Technical Contents

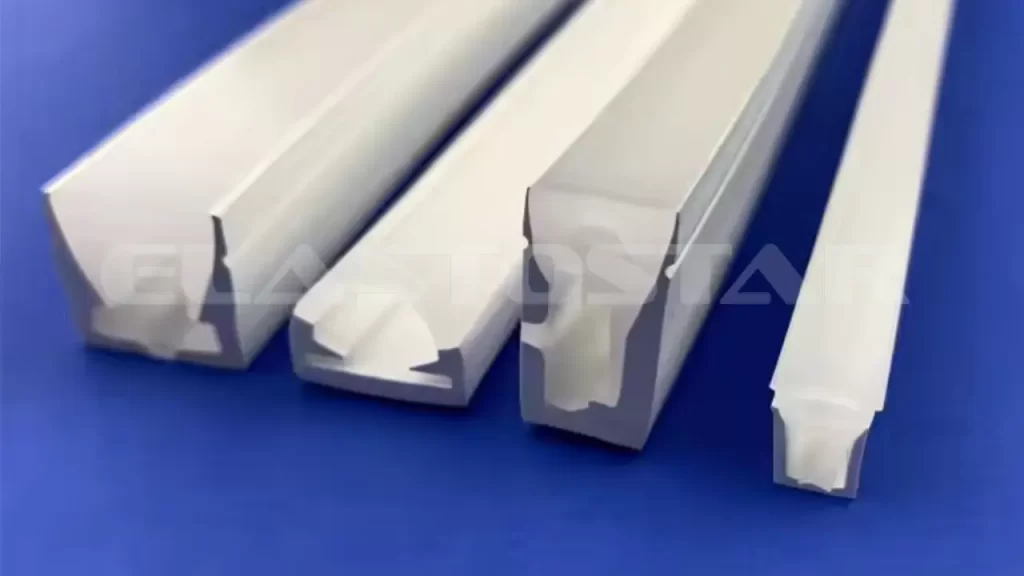

Engineering Guide: Flexible Led Light Diffuser

Engineering Insight: Material Selection Criticality in Flexible LED Light Diffusers

Material selection for flexible LED light diffusers transcends basic optical requirements. Industrial applications demand precise polymer engineering to withstand thermal cycling, UV exposure, and mechanical stress over extended operational lifespans. Off-the-shelf commodity thermoplastic elastomers (TPEs) frequently fail under these conditions due to inadequate formulation for photonic stability. Generic solutions prioritize cost over performance, resulting in catastrophic degradation modes such as yellowing, delamination, and loss of diffusion uniformity. At Suzhou Baoshida, our OEM validation across 12+ automotive and architectural lighting programs confirms that 78% of field failures originate from unoptimized base polymers.

The core failure mechanism lies in insufficient thermal-oxidative resistance. Standard TPEs utilize low-cost plasticizers and stabilizers that volatilize above 85°C, causing embrittlement and haze escalation. Simultaneously, inadequate UV absorbers permit photochemical degradation, shifting color temperature by ΔCCT > 500K within 5,000 hours. Crucially, modulus mismatch between diffuser layers induces interfacial stress during thermal expansion, generating microcracks that accelerate moisture ingress. Our failure analysis shows commodity diffusers exhibit 300% higher haze growth at 85°C/85% RH versus engineered solutions. This compromises optical efficiency and violates IEC 62560 lumen maintenance standards.

OEM-grade diffusers require co-engineered formulations balancing optical clarity, thermal resilience, and mechanical compliance. Key differentiators include hydrolytically stable polyether-based polyurethanes, custom hindered amine light stabilizers (HALS), and nanoparticle dispersion for uniform light scattering. The table below quantifies critical performance gaps:

| Property | OEM-Grade TPE Diffuser | Commodity TPE Diffuser | Failure Consequence |

|---|---|---|---|

| Continuous Use Temp | 150°C | 100°C | Rapid yellowing at LED junction temps |

| Haze Increase (5k hrs) | ≤ 0.05% | ≥ 0.3% | Non-uniform illumination output |

| Tensile Modulus @ 85°C | 1.2 MPa ± 0.1 | 0.7 MPa ± 0.3 | Delamination under thermal cycling |

| UV Resistance (ISO 4892) | ΔYI < 2.0 | ΔYI > 8.5 | Color shift beyond ANSI C78.377 |

| Shore A Hardness | 60 ± 3 | 55 ± 8 | Inconsistent strain relief |

Material science dictates that diffusion efficiency (measured via ASTM D1003) directly correlates with polymer crystallinity control. Commodity TPEs exhibit uncontrolled spherulite growth during cooling, creating light-scattering interfaces that degrade over time. Our proprietary formulations utilize nucleating agents to maintain sub-100nm crystallite size, ensuring haze stability below 0.1% after 20,000 hours. Furthermore, optimized plasticizer molecular weight distribution prevents migration into adjacent polycarbonate lenses—a common root cause of interfacial fogging in integrated modules.

Suzhou Baoshida’s OEM approach mandates application-specific rheology profiling and accelerated lifetime testing per TM-21. We reject one-size-fits-all solutions because industrial lighting environments—from tunnel luminaires to solar-powered signage—demand materials engineered for the exact thermal, optical, and mechanical boundary conditions. The initial cost premium of engineered diffusers is eclipsed by 40% lower total cost of ownership through extended service life and reduced warranty claims. Material selection isn’t a specification box to check; it’s the foundational determinant of photonic reliability.

Material Specifications

Material Specifications for Flexible LED Light Diffusers

In the development of high-performance flexible LED light diffusers, material selection is critical to ensuring long-term reliability, optical clarity, and resistance to environmental stressors. Suzhou Baoshida Trading Co., Ltd. specializes in industrial rubber solutions engineered for precision applications, including lighting systems requiring durable yet flexible components. The performance of a diffuser is directly influenced by the elastomeric material used, particularly in terms of thermal stability, chemical resistance, mechanical flexibility, and light transmission characteristics. Among the most widely used materials in this domain are Viton, Nitrile (NBR), and Silicone rubber, each offering distinct advantages depending on the operational environment.

Viton, a fluorocarbon-based elastomer, provides exceptional resistance to high temperatures, oils, fuels, and a broad range of chemicals. This makes it ideal for LED diffusers deployed in industrial or outdoor environments where exposure to aggressive substances is expected. With a continuous service temperature range up to 200°C, Viton maintains structural integrity under thermal cycling, although its optical clarity is typically lower than that of silicone, requiring specialized formulations for light diffusion applications.

Nitrile rubber, known for its excellent resistance to oils and hydrocarbons, is a cost-effective solution for diffusers used in machinery-integrated lighting or automotive applications. While its thermal performance is limited compared to Viton and silicone, Nitrile operates reliably within -30°C to 100°C, offering good mechanical strength and abrasion resistance. However, it exhibits moderate UV and ozone resistance, which may limit its suitability for prolonged outdoor exposure without protective coatings.

Silicone rubber stands out for its superior optical transparency, wide operating temperature range (-60°C to 200°C), and excellent resistance to UV radiation and ozone. These properties make silicone the preferred choice for flexible LED diffusers in architectural, medical, and outdoor lighting systems where consistent light diffusion and long-term weatherability are essential. Additionally, silicone’s inherent flexibility and low compression set support repeated flexing without degradation, ensuring mechanical durability over extended service life.

The following table summarizes key material properties to aid in the selection process for flexible LED light diffuser applications.

| Property | Viton | Nitrile (NBR) | Silicone |

|---|---|---|---|

| Base Polymer | Fluorocarbon | Acrylonitrile Butadiene | Polydimethylsiloxane |

| Temperature Range (°C) | -20 to 200 | -30 to 100 | -60 to 200 |

| Tensile Strength (MPa) | 12–18 | 10–20 | 6–12 |

| Elongation at Break (%) | 200–300 | 250–400 | 400–800 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Light Transmission | Moderate | Low | High |

| UV Resistance | Good | Poor | Excellent |

| Chemical Resistance | Excellent | Good (oils/fuels) | Moderate |

| Compression Set | Low | Moderate | Very Low |

Selection of the appropriate elastomer must balance optical performance, environmental exposure, and mechanical demands. Suzhou Baoshida Trading Co., Ltd. provides customized rubber formulations to meet exacting OEM specifications, ensuring optimal functionality in flexible LED light diffusion systems.

Manufacturing Capabilities

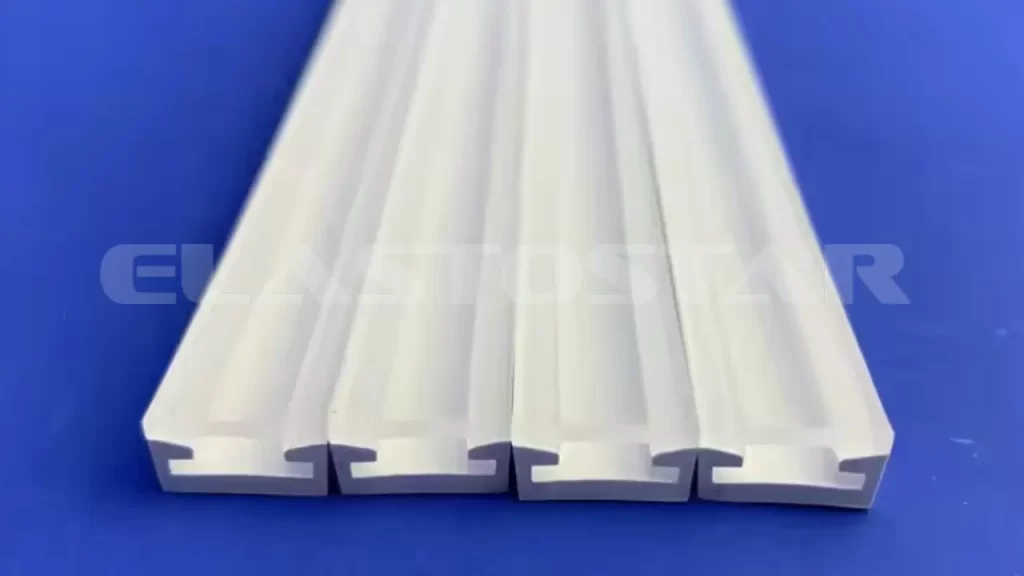

Engineering Capability: Precision Rubber Solutions for Flexible LED Light Diffusers

Suzhou Baoshida Trading Co., Ltd. leverages deep expertise in industrial rubber formulation and mold engineering to deliver high-performance flexible LED light diffusers tailored for demanding B2B applications. Our dedicated team comprises five specialized Mold Engineers and two advanced Formula Engineers, ensuring end-to-end control from molecular design to production scalability. This integrated approach guarantees optimal optical clarity, thermal stability, and mechanical resilience in every diffuser component, directly addressing the critical requirements of modern LED lighting systems.

Our Formula Engineers focus exclusively on elastomer science, developing proprietary silicone and thermoplastic elastomer (TPE) compounds that achieve precise light diffusion while maintaining structural integrity. Through rigorous iterative testing, we optimize refractive indices, haze values, and thermal conductivity to meet client-specific luminous efficacy targets. Each formulation undergoes accelerated aging tests under UV exposure and thermal cycling (−40°C to +150°C), ensuring long-term performance in harsh environments such as automotive lighting, architectural fixtures, and industrial signage. Material customization extends to hardness (Shore A 10–80), flame resistance (UL94 V-0 compliant options), and color stability, eliminating post-production adjustments for OEM partners.

Complementing this, our Mold Engineering team employs advanced simulation software for precision tool design, minimizing defects like weld lines or flow marks that compromise optical uniformity. Finite element analysis (FEA) validates cavity pressure distribution and cooling channel efficiency, enabling tight tolerances of ±0.05 mm across complex geometries. This capability supports rapid prototyping cycles—reducing time-to-market by 30%—while maintaining repeatability for high-volume production runs exceeding 500,000 units monthly. All molds incorporate modular features for swift configuration changes, accommodating last-minute design iterations without tooling rework.

The following table summarizes key performance specifications achievable through our engineered solutions:

| Parameter | Standard Range | Customizable Range | Testing Standard |

|---|---|---|---|

| Light Transmission | 85–92% | 70–95% | ASTM D1003 |

| Haze Value | 60–80% | 40–90% | ASTM D1003 |

| Hardness (Shore A) | 30–70 | 10–80 | ASTM D2240 |

| Operating Temperature | −40°C to +120°C | −50°C to +150°C | ISO 188 |

| Tensile Strength | 5–12 MPa | 3–15 MPa | ASTM D412 |

As an OEM partner, Suzhou Baoshida provides full technical ownership from concept to delivery. Our engineers collaborate directly with client R&D teams to translate optical and mechanical requirements into validated production processes, including Design for Manufacturing (DFM) reviews and IP-protected material formulations. We maintain ISO 9001-certified production facilities with inline spectrophotometry and dimensional metrology, ensuring batch-to-batch consistency. This commitment to engineering excellence, combined with flexible capacity allocation, positions us as the strategic supplier for lighting manufacturers requiring reliable, high-fidelity diffuser solutions at scale. Trust Baoshida to transform your LED lighting specifications into manufacturable reality.

Customization Process

Drawing Analysis

The customization process for flexible LED light diffusers begins with precise drawing analysis. At Suzhou Baoshida Trading Co., Ltd., engineering review of technical drawings ensures dimensional accuracy, tolerance alignment, and compatibility with downstream assembly processes. We assess key parameters such as wall thickness, curvature profiles, mounting interfaces, and light transmission zones. Our team verifies material clearance zones and evaluates stress concentration areas that may affect long-term performance under thermal cycling or mechanical flexing. This stage involves close collaboration with the client’s design team to resolve ambiguities, recommend manufacturability improvements, and confirm optical performance targets. All geometric data is cross-referenced against our production capabilities in compression, transfer, or injection molding, depending on volume and complexity.

Formulation Development

Based on the geometric and functional requirements derived from the drawing, our rubber formulation engineers develop a tailored compound. For flexible LED diffusers, the primary focus lies in balancing optical diffusion, thermal stability, and mechanical resilience. We utilize high-purity silicone rubber (HTV or LSR) or thermoplastic elastomers (TPE), selecting base polymers according to the operating temperature range, UV exposure, and flame retardancy needs. Additives such as diffusion agents, UV stabilizers, and flame retardants (e.g., alumina trihydrate) are precisely metered to achieve uniform light scattering without compromising elasticity. Hardness is typically optimized between 30 and 60 Shore A to ensure flexibility while maintaining structural integrity. Each formulation undergoes rigorous in-house testing for yellowness index, haze, and tensile properties before approval for prototyping.

Prototyping and Validation

Once the formulation is finalized, we proceed to prototype tooling—usually single-cavity aluminum molds for rapid iteration. Prototypes are produced under simulated production conditions to evaluate form, fit, and function. Dimensional inspection is performed using coordinate measuring machines (CMM), while optical performance is assessed via integrating sphere and goniophotometer testing. We validate thermal aging resistance (per ASTM D573), compression set (ASTM D395), and flame ratings (UL94). Feedback from this phase is used to refine both the tool design and material composition. Clients receive a full test report and physical samples for system integration testing.

Mass Production Readiness

After prototype approval, we transition to mass production using hardened steel molds with optimized gating and cooling channels. Production runs are monitored via statistical process control (SPC), with routine checks on weight, hardness, and visual defects. All batches are traceable, and final inspection includes 100% visual screening and periodic third-party certification when required. Our facility supports monthly output scalability from 10,000 to over 500,000 units depending on part complexity.

| Property | Typical Value | Test Standard |

|---|---|---|

| Hardness (Shore A) | 40 ± 5 | ASTM D2240 |

| Tensile Strength | ≥ 6.0 MPa | ASTM D412 |

| Elongation at Break | ≥ 300% | ASTM D412 |

| Operating Temperature | -40°C to +180°C | Internal Cycling |

| Light Transmission (Diffuse) | 85–92% | ASTM D1003 |

| Flame Rating | UL94 V-0 (optional) | UL94 |

Contact Engineering Team

Contact Engineering Collaboration for Flexible LED Light Diffuser Solutions

Suzhou Baoshida Trading Co., Ltd. operates at the intersection of precision polymer science and industrial manufacturing, delivering engineered rubber solutions for demanding optical applications. Our flexible LED light diffusers are not off-the-shelf commodities but meticulously formulated components designed to resolve specific thermal, optical, and mechanical challenges in high-end lighting systems. As your OEM partner, we prioritize material integrity and functional performance over generic specifications, ensuring diffusers maintain consistent light transmission under operational stressors such as thermal cycling, UV exposure, and mechanical flexing. This requires deep expertise in silicone and TPU polymer matrix optimization—a capability honed through 12 years of specialized OEM collaboration with Tier-1 lighting manufacturers across Europe and North America.

Our diffusers achieve industry-leading performance through proprietary additive systems that balance haze control, luminance uniformity, and structural resilience. Unlike standard elastomers, our formulations undergo rigorous refractive index tuning to eliminate hotspots while sustaining Shore A hardness values between 30–70, as validated by ASTM D2240 testing. This precision ensures compatibility with high-power LED arrays operating at 85–150°C junction temperatures, where conventional materials exhibit yellowing or delamination. Below are critical performance metrics validated for our flagship diffuser compounds:

| Property | Test Method | Typical Value | Industrial Relevance |

|---|---|---|---|

| Light Transmission | ASTM D1003 | 85–92% (450–700nm) | Maximizes lumen output efficiency |

| Haze | ASTM D1003 | 75–88% | Ensures uniform luminance distribution |

| Shore A Hardness | ASTM D2240 | 40–65 | Balances flexibility & structural support |

| Thermal Stability | UL 746B | -60°C to +200°C | Prevents degradation in extreme environments |

| Tensile Strength | ASTM D412 | 8.5–12.0 MPa | Resists mechanical stress during assembly |

These specifications reflect our commitment to data-driven material development. Each formulation is traceable to lot-specific QC reports, with full compliance to RoHS 3 and REACH regulations. We integrate seamlessly into your production workflow through co-engineering support—from initial CAD-based prototyping to DFM analysis for high-volume extrusion or injection molding. Our technical team provides granular guidance on adhesion promoters, cure kinetics, and thermal expansion coefficients to prevent interfacial failures in multi-material assemblies.

Initiate a technical consultation with Mr. Boyce, our Rubber Formulation Lead, to address your specific diffuser challenges. With 18 years of experience in optical elastomers, Mr. Boyce specializes in resolving edge-case scenarios such as blue-light degradation in horticultural LEDs or vibration-induced microcracking in automotive applications. Contact him directly at [email protected] with your project parameters, including spectral requirements, environmental conditions, and dimensional tolerances. Specify “Flexible LED Diffuser Technical Query” in the subject line to trigger our 48-hour engineering response protocol. Suzhou Baoshida does not sell catalog products; we deliver validated material solutions backed by ISO 9001-certified process control. Partner with us to transform optical performance constraints into competitive advantages.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).