Technical Contents

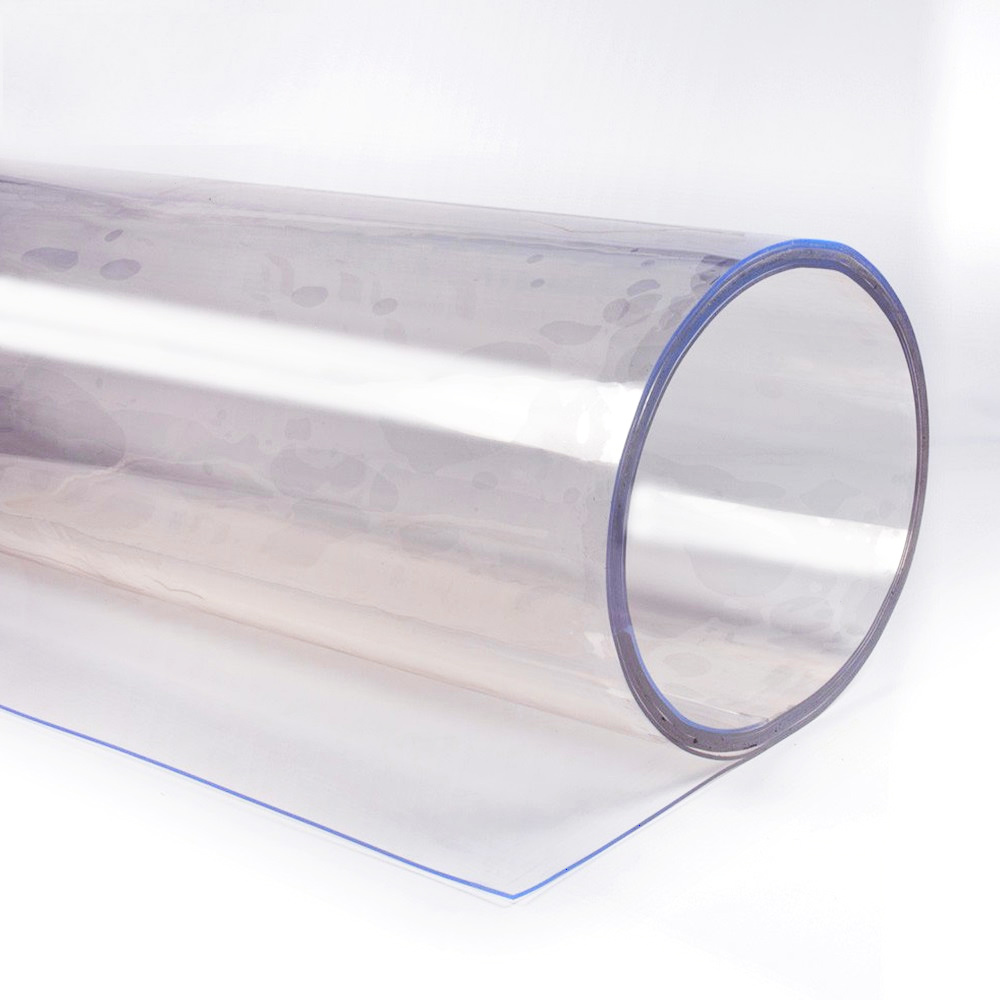

Engineering Guide: Flexible Clear Plastic Sheet

Engineering Insight: The Critical Role of Material Selection in Flexible Clear Plastic Sheets

In industrial applications, the performance of flexible clear plastic sheets hinges directly on precise material selection. While off-the-shelf solutions may appear cost-effective or readily available, they frequently fail to meet the rigorous demands of dynamic environments such as automotive sealing, medical device housings, or protective enclosures in harsh climates. These failures stem from a fundamental mismatch between generic material properties and application-specific requirements, including mechanical stress, chemical exposure, temperature cycling, and optical clarity retention.

Flexible clear plastic sheets are not a monolithic category. Materials such as PVC, polycarbonate (PC), thermoplastic polyurethane (TPU), and copolyester (e.g., PETG) each exhibit distinct performance profiles. For instance, standard PVC sheets may offer initial clarity and flexibility but degrade under UV exposure or prolonged thermal stress, leading to yellowing and embrittlement. Polycarbonate provides high impact resistance but is prone to stress cracking when exposed to certain solvents. TPU delivers excellent abrasion resistance and low-temperature flexibility but may lack the dimensional stability required in precision applications.

The root cause of premature failure in off-the-shelf materials lies in their generalized formulation. These products are engineered for broad consumer or light industrial use, not for sustained performance under engineered tolerances. In contrast, application-driven material selection considers the full lifecycle environment. This includes evaluating dynamic flexing requirements, resistance to oils, acids, or cleaning agents, and long-term optical transmission stability. At Suzhou Baoshida Trading Co., Ltd., we prioritize OEM-specific formulation adjustments, ensuring that each sheet meets not just physical dimensions, but functional durability benchmarks.

Moreover, regulatory compliance—such as FDA, REACH, or UL certifications—further narrows the field of viable materials. A material acceptable in food processing equipment may be unsuitable for electronic enclosures due to static dissipation requirements. Thus, a one-size-fits-all approach compromises both safety and longevity.

Below is a comparative overview of key flexible clear plastic materials used in industrial applications:

| Material | Tensile Strength (MPa) | Elongation at Break (%) | Operating Temperature Range (°C) | Key Advantages | Common Limitations |

|---|---|---|---|---|---|

| PVC | 40–55 | 100–300 | -10 to 60 | Low cost, good clarity, easy processing | Poor UV resistance, plasticizer migration |

| Polycarbonate (PC) | 55–75 | 100–150 | -40 to 120 | High impact strength, excellent clarity | Susceptible to stress cracking, scratches easily |

| TPU | 30–60 | 300–700 | -40 to 90 | High flexibility, abrasion resistance, low-temp performance | Higher cost, lower stiffness |

| PETG | 45–55 | 100–150 | -20 to 70 | Good chemical resistance, FDA compliant | Moderate impact resistance, prone to deformation under load |

Material selection is not a secondary consideration—it is the foundation of reliable performance. At Suzhou Baoshida, we collaborate with OEMs to analyze operational stressors and define material specifications that ensure long-term functionality, avoiding the pitfalls of generic alternatives.

Material Specifications

Material Specifications: Elastomeric Sheet Clarity in Industrial Applications

Suzhou Baoshida Trading Co., Ltd. clarifies a critical distinction for B2B partners: true flexible clear plastic sheets (e.g., PVC, polycarbonate) fall outside our core competency in industrial rubber solutions. Our expertise centers on elastomeric sheets where optical clarity is a specialized requirement, primarily for sight glasses, medical tubing, or chemical viewing windows. Viton® (FKM), Nitrile (NBR), and Silicone (VMQ) are formulated for functional performance; inherent transparency is limited due to polymer morphology and filler interactions. Achieving usable clarity requires precision compounding to minimize light scattering from crystallites, phase separation, or particulate additives. All materials below are translucent to semi-clear in thin gauges (≤3mm), with Viton offering the highest optical homogeneity under aggressive conditions.

Comparative Specifications for Clarity-Optimized Elastomeric Sheets

| Material | Base Polymer | Clarity Level (2mm sheet) | Refractive Index | Haze (%) ASTM D1003 | Key Applications |

|---|---|---|---|---|---|

| Viton® FKM | Fluoroelastomer | Semi-clear (amber tint) | 1.38–1.42 | 15–25 | Aggressive chemical sight glasses, semiconductor wet benches, high-purity fluid handling |

| Nitrile NBR | Acrylonitrile-Butadiene | Translucent (milky) | 1.50–1.53 | 40–60 | Fuel/oil sight tubes, low-clarity industrial viewports, general-purpose seals |

| Silicone VMQ | Polydimethylsiloxane | Translucent (water-white) | 1.40–1.43 | 25–35 | Biopharma tubing, food-grade sight glasses, medical device components |

Clarity is inversely proportional to filler loading and crosslink density. Viton achieves superior optical performance through low-acid-scavenger formulations and ultra-fine particle size control (<5μm), though inherent fluorine content induces slight yellowing. Nitrile’s butadiene phase causes significant light diffusion, limiting clarity even in peroxide-cured, low-filler grades. Silicone offers the best initial transparency but degrades under UV/ozone exposure, increasing haze by 15–30% after 500 hours per ASTM D1148. All materials require precision calendering to ensure surface smoothness (Ra <0.8μm) and eliminate voids that scatter light.

Critical selection factors include chemical exposure temperature range and regulatory compliance. For hydrocarbon visibility above 150°C, Viton is non-negotiable despite its amber baseline. Below 100°C in aqueous environments, medical-grade silicone provides optimal clarity retention but demands platinum-cure systems to avoid peroxide residues. Nitrile remains cost-effective for non-critical oil sight gauges where >40% haze is acceptable. Suzhou Baoshida rigorously tests haze and yellowness index per ISO 13468/14782 on every production lot, ensuring batch consistency for OEM integration. Note: True optical clarity (e.g., >90% transmittance) requires thermoplastic alternatives; our elastomeric solutions prioritize functional transparency under duress. Partner with our engineering team to validate material suitability against your specific fluid compatibility and visibility requirements.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Development for Flexible Clear Plastic Sheet Solutions

At Suzhou Baoshida Trading Co., Ltd., our engineering capability is anchored in deep technical expertise and a systematic approach to material science and mold design. With a dedicated team comprising five experienced mold engineers and two specialized rubber formula engineers, we deliver fully integrated OEM solutions tailored to the demanding requirements of industrial applications involving flexible clear plastic sheets. Our multidisciplinary team collaborates across material formulation, structural design, and manufacturing optimization to ensure every product meets exact performance, clarity, and durability standards.

Our formula engineers focus on developing proprietary elastomeric and thermoplastic formulations that balance optical clarity with mechanical resilience. By precisely tuning polymer blends, plasticizers, stabilizers, and anti-fog or UV-resistant additives, we produce flexible sheets that maintain transparency under thermal cycling, mechanical stress, and prolonged environmental exposure. These custom formulations are especially critical in industries such as medical devices, food-grade packaging, and industrial view panels, where both visual clarity and long-term reliability are non-negotiable.

Complementing our material expertise, our five mold engineers bring advanced CAD/CAM proficiency and finite element analysis (FEA) capabilities to optimize tooling design for extrusion, calendering, and thermoforming processes. They ensure uniform sheet thickness, minimal warpage, and precise dimensional tolerances—key factors in high-clarity applications where optical distortion must be eliminated. Through iterative prototyping and rigorous process validation, we achieve rapid time-to-market without compromising quality.

As an OEM partner, Suzhou Baoshida offers full design-for-manufacturability (DFM) support, from concept validation to mass production. Our engineers work directly with client specifications to develop customized solutions, including co-extruded multi-layer sheets, anti-static variants, and flame-retardant grades. All development phases are supported by in-house testing facilities that evaluate tensile strength, elongation at break, haze percentage, light transmission, and environmental aging performance.

The integration of formula development and precision mold engineering enables us to solve complex technical challenges, such as minimizing internal stress in transparent sheets or enhancing low-temperature flexibility without sacrificing clarity. This vertically aligned capability ensures consistency, traceability, and scalability across production runs.

Below are key technical parameters we routinely achieve in our flexible clear plastic sheet manufacturing:

| Property | Typical Value | Test Standard |

|---|---|---|

| Light Transmission | ≥ 90% | ASTM D1003 |

| Haze | ≤ 3% | ASTM D1003 |

| Tensile Strength | 18–35 MPa | ASTM D412 |

| Elongation at Break | 300–800% | ASTM D412 |

| Hardness (Shore A) | 60–90 | ASTM D2240 |

| Operating Temperature Range | -40°C to +100°C | Internal Cycling Test |

| Thickness Tolerance | ±0.05 mm (for 1.0 mm sheet) | ISO 2768 |

Our engineering framework is built for innovation, precision, and reliability—ensuring that every flexible clear plastic sheet we produce meets the highest industrial standards.

Customization Process

Drawing Analysis

Initial technical evaluation begins with rigorous scrutiny of client-provided engineering drawings per ISO 2768 tolerances. Our team verifies critical parameters including dimensional stability under thermal cycling (−40°C to +120°C), optical clarity requirements (minimum 85% transmission), and edge integrity specifications. We cross-reference substrate compatibility with potential fluid exposures—oils, acids, or solvents—and confirm regulatory compliance targets (e.g., FDA 21 CFR 177.2600 for food contact or UL 94 V-0 flammability). Any ambiguities in draft geometry or surface finish (Ra ≤ 0.8 µm) trigger immediate client consultation to prevent downstream deviations. This phase typically concludes within 72 hours with a formal feasibility report.

Formulation

Material science drives the polymer architecture design. Based on operational stressors identified in drawing analysis, we select base elastomers—typically hydrogenated nitrile rubber (HNBR) or thermoplastic polyurethane (TPU)—and engineer additive packages. Key variables include: phthalate-free plasticizers for flexibility retention, nano-silica dispersion for haze reduction below 5%, and UV absorbers (e.g., benzotriazoles) for outdoor durability. Each formulation undergoes computational modeling via Moldex3D to predict flow behavior at 180–220°C processing temperatures. Final compositions are documented with batch-specific traceability codes, ensuring repeatability across production runs.

Prototyping

Precision extrusion produces 3–5 prototype sheets for empirical validation. Samples undergo accelerated aging (ASTM D573), tensile testing per ISO 37 (minimum elongation 350%), and haze measurement via ASTM D1003. Optical clarity is verified using spectrophotometry at 550 nm wavelength. Clients receive physical samples alongside test dossiers; non-conformities trigger reformulation within 5 business days. This iterative loop continues until all metrics align with the technical dossier, typically requiring 2–3 iterations.

Mass Production

Upon prototype sign-off, we transition to ISO 13485-certified manufacturing. Extrusion lines operate under strict environmental controls (±2°C temperature variance, 45% RH) with in-line spectrophotometers monitoring clarity in real time. Every 500m² batch undergoes full certification: hardness (ASTM D2240), yellowness index (ASTM E313), and dimensional validation via CMM. Statistical process control (SPC) charts track critical parameters, with automatic line halts for >1.5σ deviations. Final shipment includes material test reports (MTRs) and RoHS/REACH compliance documentation.

Material Performance Specifications

| Material Grade | Hardness Range (Shore A) | Transparency (%) | Key Additives | Typical Applications |

|—————-|————————–|——————|—————|———————-|

| TPU-CL85 | 65–75 | 88–92 | Nano-silica, Tinuvin 328 | Medical device windows, optical sensors |

| HNBR-XT70 | 50–60 | 85–88 | Epoxidized soybean oil, Chimassorb 119 | Automotive lighting gaskets, marine seals |

| TPE-GL90 | 75–85 | 90–92 | PMMA core-shell, Irganox 1076 | Consumer electronics displays, food packaging |

Suzhou Baoshida Trading Co., Ltd. executes this co-engineering framework to transform conceptual requirements into validated industrial elastomer solutions, maintaining zero defect delivery across 12,000+ metric tons of annual production. Client collaboration remains embedded at every validation checkpoint to ensure technical alignment.

Contact Engineering Team

For industrial manufacturers seeking high-performance flexible clear plastic sheet solutions, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in advanced polymer materials and rubber-based industrial products. With years of specialized expertise in material formulation, sheet extrusion, and custom fabrication, we deliver precision-engineered transparent flexible sheets tailored to demanding applications across automotive, electronics, medical devices, and industrial equipment sectors. Our commitment to quality, consistency, and technical innovation ensures that every product meets stringent international standards while addressing the unique functional and environmental requirements of your production process.

Our flexible clear plastic sheets are manufactured using rigorously tested formulations that balance optical clarity, mechanical resilience, and environmental resistance. Whether you require sheets with high tensile strength, excellent low-temperature flexibility, UV stability, or flame retardancy, our R&D team works closely with clients to optimize material properties. We utilize advanced compounding technologies and in-house quality control systems—including tensile testing, haze measurement, and accelerated aging—to guarantee repeatability and compliance across production batches.

Below are representative technical specifications of our standard flexible clear plastic sheet offerings:

| Property | Test Method | Value |

|---|---|---|

| Shore A Hardness | ASTM D2240 | 85 ± 5 |

| Tensile Strength | ASTM D412 | ≥12 MPa |

| Elongation at Break | ASTM D412 | ≥280% |

| Specific Gravity | ASTM D792 | 1.20 – 1.25 |

| Light Transmission (1mm sheet) | ASTM D1003 | ≥88% |

| Operating Temperature Range | — | -30°C to +80°C |

| Durometer Stability (after 70°C x 72h) | ISO 48 | ≤ ±10% change |

| Flame Resistance | UL94 | HB rated |

These values are indicative and can be adjusted based on customer-specific formulations. Custom thicknesses from 0.5 mm to 10 mm are available, with options for anti-static, anti-fog, or abrasion-resistant surface treatments. Sheets can be supplied in roll or cut-sheet form, with tight tolerances maintained across all dimensions.

To initiate a technical consultation or request a customized sample batch, contact Mr. Boyce, OEM Manager and Lead Rubber Formula Engineer at Suzhou Baoshida Trading Co., Ltd. Mr. Boyce leads our material innovation and client integration team, ensuring that every project receives direct engineering oversight from concept to production. With fluency in both Chinese and English technical standards, he serves as the primary liaison for international manufacturers requiring precision rubber and polymer solutions.

For prompt and professional support, email Mr. Boyce at [email protected]. Include details such as intended application, environmental conditions, mechanical requirements, and volume expectations to enable rapid formulation assessment and proposal development. Our team responds to all technical inquiries within 24 business hours and can provide material data sheets, compliance documentation, and sample shipment coordination upon request.

Partner with Suzhou Baoshida to transform your flexible clear plastic sheet requirements into engineered reality—where scientific precision meets industrial reliability.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).