Technical Contents

Engineering Guide: Floor Protector

Engineering Insight: The Critical Role of Material Selection in Floor Protector Performance

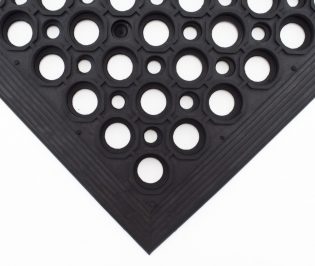

In industrial and commercial environments, floor protectors are not merely accessories—they are engineered components designed to preserve infrastructure, ensure safety, and support operational continuity. Despite their apparent simplicity, the performance of floor protectors is deeply dependent on precise material selection. Off-the-shelf solutions often fail because they are formulated for generalized applications, lacking the tailored properties required to withstand specific mechanical, chemical, and thermal stresses encountered in real-world settings.

Standard rubber or plastic mats available in retail or generic industrial supply channels are typically manufactured from low-cost elastomers such as recycled SBR (styrene-butadiene rubber) or PVC. These materials exhibit poor resistance to abrasion, ozone degradation, and oil exposure. When deployed under heavy machinery, rolling loads, or in environments with frequent chemical spills, they rapidly deteriorate—cracking, deforming, or losing traction. This premature failure not only compromises floor integrity but also increases maintenance costs and safety risks.

At Suzhou Baoshida Trading Co., Ltd., we approach floor protection as a precision engineering challenge. Our industrial rubber solutions are formulated using high-performance compounds such as nitrile rubber (NBR), ethylene propylene diene monomer (EPDM), and polyurethane (PU), each selected based on the operational profile of the application. NBR, for example, provides exceptional oil and fuel resistance, making it ideal for automotive and manufacturing floors exposed to lubricants. EPDM offers superior weather and UV resistance, suitable for outdoor or high-moisture environments. PU delivers unmatched abrasion resistance and load-bearing capacity, critical for high-traffic zones with heavy equipment movement.

Beyond chemical compatibility, mechanical properties such as hardness, tensile strength, and compression set must be optimized. A protector that is too soft will deform under load, reducing stability and increasing slip hazards. One that is too rigid may transfer vibration and fail to conform to floor irregularities, leading to edge lifting and accelerated wear.

The following table outlines key material properties and their industrial relevance in floor protector applications:

| Material | Hardness (Shore A) | Tensile Strength (MPa) | Oil Resistance | Abrasion Resistance | Primary Use Case |

|---|---|---|---|---|---|

| NBR | 60–80 | 10–18 | Excellent | Good | Oil-exposed workshops, garages |

| EPDM | 50–75 | 7–15 | Poor | Moderate | Outdoor platforms, washdown areas |

| PU | 70–95 | 20–40 | Good | Excellent | Heavy machinery zones, logistics hubs |

| SBR (Recycled) | 50–65 | 5–10 | Poor | Poor | Light-duty, temporary use |

Custom formulation allows for hybrid compounds that balance elasticity, durability, and cost-efficiency. By analyzing load dynamics, environmental exposure, and expected service life, we engineer floor protectors that outperform generic alternatives by 300% in lifecycle testing. Material selection is not a commodity decision—it is the foundation of reliable, long-term performance.

Material Specifications

Material Selection Rationale for Industrial Floor Protectors

Precision material selection is paramount for industrial floor protectors subjected to chemical exposure, thermal cycling, and mechanical abrasion. At Suzhou Baoshida Trading Co., Ltd., our engineering team rigorously evaluates polymer chemistry to ensure optimal substrate integrity and service life. Viton (FKM), Nitrile (NBR), and Silicone (VMQ) represent core solutions, each engineered for specific operational hazards. Material performance directly correlates with resistance to plasticization, compression set, and surface degradation under load.

Viton (FKM) Specifications

Viton fluorocarbon elastomers deliver exceptional resistance to aggressive chemicals including concentrated acids, amines, and hydrocarbon fuels. Our proprietary FKM formulations achieve Shore A hardness of 70–90, maintaining structural stability from -20°C to +250°C continuous service. Critical for semiconductor and petrochemical facilities, Viton exhibits minimal swelling (<15%) in ASTM D471 testing with toluene and hydraulic fluids. Compression set remains below 25% after 70 hours at 200°C, ensuring long-term sealant integrity under static loads.

Nitrile (NBR) Specifications

NBR compounds provide cost-effective resilience against oils, greases, and aliphatic hydrocarbons prevalent in automotive and manufacturing environments. Baoshida’s high-acrylonitrile NBR variants (45–50% ACN content) achieve Shore A 60–85 hardness with a functional range of -30°C to +120°C. These formulations demonstrate <20% volume swell in ASTM D471 tests with IRM 903 oil, balancing flexibility and abrasion resistance. Compression set tolerance is maintained at ≤35% after 70 hours at 100°C, suitable for dynamic machinery mounting.

Silicone (VMQ) Specifications

Silicone rubber excels in extreme temperature applications requiring non-toxic, non-staining performance. Our platinum-cured VMQ compounds operate reliably from -60°C to +230°C with Shore A hardness of 40–80. While exhibiting moderate resistance to non-polar solvents, silicone offers superior ozone and UV stability for outdoor or sterilization-critical settings (e.g., pharmaceutical cleanrooms). Compression set is controlled to ≤20% after 70 hours at 200°C, though mechanical strength requires reinforcement for high-load scenarios.

Comparative Material Performance

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Hardness Range (Shore A) | 70–90 | 60–85 | 40–80 |

| Continuous Temp Range | -20°C to +250°C | -30°C to +120°C | -60°C to +230°C |

| Compression Set (100°C/70h) | ≤25% | ≤35% | ≤20% |

| Toluene Swell (ASTM D471) | <15% | 30–50% | >100% |

| IRM 903 Oil Swell | <10% | <20% | 50–80% |

| Key Industrial Use Case | Chemical processing | Automotive fluids | Cleanroom/sterilization |

Suzhou Baoshida Trading Co., Ltd. tailors compound formulations to client fluid exposure profiles and mechanical stress parameters. Our OEM engineering process includes dynamic compression testing per ISO 3384 and chemical immersion validation per ASTM D471, ensuring protector longevity exceeds 5-year operational benchmarks in targeted environments. Material certification documentation and lot-specific QC reports are integral to every shipment.

Manufacturing Capabilities

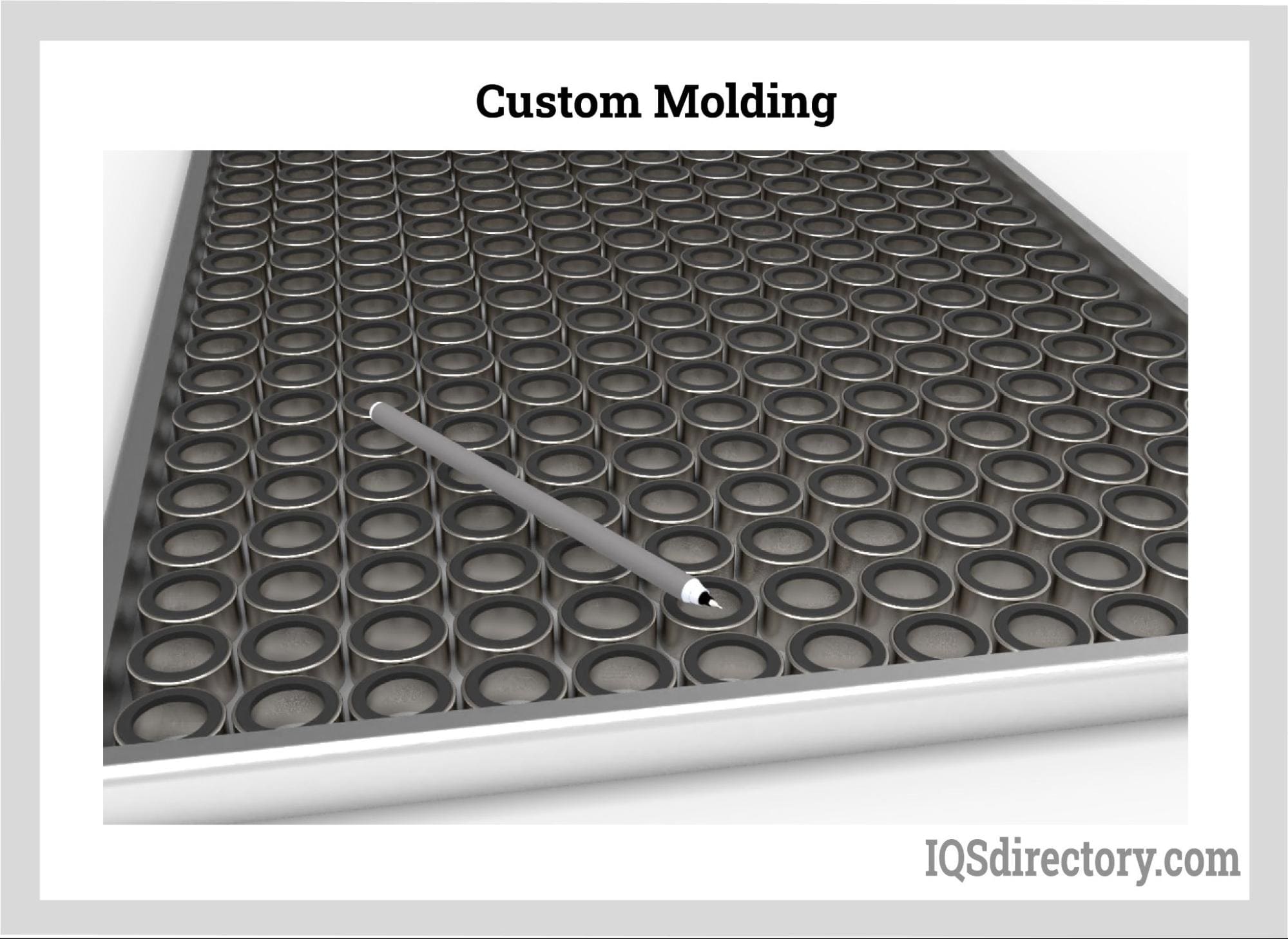

Engineering Capability: Precision-Driven Rubber Solutions for Industrial Floor Protectors

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the development and production of high-performance floor protectors. With a dedicated team comprising five specialized mould engineers and two advanced formula engineers, we integrate material science with precision tooling to deliver tailored, durable, and application-specific rubber products for demanding industrial environments.

Our formula engineers focus on polymer chemistry and material performance optimization. They design custom rubber compounds using natural rubber (NR), styrene-butadiene rubber (SBR), ethylene propylene diene monomer (EPDM), and nitrile rubber (NBR), depending on the operational requirements such as abrasion resistance, load-bearing capacity, oil resistance, and temperature stability. Each formulation is engineered to meet exact mechanical and environmental specifications, ensuring that our floor protectors maintain integrity under continuous mechanical stress, chemical exposure, and dynamic loading conditions. Rigorous in-house testing protocols validate hardness (Shore A), tensile strength, elongation at break, compression set, and anti-slip coefficients before final approval.

Complementing our material expertise, our five mould engineers specialize in precision mould design and manufacturing for rubber compression, transfer, and injection moulding processes. They utilize advanced CAD/CAM software (SolidWorks, AutoCAD, and Moldflow) to develop robust, high-tolerance tooling systems that ensure dimensional accuracy and repeatability across large production runs. Our mould designs incorporate optimized gating, venting, and cooling channels to minimize defects such as flash, voids, or incomplete curing—critical for maintaining surface integrity and functional performance in floor protection applications.

We maintain full OEM (Original Equipment Manufacturer) capabilities, enabling seamless collaboration with partners to develop proprietary floor protector designs from concept to mass production. Our integrated engineering workflow supports rapid prototyping, design for manufacturability (DFM) analysis, and iterative refinement—reducing time-to-market while ensuring compliance with international quality standards. Whether the requirement is for custom thickness, embossed anti-slip patterns, cutouts for equipment fitment, or color-coded identification zones, our team delivers engineered-to-order solutions with strict adherence to client specifications.

The synergy between formulation science and precision tooling allows us to produce floor protectors that exceed performance benchmarks in industrial settings, including automotive assembly lines, warehouse logistics, and heavy machinery operations.

Typical Floor Protector Material Specifications

| Property | Test Method | NR Compound | SBR Compound | EPDM Compound | NBR Compound |

|---|---|---|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 60 ± 5 | 65 ± 5 | 70 ± 5 | 75 ± 5 |

| Tensile Strength (MPa) | ASTM D412 | ≥18 | ≥15 | ≥12 | ≥10 |

| Elongation at Break (%) | ASTM D412 | ≥350 | ≥300 | ≥250 | ≥200 |

| Compression Set (22h, 70°C) | ASTM D395 | ≤20% | ≤25% | ≤30% | ≤35% |

| Abrasion Loss (mm³) | ASTM D1630 | ≤120 | ≤140 | ≤150 | ≤160 |

| Operating Temperature Range | — | -20°C to +80°C | -30°C to +90°C | -40°C to +120°C | -20°C to +100°C |

This technical depth, combined with scalable manufacturing infrastructure, positions Suzhou Baoshida as a strategic engineering partner for industrial floor protection solutions worldwide.

Customization Process

Customization Process for Industrial Floor Protectors

At Suzhou Baoshida Trading Co., Ltd., our customization process for industrial rubber floor protectors integrates material science with precision manufacturing. This four-stage workflow ensures optimal performance for demanding applications while adhering to OEM specifications and international standards.

Drawing Analysis

We initiate with rigorous technical drawing evaluation, scrutinizing client-provided CAD files or sketches for dimensional tolerances, surface textures, and load-bearing requirements. Our engineering team cross-references ISO 2768 geometric tolerances and assesses manufacturability against rubber flow dynamics during vulcanization. Critical parameters such as edge radii, thickness gradients, and interlocking features are validated to prevent sink marks or voids. This phase includes feasibility feedback within 72 hours, addressing potential risks like excessive draft angles or non-uniform wall sections that could compromise structural integrity.

Formulation

Based on operational environment data from the client (e.g., chemical exposure, temperature range, static dissipation needs), our rubber chemists develop a tailored compound. We prioritize SBR, NBR, or EPDM polymers modified with specialized additives: silica for abrasion resistance, carbon black for UV stability, or conductive fillers for ESD protection. Formulation targets are quantified through predictive modeling of crosslink density and filler dispersion. Key performance indicators are defined in the table below, ensuring alignment with industry benchmarks.

| Specification | Target Range | Test Standard | Relevance for Floor Protectors |

|---|---|---|---|

| Hardness (Shore A) | 60–85 | ASTM D2240 | Balances impact absorption & load distribution |

| Tensile Strength | ≥12 MPa | ISO 37 | Prevents tearing under heavy equipment |

| Elongation at Break | 250–450% | ISO 37 | Accommodates thermal expansion cycles |

| Tear Resistance | ≥40 kN/m | ASTM D624 | Resists damage from sharp debris |

| Volume Swell (in oil) | ≤25% | ISO 1817 | Critical for workshop/facility safety |

Prototyping

Mold tooling is CNC-machined to ±0.05 mm tolerances using pre-hardened P20 steel. Three prototype batches undergo accelerated lifecycle testing: 500+ cycles of 5-ton forklift simulation, 72-hour chemical immersion (oil, acids), and ISO 4869 noise reduction validation. We measure compression set (ISO 815) at 70°C for 24 hours to verify long-term recovery. Client approval requires ≤5% deviation from target hardness and zero surface cracking. Iterations conclude within 15 days through real-time collaboration via shared digital twin platforms.

Mass Production

Approved prototypes transition to automated production lines with embedded IoT sensors monitoring cure time, temperature, and pressure. Each batch undergoes 100% visual inspection via machine vision systems and statistical process control (SPC) of critical dimensions. Traceability is maintained through laser-etched batch codes linked to raw material certificates (RoHS/REACH compliant). Final shipment includes certified test reports per ASTM D2000, with dimensional rechecks at 5% random sampling intervals. This closed-loop system guarantees ≤0.1% defect rates at volumes up to 50,000 units monthly.

Our end-to-end customization reduces time-to-market by 30% versus industry averages while ensuring floor protectors withstand 10+ years of industrial abuse. All processes comply with IATF 16949, reflecting Suzhou Baoshida’s commitment to precision rubber engineering for global OEM partnerships.

Contact Engineering Team

Contact Suzhou Baoshida for Premium Floor Protector Solutions

At Suzhou Baoshida Trading Co., Ltd., we specialize in high-performance industrial rubber solutions designed to meet the rigorous demands of modern manufacturing, warehousing, and logistics environments. Our floor protector products are engineered for durability, chemical resistance, and long-term structural integrity, ensuring optimal performance under heavy mechanical loads and extreme operational conditions. As a trusted OEM partner, we deliver precision-crafted rubber components that align with international quality standards and specific client requirements.

If you are seeking a reliable, scalable, and technically advanced floor protection system, we invite you to contact Mr. Boyce, our dedicated OEM Manager and Rubber Formula Engineer. With over 15 years of experience in polymer formulation and industrial application development, Mr. Boyce leads technical consultations to ensure every floor protector solution is optimized for performance, cost-efficiency, and environmental resilience. Whether your facility requires custom thickness, Shore hardness, dimensional tolerances, or specialized surface textures, our team provides end-to-end support from material selection to final production.

We understand that industrial flooring systems must withstand abrasion, oil exposure, thermal fluctuations, and dynamic loading. That is why our rubber compounds are formulated using advanced sulfur-cure systems, reinforced with high-tensile synthetic elastomers, and tested rigorously for compression set, tensile strength, and elongation at break. Each floor protector is manufactured under ISO 9001-certified processes, guaranteeing consistency and reliability across large-volume orders.

To initiate a technical discussion or request a sample for evaluation, please reach out directly to Mr. Boyce via email at [email protected]. Include your application details, performance requirements, and preferred dimensions to receive a tailored proposal with material specifications, lead times, and pricing. Our team supports multilingual communication and global logistics, enabling seamless collaboration with clients across North America, Europe, and Asia.

For your reference, below are the standard technical specifications of our most widely deployed floor protector series. Custom modifications are available upon request.

| Property | Specification | Test Method |

|---|---|---|

| Material Composition | SBR/NR Blend (Custom EPDM available) | ASTM D412 |

| Hardness (Shore A) | 60 ± 5 to 80 ± 5 | ASTM D2240 |

| Tensile Strength | ≥ 15 MPa | ASTM D412 |

| Elongation at Break | ≥ 350% | ASTM D412 |

| Compression Set (70°C × 22h) | ≤ 25% | ASTM D395 |

| Thickness Tolerance | ± 0.5 mm (1–10 mm range) | ISO 23529 |

| Standard Dimensions | Up to 1200 × 2000 mm | Custom cuts |

| Color Options | Black, Grey, Blue, Yellow | RAL Matching |

| Operating Temperature | -30°C to +80°C | Continuous |

Partner with Suzhou Baoshida to integrate scientifically formulated rubber floor protectors into your industrial infrastructure. Contact Mr. Boyce today at [email protected] to elevate your facility’s durability, safety, and operational efficiency with engineered elastomeric solutions.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).