Technical Contents

Engineering Guide: Fluorinated Ethylene Propylene

Engineering Insight: Fluorinated Ethylene Propylene Material Selection Imperatives

Fluorinated ethylene propylene (FEP) represents a critical class of perfluoropolymers valued for extreme chemical resistance, thermal stability up to 200°C, and exceptional electrical properties. However, its deployment in demanding industrial sealing, fluid handling, and semiconductor applications reveals a harsh reality: generic, off-the-shelf FEP formulations frequently precipitate premature component failure. This stems from a fundamental misalignment between standardized commercial grades and the precise physicochemical demands of complex operational environments. OEMs selecting base FEP resins without rigorous application-specific engineering oversight encounter significant risks including catastrophic seal degradation, permeation breaches in aggressive media, and accelerated thermal aging under cyclic stress. These failures translate directly to unplanned downtime, safety hazards, and substantial financial penalties far exceeding initial material cost savings.

The core deficiency lies in the homogenized nature of commodity FEP. Standard production batches prioritize broad market suitability over the nuanced requirements of critical industrial systems. Unmodified FEP often exhibits suboptimal melt flow characteristics for complex extrusion or molding geometries, leading to internal stresses and voids. Its inherent crystallinity profile may be unsuitable for dynamic sealing applications, causing rapid compression set failure. Crucially, standard grades lack the tailored filler systems necessary to enhance wear resistance against abrasive media or to stabilize electrical properties under high-voltage DC conditions prevalent in modern power systems. Relying on catalog datasheets alone ignores critical secondary properties like outgassing rates in vacuum environments or resistance to specific plasma chemistries in semiconductor processing – parameters where minor molecular variations induce major performance deltas.

Suzhou Baoshida Trading Co., Ltd. emphasizes that successful FEP implementation necessitates deep material science collaboration. We reject the notion of a universal FEP solution. Instead, our engineering process begins with deconstructing the operational profile: exact chemical exposure, temperature-pressure cycles, mechanical loads, and regulatory constraints. This analysis informs precise resin modification – adjusting molecular weight distribution, incorporating specialized fillers like mica or carbon nanotubes, and optimizing crystallization kinetics. The result is a purpose-built compound where every attribute serves the application’s survival.

The following table contrasts critical performance parameters between standard commercial FEP and engineered solutions developed for high-reliability industrial use:

| Property | Standard Commercial FEP | Engineered Industrial FEP | Impact of Optimization |

|---|---|---|---|

| Melt Flow Index (g/10min) | 5-15 (Variable) | 8-10 (Tightly Controlled) | Ensures consistent extrusion, eliminates voids |

| Crystallinity (%) | 35-45 | 25-30 (Controlled) | Reduces compression set, enhances dynamic seal life |

| Tensile Strength (MPa) | 20-25 | 28-32 (+15-25%) | Withstands higher mechanical loads |

| Permeation Rate (He) | Baseline | Reduced by 40-60% | Critical for ultra-high vacuum integrity |

| Arc Resistance (sec) | 180 | >300 | Essential for high-voltage insulation |

Material selection for FEP is not a procurement exercise; it is an engineering discipline. Suzhou Baoshida Trading Co., Ltd. provides the formulation expertise and OEM partnership required to transform FEP’s theoretical potential into field-proven reliability. Avoiding the pitfalls of off-the-shelf solutions demands this precision-engineered approach, ensuring component longevity and system integrity in the world’s most challenging industrial settings.

Material Specifications

Fluorinated ethylene propylene (FEP) is a high-performance fluoropolymer widely utilized in industrial rubber solutions due to its exceptional chemical resistance, thermal stability, and low dielectric constant. At Suzhou Baoshida Trading Co., Ltd., we integrate FEP into advanced sealing and insulation systems where long-term reliability under extreme conditions is critical. While FEP itself is not a rubber, it is often paired with elastomeric materials such as Viton, Nitrile, and Silicone in composite sealing applications. These elastomers provide flexibility, resilience, and dynamic sealing performance, while FEP enhances surface durability and chemical inertness. Understanding the material characteristics of these elastomers is essential for optimizing performance in demanding industrial environments.

Viton, a fluorocarbon-based elastomer, exhibits outstanding resistance to high temperatures, oils, fuels, and a broad range of chemicals. It maintains mechanical integrity between -20°C and 230°C, making it ideal for aerospace, automotive, and chemical processing applications. Its low gas permeability and excellent aging properties under thermal stress further enhance its suitability for critical sealing tasks. However, Viton has limited flexibility at sub-zero temperatures and higher material costs compared to alternatives.

Nitrile rubber (NBR) is a cost-effective solution for applications involving petroleum-based fluids, hydraulic fluids, and aliphatic hydrocarbons. It performs reliably within a temperature range of -30°C to 120°C, with excellent abrasion resistance and tensile strength. Nitrile is commonly used in seals, gaskets, and hoses in industrial hydraulics and fuel systems. Despite its favorable mechanical properties, it exhibits poor resistance to ozone, UV radiation, and polar solvents, limiting its use in outdoor or highly oxidative environments.

Silicone rubber offers superior flexibility across a wide temperature range, from -60°C to 200°C, with short-term exposure tolerance up to 250°C. It is highly resistant to UV, ozone, and weathering, making it ideal for outdoor and medical applications. Silicone also possesses excellent electrical insulation properties and low toxicity. However, it has relatively low tensile strength and poor resistance to hydrocarbon fuels and oils, necessitating careful selection in fluid-exposed environments.

The following table summarizes key physical and chemical properties of these elastomers for comparative evaluation in industrial applications.

| Property | Viton | Nitrile (NBR) | Silicone |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 120 | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–10 |

| Elongation at Break (%) | 150–300 | 200–500 | 200–700 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils/Fuels | Excellent | Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Fair | Excellent |

| Electrical Insulation | Good | Good | Excellent |

| Compression Set Resistance | Excellent | Good | Fair to Good |

Selection of the appropriate elastomer must consider fluid compatibility, thermal exposure, mechanical stress, and regulatory requirements. At Suzhou Baoshida Trading Co., Ltd., we support OEMs with material testing, formulation customization, and technical validation to ensure optimal performance in real-world industrial systems.

Manufacturing Capabilities

Engineering Capability: Precision Fluoropolymer Solutions for Demanding Applications

Suzhou Baoshida Trading Co., Ltd. delivers engineered fluorinated ethylene propylene (FEP) components meeting the exacting demands of advanced industrial sectors. Our core strength lies in the integrated expertise of a dedicated technical team specializing in both material science and precision manufacturing. This synergy between formulation and mould engineering is critical for unlocking FEP’s full potential in complex applications where chemical inertness, thermal stability, and electrical properties are non-negotiable.

Our engineering capability centers on a specialized team comprising five certified Mould Engineers and two advanced Formula Engineers. This structure ensures comprehensive control from raw material development through to final part production. The Formula Engineers possess deep expertise in fluoropolymer chemistry, focusing on optimizing FEP compound formulations for specific client requirements. This includes precise modification of melt flow index for enhanced processability, strategic incorporation of high-purity fillers to improve wear resistance or thermal conductivity without compromising chemical resistance, and rigorous stabilization protocols to ensure long-term performance under extreme conditions. Concurrently, the Mould Engineering team applies advanced simulation software (Moldflow) and decades of practical experience to design and validate moulds that perfectly accommodate FEP’s unique processing characteristics, such as its high melt viscosity and sensitivity to shear heating. This dual-engineering approach minimizes defects like flow lines, voids, or dimensional instability, directly translating to higher yield rates and superior part consistency for our clients.

As a certified OEM partner, Suzhou Baoshida provides a seamless, end-to-end manufacturing solution. We excel in translating client specifications – from initial concept sketches to detailed CAD models and stringent performance criteria – into fully validated, production-ready FEP components. Our OEM process encompasses collaborative design for manufacturability (DFM) reviews, rigorous material qualification against international standards, development of robust process parameters with full statistical process control (SPC), and comprehensive dimensional tolerance verification. We maintain strict batch traceability and provide full regulatory documentation support, essential for industries like semiconductor manufacturing, chemical processing, and medical device assembly where compliance is paramount. This integrated capability significantly reduces our clients’ development timelines and supply chain complexity.

The fundamental properties of FEP enabling these high-performance solutions are quantifiable and rigorously controlled within our processes. Key specifications are maintained to the highest industry benchmarks:

| Property | Typical Value (ASTM Test Method) | Significance for Industrial Use |

|---|---|---|

| Continuous Service Temperature | 200°C (392°F) (ASTM D2584) | Stable operation in high-heat environments |

| Tensile Strength at Yield | 23 MPa (3300 psi) (ASTM D638) | Mechanical integrity under load |

| Dielectric Strength (1mm) | 60 kV/mm (ASTM D149) | Reliable electrical insulation in critical systems |

| Chemical Resistance | Excellent (Per MIL-STD-810H) | Unmatched performance in aggressive chemical exposure |

| Melt Flow Index (372°C/5kg) | 5-25 g/10 min (ASTM D3364) | Tailored for complex moulding processes |

This commitment to material science precision, combined with advanced mould engineering and a proven OEM framework, allows Suzhou Baoshida to consistently deliver FEP solutions that mitigate risk and enhance performance in the world’s most challenging industrial applications. We transform demanding specifications into reliable, high-value components.

Customization Process

Customization Process for Fluorinated Ethylene Propylene (FEP) Components

At Suzhou Baoshida Trading Co., Ltd., our approach to manufacturing fluorinated ethylene propylene (FEP) components is rooted in precision engineering and material science. FEP, a high-performance fluoropolymer, offers exceptional chemical resistance, thermal stability, and electrical insulation properties, making it ideal for demanding industrial applications in semiconductor, chemical processing, and aerospace sectors. Our customization process ensures that each product meets exact OEM specifications while maintaining consistency and reliability from design to mass production.

The process begins with Drawing Analysis, where our technical team evaluates customer-provided engineering drawings and 3D models. We assess critical dimensions, tolerances, surface finish requirements, and functional constraints. This phase includes a thorough review of environmental exposure conditions such as operating temperature, chemical contact, and mechanical stress. Our engineers use CAD software and tolerance stack-up analysis to identify potential manufacturing challenges early, ensuring design for manufacturability (DFM) compliance. Any discrepancies or optimization opportunities are communicated directly to the client for collaborative refinement.

Following drawing validation, we proceed to Formulation Development. While FEP is inherently a melt-processable fluoropolymer with excellent purity, we tailor additives and processing parameters to meet specific performance criteria. These may include UV stabilizers, conductive fillers, or pigments for identification, all selected to preserve FEP’s core attributes. Our rubber formula engineers conduct rheological and thermal analyses to optimize flow behavior during extrusion or molding. Each formulation is documented and batch-traceable, adhering to ISO 9001 standards and customer-specific quality protocols.

The next phase is Prototyping, where small-batch samples are produced using the finalized design and formulation. Prototypes are manufactured via precision extrusion, injection molding, or compression molding, depending on geometry and application. Each sample undergoes rigorous testing, including dimensional verification, dielectric strength measurement, and chemical immersion resistance. Performance data is compiled into a test report, which is submitted for customer approval. Iterative adjustments are made if necessary, ensuring functional alignment before scale-up.

Upon successful prototype validation, the project transitions to Mass Production. Our facility leverages automated processing lines with real-time monitoring to maintain tight control over temperature, pressure, and cycle times. In-process quality checks and final inspections are conducted per AQL standards. All finished components are packaged to prevent contamination, especially critical for cleanroom applications.

The following table summarizes key technical specifications achievable with customized FEP components:

| Property | Typical Value | Test Standard |

|---|---|---|

| Continuous Use Temperature | -200°C to +205°C | ASTM D149 |

| Dielectric Strength | 60 kV/mm | ASTM D876 |

| Tensile Strength | 23 MPa | ASTM D638 |

| Elongation at Break | 300% | ASTM D638 |

| Melt Flow Rate (265°C/5kg) | 5–15 g/10 min | ASTM D1238 |

| Chemical Resistance | Excellent (resists acids, bases, solvents) | ASTM D543 |

Through this structured customization process, Suzhou Baoshida ensures that every FEP component delivers optimal performance in its intended industrial environment.

Contact Engineering Team

Contact Suzhou Baoshida for Precision Fluorinated Ethylene Propylene Solutions

Fluorinated ethylene propylene (FEP) represents a critical material class for demanding industrial applications where extreme chemical resistance, thermal stability, and ultra-pure fluid handling are non-negotiable. Its unique molecular structure delivers exceptional performance in semiconductor processing, high-purity chemical transfer, aerospace fluid systems, and advanced analytical instrumentation. Successfully integrating FEP into complex manufacturing processes, however, demands more than just material supply; it requires deep formulation expertise, rigorous quality control, and OEM-level partnership to navigate processing challenges and meet exacting application specifications. Suzhou Baoshida Trading Co., Ltd. operates at this precise intersection of advanced polymer science and industrial manufacturing execution.

Our engineering team possesses specialized knowledge in FEP compound formulation, extrusion dynamics, and post-processing techniques essential for achieving optimal part performance and consistency. We understand the critical interplay between melt viscosity, crystallization behavior, and final part properties. This expertise translates directly into reliable, high-yield production for our OEM partners. We do not merely supply raw material; we provide engineered solutions backed by comprehensive technical support, from initial feasibility assessment through to full-scale production validation. Our commitment to quality is evidenced by adherence to stringent international standards and our vertically integrated quality management system, ensuring every batch of FEP compound or fabricated component meets the highest benchmarks for purity, mechanical integrity, and functional reliability.

The table below summarizes key technical parameters for standard FEP grades we supply and process, reflecting the baseline performance characteristics achievable through our controlled manufacturing protocols. These values represent typical properties; specific formulations can be tailored to meet unique application demands.

| Property | Test Method | Typical Value Range | Units |

|---|---|---|---|

| Melt Flow Index (280°C, 2.16 kg) | ASTM D3364 | 5 – 50 | g/10 min |

| Continuous Service Temperature | ASTM D2584 | -200 to +205 | °C |

| Tensile Strength (Yield) | ASTM D638 | 20 – 28 | MPa |

| Elongation at Break | ASTM D638 | 150 – 350 | % |

| Dielectric Strength (Short Term) | ASTM D149 | 45 – 60 | kV/mm |

| Specific Gravity | ASTM D792 | 2.12 – 2.17 | – |

Partnering with Suzhou Baoshida means gaining access to a responsive, technically proficient team dedicated to solving your most complex FEP material and manufacturing challenges. Whether you require custom compound development, precision extrusion of complex profiles, rigorous lot traceability, or support optimizing your conversion processes, our OEM management and engineering staff provide the necessary depth of knowledge and collaborative approach. We recognize that delays in material qualification or production instability directly impact your time-to-market and operational costs. Our focus is on delivering not just material, but predictable, scalable, and high-performance FEP solutions that integrate seamlessly into your manufacturing workflow.

Initiate a technical consultation to discuss your specific FEP requirements. Contact Mr. Boyce, our dedicated OEM Manager and Rubber Formula Engineering lead, directly at [email protected]. Provide details regarding your application environment, performance targets, dimensional specifications, and volume requirements. Mr. Boyce possesses the authority and technical background to evaluate your needs, coordinate our laboratory and production resources, and develop a precise path forward. Do not navigate the complexities of high-performance fluoropolymer manufacturing alone. Reach out to Suzhou Baoshida today to establish a partnership built on scientific rigor, industrial precision, and a shared commitment to engineering excellence in every FEP component produced. Your project demands a supplier who understands the molecular intricacies as deeply as the production realities – contact us for precision-engineered solutions.

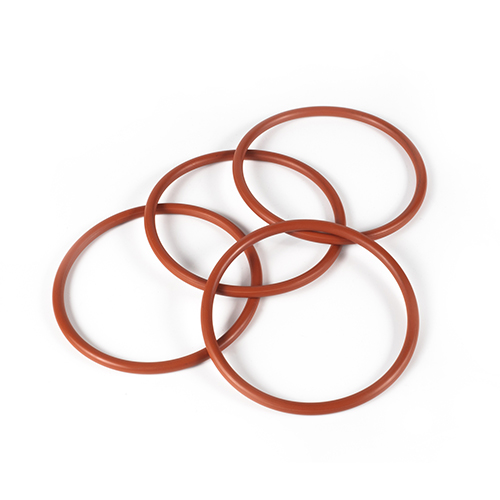

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).