Technical Contents

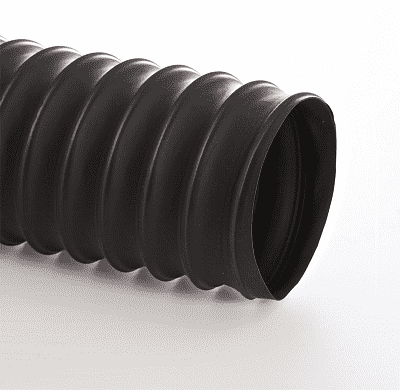

Engineering Guide: Flex Air Duct Hose

Engineering Insight: Material Selection Criticality in Flex Air Duct Hose Performance

Industrial flex air duct hoses operate under extreme mechanical stress, thermal cycling, and chemical exposure. Generic off-the-shelf solutions frequently fail prematurely because they utilize standardized rubber compounds optimized for cost, not application-specific durability. Material selection is not a commodity decision; it is a precision engineering requirement dictating service life, safety, and total operational cost. Standard hoses often employ generic EPDM or SBR blends with inadequate polymer architecture, inconsistent filler dispersion, or suboptimal vulcanization systems. These compromises manifest as catastrophic failures: rapid ozone cracking in outdoor environments, plasticizer migration under heat leading to hardening and brittleness, or catastrophic fatigue failure at stress points after minimal flexing cycles. The consequence is unplanned downtime, safety hazards from ruptured ducts, and recurring replacement costs that far exceed the initial premium for engineered materials.

The core failure mechanism lies in the misalignment between bulk material properties and dynamic operational demands. Flex ducts undergo continuous bending, compression, and tension. A hose rated for static air transfer will fracture under cyclic flexing if its compound lacks sufficient molecular chain flexibility or fatigue resistance. For instance, standard compounds may achieve basic temperature resistance on paper but lack the tailored cross-link density required to maintain elasticity after 10,000+ flex cycles at -40°C to +120°C. Similarly, inadequate resistance to oils, solvents, or UV radiation in non-specialized formulations accelerates degradation in automotive or chemical processing environments. Off-the-shelf hoses rarely specify critical parameters like dynamic flex life or crack growth resistance, focusing instead on static tensile strength—a metric irrelevant to real-world hose movement.

Suzhou Baoshida Trading Co., Ltd. addresses this through OEM-driven compound engineering. We develop proprietary rubber formulations where polymer selection, filler type/ratio, and curing kinetics are calibrated to the exact operational profile: airflow velocity, bend radius frequency, media composition, and ambient conditions. This eliminates the guesswork of generic solutions. Below is a comparative analysis of failure points:

| Parameter | Standard Off-the-Shelf Hose | Engineered Hose (Baoshida OEM Solution) | Typical Failure Consequence |

|---|---|---|---|

| Flex Life (Cycles) | 15,000 – 25,000 | 100,000+ | Premature cracking at bends |

| Ozone Resistance (pphm) | 50 | 150+ | Surface checking within 6 months |

| Temp Range (Dynamic) | -20°C to +100°C | -45°C to +150°C | Hardening/leaks at extremes |

| Oil/Solvent Resistance | Poor (Swelling >25%) | Excellent (Swelling <8%) | Loss of structural integrity |

| Critical Stress Failure | Unspecified | Validated per OEM load profile | Catastrophic rupture under peak load |

Material science must drive flex duct design, not vice versa. Suzhou Baoshida’s OEM engineering process begins with rigorous application analysis—mapping pressure cycles, environmental contaminants, and mechanical stresses—then formulates compounds with targeted resilience. This prevents the hidden costs of failure: production halts, safety incidents, and wasted capital on disposable components. In industrial airflow systems, the hose is not a passive conduit; it is a dynamic engineered component. Specifying based solely on price invites operational risk. Partnering with a technical manufacturer ensures material integrity matches mechanical reality, delivering longevity and reliability where standard solutions cannot.

Material Specifications

Material Specifications for Flex Air Duct Hose – Industrial Rubber Solutions

Suzhou Baoshida Trading Co., Ltd. provides high-performance flex air duct hoses engineered for demanding industrial environments. The selection of base elastomer is critical to ensuring operational reliability, chemical resistance, temperature stability, and mechanical durability. Our flex air duct hoses are manufactured using three primary elastomeric materials: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material offers distinct advantages tailored to specific application requirements, from high-temperature resilience to exceptional resistance against oils, fuels, and ozone.

Viton, a fluorocarbon-based rubber, delivers superior performance in extreme thermal and chemical environments. It exhibits outstanding resistance to a broad range of hydrocarbons, fuels, oils, and many acids, making it ideal for aerospace, petrochemical, and high-performance automotive applications. Viton maintains structural integrity from -20°C to +200°C, with short-term exposure capability up to 250°C. Its low gas permeability and excellent aging characteristics further enhance long-term reliability in sealed systems.

Nitrile rubber, or NBR, is widely used for its excellent resistance to petroleum-based oils and fuels. It offers good abrasion resistance and mechanical strength, making it a cost-effective solution for general industrial air and fluid transfer applications. Nitrile performs reliably within a temperature range of -30°C to +100°C, with certain formulations extending to +125°C. While not as thermally stable as Viton or Silicone, NBR provides optimal balance between performance and cost for applications involving hydraulic fluids, lubricating oils, and compressed air systems.

Silicone rubber (VMQ) is selected for its exceptional flexibility and thermal stability across extreme temperatures, ranging from -60°C to +200°C. It demonstrates excellent resistance to ozone, UV radiation, and weathering, making it suitable for outdoor and high-cyclic movement applications. While silicone has lower tensile strength and abrasion resistance compared to Viton and Nitrile, it offers superior flexibility at low temperatures and is often used in food-grade, medical, and cleanroom environments due to its inert nature and compliance with regulatory standards.

The following table summarizes key material properties to guide optimal selection based on operational demands.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +200 (up to 250°C short-term) | -30 to +100 (up to +125°C intermittent) | -60 to +200 |

| Oil & Fuel Resistance | Excellent | Excellent | Poor to Fair |

| Chemical Resistance | Excellent (acids, bases, hydrocarbons) | Good (limited to oils/fuels) | Moderate (poor with hydrocarbons) |

| Ozone & UV Resistance | Excellent | Good | Excellent |

| Flexibility at Low Temp | Good | Good | Excellent |

| Abrasion Resistance | Good | Excellent | Fair |

| Gas Permeability | Low | Moderate | High |

| Typical Applications | Aerospace, chemical processing, high-temp seals | Hydraulic systems, fuel lines, industrial air ducts | HVAC, medical devices, outdoor ducting |

Selection of the appropriate elastomer must consider the full operational profile, including media type, temperature exposure, mechanical stress, and regulatory compliance. Suzhou Baoshida Trading Co., Ltd. supports OEMs and industrial partners with material testing, custom formulations, and performance validation to ensure optimal hose performance in real-world conditions.

Manufacturing Capabilities

Engineering Capability: Precision Development for Flex Air Duct Hose Systems

Suzhou Baoshida Trading Co., Ltd. leverages deep engineering expertise specifically tailored for demanding industrial flex air duct hose applications. Our core strength resides in the integrated capabilities of our dedicated engineering teams: five specialized Mould Engineers and two advanced Rubber Formula Engineers. This structure ensures rigorous scientific development from molecular compound design through to precision tooling and final product validation, directly addressing the critical performance parameters of airflow efficiency, structural integrity under cyclic stress, and environmental resistance required in modern industrial systems.

Our Rubber Formula Engineers focus on the fundamental science of elastomer performance. They meticulously develop and optimize proprietary rubber compounds, analyzing polymer matrix interactions to achieve the precise balance of flexibility, rebound resilience, and dynamic flex fatigue resistance essential for long service life in pulsating air delivery systems. Key considerations include low-temperature flexibility down to -50°C, resistance to ozone cracking prevalent in compressed air lines, and reinforcement strategies to prevent kinking or collapse under vacuum conditions. Every formulation undergoes accelerated aging protocols and dynamic mechanical analysis (DMA) to predict real-world behavior under continuous thermal cycling and mechanical load, ensuring consistent performance across diverse operational environments from factory floors to mobile equipment.

Complementing compound science, our five Mould Engineers possess extensive experience in designing and refining the complex tooling required for seamless, high-integrity flex duct production. They utilize advanced CAD/CAM systems and mold flow simulation software to optimize wall thickness uniformity, braid reinforcement placement accuracy, and mandrel geometry for critical features like bellows profiles and end fittings. This precision engineering minimizes internal turbulence, maximizes airflow coefficient (Cv), and guarantees dimensional stability during extrusion and vulcanization cycles. Rigorous in-process tooling validation, including cavity pressure monitoring and first-article inspection against ISO 3302 tolerances, ensures repeatability and adherence to the tightest customer specifications.

This integrated engineering approach forms the bedrock of our OEM partnership model. We excel in transforming client performance requirements into manufacturable solutions. Our process begins with collaborative technical scoping, where material science and tooling constraints are transparently discussed. We provide comprehensive DFM (Design for Manufacturability) feedback early in the development cycle, significantly reducing time-to-market. Suzhou Baoshida maintains strict IP protection protocols and offers full traceability from raw material batch to finished hose, supported by detailed material certifications and in-house physical testing data. Our facility is equipped for low-volume prototyping through to high-volume production, ensuring seamless scale-up without compromising the engineered performance validated during the development phase.

The following table illustrates key performance characteristics achievable through our targeted engineering process for standard and custom flex air duct hose solutions:

| Property | Standard Specification | Custom Capability Range | Testing Method |

|---|---|---|---|

| Operating Temperature | -30°C to +120°C | -50°C to +150°C | ISO 188, ASTM D573 |

| Max Working Pressure | 15 PSI | Up to 50 PSI | ISO 1402 |

| Vacuum Resistance | 25 inHg | Up to 29 inHg | ISO 10360 |

| Bend Radius (Static) | 1.5x ID | As low as 1.0x ID | Internal Procedure |

| Abrasion Resistance | 100 mm³ loss (DIN 53516) | <50 mm³ loss achievable | DIN 53516 |

| Ozone Resistance (50pphm) | 72 hrs, no cracks | 168+ hrs, no cracks | ASTM D1149 |

| Flame Resistance | UL 94 HB | UL 94 V-0 achievable | UL 94 |

This systematic application of material science and precision tooling engineering ensures Suzhou Baoshida delivers flex air duct hose solutions that consistently meet the highest demands of reliability and performance in critical industrial air management applications.

Customization Process

Drawing Analysis

The customization process for flex air duct hose begins with precise drawing analysis. At Suzhou Baoshida Trading Co., Ltd., engineering teams conduct a comprehensive review of client-provided technical drawings, focusing on dimensional accuracy, geometric tolerances, and interface compatibility. This stage involves cross-validation of inner diameter (ID), outer diameter (OD), wall thickness, bend radius, and end-fitting specifications. Critical performance parameters such as operating pressure, temperature range, and environmental exposure are extracted to inform downstream development. Where necessary, our engineers collaborate directly with OEM design teams to resolve ambiguities, recommend material-compatible adjustments, and ensure manufacturability without compromising functional integrity. This phase establishes the foundational blueprint for formulation development.

Formulation Engineering

Following drawing validation, our rubber formulation specialists design a compound tailored to the operational demands of the flex air duct hose. The base polymer is selected based on thermal stability, ozone resistance, and flexibility at low temperatures—commonly using NR (Natural Rubber), SBR (Styrene-Butadiene Rubber), or EPDM for general air transfer, or FKM (Fluoroelastomer) for high-temperature or chemically aggressive environments. Reinforcing fillers, plasticizers, vulcanizing agents, and anti-aging additives are precisely dosed to achieve target hardness (Shore A), tensile strength, elongation at break, and compression set resistance. The formulation is optimized for extrusion processing and adhesion to fabric or metal reinforcement layers. All compounds are developed in accordance with ISO 1817 and ASTM D471 standards for fluid resistance and long-term durability.

Prototyping and Validation

A functional prototype is produced using calibrated extrusion and curing equipment, replicating intended production methods. The prototype hose undergoes rigorous in-house testing, including burst pressure evaluation, flex fatigue cycling, thermal aging, and dimensional inspection. Performance data is compared against OEM specifications and international standards such as SAE J517 or ISO 1307. Clients receive a detailed test report and physical samples for field evaluation. Feedback is incorporated into iterative refinements, ensuring final design compliance. This phase typically spans 2–3 design cycles, depending on complexity.

Mass Production and Quality Assurance

Once approved, the design transitions to mass production under strict ISO 9001-certified protocols. Continuous extrusion lines, automated braiding (if reinforcement is required), and precision cutting ensure consistency. Each production batch undergoes statistical process control (SPC), with samples tested for dimensional stability, adhesion strength, and pressure endurance. Traceability is maintained through batch coding and material certifications (e.g., RoHS, REACH). Final products are packaged per client logistics requirements, with full documentation including CoA (Certificate of Analysis) and dimensional reports.

| Property | Typical Value | Test Standard |

|---|---|---|

| Inner Diameter | 25–300 mm | ISO 1307 |

| Operating Temperature | -40°C to +150°C (up to +250°C for FKM) | ASTM D1329 |

| Pressure Rating | 10–30 bar (burst up to 60 bar) | ISO 1436 |

| Material Hardness | 55–75 Shore A | ASTM D2240 |

| Bend Radius | 1.5× ID minimum | Internal Specification |

Contact Engineering Team

Technical Collaboration for Precision Airflow Solutions

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of industrial rubber engineering, specializing in the development and manufacturing of high-performance flexible air duct hoses for critical OEM applications. Our solutions address complex challenges in thermal management, chemical exposure, and mechanical stress across automotive, aerospace, and industrial machinery sectors. Unlike generic suppliers, we integrate material science with application-specific design, utilizing proprietary rubber compounding techniques to optimize durability, flexibility, and flow efficiency. Each hose undergoes rigorous validation against ISO 1307 and SAE J2412 standards, ensuring compliance with global regulatory frameworks while exceeding operational lifespan expectations.

Our engineering team collaborates directly with OEMs to refine specifications through finite element analysis (FEA) and accelerated life testing. This methodology minimizes field failures by preemptively resolving stress points at joints, bends, and transition zones. Key differentiators include custom polymer blends resistant to ozone degradation at 125°C continuous exposure and reinforcement layers engineered for 50,000+ dynamic flex cycles without delamination. We prioritize traceability via batch-specific material certifications and real-time production data logging, essential for aerospace and medical device manufacturers requiring full audit trails.

The following technical parameters represent our baseline industrial-grade flexible air duct hose specification. Custom formulations for extreme environments (e.g., -60°C cryogenic or 300°C intermittent exposure) are developed through joint feasibility studies.

| Parameter | Standard Value | Test Standard | Application Relevance |

|---|---|---|---|

| Material Composition | EPDM/Silicone/NBR | ASTM D2000 | Chemical/oil resistance |

| Temperature Range | -40°C to +150°C | ISO 188 | Engine bay compatibility |

| Burst Pressure | ≥ 1.5 MPa | ISO 1402 | Safety margin for 3x working |

| Bend Radius (Static) | 1.5x ID | SAE J1401 | Compact installation routing |

| Flame Resistance | UL 94 V-0 | FMVSS 302 | Regulatory compliance |

| Conductivity | 10⁴–10⁶ Ω·m | ISO 8031 | Static dissipation critical |

Partnering with Suzhou Baoshida transforms airflow system design from a component specification into a strategic advantage. Our OEM management process begins with a technical deep dive into your operational environment, including fluid dynamics analysis and failure mode assessment. We then prototype solutions using in-house mixing and vulcanization facilities, enabling rapid iteration cycles that reduce time-to-market by 30–45% compared to conventional supply chains. All products ship with comprehensive validation dossiers, including pressure decay test results and dimensional conformance reports per ASME Y14.5.

For immediate engineering collaboration on your next-generation flexible air duct system, contact Mr. Boyce, our dedicated OEM Solutions Manager. Mr. Boyce possesses 18 years of experience in rubber compounding for Tier-1 automotive and industrial clients, ensuring your technical requirements are translated into manufacturable, cost-optimized solutions. He will coordinate material selection, prototype validation, and volume production scheduling while maintaining strict IP confidentiality under NDA frameworks. Direct inquiries to [email protected] with your project specifications, target performance metrics, and annual volume requirements. Suzhou Baoshida commits to providing a detailed technical and commercial proposal within 72 business hours of receiving your documentation. Elevate your airflow system integrity through engineered rubber science—contact Mr. Boyce to initiate the qualification process today.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).