Technical Contents

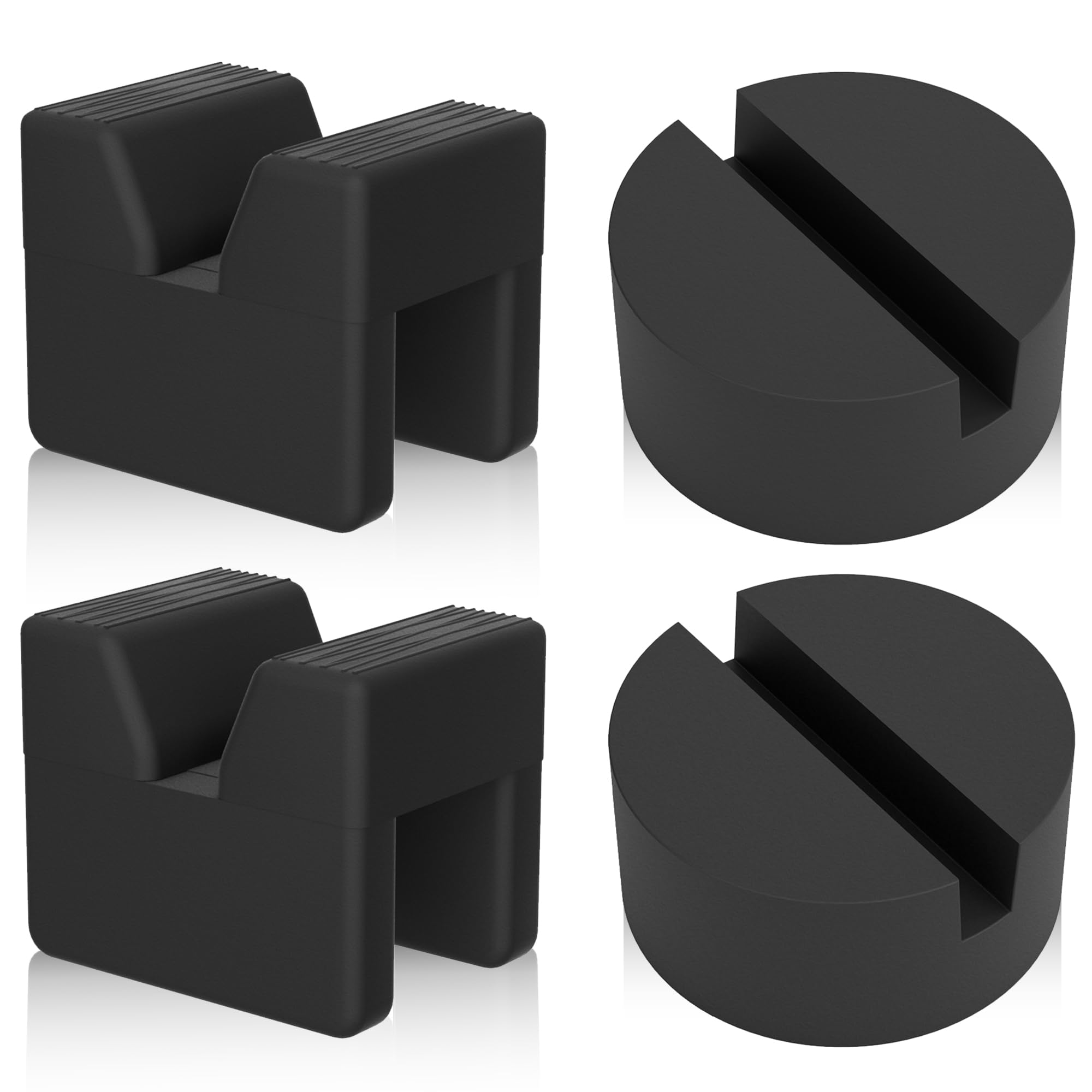

Engineering Guide: Floor Jack Pinch Weld Adapter

Engineering Insight: Material Science in Floor Jack Pinch Weld Adapter Performance

The floor jack pinch weld adapter serves as a critical interface between hydraulic lifting equipment and vehicle structural points. Material selection directly dictates operational safety and longevity, yet generic solutions frequently fail due to inadequate polymer engineering. Off-the-shelf adapters often utilize low-cost thermoplastics or poorly formulated elastomers that cannot withstand the complex stress profile encountered during use. These materials exhibit rapid compression set under sustained load, leading to permanent deformation and loss of critical dimensional stability. Simultaneously, insufficient tensile strength results in catastrophic cracking when subjected to lateral shear forces inherent in pinch weld contact. This failure mode compromises vehicle body integrity during lifting, risking severe damage to unibody structures and creating significant liability exposure for service facilities. The root cause lies in the misapplication of commodity-grade materials to an application demanding specialized elastomeric properties.

High-performance pinch weld adapters require elastomers engineered for extreme compressive resilience, high tear resistance, and minimal permanent deformation. Standard thermoplastic polyurethanes (TPU) or ethylene propylene diene monomer (EPDM) compounds commonly found in generic adapters lack the necessary balance of hardness retention and elastic recovery. Under repeated loading cycles, these materials undergo microstructural degradation, accelerating fatigue failure. Temperature fluctuations in shop environments further exacerbate material breakdown, as many commodity polymers exhibit poor thermal stability below 0°C or above 60°C. Crucially, the adapter must maintain precise Shore A hardness to distribute load evenly across the pinch weld flange without inducing localized stress concentrations. Off-the-shelf variants typically prioritize cost over performance, utilizing fillers and plasticizers that migrate over time, embrittling the compound and reducing service life by up to 70% compared to engineered solutions.

Suzhou Baoshida Trading Co., Ltd. addresses these failure mechanisms through proprietary rubber formulations developed specifically for automotive lifting applications. Our compound leverages high-purity nitrile butadiene rubber (NBR) with reinforced carbon black matrices and thermally stable additives, ensuring consistent performance across -40°C to +120°C operating ranges. The following specifications highlight the critical performance gap:

| Property | Generic Adapter Material | Baoshida Engineered Compound | Test Standard |

|---|---|---|---|

| Shore A Hardness (23°C) | 70 ± 5 | 85 ± 2 | ASTM D2240 |

| Tensile Strength | 12 MPa | 28 MPa | ASTM D412 |

| Elongation at Break | 250% | 420% | ASTM D412 |

| Compression Set (22h/70°C) | 35% | 8% | ASTM D395 |

| Operating Temperature | -10°C to +70°C | -40°C to +120°C | ISO 188 |

This engineered approach prevents plastic deformation during extended lifts and resists cracking under impact loads, directly mitigating the primary failure modes observed in generic products. The enhanced elastic recovery ensures consistent load distribution across the pinch weld flange, eliminating stress points that cause body panel distortion. For automotive service centers and OEM assembly lines, specifying adapters with rigorously validated material properties is not merely an operational consideration—it is a fundamental requirement for asset protection and process integrity. Suzhou Baoshida’s formulations undergo 500+ cycle validation testing to guarantee dimensional stability under 3-ton loads, providing the reliability demanded in professional lifting environments.

Material Specifications

Material Specifications for Floor Jack Pinch Weld Adapter Components

The floor jack pinch weld adapter is a critical interface component designed to protect vehicle pinch welds during lifting operations. As part of our industrial rubber solutions portfolio, Suzhou Baoshida Trading Co., Ltd. emphasizes material performance, longevity, and compatibility with demanding mechanical environments. The selection of elastomer material directly influences the adapter’s resistance to compression set, oil exposure, temperature extremes, and mechanical wear. For this application, three primary rubber compounds are recommended: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material offers distinct advantages based on operational requirements and environmental exposure.

Viton is a fluorocarbon-based rubber known for its exceptional resistance to high temperatures, oils, fuels, and chemical solvents. This makes it ideal for use in automotive service environments where exposure to aggressive fluids is common. Viton adapters maintain structural integrity at continuous operating temperatures up to 200°C and exhibit low compression set, ensuring long-term sealing and load-bearing performance. However, Viton is less flexible at low temperatures and carries a higher material cost, making it best suited for high-performance or specialty applications.

Nitrile rubber, or Buna-N, is a widely used elastomer in industrial applications due to its excellent resistance to petroleum-based oils and fuels. It offers good mechanical properties, abrasion resistance, and compressive strength, making it a cost-effective and reliable choice for standard floor jack adapters. Nitrile performs well in temperature ranges from -30°C to +100°C, which covers most ambient service conditions. While it is less resistant to ozone and UV degradation compared to other materials, its balance of performance and affordability makes it a preferred selection for general-purpose use.

Silicone rubber provides superior flexibility and thermal stability across a wide temperature range, typically from -60°C to +200°C. It exhibits excellent resistance to ozone and UV radiation, making it suitable for outdoor or variable climate environments. However, silicone has lower tensile and tear strength compared to Viton and Nitrile, and it is less resistant to petroleum-based fluids. Its use in pinch weld adapters is recommended when thermal cycling or environmental exposure is the primary concern, rather than mechanical loading or oil contact.

Material selection should be guided by the specific operational profile, including temperature, chemical exposure, and mechanical stress.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 | -30 to 100 | -60 to 200 |

| Oil & Fuel Resistance | Excellent | Excellent | Poor |

| Compression Set Resistance | Very Good | Good | Good |

| Tensile Strength | High | High | Moderate |

| Abrasion Resistance | Good | Very Good | Fair |

| Ozone/UV Resistance | Excellent | Fair | Excellent |

| Hardness (Shore A) | 70–90 | 60–80 | 40–80 |

| Typical Applications | High-temp, chemical-rich | General automotive use | Extreme temp cycling |

Manufacturing Capabilities

Engineering Precision for Floor Jack Pinch Weld Adapters

Suzhou Baoshida Trading Co., Ltd. delivers mission-critical rubber components for automotive service equipment through integrated material science and precision tooling. Our engineering team comprises five dedicated mold designers and two specialized rubber formulation experts, ensuring every pinch weld adapter meets stringent OEM performance and safety standards. This dual-discipline approach addresses the unique challenge of balancing structural resilience with controlled flexibility required to protect vehicle pinch welds during lifting operations.

Our formulation engineers develop custom elastomer compounds using advanced polymer blends, reinforcing fillers, and specialized additives. Each compound is engineered to withstand hydraulic fluid exposure, extreme temperature fluctuations (-40°C to +120°C), and repetitive compressive loading without permanent deformation. Critical properties such as durometer stability, tear strength, and compression set are rigorously optimized to prevent slippage or vehicle damage—a non-negotiable requirement in professional automotive repair environments. Concurrently, our mold engineering team leverages 3D simulation software to design cavity geometries that ensure uniform material flow, eliminate knit lines at stress points, and maintain micron-level dimensional accuracy across production runs. This synergy between material composition and mold architecture guarantees consistent part integrity, directly impacting adapter reliability during high-load applications.

OEM collaboration is central to our process. We integrate client specifications at the earliest design phase, providing material data sheets, mold flow analysis reports, and prototype validation within 15 business days. Our ISO 9001-certified facility supports rapid iteration through in-house tooling modification capabilities, reducing time-to-market by up to 30% compared to industry averages. All compounds undergo accelerated aging tests per ASTM D2240 and SAE J2236 protocols to validate long-term performance under real-world stress conditions.

Critical Performance Specifications for Pinch Weld Adapters

| Property | Target Range | Test Standard | Significance |

|---|---|---|---|

| Shore A Hardness | 70 ± 5 | ASTM D2240 | Optimal grip without marring vehicle surfaces |

| Tensile Strength | ≥ 18 MPa | ASTM D412 | Resists splitting under jack force |

| Compression Set (22h) | ≤ 12% | ASTM D395 | Maintains shape after repeated compression |

| Oil Resistance (IRMOG) | Volume swell ≤ 15% | ASTM D471 | Prevents degradation from hydraulic fluids |

| Operating Temperature | -40°C to +120°C | ISO 188 | Ensures functionality in all climates |

This engineering framework enables us to deliver adapters that consistently achieve ≤ 0.05mm dimensional variance across batches, directly supporting OEM compliance with I-CAR safety guidelines. Our co-engineering model extends beyond manufacturing: we provide failure mode analysis and compound recalibration services to address field feedback, ensuring continuous improvement in adapter performance. By unifying rubber chemistry expertise with precision mold engineering, Suzhou Baoshida eliminates the compromise between durability and adaptability in pinch weld protection systems—delivering components that safeguard both vehicles and technician productivity.

Customization Process

Drawing Analysis

The customization process for floor jack pinch weld adapters begins with a comprehensive drawing analysis. At Suzhou Baoshida Trading Co., Ltd., we receive detailed technical drawings from OEM partners or end-users, which include dimensional specifications, tolerance requirements, load-bearing parameters, and mating surface geometries. Our engineering team conducts a geometric and functional assessment to ensure compatibility with standard floor jack mechanisms and vehicle pinch weld profiles. Critical features such as contact radius, base width, and taper angle are verified using CAD cross-referencing tools. This stage also involves material clearance analysis to determine optimal rubber-to-metal bonding zones, especially when adapters incorporate embedded steel inserts for structural integrity. Any discrepancies or design risks are communicated through formal engineering change proposals (ECPs) before progression.

Formulation Development

Following drawing validation, our rubber formulation engineers initiate compound development tailored to mechanical and environmental demands. Floor jack pinch weld adapters require elastomers with high tensile strength, abrasion resistance, and low compression set to maintain clamping force during repeated use. We primarily utilize hydrogenated nitrile rubber (HNBR) or ethylene propylene diene monomer (EPDM), depending on operating temperature range and oil resistance needs. Hardness is precisely tuned between 70–85 Shore A to balance flexibility and structural support. Additives such as reinforcing carbon black, anti-degradation packages, and adhesion promoters for metal bonding are incorporated at this stage. The final compound is subjected to preliminary testing for durometer, tensile properties, and thermal stability per ASTM D412 and ISO 37 standards.

Prototyping and Validation

Once the compound is finalized, we proceed to prototype manufacturing using precision compression or transfer molding techniques. Prototypes are produced in small batches (typically 10–20 units) and undergo rigorous functional and dimensional inspection. Key performance tests include load-cycle endurance (simulating 1,000+ jack operations), shear strength evaluation at the rubber-metal interface, and dimensional conformity via coordinate measuring machine (CMM) scanning. Feedback from prototype testing informs minor geometry or formulation adjustments if required. Approved prototypes are then submitted to the client for field validation under real-world lifting conditions.

Mass Production Readiness

After client sign-off, we transition to mass production using fully documented process control plans. All molds are hardened steel with polished cavities to ensure surface finish consistency. Production batches follow strict ISO 9001-compliant procedures, including in-process checks for weight, cure time, and visual defects. Each batch is traceable through lot numbering, and material certifications are provided. Final inspection includes抽样 testing per AQL 1.0 standards.

Typical Physical Properties of Pinch Weld Adapter Rubber Compounds

| Property | Test Method | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 75 ± 5 |

| Tensile Strength | ASTM D412 | ≥18 MPa |

| Elongation at Break | ASTM D412 | ≥350% |

| Compression Set (22h, 70°C) | ASTM D395 | ≤20% |

| Tear Strength | ASTM D624 | ≥30 kN/m |

| Operating Temperature Range | — | -40°C to +120°C |

Contact Engineering Team

Technical Collaboration for Floor Jack Pinch Weld Adapter Solutions

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of industrial rubber engineering, specializing in precision-critical components for automotive service equipment. Our floor jack pinch weld adapters represent the culmination of advanced elastomeric formulation and rigorous OEM validation protocols. These adapters are engineered to eliminate body panel deformation during vehicle lifting by uniformly distributing hydraulic load across pinch weld seams—a non-negotiable requirement for modern collision repair facilities and dealership service centers. Achieving zero-defect performance demands exacting material science and dimensional control, which is why direct technical engagement with our engineering team is essential for seamless integration into your lifting systems.

The following specifications reflect our standard pinch weld adapter formulation, developed under ISO 9001-certified processes. Customization for load capacity, vehicle OEM requirements, or environmental exposure is executed through our collaborative design-for-manufacturing workflow.

| Parameter | Specification | Test Standard |

|---|---|---|

| Material Composition | High-durometer EPDM/NBR blend | ASTM D2000 |

| Hardness Range | 85–90 Shore A | ASTM D2240 |

| Maximum Load Capacity | 4,500 kg per adapter | ISO 3100 |

| Temperature Resistance | -40°C to +120°C (continuous) | ASTM D1329 |

| Compression Set (22h) | ≤15% at 100°C | ASTM D395 |

| OEM Compatibility | Validated for Ford, GM, Stellantis | SAE J2473 |

Our adapters undergo 100% dimensional inspection via CMM and multi-axis fatigue testing to 50,000 cycles, ensuring consistent performance under dynamic loads. Unlike generic alternatives, Baoshida’s formulations incorporate reinforced polymer matrices that resist oil degradation and maintain structural integrity after repeated compression events. This precision directly translates to reduced warranty claims for lift manufacturers and absolute safety compliance in technician workflows.

As your OEM partner, we prioritize technical alignment over transactional sales. Our engineering team collaborates from prototype validation through volume production, leveraging Suzhou-based material labs for rapid compound iteration. We provide full material traceability, DFMEA documentation, and on-site technical support for assembly line integration. For global automotive equipment manufacturers, this eliminates supply chain risk while meeting stringent Tier-1 quality gate requirements.

Initiate your technical partnership by contacting Mr. Boyce, our dedicated OEM Engineering Manager, with your specific application parameters. Include your target load profile, vehicle platform requirements, and production volume timeline to expedite our engineering response. Mr. Boyce will coordinate a cross-functional review within 48 hours, delivering a comprehensive technical package including material certifications, 3D tolerance analysis, and lifecycle cost projections.

Direct all engineering inquiries to [email protected] with subject line: “Pinch Weld Adapter OEM Technical Request – [Your Company Name]”. We require no NDAs for initial technical discussions, enabling immediate evaluation of your performance criteria against our validated material databases. For urgent validation support, reference your project timeline in the email to trigger priority lab scheduling. Suzhou Baoshida’s commitment to engineering excellence begins with precise technical dialogue—contact Mr. Boyce today to transform your pinch weld adapter specifications into certified production reality.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).