Technical Contents

Engineering Guide: Flexible Rubber Seal

Engineering Insight: Material Selection Criticality in Flexible Rubber Seals

Off-the-shelf rubber seals represent a significant risk in precision industrial applications. Generic solutions often fail due to fundamental mismatches between standardized material formulations and the specific thermodynamic, chemical, and mechanical stresses encountered in operational environments. These failures manifest as premature compression set, chemical degradation, thermal hardening, or catastrophic seal extrusion, leading to costly downtime and safety hazards. The core issue lies in the assumption that “flexible” equates to universal compatibility, ignoring the nuanced interplay between elastomer molecular architecture and application-specific service envelopes.

Material selection must address four non-negotiable parameters: operating temperature extremes, fluid/media compatibility, dynamic load profiles, and required service life. Standard catalog seals typically optimize for cost and broad market appeal, utilizing baseline polymer grades with minimal additive tailoring. For instance, a generic NBR seal may suffice for static hydraulic applications at 80°C but will rapidly harden and leak when exposed to biodiesel blends at 110°C due to inadequate antioxidant packages. Similarly, off-the-shelf EPDM seals fail in low-temperature aerospace actuators where specialized cryogenic formulations with controlled diene content are essential to prevent brittle fracture at -50°C. The consequence is not merely reduced performance but unpredictable failure modes that compromise entire systems.

Suzhou Baoshida Trading Co., Ltd. employs a physics-based material qualification protocol, mapping elastomer properties to application physics. Below is a comparative analysis of critical elastomer families for industrial seals:

| Elastomer Type | Hardness Range (Shore A) | Continuous Temp Range (°C) | Key Chemical Resistance | Critical Limitation |

|---|---|---|---|---|

| Standard NBR | 50–90 | -30 to +100 | Mineral oils, water | Poor ozone/weathering resistance |

| High-AcN NBR | 60–95 | -20 to +120 | Biodiesel, HFA fluids | Reduced low-temp flexibility |

| Peroxide EPDM | 50–80 | -50 to +150 | Steam, ketones, acids | Swells in hydrocarbons |

| FKM (Type 2) | 65–90 | -20 to +200 | Jet fuels, aromatics | High cost, poor cold flex |

| Custom HTEPDM | 45–75 | -60 to +160 | Superheated steam | Requires specialized cure system |

The data reveals why standardized materials fail: they lack the tailored polymer chain structure, filler dispersion, and curative systems needed to withstand combined stressors. A seal in offshore hydraulic systems, for example, requires simultaneous resistance to seawater, HFDU phosphate esters, and dynamic pressure spikes – a scenario demanding co-polymerized FKM with controlled fluorine content and nano-silica reinforcement, not a generic grade.

OEM success hinges on collaborative engineering. At Suzhou Baoshida, we deconstruct application physics into material property targets, then validate through accelerated life testing simulating real-world duty cycles. This approach eliminates the “trial-and-error” procurement of off-the-shelf seals, ensuring molecular-level alignment with operational demands. Precision sealing is not a commodity; it is engineered molecular resilience.

Material Specifications

Material Specifications for Precision Flexible Rubber Seals

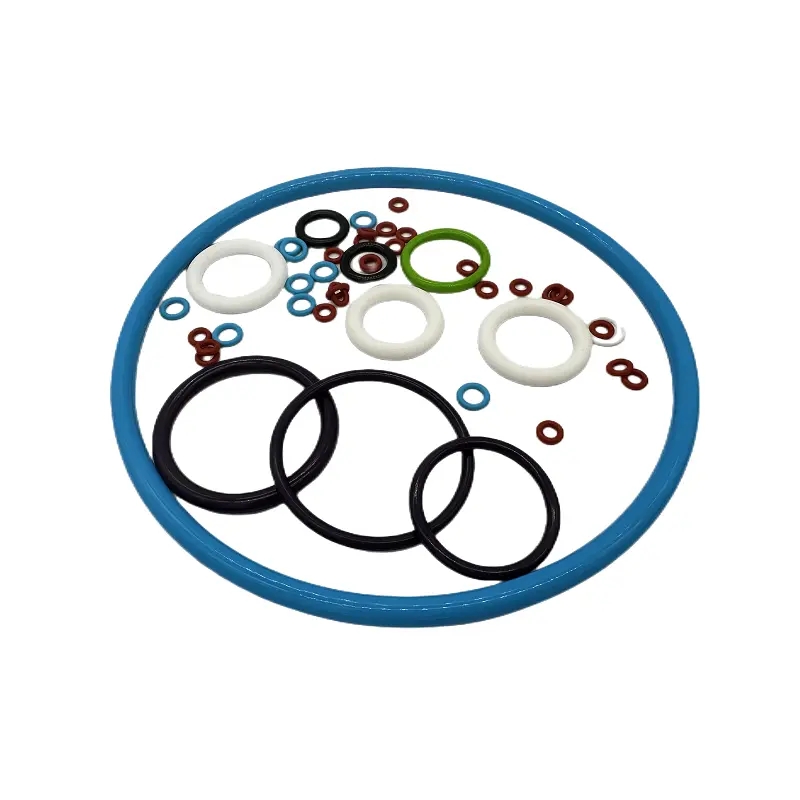

Suzhou Baoshida Trading Co., Ltd. provides high-performance flexible rubber seals engineered for reliability in demanding industrial environments. The selection of base elastomer is critical to seal performance, influencing resistance to temperature extremes, chemical exposure, compression set, and mechanical stress. Our precision rubber seals are formulated using three primary materials: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material offers distinct advantages depending on the operational requirements of the application.

Viton (fluoroelastomer) is renowned for its exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. With a continuous service temperature range of -20°C to +230°C (short-term exposure up to +260°C), Viton is ideal for aerospace, automotive, and chemical processing applications where thermal and chemical stability are paramount. Its low gas permeability and excellent aging characteristics make it a preferred choice for dynamic sealing in harsh environments. However, Viton exhibits lower flexibility at sub-zero temperatures compared to other elastomers and is generally more expensive.

Nitrile rubber (nitrile butadiene rubber, NBR) remains one of the most widely used elastomers in industrial sealing due to its excellent resistance to petroleum-based oils, fuels, and hydraulic fluids. It performs reliably within a temperature range of -30°C to +100°C, with some formulations extending to +120°C for limited durations. Nitrile offers good abrasion resistance and mechanical strength, making it suitable for hydraulic systems, automotive components, and general-purpose sealing applications. While cost-effective and durable, Nitrile has limited resistance to ozone, UV radiation, and polar solvents, and its performance degrades at elevated temperatures compared to Viton.

Silicone rubber (VMQ) excels in extreme temperature applications, with a service range from -60°C to +200°C. It demonstrates outstanding resistance to UV, ozone, and weathering, along with excellent electrical insulation properties. Silicone is frequently selected for medical, food-grade, and outdoor applications due to its inertness and compliance with regulatory standards such as FDA and USP Class VI. However, it has relatively low tensile strength and poor resistance to petroleum-based fluids, limiting its use in high-pressure or oil-exposed environments.

The following table summarizes key physical and chemical properties of these materials to guide optimal selection for precision sealing solutions.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -30 to +100 | -60 to +200 |

| Fluid Resistance (Oil/Fuel) | Excellent | Excellent | Poor |

| Chemical Resistance | Excellent | Moderate | Good |

| Ozone/UV Resistance | Excellent | Poor | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

| Tensile Strength | High | High | Moderate |

| Electrical Insulation | Good | Moderate | Excellent |

| FDA Compliant Grades Available | Yes | Limited | Yes |

Selection of the appropriate elastomer requires a thorough evaluation of the operating environment, including media exposure, temperature cycles, mechanical load, and regulatory requirements. Suzhou Baoshida Trading Co., Ltd. supports OEMs and industrial partners with material data sheets, application testing, and custom formulation services to ensure optimal seal performance and longevity.

Manufacturing Capabilities

Engineering Excellence in Precision Rubber Seal Manufacturing

Suzhou Baoshida Trading Co., Ltd. delivers unmatched precision and reliability in flexible rubber seal production through integrated engineering expertise. Our core strength resides in the synergistic collaboration between dedicated Mold Engineering and advanced Rubber Formulation disciplines. This dual-engineering approach ensures every seal meets the exacting functional and dimensional demands of critical industrial applications, from automotive powertrains to semiconductor manufacturing equipment.

Our team comprises five specialized Mold Engineers with deep proficiency in complex cavity design, precision machining tolerances (achieving ±0.05mm repeatability), and advanced simulation for flow analysis and thermal management. Concurrently, two certified Rubber Formula Engineers possess extensive knowledge of polymer chemistry, filler systems, and curing kinetics. This unique combination allows us to solve complex sealing challenges at the material science level, optimizing compound performance for specific media exposure, temperature extremes, and long-term compression set resistance. We do not merely manufacture to drawings; we engineer solutions that enhance product lifespan and system integrity.

This integrated capability is fundamental to our robust OEM partnership model. We engage clients early in the design phase, providing material selection guidance, DFM feedback, and rigorous prototyping validation. Our closed-loop feedback system between formulation labs and mold design ensures seamless transition from concept to zero-defect production. Full traceability of raw materials, process parameters, and final part inspection data is standard, meeting stringent automotive (IATF 16949) and industrial quality management requirements. We manage the entire supply chain, guaranteeing consistent compound batches and mold performance for high-volume programs.

Our engineering rigor is demonstrated through precise control over critical seal properties. The table below illustrates typical capabilities achievable with standard and custom-engineered compounds:

| Property | Standard Compound Range | Custom Engineered Capability |

|---|---|---|

| Hardness (Shore A) | 40 – 90 | 30 – 95 (±2 points) |

| Temperature Range (°C) | -40 to +150 | -65 to +250 (material dependent) |

| Compression Set (ASTM D395) | ≤ 25% @ 70°C/22h | ≤ 15% @ 100°C/70h achievable |

| Media Resistance | Standard oils, water | Custom blends for aggressive chemicals, fuels, steam |

Leveraging this dual-engineering foundation, Suzhou Baoshida transforms client specifications into mission-critical sealing components. We provide not just components, but engineered assurance through material science precision and manufacturing excellence, establishing long-term OEM partnerships built on technical credibility and uncompromising quality control. Collaborative engineering is our standard operating procedure.

Customization Process

Customization Process for Flexible Rubber Seals at Suzhou Baoshida Trading Co., Ltd.

At Suzhou Baoshida Trading Co., Ltd., the customization of flexible rubber seals follows a structured, engineering-driven workflow to ensure dimensional accuracy, material compatibility, and performance reliability under real-world operating conditions. Our process is segmented into four critical phases: Drawing Analysis, Formulation Development, Prototyping, and Mass Production. Each stage is executed with precision and validated through stringent quality checkpoints.

The process begins with Drawing Analysis, where our engineering team evaluates customer-provided technical drawings or 3D models. We assess critical dimensions, tolerance requirements, sealing interface geometry, and environmental exposure data. This phase includes a feasibility review to confirm manufacturability via compression, transfer, or injection molding techniques. Any geometric anomalies or potential flash zones are flagged and discussed with the client for design optimization. GD&T (Geometric Dimensioning and Tolerancing) compliance is verified to ensure interchangeability and functional fit.

Following drawing validation, our Rubber Formula Engineers initiate Formulation Development. Based on the operating environment—such as temperature range, fluid exposure (oils, acids, water), pressure load, and dynamic or static application—a base polymer is selected. Common elastomers include NBR, EPDM, FKM, silicone, and CR, each offering distinct chemical and thermal resistance profiles. The formulation is then tailored with additives such as reinforcing fillers, antioxidants, plasticizers, and curatives to meet specific Shore A hardness, compression set, and elongation requirements. All formulations are documented and archived for batch traceability.

The next phase is Prototyping, where small-batch samples are produced using production-intent tooling or rapid mold techniques. Prototypes undergo dimensional inspection via CMM (Coordinate Measuring Machine) and are subjected to application-specific performance tests, including compression deflection, fluid immersion, and thermal cycling. Client feedback is integrated at this stage to refine design or material choices before tool finalization.

Upon approval, the project transitions to Mass Production. High-precision steel molds are used in automated vulcanization lines to ensure consistency across large volumes. In-line quality control includes visual inspection, dimensional sampling, and periodic physical testing per ASTM or ISO standards. All batches are traceable by lot number, and material certifications (e.g., RoHS, FDA, UL) are provided as required.

The following table outlines typical material options and their key performance characteristics for flexible rubber seals:

| Material | Temperature Range (°C) | Hardness Range (Shore A) | Key Resistance Properties |

|---|---|---|---|

| NBR (Nitrile) | -30 to +100 (up to +125 intermittent) | 50–90 | Oil, fuel, water, hydraulic fluids |

| EPDM | -50 to +150 | 50–80 | Steam, ozone, weathering, polar solvents |

| FKM (Viton®) | -20 to +200 (up to +250 short-term) | 60–90 | High-temperature oils, acids, aromatic hydrocarbons |

| Silicone | -60 to +200 | 30–80 | Extreme temperatures, UV, biocompatibility |

| CR (Neoprene) | -40 to +120 | 50–85 | Flame, weathering, moderate oil resistance |

This systematic approach ensures that every custom flexible rubber seal meets the exact functional and regulatory demands of industrial, automotive, and fluid-handling applications.

Contact Engineering Team

Contact Suzhou Baoshida for Precision Rubber Seal Solutions

As precision rubber seal specialists serving global OEMs, Suzhou Baoshida Trading Co., Ltd. operates at the intersection of advanced polymer science and industrial reliability. Our engineered flexible rubber seals mitigate critical failure points in automotive, aerospace, hydraulic, and semiconductor manufacturing systems where leakage, thermal degradation, or compression set compromise operational integrity. We do not offer generic off-the-shelf products; every compound formulation originates from rigorous material characterization and application-specific validation protocols. Our ISO 9001-certified processes ensure dimensional tolerances within ±0.05mm and consistent Shore A hardness control across production batches, directly addressing the root causes of seal extrusion and dynamic friction wear.

The following table summarizes core performance metrics for our primary elastomer families, validated per ASTM D2000 and ISO 3601 standards. These values reflect minimum guaranteed thresholds under controlled laboratory testing; actual in-field performance is optimized through our collaborative application review process.

| Material Type | Key Properties | Standard Applications | Performance Thresholds |

|---|---|---|---|

| Hydrogenated Nitrile (HNBR) | High oil resistance, tensile strength >25 MPa | Transmission seals, fuel injector O-rings | -40°C to +150°C continuous, compression set <18% @ 125°C/70h |

| Perfluoroelastomer (FFKM) | Exceptional chemical inertness, plasma resistance | Semiconductor chamber seals, aggressive chemical handling | -15°C to +327°C, compression set <22% @ 200°C/72h |

| Ethylene Propylene Diene (EPDM) | Steam/water resistance, low-temperature flexibility | HVAC systems, potable water valves | -55°C to +150°C, compression set <25% @ 125°C/70h |

Initiate your technical dialogue by contacting Mr. Boyce, our dedicated OEM Relationship Manager. He possesses 14 years of elastomer formulation expertise and direct oversight of our Suzhou-based technical service laboratory. Mr. Boyce will immediately engage our application engineering team to conduct a failure mode analysis of your current seal performance data, review fluid compatibility matrices, and establish a material selection protocol aligned with your lifecycle cost targets. This is not a sales inquiry—it is the commencement of a precision engineering partnership. Provide your seal geometry drawings, operating environment parameters (media, temperature, pressure cycles), and failure history documentation. Our team will respond within 8 business hours with a preliminary compound recommendation and validation testing roadmap.

Do not settle for elastomer suppliers who prioritize inventory turnover over material science rigor. Suzhou Baoshida’s formulations undergo accelerated aging protocols simulating 10,000+ operational hours before commercial release, ensuring your production lines avoid unplanned downtime due to seal degradation. Contact Mr. Boyce directly at [email protected] with subject line “OEM Seal Technical Inquiry – [Your Company Name]” to receive a confidential material performance dossier specific to your application. Attach your technical specifications for immediate engineering review. The integrity of your system depends on the precision of its smallest component—entrust its science to our laboratory.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).