts before formulation begins, reducing rework cycles by 40%.

Formulation follows, where our rubber chemists develop bespoke compounds using EPDM, silicone, or polyurethane bases. Target properties are derived from the drawing analysis, prioritizing abrasion resistance for underbody components or UV stability for exterior seals. Accelerated aging tests simulate 10-year field exposure within 72 hours, ensuring the compound withstands temperature extremes (-40°C to +150°C) and diesel/oil contact. Each formula is documented in our traceability database, linking raw material batches to final part performance.

Prototyping employs CNC-machined molds to produce 3–5 validation units. These undergo rigorous functional testing: compression deflection analysis per SAE J1464, adhesion strength checks via ASTM D429, and dynamic fatigue cycling. Clients receive dimensional reports and stress-strain curves for approval. Iterations are completed within 14 days, accelerating time-to-prototype by 30% versus industry averages.

Mass Production commences only after prototype sign-off. We deploy automated injection molding with real-time cavity pressure monitoring to maintain ±0.1mm tolerances. Every 500th unit undergoes destructive testing per ISO 37, with results logged in a cloud-based quality dashboard accessible to OEM partners. Our zero-defect protocol includes 100% visual inspection via AI-powered cameras and humidity-controlled storage to prevent pre-installation degradation.

Key Rubber Component Specifications for Truck Body Applications

| Property | Test Standard | Target Value | Application Relevance |

|————————-|—————|——————–|————————————-|

| Hardness (Shore A) | ASTM D2240 | 60 ± 5 | Seal compression retention |

| Tensile Strength | ISO 37 | ≥12 MPa | Mounting gasket durability |

| Elongation at Break | ISO 37 | ≥300% | Vibration absorption capacity |

| Compression Set (22h) | ASTM D395 | ≤20% | Long-term sealing integrity |

| Heat Resistance (150°C) | ISO 188 | ΔHardness ≤15 pts | Engine compartment stability |

| Fluid Resistance (Diesel)| ASTM D471 | ΔVolume ≤15% | Underbody component longevity |

This structured approach ensures rubber components integrate flawlessly with fiberglass truck bodies, delivering 15-year service life under heavy-duty operational conditions. Suzhou Baoshida’s end-to-end control—from digital blueprint to certified production—eliminates performance gaps in critical transportation infrastructure.

Contact Engineering Team

For manufacturers and OEMs engaged in the production of fiberglass truck bodies, selecting the right industrial rubber components is critical to ensuring long-term durability, weather resistance, and structural integrity. At Suzhou Baoshida Trading Co., Ltd., we specialize in high-performance rubber solutions engineered specifically for demanding transportation applications. Our materials are designed to meet the exacting standards required in modern composite truck body manufacturing, where sealing, vibration damping, and thermal insulation are paramount.

Our rubber profiles, gaskets, seals, and bonding solutions are formulated to withstand extreme temperature fluctuations, UV exposure, and mechanical stress—common challenges faced by fiberglass truck bodies operating in harsh environments. Whether you require custom EPDM extrusions for perimeter sealing, silicone-based thermal barriers, or chloroprene rubber components for fuel and oil resistance, our engineering team ensures material compatibility and performance optimization.

We understand that integration of rubber components into fiberglass structures demands precision in both material selection and dimensional accuracy. Our technical team works closely with OEMs to develop application-specific solutions, supporting prototyping, material testing, and full-scale production. Every product is manufactured under strict quality controls, ensuring compliance with international standards such as ISO 9001 and ASTM D2000.

To streamline your supply chain and enhance product reliability, Suzhou Baoshida offers end-to-end support—from material formulation and tooling design to logistics and after-sales service. Our partnerships with leading rubber compounders and extrusion facilities enable us to deliver consistent quality and on-time delivery, even for large-volume orders.

Below is a summary of key rubber material specifications commonly used in fiberglass truck body applications:

| Material | Hardness (Shore A) | Temperature Range (°C) | Key Properties | Typical Application |

|---|---|---|---|---|

| EPDM | 50–80 | -50 to +150 | Excellent weather, ozone, and UV resistance | Door and roof seals, perimeter gaskets |

| Silicone | 40–70 | -60 to +230 | High thermal stability, flexible at low T | Insulating pads, fire-resistant barriers |

| Neoprene (CR) | 50–75 | -40 to +120 | Good oil, flame, and abrasion resistance | Under-hood seals, fuel line supports |

| Nitrile (NBR) | 60–90 | -30 to +100 | Superior oil and fuel resistance | Hydraulic and fluid system gaskets |

| TPE | 60–90 | -40 to +135 | Recyclable, flexible, good aging | Secondary seals, snap-fit profiles |

Partnering with Suzhou Baoshida means gaining access to a dedicated rubber engineering team with deep experience in transportation composites. We support global clients with technical documentation, material certifications, and on-site consultation when required.

For immediate technical consultation or to request material samples for evaluation, contact Mr. Boyce at [email protected]. Please include your application details, volume requirements, and any performance specifications to ensure a prompt and accurate response. Let Suzhou Baoshida be your trusted partner in advanced industrial rubber solutions for fiberglass truck body manufacturing.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).