Technical Contents

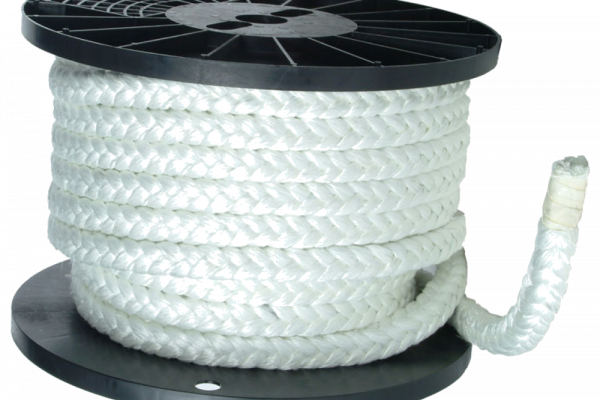

Engineering Guide: Fibreglass Rope Gasket

Engineering Insight: Fibreglass Rope Gasket Material Selection Imperatives

The operational integrity of high-temperature and chemically aggressive industrial sealing applications hinges critically on precise fibreglass rope gasket material selection. Generic off-the-shelf solutions frequently fail to meet demanding service conditions, leading to catastrophic seal degradation, unplanned downtime, and significant safety hazards. This failure stems from a fundamental misconception: treating fibreglass rope gaskets as commodity items rather than engineered components requiring application-specific formulation. Standard products utilize generic resin binders and inconsistent fibre matrices optimized for cost, not performance. Under sustained thermal cycling exceeding 250°C or exposure to aggressive media like concentrated acids, alkalis, or hydrocarbons, these materials exhibit rapid thermal degradation, excessive compression set, and chemical attack. The resulting loss of resilience and dimensional stability compromises the seal face, permitting leakage paths that escalate maintenance costs and risk environmental non-compliance.

Material science dictates that successful fibreglass rope gaskets require tailored resin chemistry and fibre architecture. High-purity E-glass or S-glass fibres must be impregnated with thermoset resins specifically formulated for the target environment. Silicone resins offer broad chemical resistance but limited high-temperature stability above 300°C. Phenolic resins provide superior thermal endurance but suffer from brittleness and poor acid resistance. Advanced formulations incorporating ceramic modifiers or hybrid resin systems achieve the necessary balance of flexibility, thermal stability, and chemical inertness. Crucially, the resin-to-fibre ratio and cure profile must be optimized to ensure complete crosslinking without fibre embrittlement. Off-the-shelf variants lack this precision engineering, using suboptimal cure schedules and resin loads that create internal stresses and micro-voids. These defects become initiation points for crack propagation under operational pressure and thermal shock, accelerating seal failure.

Suzhou Baoshida Trading Co., Ltd. addresses this through OEM-driven material engineering. We reject one-size-fits-all approaches, instead analyzing the specific temperature profile, chemical exposure, pressure dynamics, and flange geometry of each application. Our precision rubber seals leverage proprietary resin blends and controlled fibre orientation to deliver consistent performance where generic products falter. The table below illustrates key performance differentiators between standard offerings and our engineered solutions.

| Parameter | Generic Fiberglass Rope | Baoshida Precision Rope |

|---|---|---|

| Max Continuous Temp (°C) | 250 | 315 |

| H₂SO₄ Resistance (50%, 80°C) | Poor (Swelling >15%) | Excellent (<3% Swell) |

| Compression Set (24h, 200°C) | 45% | 18% |

| Tensile Strength (MPa) | 8.5 | 14.2 |

| Density (g/cm³) | 1.6 | 1.9 |

This performance gap translates directly to operational reliability. Our engineered gaskets maintain seal integrity through repeated thermal cycles and chemical exposure, minimizing fugitive emissions and extending service life by 300% in validated OEM applications. Material selection is not a cost line item; it is the foundational engineering decision determining system safety and lifecycle economics. Consult our technical team with your specific operating parameters to eliminate gasket-related failures through precision-engineered solutions.

Material Specifications

Material Specifications for Fibreglass Rope Gaskets

Fibreglass rope gaskets are engineered for high-performance sealing in extreme thermal and chemical environments. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision rubber seals, integrating advanced elastomer coatings with high-purity fibreglass rope substrates. The selection of elastomer material is critical to the gasket’s functional reliability, influencing resistance to temperature, pressure, chemical exposure, and mechanical degradation. Our standard elastomer options—Viton, Nitrile, and Silicone—are applied in controlled processes to ensure uniform coverage and adhesion, enhancing sealing integrity and service life.

Viton (FKM) offers the highest level of chemical resistance among the three materials, making it ideal for aggressive media such as acids, hydrocarbons, and halogenated solvents. It maintains structural stability across a broad temperature range from -20°C to +230°C, with intermittent peaks up to 300°C. Viton-coated fibreglass rope gaskets are commonly specified in petrochemical, aerospace, and high-temperature industrial applications where long-term chemical inertness is required. However, its higher cost and reduced flexibility at low temperatures must be considered in system design.

Nitrile rubber (NBR) provides excellent resistance to oils, fuels, and aliphatic hydrocarbons, with good abrasion resistance and mechanical strength. It operates effectively between -30°C and +120°C, making it suitable for hydraulic systems, engine compartments, and general industrial machinery. While NBR is less resistant to ozone and UV exposure compared to Viton or Silicone, its cost-effectiveness and robust performance in oil-rich environments make it a preferred choice for many OEM sealing solutions.

Silicone rubber (VMQ) excels in extreme temperature applications, functioning reliably from -60°C to +200°C, with short-term exposure tolerance up to 250°C. It exhibits superior resistance to weathering, ozone, and UV radiation, making it ideal for outdoor or high-cyclic thermal environments. Silicone-coated fibreglass rope gaskets are frequently used in food processing, pharmaceutical, and electrical insulation applications due to their low toxicity and excellent dielectric properties. However, silicone has lower tensile strength and is less resistant to petroleum-based fluids compared to NBR or FKM.

The following table summarizes key material properties for informed selection:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -30 to +120 | -60 to +200 |

| Chemical Resistance | Excellent | Good (oils, fuels) | Fair (ozone, water) |

| Oil and Fuel Resistance | Outstanding | Excellent | Poor |

| UV/Ozone Resistance | Excellent | Fair | Excellent |

| Tensile Strength | High | High | Moderate |

| Flexibility at Low Temp | Moderate | Good | Excellent |

| Dielectric Strength | Good | Moderate | Excellent |

| Typical Applications | Petrochemical, aerospace | Automotive, hydraulics | Food, medical, electrical |

Selection of the appropriate elastomer coating must align with operational parameters, regulatory standards, and lifecycle expectations. Suzhou Baoshida Trading Co., Ltd. supports OEM clients with material testing data and application engineering to ensure optimal gasket performance.

Manufacturing Capabilities

Engineering Excellence in Fibreglass Rope Gasket Manufacturing

Suzhou Baoshida Trading Co., Ltd. delivers superior fibreglass rope gasket performance through deeply integrated engineering expertise, specifically structured to address the demanding requirements of industrial sealing applications. Our Precision Rubber Seals division operates on the fundamental principle that material science and precision tooling are inseparable for achieving optimal gasket integrity, longevity, and reliability under extreme conditions. This commitment is embodied by our dedicated core engineering team: five specialized Mould Engineers and two advanced Formula Engineers, working in continuous synergy from initial concept through to validated production.

Our Formula Engineers possess advanced proficiency in thermoset polymer chemistry and composite material systems. They meticulously develop and optimize proprietary resin binders and impregnation formulations specifically for fibreglass rope substrates. This expertise ensures critical enhancements in thermal stability, chemical resistance, compressibility, and recovery characteristics. By precisely controlling the interaction between the fibreglass reinforcement and the elastomeric or thermoset matrix, we achieve gaskets capable of maintaining seal integrity across wide operational ranges, resisting degradation from aggressive media, and minimizing creep relaxation under sustained load. Every formulation undergoes rigorous Design of Experiments (DOE) and accelerated life testing to guarantee performance against client specifications.

Complementing this material science capability, our five Mould Engineers focus on the precision tooling and manufacturing processes essential for dimensional accuracy and consistent part quality. They employ advanced CAD/CAM software and Finite Element Analysis (FEA) to design and validate mould cavities that ensure uniform compression, eliminate flash, and maintain critical cross-sectional tolerances within tight industrial standards. Their deep understanding of material flow dynamics during the compression or injection moulding process for rope gasket formation is critical for achieving homogeneous density and eliminating weak points. This precision engineering directly translates to gaskets that seat correctly, distribute stress evenly, and prevent leakage paths in flange assemblies.

This integrated engineering capability forms the backbone of our robust OEM service model. We do not merely manufacture to drawings; we partner with clients to solve complex sealing challenges. From initial material selection and formulation tailoring based on specific media, temperature, and pressure profiles, through iterative mould design validation and process optimization, to final in-house performance testing, our engineers provide full technical ownership. Clients benefit from reduced development cycles, minimized field failure risks, and gaskets engineered for the exact demands of their application, ensuring long-term operational safety and cost efficiency.

The following table summarizes key performance specifications achievable through our engineered fibreglass rope gasket solutions:

| Property | Typical Range/Value | Test Standard |

|---|---|---|

| Continuous Service Temp | -200°C to +550°C | ASTM D573 |

| Max. Short-Term Temp | Up to 1000°C | Custom Validation |

| Pressure Resistance | Up to 350 bar | ISO 7205 |

| Tensile Strength | 8 – 15 MPa | ASTM D412 |

| Media Resistance | Excellent: Steam, Oils, Mild Acids/Bases; Good: Strong Acids; Fair: Strong Oxidizers | ASTM D471 |

| Compression Set (24h, 200°C) | ≤ 25% | ASTM D395 |

| Density | 1.4 – 1.8 g/cm³ | ASTM D297 |

This engineering-driven approach, combining advanced material formulation with precision tooling science, ensures Suzhou Baoshida delivers fibreglass rope gaskets that consistently exceed the rigorous demands of global industrial OEMs, providing measurable performance and reliability advantages.

Customization Process

Customization Process for Fibreglass Rope Gaskets at Suzhou Baoshida Trading Co., Ltd.

At Suzhou Baoshida Trading Co., Ltd., the customization of fibreglass rope gaskets follows a rigorous, science-driven sequence designed to ensure dimensional accuracy, material integrity, and long-term sealing performance under industrial operating conditions. Our process integrates engineering precision with advanced rubber compounding expertise, enabling tailored solutions for demanding OEM applications across petrochemical, power generation, and high-temperature processing sectors.

The first phase, Drawing Analysis, begins with a comprehensive technical review of the customer-submitted engineering drawings or 3D models. Our engineering team evaluates critical parameters such as groove dimensions, compression requirements, flange surface finish, and operational stress points. Finite element analysis (FEA) may be applied to simulate compression set behavior and thermal expansion under expected service conditions. This step ensures the final gasket design will maintain sealing integrity while accommodating thermal cycling and mechanical load variations.

Following drawing validation, the Formulation stage initiates the development of a custom rubber compound. For fibreglass rope gaskets, the base polymer system—typically silicone (VMQ), fluorosilicone (FVMQ), or ethylene propylene diene monomer (EPDM)—is selected based on required temperature resistance, chemical exposure, and compression recovery performance. High-purity fibreglass strands are integrated as a reinforcing core, providing tensile strength and dimensional stability. Additives such as heat stabilizers, anti-aging agents, and flame retardants are precisely dosed to meet industry-specific certifications, including UL, FDA, or ASTM E136 for fire resistance.

Prototyping is conducted under controlled pilot conditions to validate both material and form. Samples are cured using production-intent tooling and subjected to a battery of tests, including compression deflection (ASTM D575), thermal aging (ASTM D573), and fluid immersion resistance. Dimensional inspection is performed via coordinate measuring machines (CMM) to confirm conformity within ±0.1 mm tolerance. Customer feedback and test data are used to refine the formulation or geometry if necessary.

Upon approval, the project transitions to Mass Production. Our automated extrusion and curing lines ensure batch-to-batch consistency, with real-time process monitoring and in-line quality checks. Each production lot undergoes full traceability, with material certificates and test reports provided. Final packaging is customized to prevent deformation during shipment.

The table below outlines typical performance specifications for standard fibreglass rope gasket configurations.

| Property | Silicone (VMQ) | Fluorosilicone (FVMQ) | EPDM |

|---|---|---|---|

| Temperature Range (°C) | -60 to +260 | -50 to +200 | -50 to +150 |

| Tensile Strength (MPa) | ≥6.0 | ≥5.5 | ≥8.0 |

| Elongation at Break (%) | ≥250 | ≥220 | ≥300 |

| Hardness (Shore A) | 50–80 | 55–75 | 50–70 |

| Compression Set (22 hrs, 177°C) | ≤25% | ≤30% | ≤20% |

| Core Material | Continuous Fibreglass | Continuous Fibreglass | Continuous Fibreglass |

Contact Engineering Team

Contact Suzhou Baoshida for Precision Fibreglass Rope Gasket Solutions

Selecting the optimal fibreglass rope gasket is a critical engineering decision impacting system integrity, operational safety, and long-term maintenance costs across demanding industrial applications. Generic solutions often fail to address the nuanced interplay of temperature extremes, chemical exposure, pressure differentials, and mechanical stress inherent in modern sealing environments. At Suzhou Baoshida Trading Co., Ltd., we operate at the intersection of advanced rubber compounding science and rigorous OEM manufacturing standards, specifically for precision seals like high-performance fibreglass rope gaskets. Our engineered formulations are not merely products; they represent validated solutions developed through iterative material science and deep application understanding. Engaging our technical team early in your design or sourcing process ensures the gasket specification aligns precisely with your operational parameters, mitigating risks of premature failure, costly downtime, and safety incidents. Generic catalog selections cannot replicate the tailored performance achieved through our collaborative engineering approach.

The core performance characteristics defining a reliable fibreglass rope gasket are non-negotiable and require precise material control. Below is a summary of key technical parameters achievable through our specialized manufacturing process, reflecting the stringent quality benchmarks we uphold for industrial clients. These values are not theoretical maximums but represent consistent, production-ready performance validated under controlled conditions.

| Parameter | Standard Value Range | Application Significance |

|---|---|---|

| Continuous Use Temp | -200°C to +550°C | Ensures structural integrity in cryogenic to extreme heat |

| Thermal Shock Resistance | > 100 cycles (RT to 500°C) | Critical for systems with rapid temperature fluctuations |

| Chemical Resistance | Broad spectrum (acids, alkalis, solvents) | Maintains seal integrity in aggressive process media |

| Tensile Strength | Min. 8.0 MPa (ASTM D412) | Resists extrusion and mechanical damage during operation |

| Compression Set (24h/300°C) | Max. 25% (ASTM D395) | Guarantees sustained sealing force under thermal load |

| Density | 1.6 – 1.8 g/cm³ | Balances resilience, conformability, and material stability |

These specifications are the foundation, but true optimization occurs when material properties are calibrated to your specific flange geometry, surface finish, bolt load, and dynamic operational profile. Our engineering team possesses extensive expertise in translating complex application data into precise gasket formulations and dimensional tolerances. We move beyond standard catalog offerings to provide OEM-level customization, whether you require enhanced resistance to a specific chemical compound, modified thermal conductivity, or bespoke dimensional configurations for unique equipment. This capability stems from our vertically integrated quality control system, tracking raw material batches through to final product validation using ISO 17025 accredited methodologies.

Initiate a technically grounded solution for your fibreglass rope gasket requirements by contacting Mr. Boyce, our dedicated OEM Manager. Mr. Boyce possesses over 12 years of direct experience managing complex rubber seal projects for global industrial clients, specializing in high-temperature and chemically aggressive environments. He will facilitate a structured technical consultation, ensuring all critical application variables are captured and addressed. Provide your project specifications, operational challenges, and performance expectations. Mr. Boyce will coordinate our formulation chemists and production engineers to develop a validated proposal, including material test data, dimensional drawings, and lifecycle cost analysis. Do not compromise system reliability with off-the-shelf compromises. Contact Mr. Boyce directly via email at [email protected] to commence a precision-engineered sealing solution. Include your company name, application context, and key performance requirements for the most efficient technical response. Suzhou Baoshida Trading Co., Ltd. stands ready to deliver the scientific precision your critical sealing applications demand.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).