Technical Contents

Engineering Guide: Floor Tiles Playroom

Engineering Insight: Material Selection for Floor Tiles in Playroom Applications

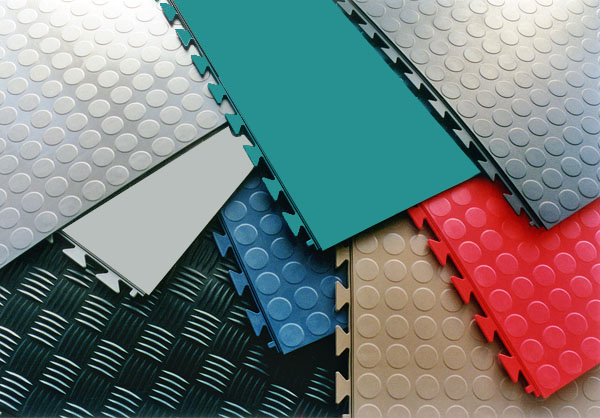

In industrial and commercial environments where floor tiles are deployed in playroom settings, material selection is not a matter of preference—it is a determinant of safety, longevity, and performance. At Suzhou Baoshida Trading Co., Ltd., we emphasize that off-the-shelf rubber flooring solutions frequently fail under real-world conditions due to inadequate material engineering. Standard consumer-grade tiles often utilize recycled rubber granules bound with weak adhesives, resulting in premature degradation when exposed to dynamic loads, moisture, or UV radiation. These failures manifest as cracking, delamination, and loss of slip resistance—posing serious safety hazards in high-traffic play areas.

The core issue lies in the polymer matrix and cross-linking density of the rubber compound. Industrial-grade ethylene propylene diene monomer (EPDM) and styrene-butadiene rubber (SBR) formulations offer superior resilience, UV stability, and abrasion resistance when properly vulcanized. Unlike generic tiles, engineered rubber systems are designed with controlled filler dispersion, optimized cure profiles, and reinforced interlocking geometries that maintain structural integrity over time. For instance, a playroom floor subjected to repeated impact from children’s activities requires a Shore A hardness of 65–75 to balance cushioning and durability. Off-the-shelf products often fall outside this range, either becoming too rigid or excessively soft, leading to fatigue failure.

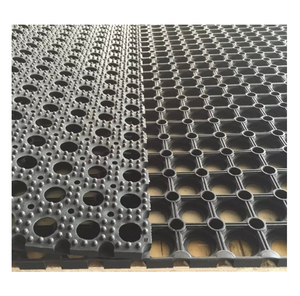

Another overlooked factor is environmental compatibility. Many commercial playrooms are located in semi-outdoor or high-humidity zones, where moisture ingress accelerates the breakdown of inferior rubber composites. Industrial solutions incorporate hydrophobic additives and closed-cell structures to resist water absorption, preventing mold growth and dimensional instability. Furthermore, standardized tiles rarely meet stringent fire safety codes such as ASTM E648 for critical radiant flux, putting facilities at regulatory risk.

At Suzhou Baoshida, we apply OEM-level material science to customize rubber flooring systems based on load profiles, climate exposure, and safety requirements. Our formulations undergo accelerated aging tests, dynamic compression analysis, and slip resistance validation to ensure compliance with international standards.

The following table outlines key performance specifications differentiating industrial-grade rubber tiles from off-the-shelf alternatives:

| Property | Industrial-Grade Rubber Tile | Off-the-Shelf Rubber Tile |

|---|---|---|

| Material Composition | Vulcanized EPDM/SBR blend with carbon black and silica reinforcement | Recycled rubber with polyurethane or latex binder |

| Shore A Hardness | 65–75 | 45–85 (inconsistent) |

| Tensile Strength | ≥10 MPa | 3–6 MPa |

| Elongation at Break | ≥250% | 100–180% |

| Water Absorption (24h) | ≤1.5% | 5–12% |

| Slip Resistance (DIN 51130 R10) | ≥0.65 DCOF | <0.45 DCOF |

| Fire Rating (ASTM E648) | Critical radiant flux ≥0.45 W/cm² | Often non-compliant |

Material selection is the foundation of reliable flooring performance. Generic solutions compromise safety and lifecycle cost-efficiency. Precision-engineered rubber tiles, developed through industrial polymer science, ensure long-term durability and compliance in demanding playroom environments.

Material Specifications

Material Specifications for Industrial Rubber Playroom Flooring Solutions

Suzhou Baoshida Trading Co., Ltd. provides precision-engineered rubber compounds for commercial playroom flooring, prioritizing safety, durability, and chemical resilience. Playroom environments demand materials resistant to frequent cleaning agents, food spills, abrasion from foot traffic, and non-toxic compliance per ASTM F963 and EN 71-3 standards. Our formulations undergo rigorous ISO 48 hardness testing and ASTM D2000 classification to ensure performance consistency. Below we detail three core elastomers optimized for this application, emphasizing functional properties over generic attributes.

Viton® (FKM) fluorocarbon rubber delivers exceptional resistance to aggressive chemicals, including bleach-based sanitizers and organic solvents commonly used in institutional cleaning. Its thermal stability spans -20°C to +200°C, preventing deformation near heating vents or under direct sunlight. However, its high cost and moderate abrasion resistance make it suitable only for high-exposure zones like daycare kitchen adjacencies. Nitrile rubber (NBR) remains the optimal balance for general playroom use, offering superior resistance to oils, fats, and aqueous solutions at 50–90 Shore A hardness. Our custom NBR blends achieve 15–25 MPa tensile strength with 300–500% elongation, ensuring impact absorption during falls while resisting staining from juice or crayon marks. Silicone rubber (VMQ) provides unmatched biocompatibility and thermal range (-60°C to +230°C), critical for sensory play areas requiring hypoallergenic surfaces. Its inherent purity meets FDA 21 CFR 177.2600 for indirect food contact, though lower tear strength necessitates reinforced backing in high-traffic corridors.

Material performance must align with specific operational demands. Viton excels in chemical-intensive zones but lacks cost efficiency for full-room coverage. Nitrile’s versatility supports 90% of playroom applications with tailored hardness for cushioning. Silicone is reserved for specialized therapeutic environments where thermal stability and non-toxicity are paramount. All compounds incorporate Baoshida’s proprietary non-black filler systems to eliminate staining risks on children’s clothing.

Critical Material Comparison for Playroom Flooring

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +200 | -30 to +120 | -60 to +230 |

| Key Chemical Resistance | Acids, solvents, ozone | Oils, greases, water | Water, steam, mild acids |

| Hardness Range (Shore A) | 60–90 | 50–90 | 30–80 |

| Tensile Strength (MPa) | 10–15 | 15–25 | 5–12 |

| Primary Playroom Use Case | Sanitizer-heavy zones | General flooring | Sensory/therapeutic areas |

Suzhou Baoshida’s OEM process tailors compound formulations to client specifications, including accelerated aging tests per ISO 188 and color stability validation under ISO 105-B02. We recommend NBR as the baseline solution for 85% of installations, leveraging its abrasion resistance and cost efficiency. Material selection must factor in localized exposure risks—Viton for medical-daycare hybrids, Silicone for autism support centers. All compounds undergo third-party heavy metal testing to exceed CPSIA thresholds. Contact our engineering team for application-specific data sheets and sample validation protocols.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. maintains a robust engineering infrastructure specifically tailored for industrial rubber applications, including high-performance floor tiles designed for specialized environments such as playrooms. Our in-house technical team comprises five dedicated mould engineers and two certified rubber formula engineers, enabling end-to-end development from concept to mass production. This integrated engineering capability ensures precision, durability, and compliance with stringent safety and performance standards required in commercial and institutional play areas.

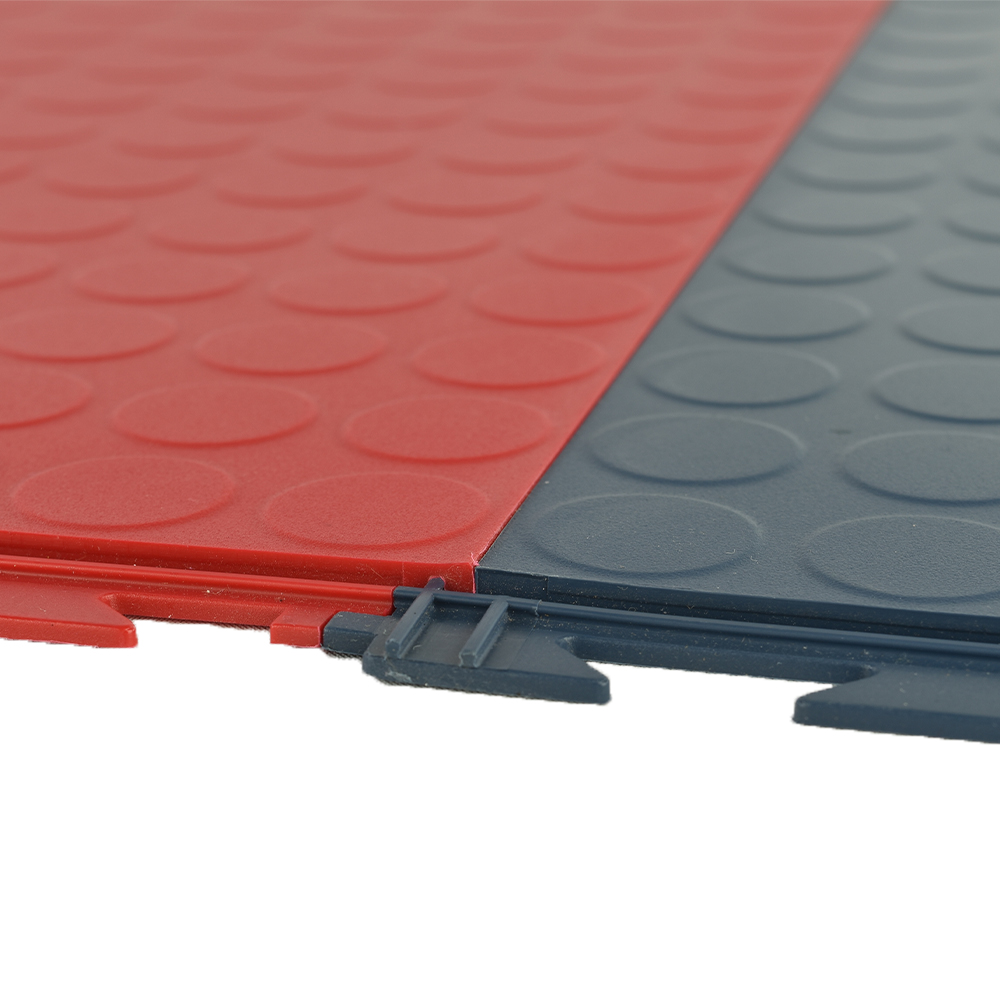

Our mould engineers specialize in designing complex, high-tolerance rubber compression and injection moulds optimized for consistent part geometry, surface texture, and dimensional stability. Utilizing advanced CAD/CAM software and CNC machining protocols, they develop mould systems that support rapid cycle times, minimal flash, and long service life—critical factors in high-volume manufacturing of rubber floor tiles. Each design undergoes rigorous simulation for flow dynamics, shrinkage prediction, and thermal distribution to prevent defects and ensure uniform curing.

Complementing this is our rubber formulation expertise. Our two formula engineers hold advanced degrees in polymer science and have over 15 years of combined experience in elastomer development. They formulate custom rubber compounds using natural rubber (NR), styrene-butadiene rubber (SBR), and ethylene propylene diene monomer (EPDM), tailored to meet specific requirements for shock absorption, slip resistance, UV stability, and non-toxicity—essential attributes for playroom flooring. All formulations comply with international safety standards, including REACH, RoHS, and EN 71-3 for toy safety, ensuring zero migration of hazardous substances.

We offer full OEM services, supporting private label manufacturing with complete confidentiality and technical ownership transfer. Clients can provide performance specifications, dimensional requirements, or aesthetic designs, and our team will deliver a fully validated product within 6–8 weeks. Our facility supports small-batch prototyping and scalable production up to 500,000 units per month, with in-line quality control and batch traceability.

The following table outlines key technical specifications for our standard rubber floor tile formulation used in playroom applications:

| Property | Test Method | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 65 ± 5 |

| Tensile Strength | ASTM D412 | ≥ 8.0 MPa |

| Elongation at Break | ASTM D412 | ≥ 250% |

| Compression Set (22 hrs at 70°C) | ASTM D395 | ≤ 20% |

| Abrasion Loss (Taber, 1000 cycles) | ASTM D1044 | ≤ 80 mg |

| Slip Resistance (DIN 51130, R-value) | DIN 51130 | R9–R11 |

| Flame Spread (ASTM E648) | ASTM E648 | Class II |

| Toxicity Compliance | EN 71-3 | Pass |

This combination of engineering depth, material science proficiency, and flexible OEM manufacturing enables Suzhou Baoshida to deliver safe, durable, and technically advanced rubber flooring solutions customized for modern playroom environments.

Customization Process

Customization Process for Industrial Rubber Playroom Floor Tiles

At Suzhou Baoshida Trading Co., Ltd., our customization process for industrial rubber playroom floor tiles integrates material science with precision manufacturing to meet stringent safety and performance requirements. This four-phase workflow ensures optimal product integrity while aligning with OEM specifications and regulatory standards for child-safe environments.

Drawing Analysis

Initial engagement begins with rigorous technical drawing review. We dissect CAD files or physical samples to evaluate dimensional tolerances, surface texture requirements, and structural geometry. Critical parameters such as tile interlock mechanisms, edge sealing, and drainage channels are validated against ASTM F1951 (accessibility) and EN 1177 (impact attenuation) standards. This phase identifies potential manufacturing constraints early, preventing costly revisions during production. Our engineering team provides actionable feedback within 72 hours, ensuring design feasibility without compromising safety or functionality.

Formulation

Material selection is driven by playroom-specific demands: non-toxicity, shock absorption, and resistance to abrasion and microbial growth. Using proprietary compounding software, we develop custom EPDM or SBR-based formulations. Key considerations include optimizing Shore A hardness for fall protection, incorporating food-grade colorants compliant with EN 71-3, and integrating UV stabilizers for indoor/outdoor versatility. Each formula undergoes accelerated aging simulations to verify 10+ year service life under high-traffic conditions.

Prototyping

Three functional prototypes are produced via precision compression molding, adhering to ±0.3 mm dimensional accuracy. Prototypes undergo exhaustive laboratory testing:

Impact testing per ASTM F1292 (critical fall height ≥ 1.5m)

Slip resistance validation (COF ≥ 0.6 wet/dry per DIN 51130)

VOC emissions screening (below 0.5 mg/m³ per ISO 16000-6)

Client feedback is incorporated within 10 business days, with iterative refinements until all performance targets are met.

Mass Production

Upon prototype approval, production transitions to our ISO 9001-certified facility. Vulcanization parameters are locked using real-time IoT-monitored presses (±2°C temperature control). Every batch undergoes inline spectrometry for color consistency and automated thickness verification. Final inspection includes 100% visual checks for surface defects and random sampling for tensile strength validation. Standard lead time from order confirmation to shipment is 25 days for 20,000 m² orders.

Critical Performance Specifications

| Parameter | Target Value | Test Standard | Tolerance |

|————————-|——————–|——————|————-|

| Shore A Hardness | 65 ± 5 | ASTM D2240 | ±3 points |

| Density | 1.15 ± 0.05 g/cm³ | ASTM D297 | ±0.03 g/cm³ |

| Rebound Resilience | ≥ 45% | ISO 4662 | ±5% |

| Tensile Strength | ≥ 7.0 MPa | ASTM D412 | ±0.5 MPa |

| Abrasion Loss | ≤ 120 mm³ | ISO 4649 | ±15 mm³ |

This structured approach guarantees playroom tiles that exceed global safety benchmarks while delivering consistent aesthetics and longevity. Suzhou Baoshida’s engineering oversight from concept to container ensures your OEM partnership translates into market-ready products with zero compromise on child safety or performance reliability.

Contact Engineering Team

For industrial-grade rubber flooring solutions tailored specifically for high-traffic playroom environments, Suzhou Baoshida Trading Co., Ltd. stands as a trusted OEM partner in precision-engineered elastomeric systems. Our expertise lies in formulating durable, non-toxic, and slip-resistant rubber compounds that meet stringent safety and performance standards required in commercial and institutional play spaces. If your project demands flooring that balances impact absorption, long-term resilience, and aesthetic consistency, direct collaboration with our technical team ensures optimal material selection and customization.

At Suzhou Baoshida, we specialize in rubber compounding using SBR, EPDM, and TPE base polymers, each formulated to deliver targeted mechanical properties. Our floor tiles are manufactured under controlled vulcanization processes, ensuring dimensional stability, colorfastness, and resistance to abrasion, UV exposure, and microbial growth—critical factors in playroom applications where safety and hygiene are non-negotiable. Whether you require custom thicknesses, interlocking profiles, or specific Shore A hardness ratings, our R&D team works closely with clients to develop formulations that align precisely with functional and regulatory requirements.

To initiate a technical consultation or request material samples, contact Mr. Boyce, OEM Project Manager at Suzhou Baoshida Trading Co., Ltd. Mr. Boyce oversees client integration from specification review to production scaling, ensuring seamless communication across engineering, quality assurance, and logistics departments. With over 12 years of experience in industrial rubber applications, he provides expert guidance on compound selection, mold design, and compliance documentation, including REACH, RoHS, and ASTM F963-17 certifications.

Our manufacturing facility in Suzhou operates under ISO 9001 and ISO 14001 standards, enabling consistent batch-to-batch repeatability and environmental compliance. Minimum order quantities start at 5,000 tiles, with standard lead times of 25–35 days from order confirmation. We support OEM branding, custom packaging, and third-party inspection services upon request.

Below are key technical specifications for our standard playroom floor tile formulation:

| Property | Test Method | Value |

|---|---|---|

| Base Polymer | — | SBR/EPDM Blend |

| Hardness (Shore A) | ASTM D2240 | 65 ± 5 |

| Tensile Strength | ASTM D412 | ≥9.5 MPa |

| Elongation at Break | ASTM D412 | ≥280% |

| Compression Set (22h, 70°C) | ASTM D395 | ≤25% |

| Slip Resistance (DIN 51130) | Pendulum Test | R9 Rating |

| Thickness Tolerance | ISO 3302 | ±0.5 mm |

| Temperature Range | — | -30°C to +80°C |

| Fire Rating | UL 94 | HB |

All formulations are subject to modification based on client performance criteria. For detailed technical data sheets, 3D mold drawings, or pricing models, direct correspondence with Mr. Boyce is recommended. He is available via email at [email protected] and responds to all technical inquiries within 4 business hours. Early-stage project discussions are encouraged to align material development with your design and compliance roadmap. Suzhou Baoshida is committed to engineering rubber solutions that perform—contact us to begin the process.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).