Technical Contents

Engineering Guide: Flange 4 150 Lbs

Engineering Insight: Material Selection for flange 4 150 lbs in Industrial Rubber Applications

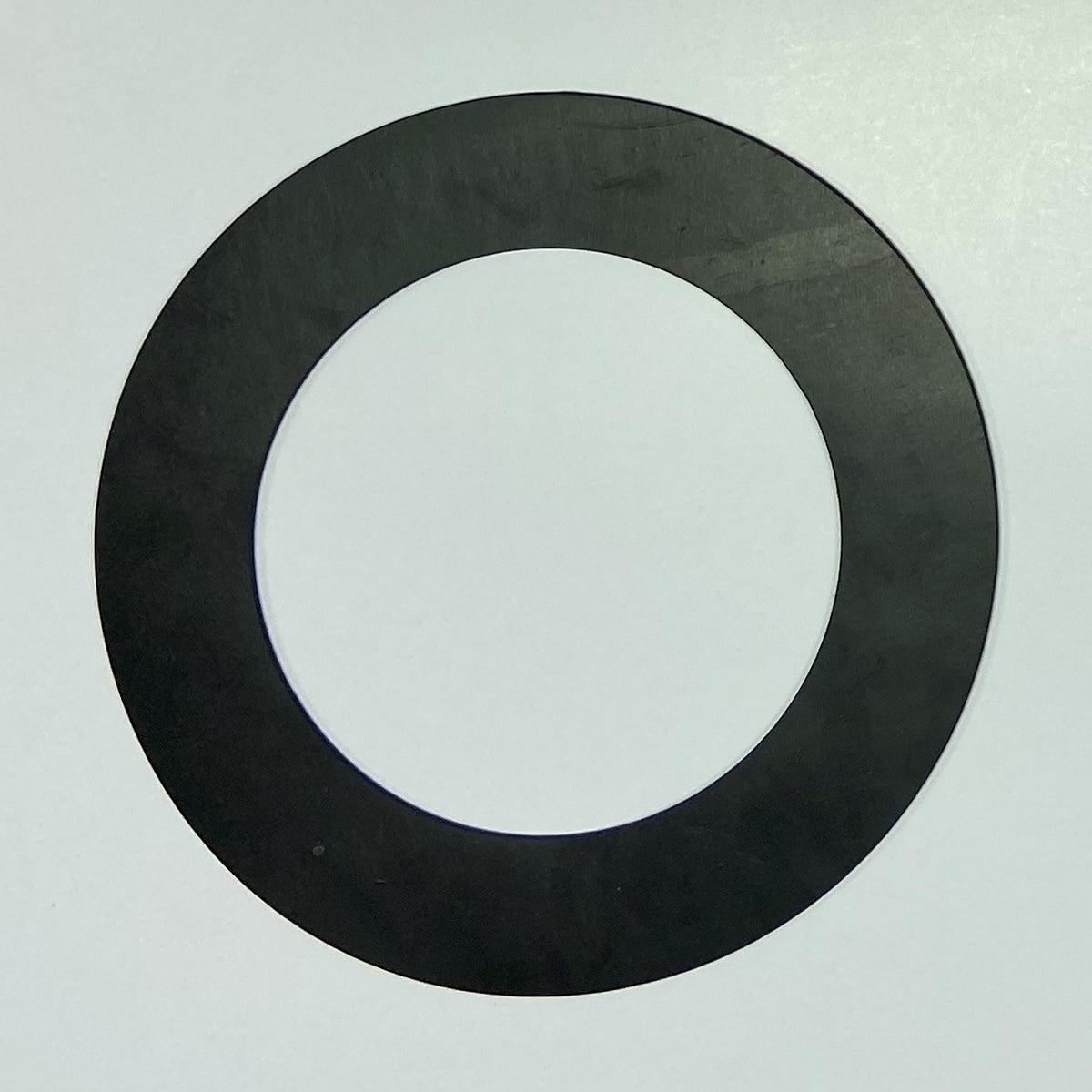

In industrial sealing systems, the flange 4 150 lbs represents a standardized connection interface commonly used in pipelines operating under moderate pressure conditions. While dimensional conformity and mechanical compatibility are essential, the long-term performance of such flange assemblies hinges critically on material selection—particularly when rubber components are involved. At Suzhou Baoshida Trading Co., Ltd., we emphasize that off-the-shelf rubber solutions often fail in real-world applications due to inadequate material engineering for specific operational environments.

The primary function of a rubber gasket or sealing element in a flange 4 150 lbs system is to maintain a leak-tight joint under fluctuating pressure, temperature, and chemical exposure. Standard elastomers such as generic NBR (nitrile butadiene rubber) or low-grade EPDM may meet basic mechanical requirements on paper, but they frequently degrade when exposed to aggressive media like aromatic hydrocarbons, ozone, or elevated temperatures. This leads to premature swelling, cracking, or compression set—resulting in costly downtime and safety hazards.

Material failure is rarely due to a single factor. Instead, it arises from the cumulative effect of chemical incompatibility, thermal cycling, and mechanical stress. For instance, a rubber gasket exposed to hot water and steam may perform adequately with standard EPDM. However, if trace amines or chlorinated compounds are present in the fluid stream, the same compound can experience rapid chain scission and loss of tensile strength. Similarly, nitrile compounds with low ACN (acrylonitrile) content may swell excessively in oil-based systems, compromising sealing force retention.

Custom-engineered rubber formulations address these challenges by tailoring polymer structure, filler systems, and cure chemistry to the application. At Baoshida, we deploy advanced compound design—leveraging fluoroelastomers (FKM) for high-temperature hydrocarbon service, hydrogenated nitrile (HNBR) for dynamic steam applications, and peroxide-cured EPDM for enhanced thermal stability. These materials are validated through ASTM-compliant testing protocols, including volume swell analysis, compression set measurement, and accelerated aging.

The following table outlines key material performance characteristics relevant to flange 4 150 lbs applications:

| Material | Temperature Range (°C) | Tensile Strength (MPa) | Elongation at Break (%) | Key Resistance Properties |

|---|---|---|---|---|

| Standard NBR | -30 to +100 | 15–20 | 250–350 | Aliphatic oils, water, hydraulic fluids |

| High-ACN NBR | -20 to +120 | 18–22 | 200–300 | Aromatic oils, fuels |

| EPDM | -50 to +150 | 16–24 | 250–400 | Steam, water, ozone, weathering |

| HNBR | -40 to +175 | 25–30 | 200–300 | Steam, oils, dynamic compression |

| FKM | -20 to +230 | 12–18 | 150–250 | Aromatic hydrocarbons, acids, high temp |

Selecting the correct elastomer is not a generic substitution exercise. It demands a holistic understanding of service conditions and material behavior. Off-the-shelf gaskets often fail because they are optimized for cost and availability—not performance fidelity. At Suzhou Baoshida, we deliver engineered rubber solutions designed to align with the precise chemical, thermal, and mechanical demands of flange 4 150 lbs systems, ensuring reliability, longevity, and operational safety.

Material Specifications

Material Specifications for Flange 4 150 lbs Industrial Sealing Applications

Selecting the optimal elastomer for Flange 4 150 lbs applications requires rigorous evaluation of operational parameters including temperature extremes, chemical exposure, pressure cycles, and mechanical stress. At Suzhou Baoshida Trading Co., Ltd., we prioritize material integrity to ensure leak-free performance in demanding industrial environments. The following specifications detail three critical elastomers validated for ASME B16.5 Class 150 flange compatibility, adhering to ASTM D2000 classification standards for precision engineering.

Viton (FKM) represents the premium solution for severe chemical and thermal conditions. Its fluorocarbon backbone delivers exceptional resistance to aromatic hydrocarbons, chlorinated solvents, jet fuels, and concentrated acids at continuous service temperatures up to 230°C (446°F). Compression set values remain below 25% after 70 hours at 200°C, critical for maintaining seal force under cyclic pressure loads. Viton formulations with 66% fluorine content (e.g., FKM 260) are mandatory for sour gas (H₂S) environments per NACE MR0175 compliance. However, cost sensitivity and poor ketone resistance necessitate careful application vetting.

Nitrile (NBR) remains the industry standard for cost-effective hydrocarbon sealing. Optimized acrylonitrile content (34-45%) balances oil resistance with low-temperature flexibility down to -30°C (-22°F). NBR excels in hydraulic systems, lubricants, and aliphatic fuels with volume swell under 15% in ASTM #3 oil at 100°C. Its tensile strength (15-20 MPa) and abrasion resistance suit high-vibration installations. Limitations include rapid degradation in ozone, phosphate esters, and polar solvents, requiring protective measures in outdoor or chemical processing settings.

Silicone (VMQ) is indispensable for extreme temperature stability but requires design compensation for mechanical limitations. It operates reliably from -60°C to 200°C (-76°F to 392°F) with minimal compression set in steam and hot air environments. Biocompatible grades meet USP Class VI and FDA 21 CFR 177.2600 for pharmaceutical applications. However, tensile strength rarely exceeds 8 MPa, and permeability to gases necessitates secondary sealing in vacuum systems. Silicone’s susceptibility to撕裂 under high shear loads mandates groove design validation per Parker O-Ring Handbook guidelines.

Material performance is quantitatively summarized below for direct comparison under Flange 4 150 lbs service conditions:

| Material | Temperature Range (°C) | Key Fluid Resistances | Pressure Rating (psi) | Critical Limitations |

|---|---|---|---|---|

| Viton (FKM) | -20 to +230 | Aromatic hydrocarbons, acids, jet fuels | 300 (static) | High cost, poor ketone resistance, stiffens below -15°C |

| Nitrile (NBR) | -30 to +120 | Aliphatic oils, hydraulic fluids, water | 250 (static) | Degrades in ozone, esters, and polar solvents |

| Silicone (VMQ) | -60 to +200 | Steam, hot air, alcohols, some acids | 150 (static) | Low tensile strength, high gas permeability, poor abrasion resistance |

Material selection must account for synergistic failure modes—e.g., NBR’s compression set accelerates at 100°C with biodiesel exposure. Suzhou Baoshida mandates application-specific validation testing per ISO 3601-3, including 72-hour fluid immersion trials and thermal aging at maximum operating temperature. Consult our engineering team for custom compound formulation to address unique chemical cocktails or dynamic movement requirements inherent in Flange 4 150 lbs systems. Precision in elastomer specification directly correlates with flange assembly lifecycle and operational safety.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Development for Flange 4 150 lbs Applications

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the design and production of high-integrity components such as the flange 4 150 lbs. Our technical team comprises five dedicated mould engineers and two specialized rubber formula engineers, enabling a fully integrated development process that spans material science, precision tooling, and application-specific performance validation. This multidisciplinary synergy ensures that every component meets the exacting demands of pressure rating, sealing efficiency, and environmental resistance required in oil & gas, petrochemical, and industrial piping systems.

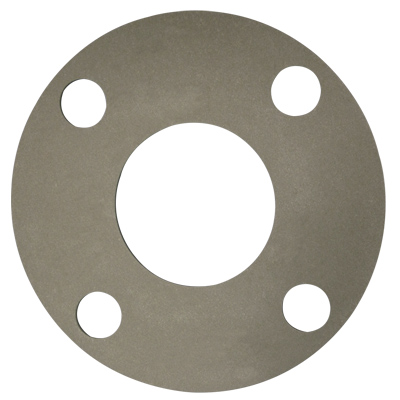

Our mould engineers bring over a decade of collective experience in designing and refining tooling for complex elastomeric components. Utilizing advanced CAD/CAM systems and precision CNC machining, they develop high-tolerance moulds that ensure dimensional accuracy and repeatability across production batches. For the flange 4 150 lbs, this translates into consistent face alignment, bolt hole positioning, and gasket interface geometry—critical factors in achieving leak-free performance under 150 psi operating pressure. Finite element analysis (FEA) is routinely applied to simulate mould flow and thermal distribution, minimizing defects such as flash, voids, or incomplete curing.

Complementing this is our in-house rubber formulation expertise. Our two formula engineers specialize in custom compounding tailored to specific service conditions, including temperature extremes, chemical exposure, and dynamic compression loads. By controlling the polymer matrix, filler systems, and vulcanization chemistry, we engineer rubber compounds that deliver optimal compression set resistance, tensile strength, and resilience. This capability is essential for flange gaskets and sealing elements that must maintain integrity over extended service cycles without degradation.

As an OEM partner, Suzhou Baoshida offers full technical collaboration from prototype to mass production. We support customer-specific material certifications (e.g., ASTM D2000, ISO 2230), conduct rigorous performance testing—including compression stress relaxation and fluid immersion—and provide traceable quality documentation. Our vertical integration allows rapid iteration and scalability, ensuring time-to-market efficiency without compromising on quality.

The following table outlines key technical specifications relevant to our flange 4 150 lbs rubber components:

| Parameter | Specification |

|---|---|

| Nominal Size | 4 inches (DN100) |

| Pressure Rating | 150 lbs (Class 150, ~20 bar) |

| Standard Flange Type | ASME B16.5, Raised Face (RF) |

| Compatible Gasket Materials | NBR, EPDM, Viton® (FKM), Silicone |

| Hardness Range (Shore A) | 60–90 ±5 |

| Operating Temperature Range | -30°C to +200°C (material-dependent) |

| Compression Set (ASTM D395) | ≤20% at 100°C, 22 hrs |

| Fluid Resistance | Oil, water, steam, mild acids/alkalis |

Through precise engineering, material science, and OEM-focused collaboration, Suzhou Baoshida delivers reliable, high-performance rubber solutions engineered to exceed the operational demands of modern industrial systems.

Customization Process

Customization Process for ASME B16.5 Class 150 Flange Gaskets (4″ Nominal Bore)

Suzhou Baoshida Trading Co., Ltd. executes a rigorous, phase-gated customization process for industrial rubber flange gaskets, specifically targeting the demanding ASME B16.5 Class 150 specification for 4″ nominal bore applications. This structured approach ensures optimal sealing performance, longevity, and compliance under defined operational parameters, mitigating leakage risks and unplanned downtime for our OEM partners.

Phase 1 initiates with comprehensive Drawing Analysis. Our engineering team meticulously reviews the client-supplied flange assembly drawings, ASME B16.5 dimensional standards, and operational requirements (pressure, temperature, media). Critical focus areas include flange face finish (RF, FF, RTJ), bolt circle dimensions, groove specifications (if applicable), and the chemical compatibility requirements of the process fluid. This analysis identifies non-negotiable dimensional tolerances per ASME standards and defines the environmental envelope the gasket must withstand. Ambiguities are resolved collaboratively with the client before progression.

Phase 2, Formulation Development, leverages the drawing analysis output. Our rubber compounding scientists select base polymers (NBR, EPDM, FKM, or specialty blends) based on the media and temperature profile. Key physical properties are engineered: compression set resistance for long-term sealing force retention, tensile strength for handling integrity, and controlled hardness to conform to flange imperfections without excessive cold flow. The target formulation must achieve the precise balance required for Class 150 service (150 psi @ 100°F, derating with temperature). Material selection adheres strictly to ASTM D2000 classification codes as specified or recommended.

The critical material properties derived from the formulation phase are validated against the application demands as shown below:

| Critical Property | Target Value (Example: NBR Blend) | ASME B16.5 Class 150 Relevance | Test Standard |

|---|---|---|---|

| Hardness (Shore A) | 65 ± 5 | Conformability vs. Extrusion | ASTM D2240 |

| Tensile Strength (MPa) | ≥ 15.0 | Handling & Installation Integrity | ASTM D412 |

| Compression Set (B) @ 24h | ≤ 25% (70°C, 22% deflection) | Long-Term Sealing Force Retention | ASTM D395 Method B |

| Fluid Resistance (IRMOG) | Volume Swell ≤ 20% | Media Compatibility Integrity | ASTM D471 |

| Temperature Range (°C) | -30 to +120 (Cont.) | Operational Envelope Coverage | Client Specification |

Phase 3, Prototyping & Validation, transforms the formulation into physical samples. Precision die-cutting or molding produces gaskets to the exact 4″ Class 150 dimensions. Rigorous in-house testing confirms dimensional accuracy per ASME B16.5 and validates critical material properties against the target table. Crucially, functional testing occurs in a simulated flange assembly under representative pressure, temperature, and media conditions. Leakage rates are measured per ASTM F37 protocols. Client approval of prototype performance data and physical samples is mandatory prior to tooling sign-off.

Phase 4, Mass Production, commences only after successful prototype validation. Production utilizes ISO 9001-certified processes with stringent in-line dimensional checks (caliper, CMM) and periodic material property requalification. Every batch undergoes traceability documentation, including rubber compound batch records and final inspection reports against the approved drawing and material spec. This ensures consistent, reliable gasket performance meeting the exacting demands of 4″ 150 lbs flange applications across our global OEM client base.

Contact Engineering Team

For precision-engineered industrial rubber solutions, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in the global manufacturing supply chain. Specializing in high-performance elastomeric components, we deliver tailored products that meet rigorous international standards. Our expertise extends to flanged rubber expansion joints, including the widely specified flange 4 150 lbs configuration, designed for reliable performance in demanding applications such as petrochemical processing, power generation, water treatment, and HVAC systems.

The flange 4 150 lbs designation refers to a 4-inch nominal pipe size with a pressure rating of 150 pounds per square inch, conforming to ASME B16.5 standards. This configuration ensures compatibility with standard piping systems while delivering superior vibration isolation, thermal expansion compensation, and misalignment correction. At Suzhou Baoshida, we manufacture these components using premium-quality synthetic rubbers—including EPDM, NBR, and SBR—selected based on operational parameters such as temperature, chemical exposure, and pressure cycles. Our production process integrates precision molding, reinforced textile plies, and rigorous quality control to ensure dimensional accuracy, long service life, and leak-free performance.

We understand that industrial applications demand more than off-the-shelf solutions. That is why our engineering team works closely with OEMs and plant operators to customize compound formulations, carcass construction, and flange materials—including carbon steel, stainless steel, and coated variants—to match specific environmental and regulatory requirements. Whether you are replacing legacy components or designing a new system, our technical staff provides full documentation, including material test reports, dimensional drawings, and compliance certifications.

To ensure seamless integration and optimal performance, we recommend direct technical consultation prior to specification finalization. Mr. Boyce, our dedicated OEM Manager and Rubber Formula Engineer, leads client technical engagement with over 15 years of experience in elastomer application engineering. He is available to review your system requirements, recommend suitable rubber formulations, and support rapid prototyping or volume production scheduling.

Contact Mr. Boyce directly at [email protected] to initiate a technical dialogue, request product specifications, or obtain a quotation. Our team responds to all inquiries within 24 business hours and supports multilingual communication to facilitate global collaboration.

Below are the standard technical specifications for the flange 4 150 lbs rubber expansion joint. Custom configurations are available upon request.

| Parameter | Standard Specification |

|---|---|

| Nominal Size | 4 inches |

| Pressure Rating | 150 lbs (ASME B16.5) |

| Flange Material | Carbon Steel (A105), Optional SS304/SS316 |

| Face Type | Raised Face (RF), RTJ available |

| Rubber Material | NBR, EPDM, SBR (custom compounds on request) |

| Temperature Range | -30°C to +135°C (varies by compound) |

| Reinforcement Layer | Polyester fabric (2-ply standard) |

| End Connection | Welding neck, slip-on flanges |

| Compliance Standards | ISO 9001, ASME B16.5, ASTM D2000 |

| Testing Protocol | Hydrostatic test @ 1.5x working pressure |

Partner with Suzhou Baoshida for engineered reliability, consistent quality, and responsive technical service. Reach out today to optimize your fluid system integrity with our flange 4 150 lbs rubber expansion joints.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).